Amp JAGUAR X308 1998 2.G Service Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 278 of 2490

Vehicle Dynamic Suspension - Vehicle Dynamic Suspension

Diagn

osis and Testing

Refer to the PDU User Guide for details of diagnosing and testing the Adaptive Damping System. The PDU interrogates the

ADCM directly via the K and L lines to the J1962 diagnostic socket.

The PDU will give an indication of the integrity of each electron ic and electrical component. It will indicate, for example, that

the accelerometers are not broken, but not that they functionin g correctly when the vehicle is in motion. However, it is

exceptional for an accelero meter to function incorrectly in its dynamic mode if it is proved to be functioning when static.

Basic Checks

The accele

rometers have the following ch

aracteristics. At 0g (no movement of the body) each vertical accelerometer

outputs approximately 2.5V steady voltage; the lateral acce lerometer outputs approximately 1.5V. The voltage output due

to body movement is proportional to acceleration in the acceleration axis, up to approximately 4.5V and down to

approximately 0.5V.

Before changing any component, refer to the circuit diagrams and check the cont inuity of relevant harness circuits; in some

instances, the PDU will not different iate between a faulty component an d a damaged connection or wiring.

Check the following fuses:

En

gine compartment fuse

box, fuse F5 (10A).

Engine m

anagement fuse

box, fuse F1 (20A).

Check the following ADCM input/output lines:

Sy stem erro

r output from the ADCM

to the instrument cluster.

Vehicl

e speed output from the inst

rument cluster to the ADCM.

Foo

tbrake signal to the ADCM.

Check any relevant connections to confirm that the connection is electrically sound and that a terminal pin has not been

pushed back into the connector shell, ie. not ma king a connection to its mating pin or socket.

