JAGUAR X308 1998 2.G Workshop Manual

X308 1998 2.G

JAGUAR

JAGUAR

https://www.carmanualsonline.info/img/21/7640/w960_7640-0.png

JAGUAR X308 1998 2.G Workshop Manual

Page 1721 of 2490

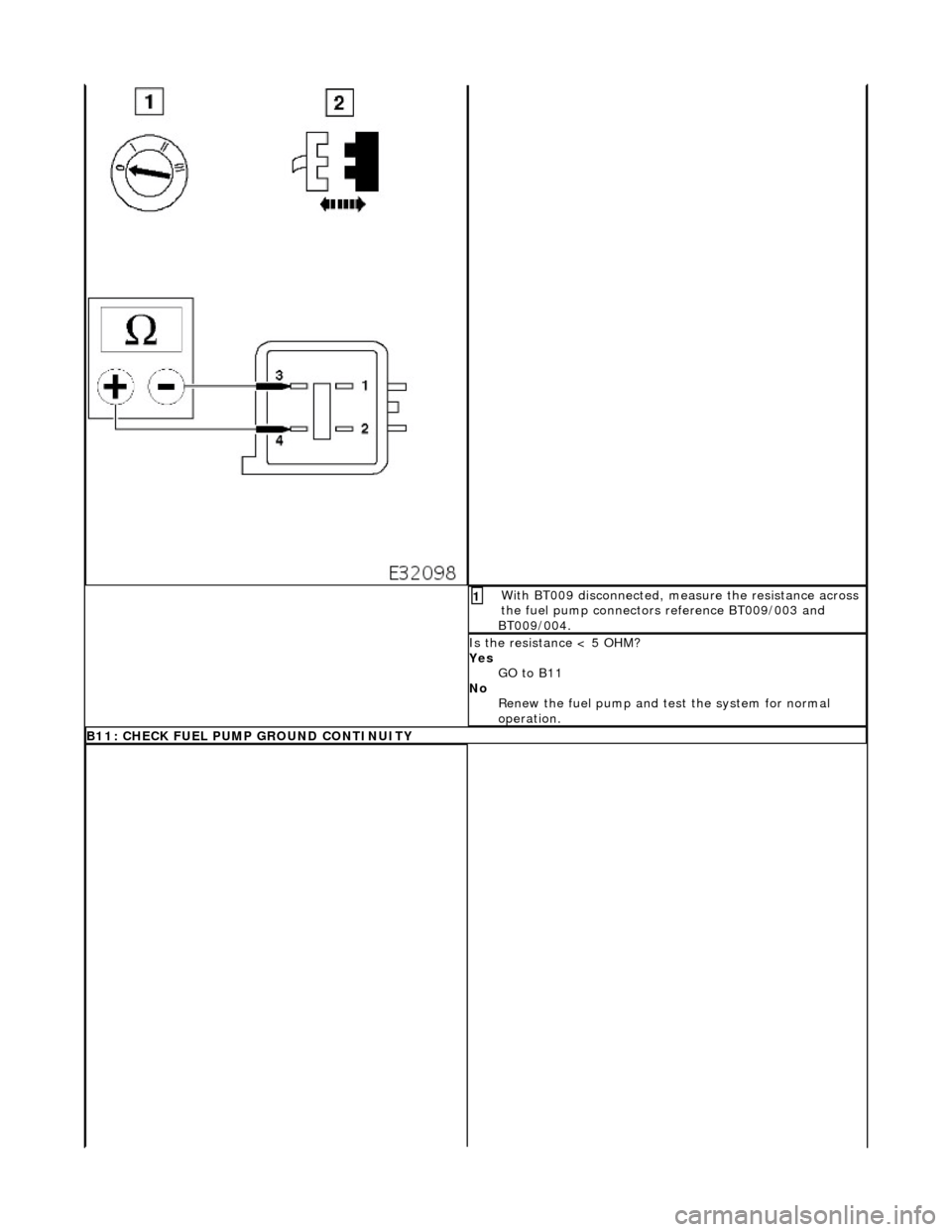

Wi

th BT009 disconnected, measure the resistance across

the fuel pump connectors reference BT009/003 and

BT009/004.

1

I

s the resistance < 5 OHM?

