weight JAGUAR X308 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1756 of 2490

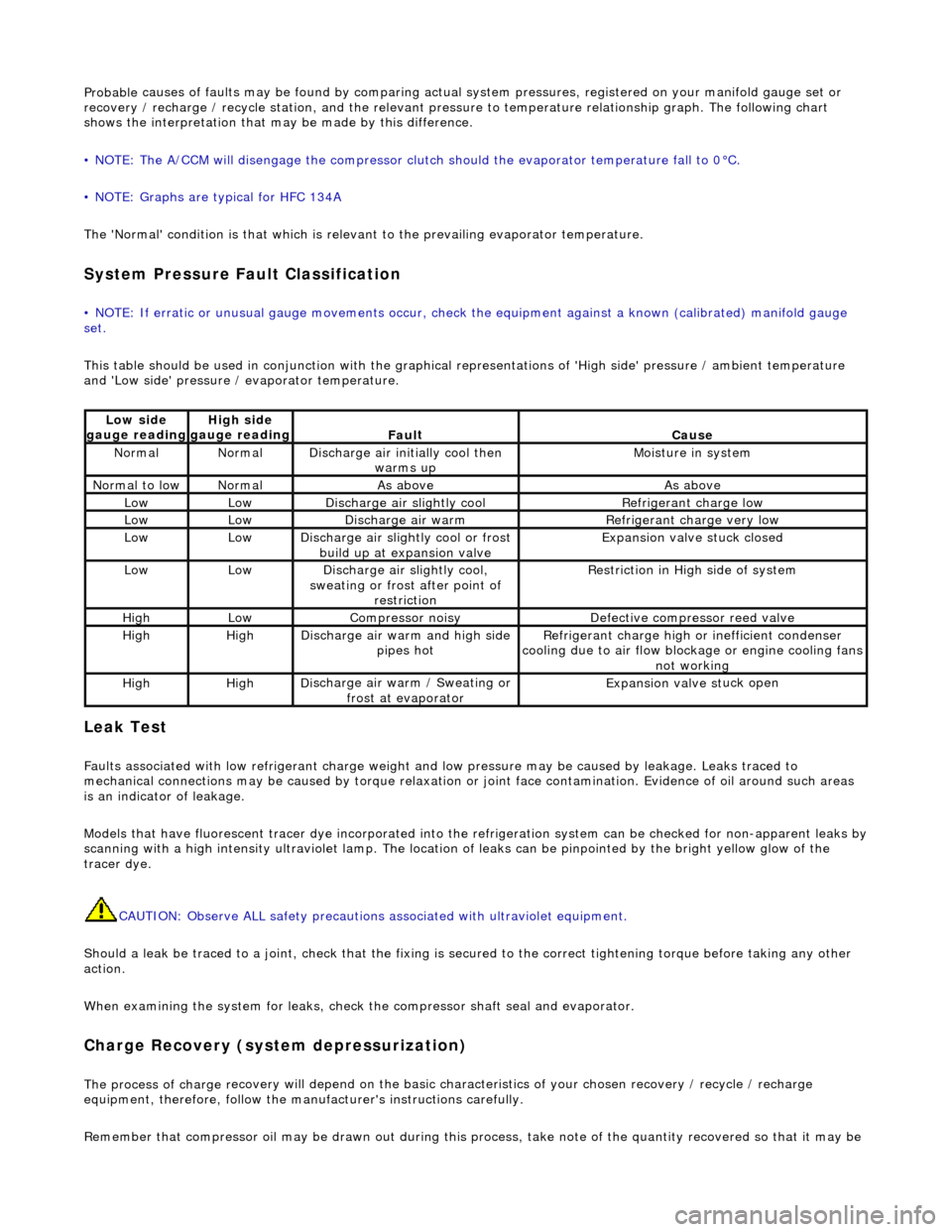

Probable

causes of faults may be found by comparing actual

system pressures, registered on your manifold gauge set or

recovery / recharge / recycle station, and the relevant pressure to temperature relationship graph. The following chart

shows the interpretation that ma y be made by this difference.

• NOTE: The A/CCM will disengage the compressor clutch should the evaporator temperature fall to 0°C.

• NOTE: Graphs are typical for HFC 134A

The 'Normal' condition is that which is relevant to the prevailing evaporator temperature.

System Pressure Fault Classification

• NOTE

: If erratic or unusual gauge move

ments occur, check the equipment against a known (calibrated) manifold gauge

set.

This table should be used in conjunction with the graphical representations of 'High side' pressure / ambient temperature

and 'Low side' pressure / evaporator temperature.

Leak

Test

F

a

ults associated with low re

frigerant charge weight and low pressure ma y be caused by leakage. Leaks traced to

mechanical connections may be caused by to rque relaxation or joint face contamination. Evidence of oil around such areas

is an indicator of leakage.

Models that have fluorescent tracer dye incorporated into the refrigeration system can be checke d for non-apparent leaks by

scanning with a high intensity ultraviolet lamp. The location of leaks can be pinpointed by the bright yellow glow of the

tracer dye.

CAUTION: Observe ALL safety precautions associated with ultraviolet equipment.

Should a leak be traced to a joint, check that the fixing is secured to the correct tightening torque before taking any other

action.