Page 284 of 2490

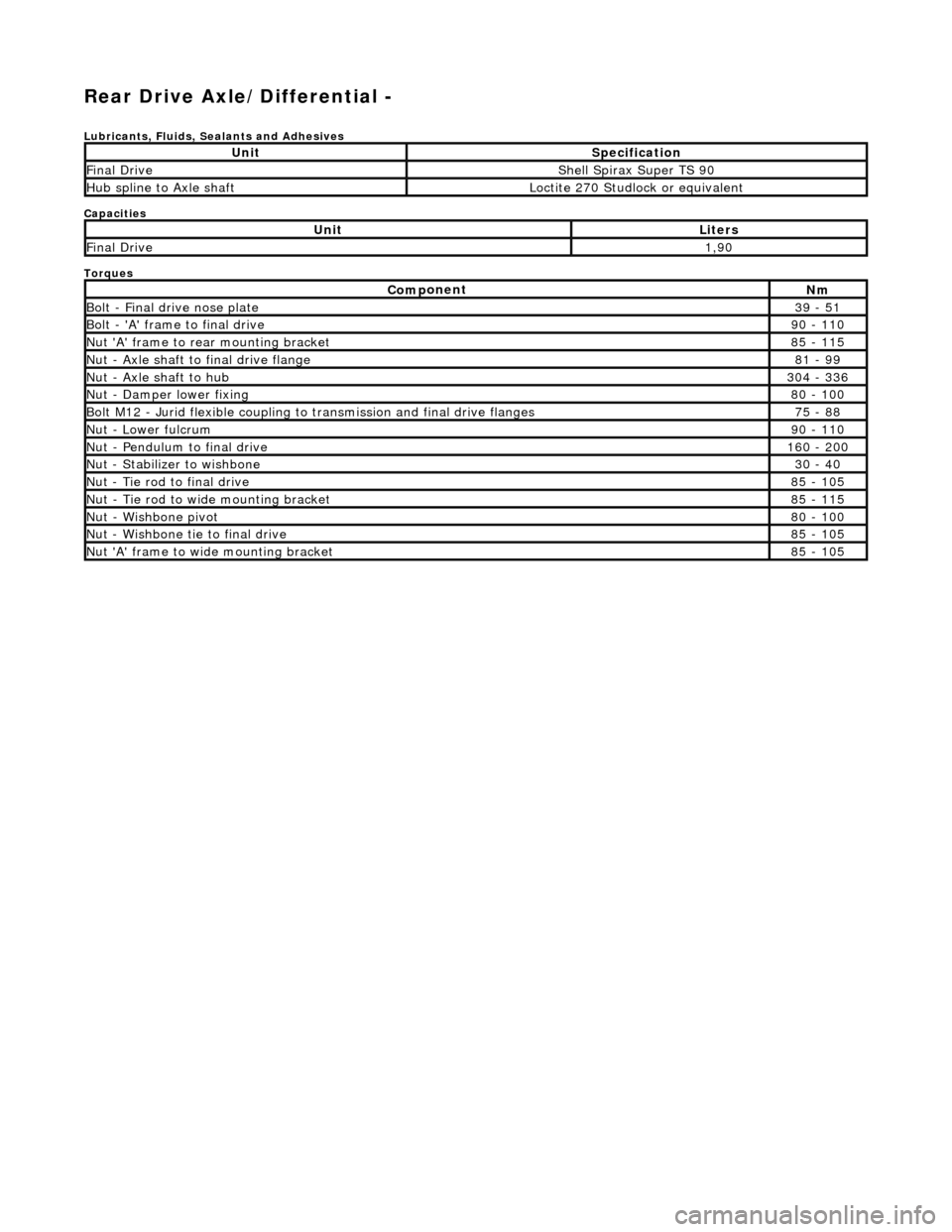

Re

ar Drive Axle/Differential -

Lubric

ants, Fluids, Sealants and Adhesives

Capacities

Torques

UnitSp

ecification

F

i

nal Drive

Shell Sp

irax Supe

r TS 90

Hub s

p

line to Axle shaft

Loct

it

e 270 Studlock or equivalent

UnitLi

t

ers

F

i

nal Drive

1,

90

Com p

onent

Nm

B

ol

t - Final drive nose plate

39

- 51

Bol t

- 'A' frame to final drive

9

0 -

110

Nu

t 'A' f

rame to rear mounting bracket

8

5 -

115

Nu

t -

Axle shaft to final drive flange

81

-

99

Nu

t -

Axle shaft to hub

3

04 -

336

N

u

t - Damper lower fixing

8

0 -

100

Bol

t

M12 - Jurid flexible coupling to