Yes GO to B11

No Renew the fuel pump and te st the system for normal

operation.

B11: CHECK FU

EL PUMP GROUND CONTINUITY

Page 1722 of 2490

With

BT009 disconnected, measure the resistance

between BT009/003 and ground BT020L.

1

I s

the resistance < 0.5 OHM?

Yes GO to B12

No Inspect harness / connector BT009, splice BTS021 and

ground BT020L for corrosion, damage, bent or pushed

back pins. Repair as requir ed and test the system for

normal operation.

B1 2

: CHECK CIRCUIT CONTINUITY

Page 1723 of 2490

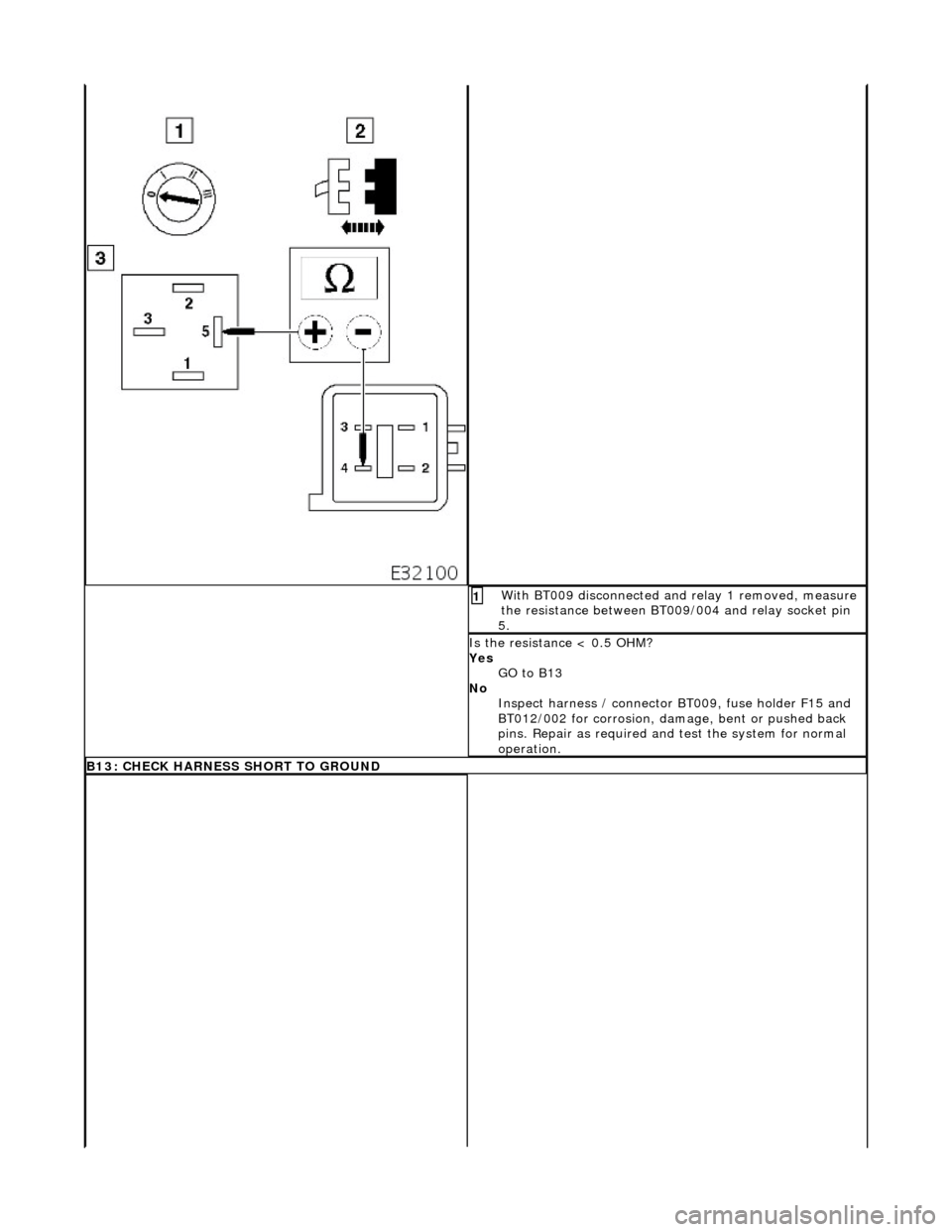

Wi

th BT009 disconnected an

d relay 1 removed, measure

the resistance between BT009/004 and relay socket pin

5.