When examining the system for leaks, chec k the compressor shaft seal and evaporator.

Charge Re

covery (system depressurization)

The process of

charge r

ecovery will depe

nd on the basic characteristics of your chosen recovery / recycle / recharge

equipment, therefore, follow the manu facturer's instructions carefully.

Remember that compressor oil may be drawn out during this process, take note of the quantity recovered so that it may be

Lo

w side

gauge reading

High s i

de

gauge reading

Fau l

t

Cause

No

r

mal

No

r

mal

Di

sc

harge air initially cool then

warms up

Mois

ture in system

N

ormal

to low

No

r

mal

As aboveAs above

LowLowD

i

scharge air slightly cool

Ref

r

igerant charge low

LowLowDi

scharge air warm

Refr

igerant charge very low

LowLowDi

scharge air slightly cool or frost

build up at expansion valve

Expansion valve st

uck closed

LowLowDi

scharge air slightly cool,

sweating or frost after point of restriction

Restri

ction in High side of system

HighLowCompressor noisyDe

fe

ctive compressor reed valve

HighHighD

i

scharge air warm and high side

pipes hot

Refri

gerant charge high or inefficient condenser

cooling due to air flow blockage or engine cooling fans

not working

HighHighD i

scharge air warm / Sweating or

frost at evaporator

Expans ion valve st

uck open

Page 1762 of 2490

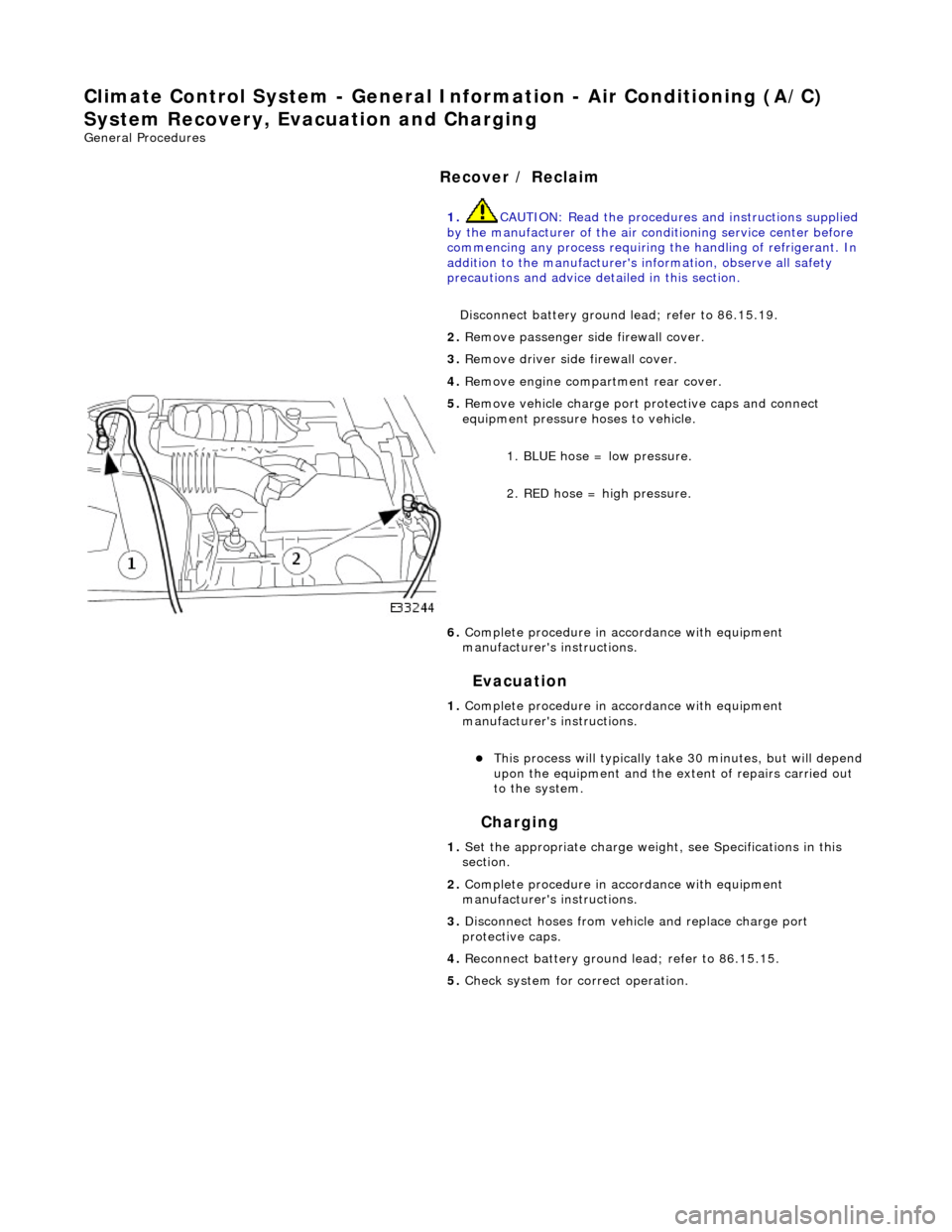

Climate Control System - General Infor

mation - Air Conditioning (A/C)

System Recovery, Evacuation and Charging

Gen e

ral Procedures

Recover / Reclaim

Ev

acuation

Charging

1.

