JAGUAR X308 1998 2.G Owner's Manual

X308 1998 2.G

JAGUAR

JAGUAR

https://www.carmanualsonline.info/img/21/7640/w960_7640-0.png

JAGUAR X308 1998 2.G Owner's Manual

Page 2388 of 2490

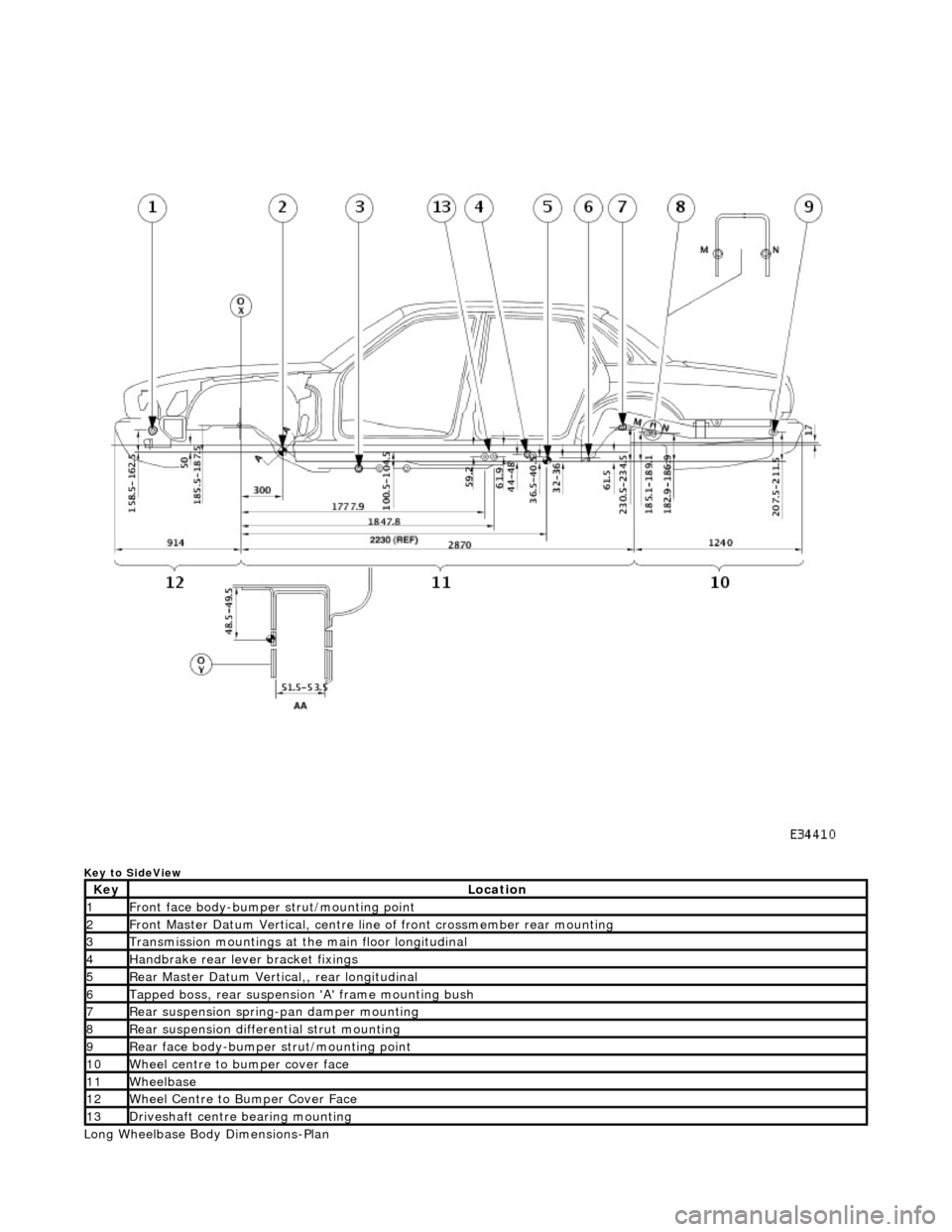

Key to SideView

Long Wheelbase Body Dimensions-Plan

KeyLocation

1Front face body-bumper strut/mounting point

2Front Master Datum Vertical, centre line of front crossmember rear mounting

3Transmission mountings at the main floor longitudinal

4Handbrake rear lever bracket fixings

5Rear Master Datum Vertical,, rear longitudinal

6Tapped boss, rear suspensi on 'A' frame mounting bush