1

I

s the resistance < 0.5 OHM?

Yes GO to B13

No Inspect harness / connector BT 009, fuse holder F15 and

BT012/002 for corrosion, damage, bent or pushed back

pins. Repair as required and test the system for normal

operation.

B13: CHECK HARNESS SHO

RT TO GROUND

Page 1724 of 2490

Wi

th EM013 and BT009 disconnected, measure the

insulation resistance between EM013/009 and ground

BT020L.

1

I s

the resistance > 10M OHM?

Yes Do not replace relay or reconnect connectors

GO to B14

No Inspect harness / connec tors EM013, EM051/008,

LS003/021, BT004/009 and BT010/005 for corrosion,

damage, bent or pushed back pins. Repair as required

and test the system for normal operation.

B1 4

: CHECK CORE TO CORE INSULATION

Page 1727 of 2490

Conne

ct the scan tool

1

Have the DTC(s) and fr

eeze

frame data been recorded?

Yes GO to C2

C2

: CHECK CONTINUITY FUEL SENSOR

W

ith connectors BT014 and BT015 disconnected check

the resistance between the fuel level sensor pins.

1

Is

the resistance >70 and <1000 OHM?

Yes GO to C3

No Renew the level sensor and test the system for normal

operation.

C3

: CHECK FOR SHORT TO GROUND

Page 1728 of 2490

Wi

th connectors FC025, FC024, BT014 and BT015

disconnected measure the insulation resistance between

FC025/013 and FC024/026.

1

Re

peat for FC025/014 and FC024/026

2

Is

the resistance > 10 MOHM?

Yes GO to C4

No Inspect harness / connectors FC025, FC024, FC001,

BT004, BT014 and BT015 for corrosion, damage, bent or

pushed back pins. Repair as required and test the system

for normal operation.

C4 : CH

ECK CORE TO CORE INSULATION

Page 1729 of 2490

W

ith connectors FC025, FC024, BT014 and BT015

disconnected measure the insulation resistance between

FC025/013 and FC025/014.

1

I

s the resistance > 10 MOHM?

Yes GO to C5

No Inspect harness / connectors FC025, FC024, FC001,

BT004, BT014 and BT015 for corrosion, damage, bent or

pushed back pins. Repair as required and test the system

for normal operation.

C5

: CHECK GROUND CONTINUITY

Page 1730 of 2490

Wi

th connectors FC025, FC024 and BT015 disconnected

measure the resistance between FC025/014 and BT015.

1

I s

the resistance < 0.5 OHM?

Yes GO to C6

No Inspect harness / connectors / pins FC025, FC001/007,

BT004/026 and BT015 for corrosion, damage, bent or

pushed back pins. Repair as required and test the system

for normal operation.