CAUTIO

N: Read the procedures and instructions supplied

by the manufacturer of the air co nditioning service center before

commencing any process requiring the handling of refrigerant. In

addition to the manufacturer's in formation, observe all safety

precautions and advice deta iled in this section.

Disconnect battery ground lead; refer to 86.15.19.

2. Remove passenger side fi

rewall cover.

3. Remove driver side firewall cover.

4. Remove engine compar tment rear cover.

5. Re

move vehicle charge port

protective caps and connect

equipment pressure hoses to vehicle.

1. BLUE hose = low pressure.

2. RED hose = high pressure.

6. Complete procedure in ac cordance with equipment

manufacturer's instructions.

1. Complete procedure in ac cordance with equipment

manufacturer's instructions.

This proc

ess will typically ta

ke 30 minutes, but will depend

upon the equipment and the ex tent of repairs carried out

to the system.

1. Set the appropriate charge weight, see Specifications in this

section.

2. Complete procedure in ac cordance with equipment

manufacturer's instructions.

3. Disconnect hoses from vehicle and replace charge port

protective caps.

4. Reconnect battery ground lead; refer to 86.15.15.

5. Check system for correct operation.

Page 1765 of 2490

Climate Co

ntrol System - General

Information - Refrigerant Adding

Gen

eral Procedures

CAUTION: If oil was drawn out during the recovery process, the correct amount may be added directly from the

recovery, recycle and recharge station (if so equipped) prior to the charging process. It must be stressed that the need to

protect compressor oil from moisture is vital, observe the pr ocedures in HANDLING LUBRICATING OIL and those concerning

excessive engine speed.

1. In order that the

air conditioning system may operate

efficiently it must contain a full refrigerant charge. The

indications of some system defects, and the results of certain

tests, will show that a low charge is the most probable cause of

the fault. In such cases the ch arge should be recovered from

the system, the weight noted, and the correct amount added.

Should refrigerant be added in liquid form, the engine speed

must not exceed 2000 rpm for a period of two minutes after

first running the compressor. If the engine speed is excessive,

compressor damage may occur du e to the lubricating oil and

the liquid refrigerant being initia lly forced around the system as

a 'slug', thus taking oil away from the compressor. These

marginal lubrication conditions in the compressor will cease as

the refrigerant becomes gaseous.

Never attempt to estimate the amount of refrigerant in a

system. Always recover and rech arge with the correct charge

weight; this is the only accurate method.