7Rear suspension spring-pan damper mounting

8Rear suspension differential strut mounting

9Rear face body-bumper strut/mounting point

10Wheel centre to bumper cover face

11Wheelbase

12Wheel Centre to Bumper Cover Face

13Driveshaft centre bearing mounting

Page 2389 of 2490

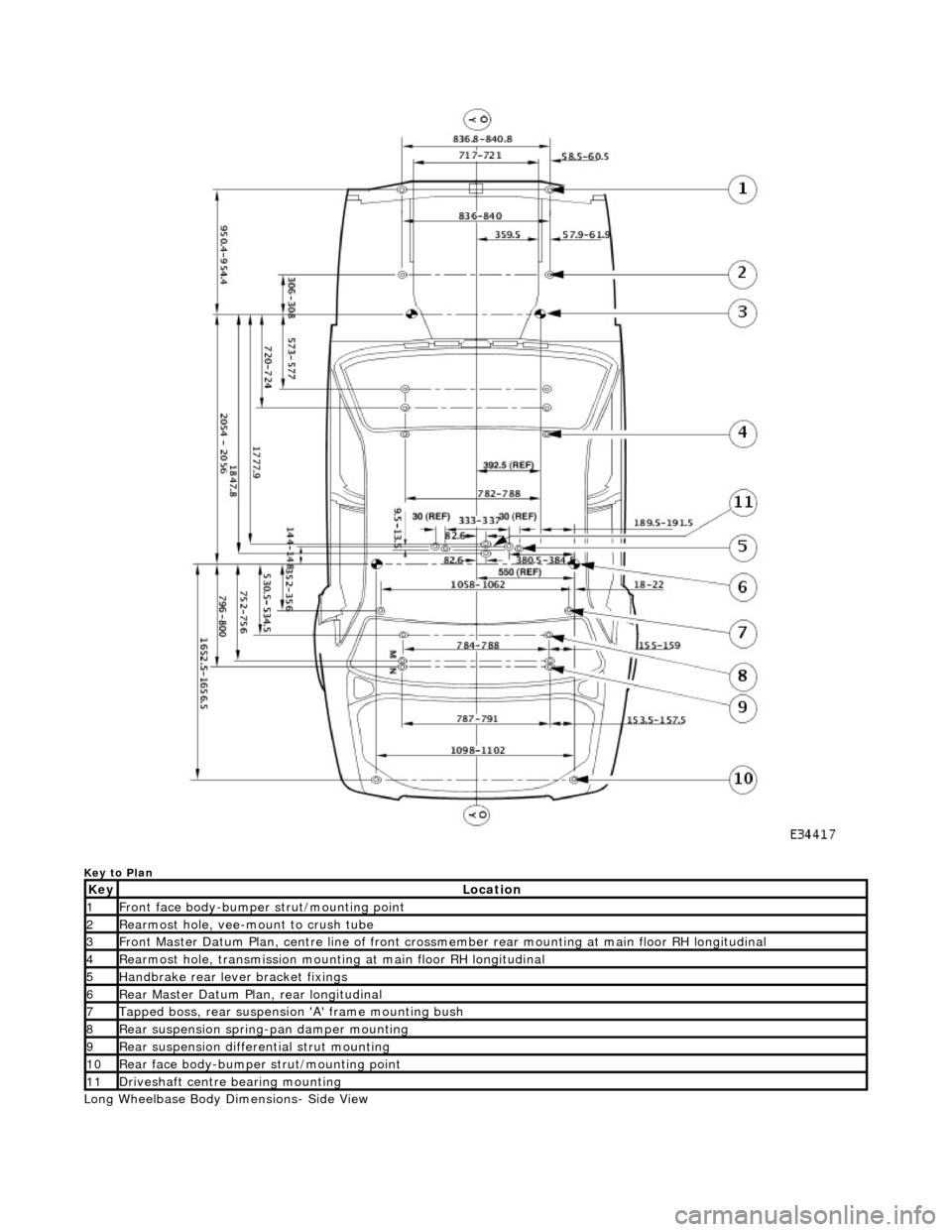

Key to Plan

Long Wheelbase Body Dimensions- Side View

KeyLocation

1Front face body-bumper strut/mounting point

2Rearmost hole, vee-mount to crush tube

3Front Master Datum Plan, centre line of front crossmember rear mount ing at main floor RH longitudinal