transmission and final drive flanges

75 -

88

N

u

t - Lower fulcrum

9

0 -

110

Nu

t -

Pendulum to final drive

1

60 -

200

N

u

t - Stabilizer to wishbone

30

-

40

N

u

t - Tie rod to final drive

8

5 -

105

Nu

t -

Tie rod to wide mounting bracket

8

5 -

115

Nu

t -

Wishbone pivot

8

0 -

100

N

u

t - Wishbone tie to final drive

8

5 -

105

N

u

t 'A' frame to wide mounting bracket

8

5 -

105

Page 300 of 2490

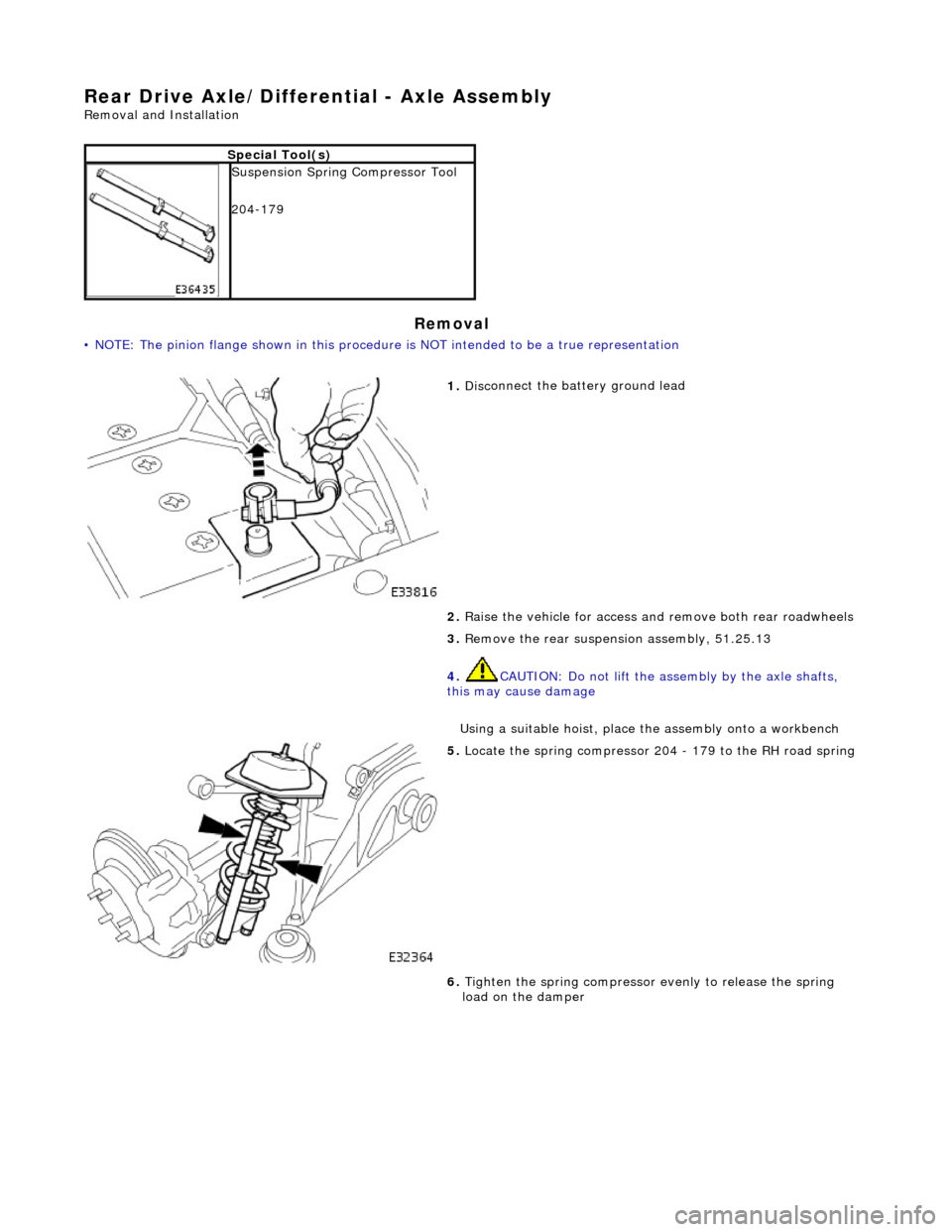

Rea

r Drive Axle/Differential - Axle Assembly

Re

mo

val and Installation

Remov

a

l

•

NOTE: The pinion flange shown in this procedure is NOT intended to be a true representation

S

p

ecial Tool(s)