Page 1876 of 2490

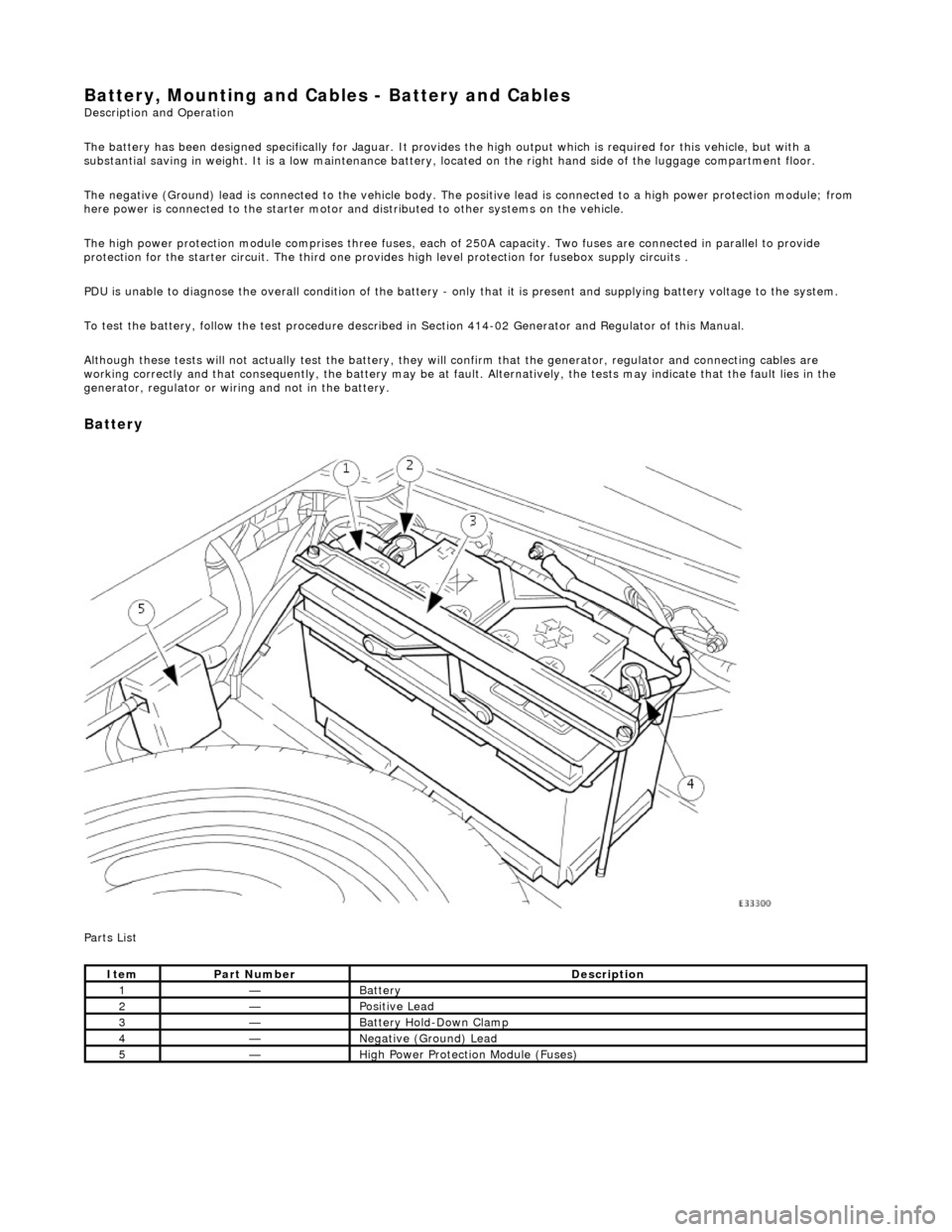

Battery, Mounting and Cables - Battery and Cables Description and Operation

The battery has been designed specifically for Jaguar. It provides the high output which is required for this vehicle, but with a

substantial saving in weight. It is a low maintenance battery, located on the right ha nd side of the luggage compartment floor.

The negative (Ground) lead is connected to the vehicle body. The positive lead is connected to a high power protection module; from

here power is connected to the starter motor an d distributed to other systems on the vehicle.

The high power protection module comprises three fuses, each of 250A capacity. Two fuses are connected in parallel to provide

protection for the starter circuit. Th e third one provides high level protection for fusebox supply circuits .

PDU is unable to diagnose the overall condition of the battery - only that it is present and supplying battery voltage to the system.

To test the battery, follow the test procedure described in Section 414-02 Generator and Regulator of this Manual.

Although these tests will not actually test the battery, they will confirm that the generator, regulator and connecting cables are

working correctly and that conseq uently, the battery may be at fault. Alternatively, the tests may indicate that the fault lies in the

generator, regulator or wiring and not in the battery.

Battery

Parts List

ItemPart NumberDescription

1—Battery

2—Positive Lead

3—Battery Hold-Down Clamp

4—Negative (Ground) Lead

5—High Power Protection Module (Fuses)

Page 2021 of 2490

Body System - General Information - Body

Description and Operation

This section covers the following areas of the vehicle body:

Front end body panels

Body closures

Aperture seals

Door seals

Instrument panel, console and radio

Centre console

Handles, locks, latches and mechanisms

Wipers and washers

Glass, frames and mechanisms

Fascia

Fuel filler flap assembly

Sun visors

Seating

Interior trim and ornamentation

Exterior trim and ornamentation

Rear view mirrors

Rear parcel tray

Roof console

Bumpers

Occupant restraints

Sliding roof

Steering column cowl

Underscuttle pad

Front End Body Panels

A false bulkhead together with two insulation covers, are installed between the engine compartment and the BIW front

bulkhead to provide optimum insulation ag ainst noise and heat intrusion. Two plenum braces bolted between the BIW upper toeboards and the plenum further increase bodyshell structural integrity. The plastic ra diator grill and vane block achieve

weight reductions over steel parts and provid e high resistance to front end corrosion.