4Rearmost hole, transmission mounting at main floor RH longitudinal

5Handbrake rear lever bracket fixings

6Rear Master Datum Plan, rear longitudinal

7Tapped boss, rear suspension 'A' frame mounting bush

8Rear suspension spring-pan damper mounting

9Rear suspension differential strut mounting

10Rear face body-bumper strut/mounting point

11Driveshaft centre bearing mounting

Page 2390 of 2490

Key to SideView

KeyLocation

1Front face body-bumper strut/mounting point

2Front Master Datum Vertical, centre line of front crossmember rear mounting

3Transmission mountings at the main floor longitudinal

4Handbrake rear lever bracket fixings

5Rear Master Datum Vertical,, rear longitudinal

6Tapped boss, rear suspensi on 'A' frame mounting bush

7Rear suspension spring-pan damper mounting

8Rear suspension differential strut mounting

9Rear face body-bumper strut/mounting point

10Wheel centre to bumper cover face

11Wheelbase

12Wheel Centre to Bumper Cover Face

13Driveshaft centre bearing mounting

Page 2481 of 2490

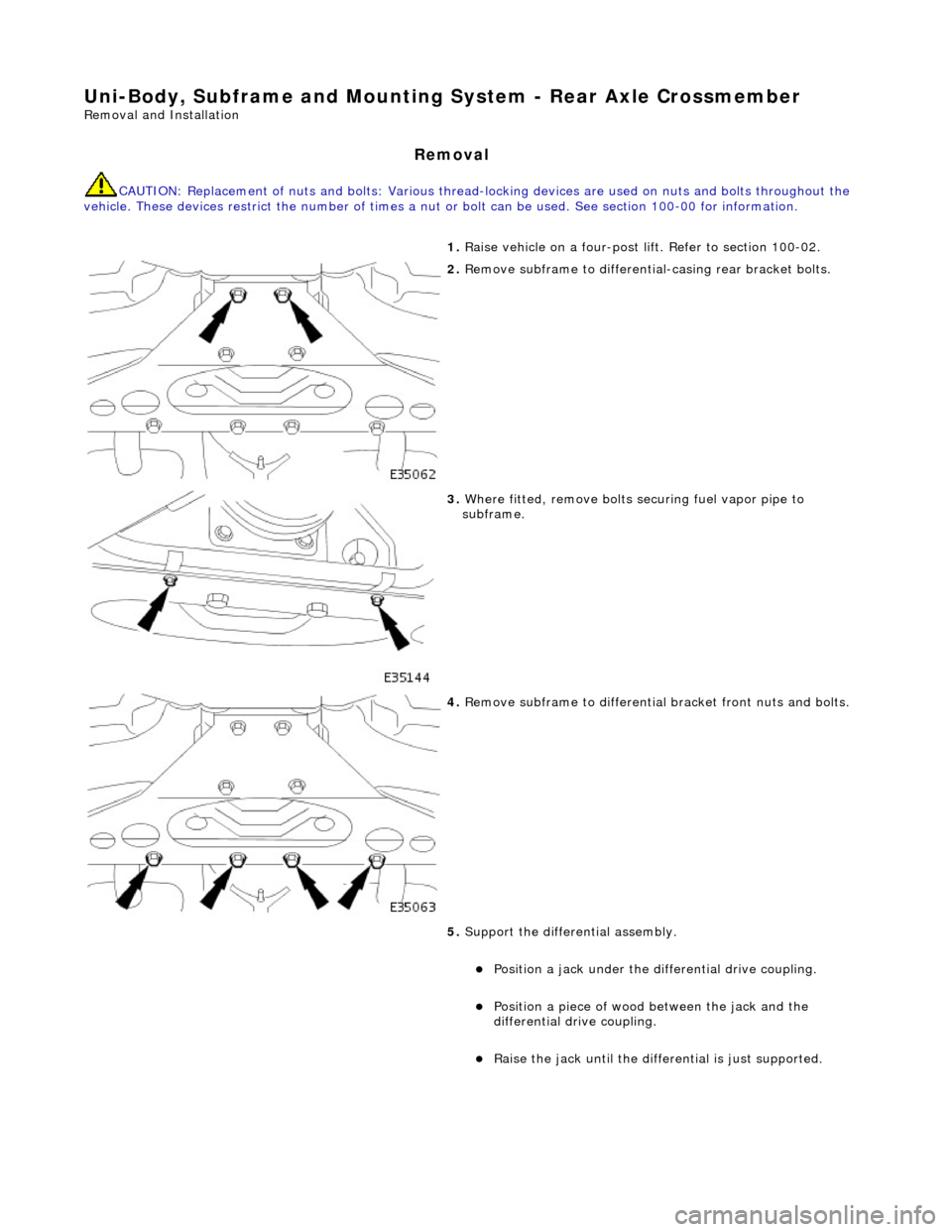

Uni-Body, Subframe and Mounting System - Rear Axle Crossmember

Removal and Installation

Removal

CAUTION: Replacement of nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

1. Raise vehicle on a four-post li ft. Refer to section 100-02.

2. Remove subframe to differentia l-casing rear bracket bolts.

3. Where fitted, remove bolts se curing fuel vapor pipe to

subframe.

4. Remove subframe to differential bracket front nuts and bolts.

5. Support the differential assembly.

Position a jack under the differential drive coupling.

Position a piece of wood between the jack and the

differential drive coupling.

Raise the jack until the diffe rential is just supported.