Suspensi

on

Spring Compressor Tool

204-179

1. Disc

onnect the battery ground lead

2. Raise the vehicle for access and remove both rear roadwheels

3. Remove the rear suspensi on assembly, 51.25.13

4. CAUTION: Do not lift the assembly by the axle shafts,

this may cause damage

Using a suitable hoist, place the assembly onto a workbench

5. Locat e

the spring compressor 204

- 179 to the RH road spring

6. Tighten the spring compressor evenly to release the spring

load on the damper

Page 301 of 2490

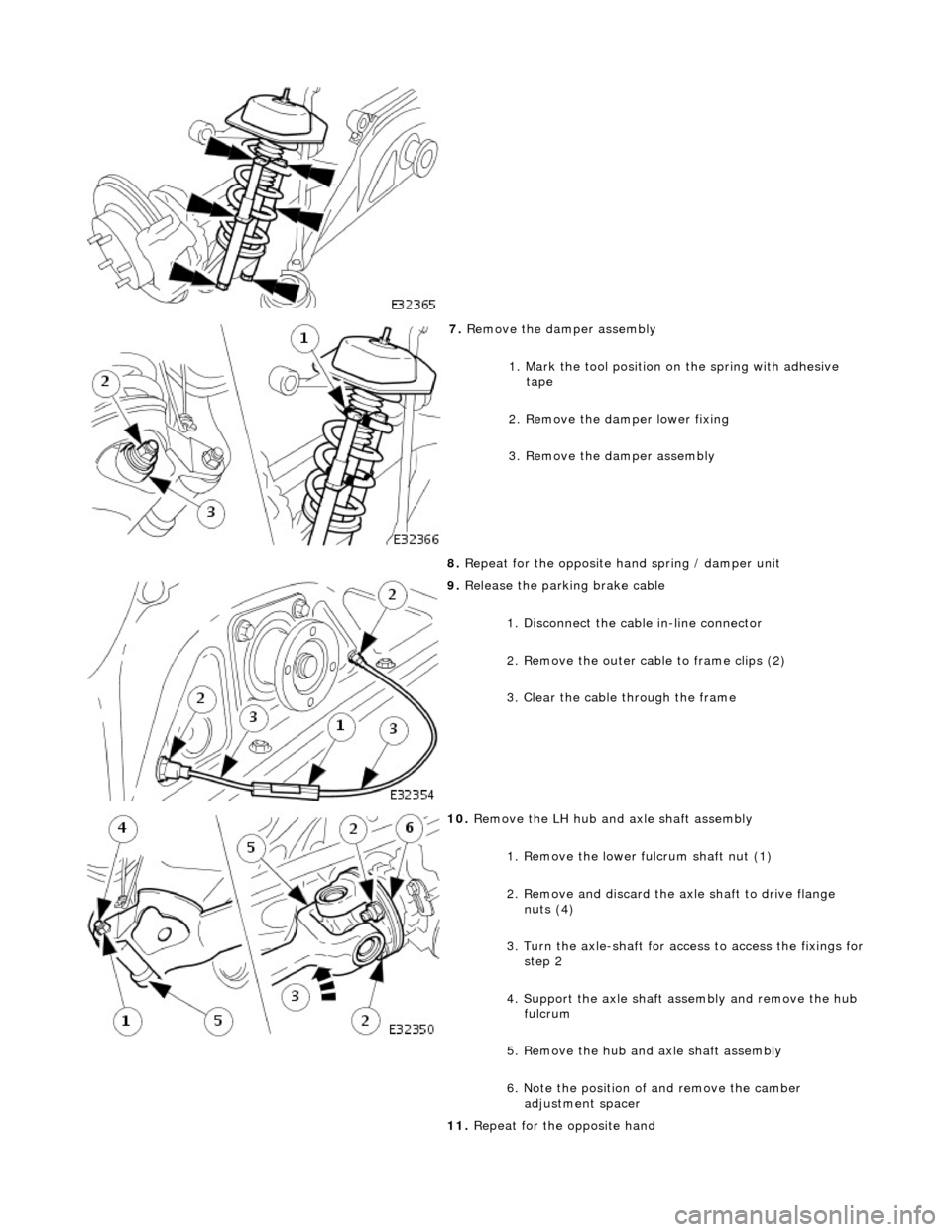

7. Re

move the damper assembly

1. Mark the tool position on the spring with adhesive

tape

2. Remove the damper lower fixing

3. Remove the damper assembly

8. Repeat for the opposite hand spring / damper unit

9. Relea

se the parking brake cable

1. Disconnect the cable in-line connector

2. Remove the outer cable to frame clips (2)

3. Clear the cable through the frame

10

.

Remove the LH hub and axle shaft assembly

1. Remove the lower fulcrum shaft nut (1)

2. Remove and discard the axle shaft to drive flange nuts (4)

3. Turn the axle-shaft for ac cess to access the fixings for

step 2

4. Support the axle shaft a ssembly and remove the hub

fulcrum

5. Remove the hub and axle shaft assembly

6. Note the position of and remove the camber adjustment spacer

11. Repeat for the opposite hand

Page 315 of 2490

Are th

ere any external brake system leaks?

Yes REPAIR as necessary. ADD fluid and BLEED the brak e system. For additional information, refer to

General Procedures in this section. TEST the system for normal operation.

No GO to F3

.

F

3: CARRY OUT A BRAKE MASTER CYLINDER BYPASS TEST

Te

st for brake master cylinder bypass condition. Re

fer to Brake Master Cylinder Component Test in

this section.

1

A

re any concerns found?

Yes INSTALL a new brake master cylinder, ADD flui d and BLEED the brake system. For additional

information, refer to General Proc edures in this section. TEST the system for normal operation.

No System is OK.

PINPO

INT TEST G : EXCESSIVE BRAKE PEDAL EFFORT

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

G1

: CHECK BRAKE PADS

Check the brake pads for wear, contamin

atio

n, correct installation, damage and type.

1

A

re any concerns found?

Yes INSTALL the front brake pads correctly or INSTALL ne w front brake pads if necessary. For additional

information, refer toSection 206

-03

Front Disc Brake

. INSTALL the

rear brake pads correctly or

INSTALL new rear brake pads if necessary. For additional information, refer toSection 206

-04

Rear

Di

sc Brake

. REPEAT road test.

No

GO to G2

.