Page 2027 of 2490

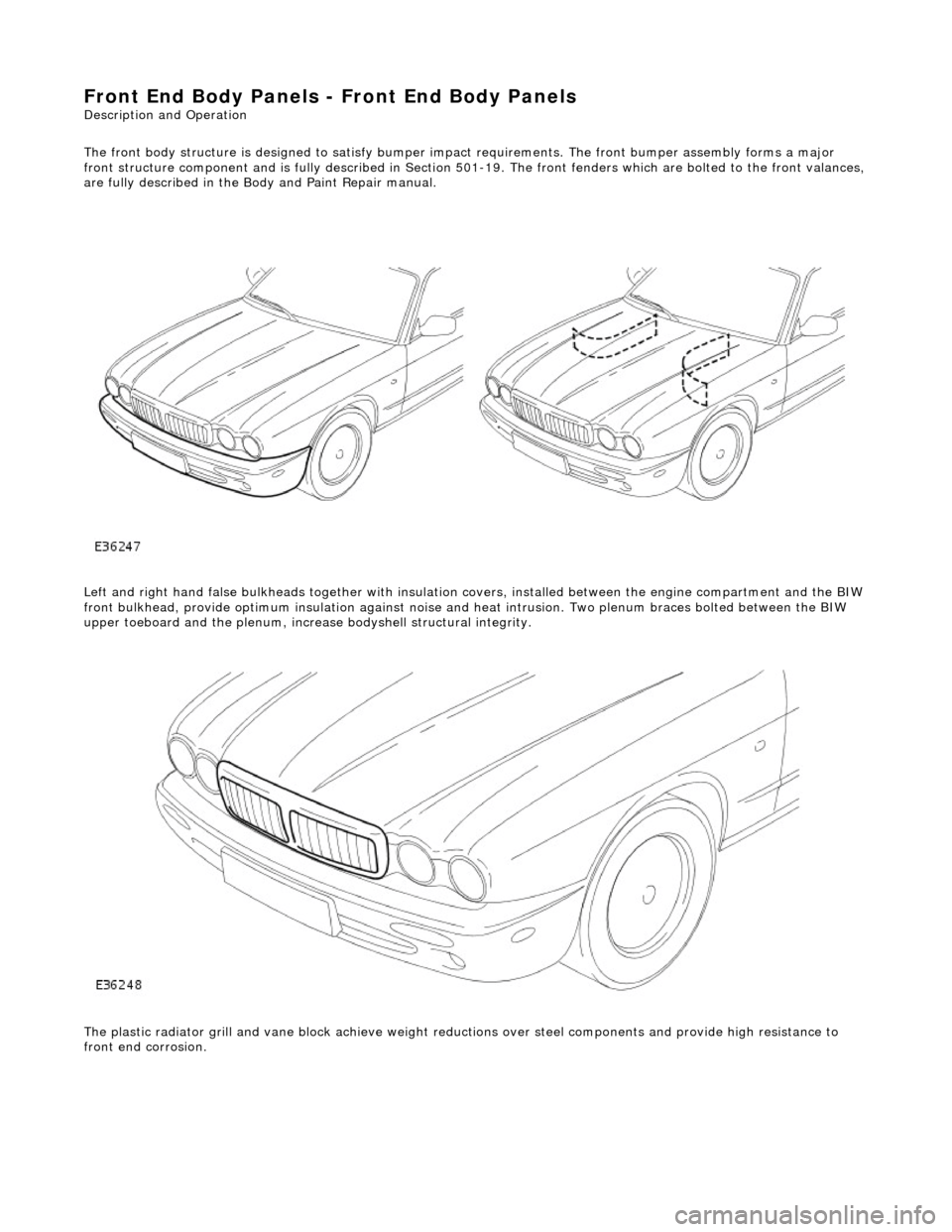

Front End Body Panels - Front End Body Panels

Description and Operation

The front body structure is de signed to satisfy bumper impact requiremen ts. The front bumper assembly forms a major

front structure component and is fully desc ribed in Section 501-19. The front fenders which are bolted to the front valances,

are fully described in the Body and Paint Repair manual.

Left and right hand false bulkheads together with insulation covers, installed between the engine compartment and the BIW

front bulkhead, provide optimum insulation against noise and heat intrusion. Two plenum braces bolted between the BIW

upper toeboard and the plenum, increa se bodyshell structural integrity.

The plastic radiator grill and vane block achieve weight reductions over steel components and provide high resistance to

front end corrosion.