Page 2482 of 2490

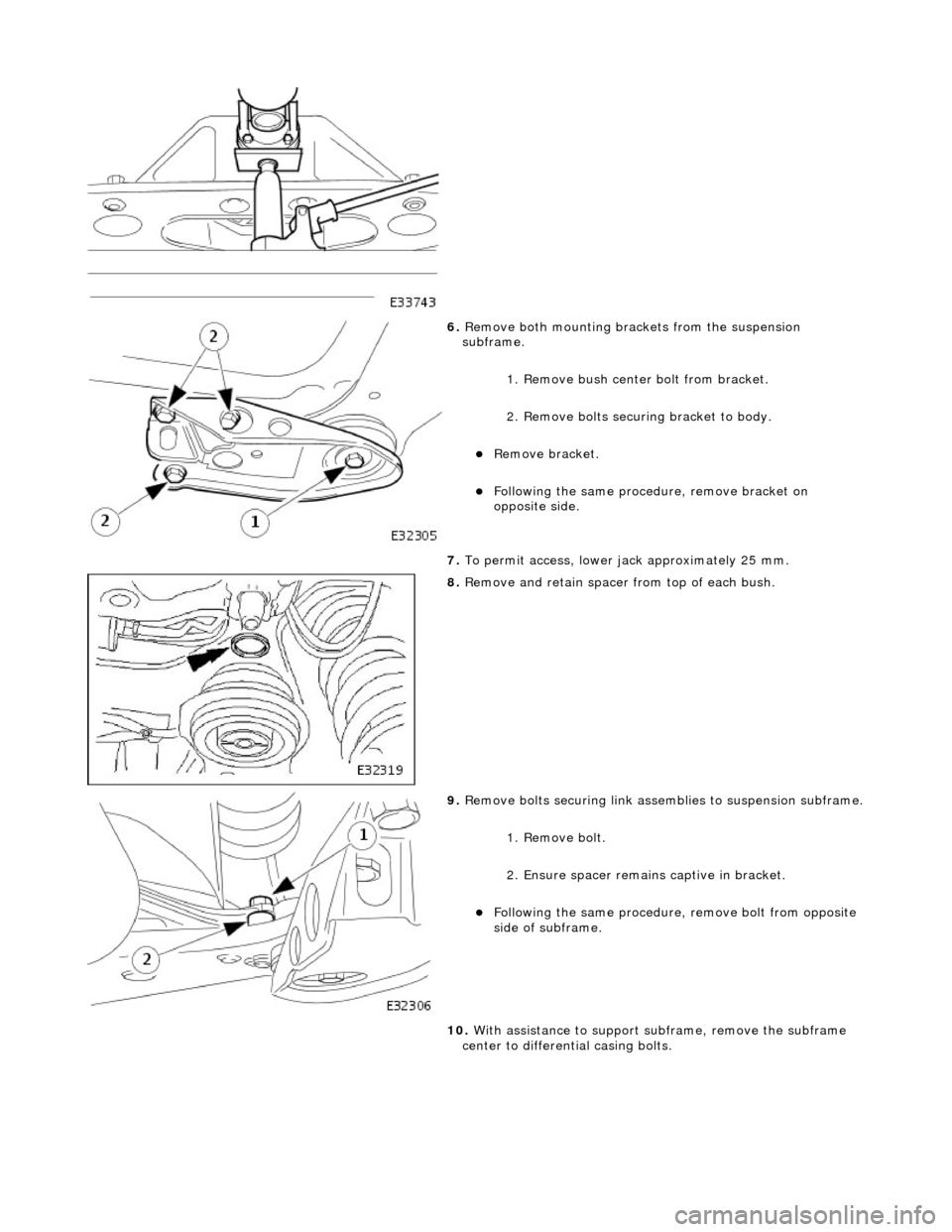

6. Remove both mounting brac kets from the suspension

subframe.

1. Remove bush center bolt from bracket.

2. Remove bolts securi ng bracket to body.

Remove bracket.

Following the same procedure, remove bracket on

opposite side.

7. To permit access, lower jack approximately 25 mm.

8. Remove and retain spacer from top of each bush.

9. Remove bolts securing link assemblies to suspension subframe.

1. Remove bolt.

2. Ensure spacer remain s captive in bracket.

Following the same procedure, remove bolt from opposite

side of subframe.

10. With assistance to support su bframe, remove the subframe

center to differential casing bolts.