G2:

CHECK VACUUM

Di

sconnect the vacuum booster hose from the booster.

1

Conne

ct a vacuum/pressure tester to the vacuum hose.

2

Ru

n the engine at normal operating temperature.

3

Re

cord the vacuum reading.

4

Is

the reading 40.5kPa (1

2 in-Hg) or greater?

Yes GO to G3

.

No

LOCATE and REPAIR the source of low vacuum . TEST the system for normal operation.

G3

: INSPECT SYSTEM

Swi

tch the engine off.

1

Re

connect the vacuum hose.

2

Inspect th

e brake booster, rubber grommet, and al

l vacuum plumbing for cracks, holes, damaged

connections, or missing clamps.

3

Pump th

e brake pedal several time

s to exhaust the vacuum. Push down on the brake pedal and hold.

4

Does th

e brake pedal move down

when the engine is started?

Yes Vacuum system is OK.

No GO to G4

.

G4

: CHECK POWER BRAKE BOOSTER VALVE

Check the brake booster valve. For

add

itional information, refer to

Brake Booster in this section.

1

Is th

e power brake booster valve OK?

Yes CHECK the brake booster. Fo r additional information, refer to Brak e Booster in this section. INSTALL a

new brake booster if necessary. TEST the system for normal operation.

No INSTALL a new brake booster valve. TEST the system for normal operation.

P

INPOINT TEST H : BRAKE LOCKUP

DURING LIGHT BRAKE PEDAL FORCE

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

H1

: TEST BRAKE LOCKUP

Page 318 of 2490

Comp

onent Tests

Bra

k

e Booster

1.

1. Chec k all

hoses and connections. All unused vacuum connectors should be capped. Hoses and their connections

should be correctly secured and in good condition with no holes and no collapsed areas. Inspect the valve on the

brake booster for damage.

2. 2. Check the hydraulic brake system for leaks or low fluid.

3. 3. With the transmission in PARK, stop the engine and apply the parking brake. Pump the brake pedal several times

to exhaust all vacuum in the system.

4. 4. With the engine switched off and all vacuum in the system exhausted, appl y the brake pedal and hold it down.

Start the engine. If the vacuum system is operating, the brake pedal will tend to move downward under constant

foot pressure. If no motion is felt, the vacuum booster system is not functioning.

5. 5. Remove the vacuum hose from the brake booster. Manifold vacuum should be available at the brake booster end

of the hose with the engine at idle speed and the transm ission in PARK or NEUTRAL. Make sure that all unused

vacuum outlets are correctly capped, hose connectors are correctly secured and vacuum hoses are in good

condition. When it is established that manifold vacuum is available to the brake booster, connect the vacuum hose

to the brake booster and repeat Step 3. If no downward movement of the brake pedal is felt, install a new brake

booster.

6. 6. Operate the engine for a minimum of 10 seconds at a fast idle. Stop the engine and allow the vehicle to stand for

10 minutes. Then, apply th e brake pedal with approximately 89 N ( 20lb) of force. The pedal feel (brake

application) should be the same as that noted with the engine running. If the brake pedal feels hard (no power

assist), install a new valve and then re peat the test. If the brake pedal still feels hard, in stall a new brake booster.

If the brake pedal movement feels spongy, bleed the brak e system. For additional information, refer to General

Procedures in this section.

Bra k

e Master Cylinder

Usual

l

y, the first and strongest

indicator of anything wrong in the brake syst em is a feeling through the brake pedal. In

diagnosing the condition of the brake master cylinder, check pedal feel as evidence of a brake concern. Check for brake

warning lamp illumination and the brake fluid le vel in the brake master cylinder reservoir.

Normal Conditio

ns

The fo

llowing conditions are considered norm

al and are not indications that the brake master cylinder is in need of repair.

New bra

ke systems are designed to produc

e a pedal effort that is not as hard as in the past. Complaints of light

pedal efforts should be compared to the pedal effort s of another vehicle of the same model and year.

The fl

uid level will fall with brake pad wear.

Abnormal Conditions

•

NOTE: Prior to carrying out any diag

nosis, make sure the brake system warning indicator is functional.

Changes in the brake pedal feel or brake pedal travel are in dicators that something could be wrong in the brake system. The

diagnostic procedure and techniques use brake pedal feel, warning indicator illu mination and low brake fluid level as

indicators to diagnosing brake system co ncerns. The following conditions are cons idered abnormal and indicate that the

brake master cylinder is in need of repair:

Brake ped a

l goes down fast. Th

is could be caused by an ex ternal or internal leak.