Page 2421 of 2490

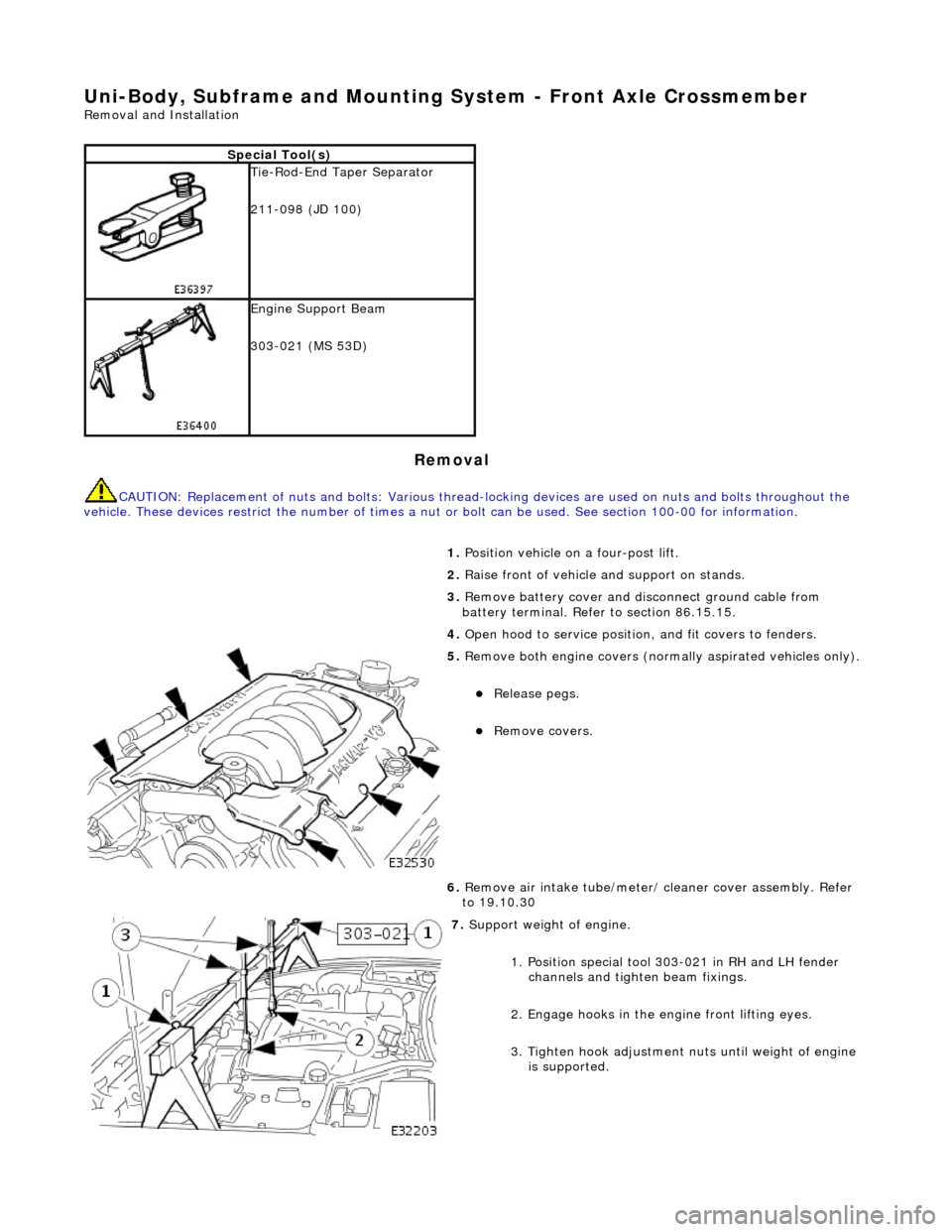

Uni-Body, Subframe and Mounting System - Front Axle Crossmember

Removal and Installation

Removal

CAUTION: Replacement of nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

Special Tool(s)

Tie-Rod-End Taper Separator

211-098 (JD 100)

Engine Support Beam

303-021 (MS 53D)

1. Position vehicle on a four-post lift.

2. Raise front of vehicle and support on stands.

3. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to section 86.15.15.

4. Open hood to service position, and fit covers to fenders.

5. Remove both engine covers (nor mally aspirated vehicles only).

Release pegs.

Remove covers.

6. Remove air intake tube/meter/ cleaner cover assembly. Refer

to 19.10.30

7. Support weight of engine.

1. Position special tool 303-021 in RH and LH fender channels and tighte n beam fixings.

2. Engage hooks in the en gine front lifting eyes.

3. Tighten hook adjustment nuts until weight of engine is supported.

Page 2425 of 2490

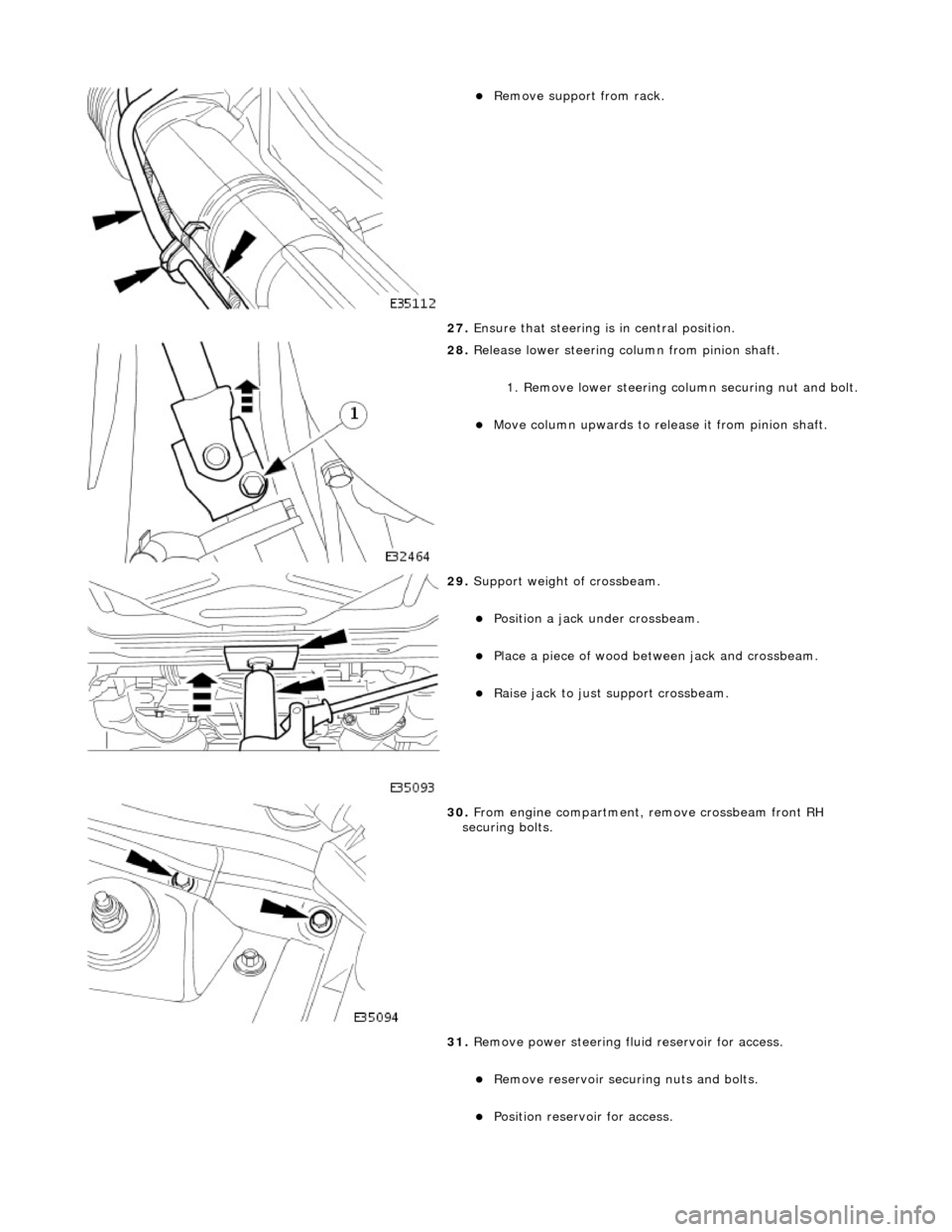

Remove support from rack.