Page 2483 of 2490

Installation

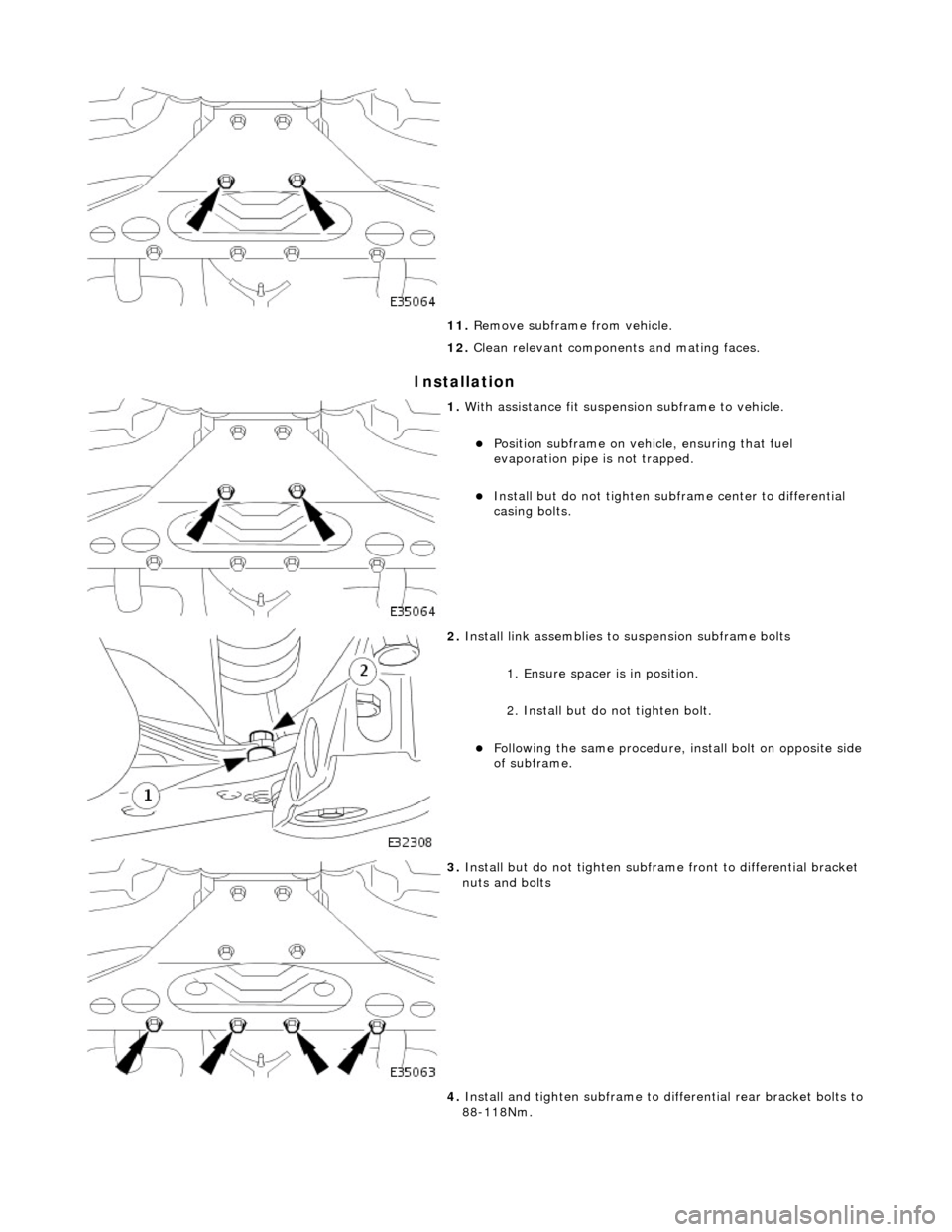

11. Remove subframe from vehicle.

12. Clean relevant components and mating faces.

1. With assistance fit suspension subframe to vehicle.

Position subframe on vehi cle, ensuring that fuel

evaporation pipe is not trapped.

Install but do not tighten sub frame center to differential

casing bolts.

2. Install link assemblies to suspension subframe bolts

1. Ensure spacer is in position.

2. Install but do not tighten bolt.

Following the same procedure, in stall bolt on opposite side

of subframe.

3. Install but do not tighten subframe front to differential bracket

nuts and bolts

4. Install and tighten sub frame to differential rear bracket bolts to

88-118Nm.