C6 : CH

ECK SIGNAL CONTINUITY

Page 1731 of 2490

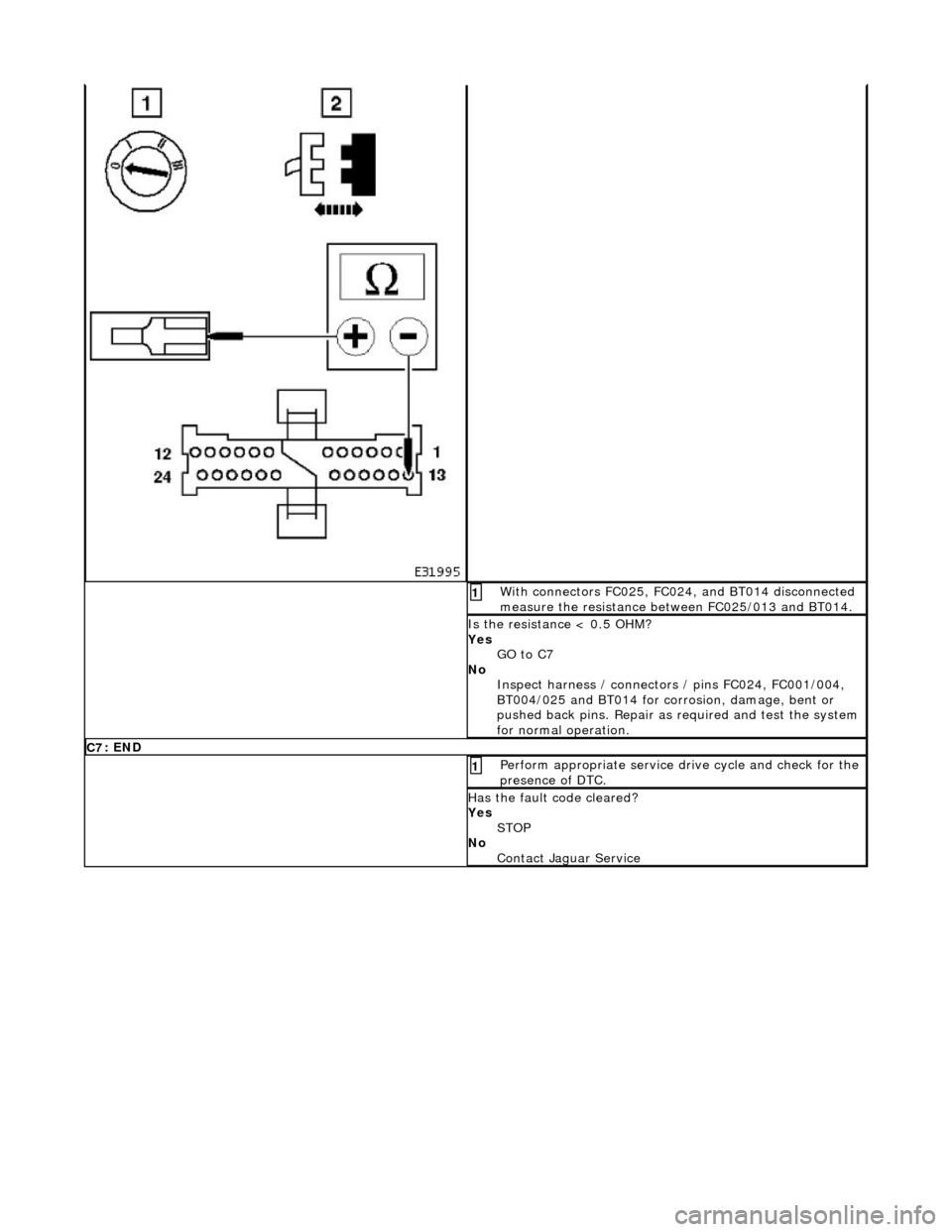

W

ith connectors FC025, FC024, and BT014 disconnected

measure the resistance between FC025/013 and BT014.

1

I

s the resistance < 0.5 OHM?

Yes GO to C7

No Inspect harness / connectors / pins FC024, FC001/004,

BT004/025 and BT014 for corrosion, damage, bent or

pushed back pins. Repair as required and test the system

for normal operation.

C7

: END

Perform

appropriate service drive cycle and check for the

presence of DTC.

1

Has

the fault code cleared?

Yes STOP

No Contact Jaguar Service

Page 1735 of 2490

10

.

Disconnect the fuel feed and return pipes from the fuel tank

пЃ¬F

it special tool JD-203 around

the pipe as shown. Press

the tool in between the fuel pipe and tank connector to

release the quick-fit tangs. While holding the tool firmly in,

pull out the fuel pipe.

пЃ¬Repeat

for the second pipe.

пЃ¬Plu

g the tank outlet connectors and the fuel pipes.

11

.

From the underside of the vehicl e, release the fuel filler latch

box drain pipe from the clip on the spare wheel well.

12

.

Disconnect and reposition the tr unk harness if it is routed

between the filler tube and the ta nk breather or pressure relief

pipe.

1. Disconnect the lefthand re ar lamp harness connector.

2. Disconnect the fuel flap lock actuator connector.

3. If fitted, disconnect the lefthand side marker lamp

connector and harness fro m the underside of the

vehicle. Withdraw the marker lamp harness and

grommet through the trunk floor access hole.

4. Release the harness securi ng clip from the mounting

bracket.

пЃ¬Wi

thdraw the trunk harness from between the filler tube

and the breather pipe or pressure relief pipe.

13. Disconnect the tank harness connections.