27. Ensure that steering is in central position.

28. Release lower steering column from pinion shaft.

1. Remove lower steering co lumn securing nut and bolt.

Move column upwards to release it from pinion shaft.

29. Support weight of crossbeam.

Position a jack under crossbeam.

Place a piece of wood between jack and crossbeam.

Raise jack to just support crossbeam.

30. From engine compartment, remove crossbeam front RH

securing bolts.

31. Remove power steering fl uid reservoir for access.

Remove reservoir securing nuts and bolts.

Position reservoir for access.

Page 2434 of 2490

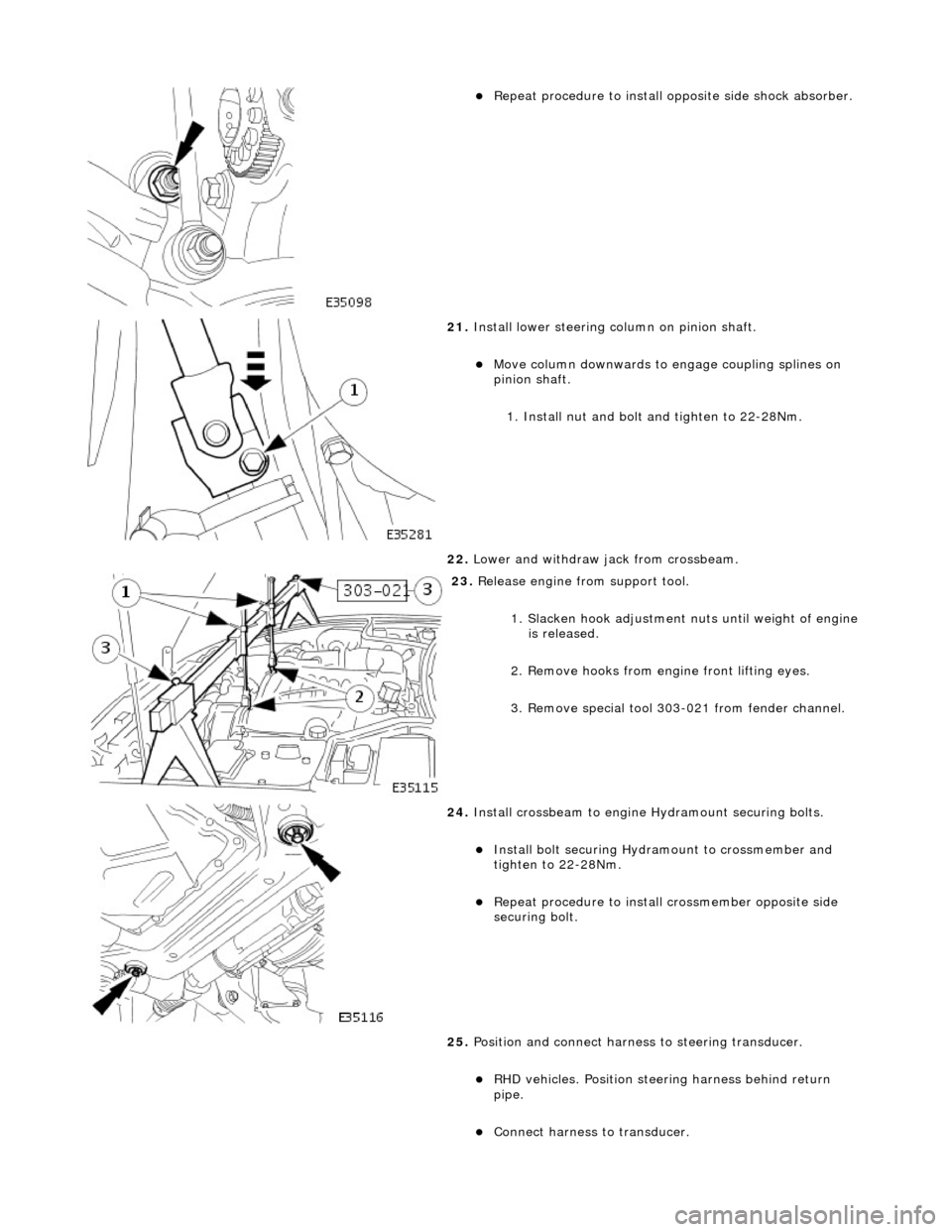

Repeat procedure to install opposite side shock absorber.

21. Install lower steering column on pinion shaft.

Move column downwards to engage coupling splines on

pinion shaft.