Page 2484 of 2490

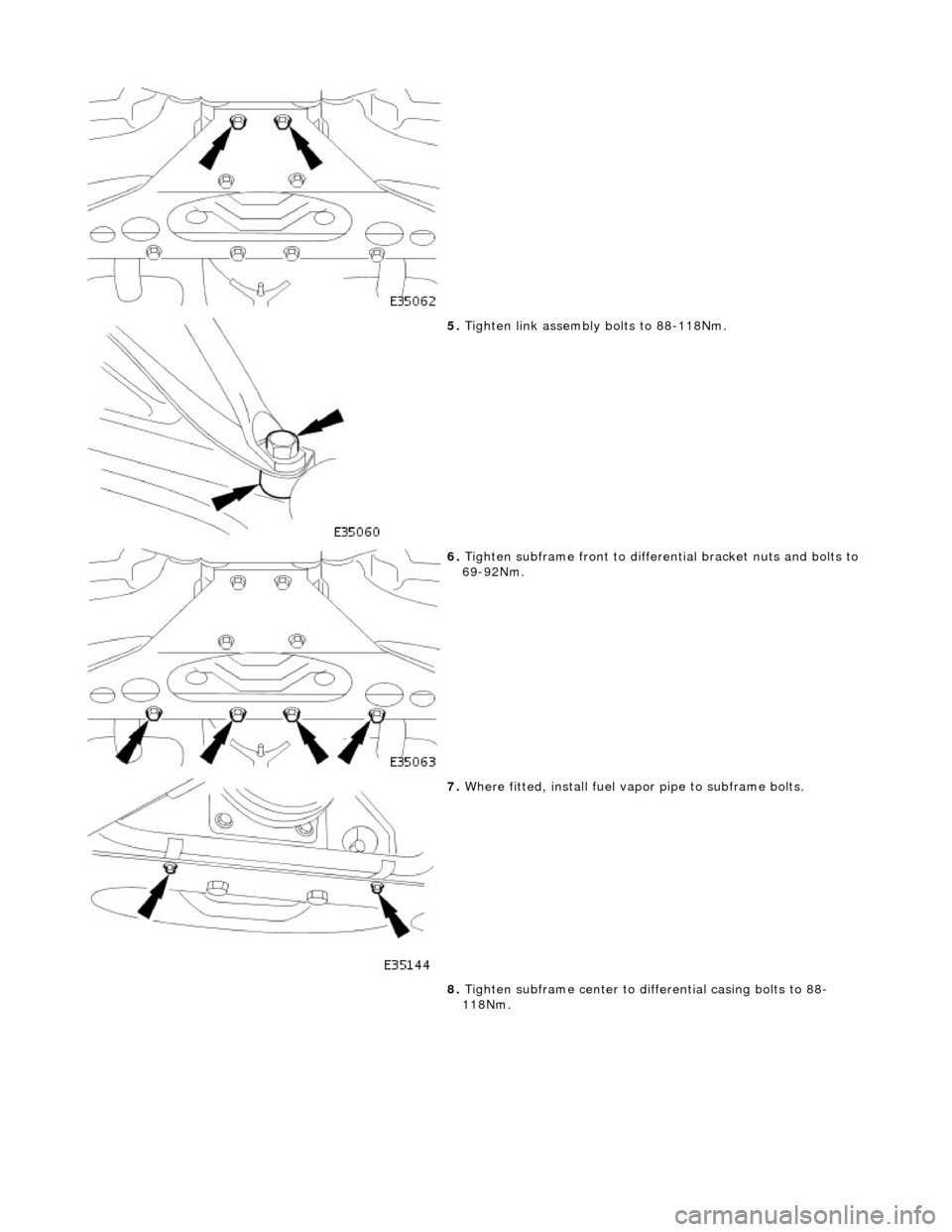

5. Tighten link assembly bolts to 88-118Nm.

6. Tighten subframe front to differential bracket nuts and bolts to

69-92Nm.

7. Where fitted, install fuel vapo r pipe to subframe bolts.

8. Tighten subframe center to di fferential casing bolts to 88-

118Nm.