1. Install nut and bolt and tighten to 22-28Nm.

22. Lower and withdraw jack from crossbeam.

23. Release engine from support tool.

1. Slacken hook adjustment nuts until weight of engine is released.

2. Remove hooks from engine front lifting eyes.

3. Remove special tool 303- 021 from fender channel.

24. Install crossbeam to engine Hydramount securing bolts.

Install bolt securing Hydr amount to crossmember and

tighten to 22-28Nm.

Repeat procedure to install crossmember opposite side

securing bolt.

25. Position and connect harnes s to steering transducer.

RHD vehicles. Position steeri ng harness behind return

pipe.

Connect harness to transducer.

Page 2439 of 2490

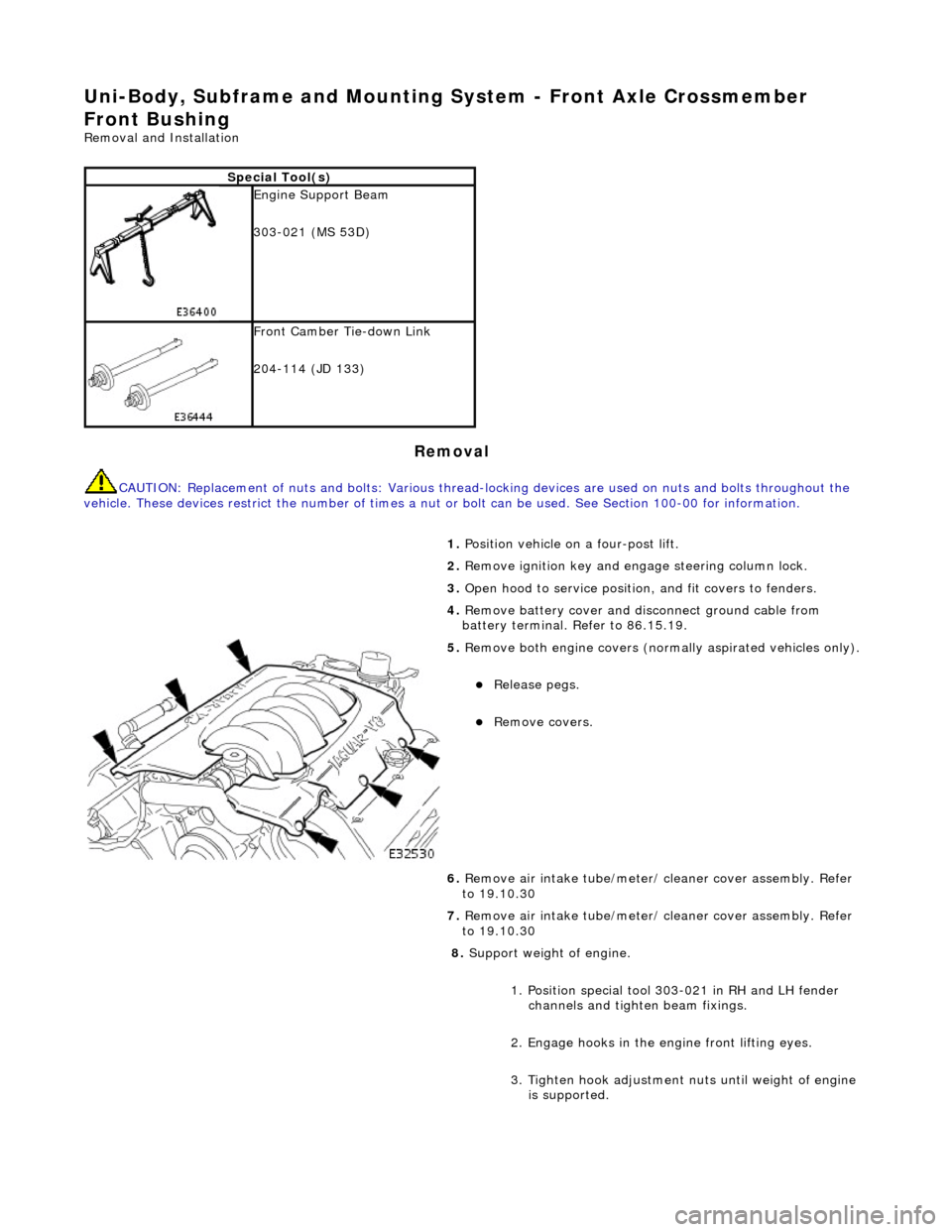

Uni-Body, Subframe and Mounting System - Front Axle Crossmember

Front Bushing

Removal and Installation

Removal

CAUTION: Replacement of nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See Section 100-00 for information.

Special Tool(s)

Engine Support Beam

303-021 (MS 53D)

Front Camber Tie-down Link

204-114 (JD 133)

1. Position vehicle on a four-post lift.

2. Remove ignition key and en gage steering column lock.

3. Open hood to service position, and fit covers to fenders.

4. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

5. Remove both engine covers (nor mally aspirated vehicles only).

Release pegs.

Remove covers.

6. Remove air intake tube/meter/ cleaner cover assembly. Refer

to 19.10.30

7. Remove air intake tube/meter/ cleaner cover assembly. Refer

to 19.10.30

8. Support weight of engine.

1. Position special tool 303-021 in RH and LH fender channels and tighte n beam fixings.

2. Engage hooks in the en gine front lifting eyes.

3. Tighten hook adjustment nuts until weight of engine is supported.