Brake pedal goes down slowly

. This could be

caused by an internal or external leak.

Brak

e pedal is low or feels spongy. This condition may be ca

used by no fluid in the brake master cylinder, reservoir

Page 340 of 2490

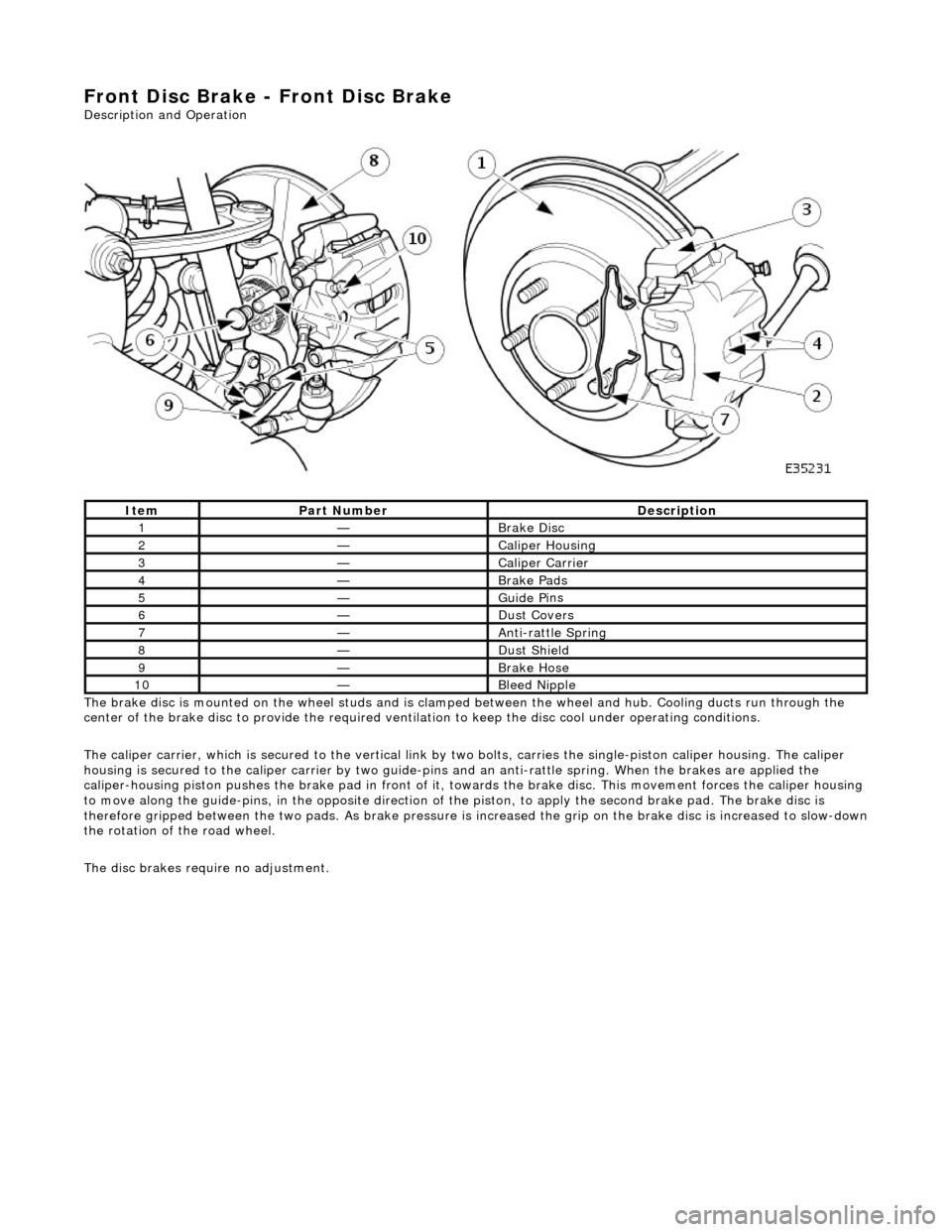

Front Disc Brake - Front Disc Brake

Description and Operation

The brake disc is mounted on the wheel studs and is clamped between the wheel and hub. Cooling ducts run through the

center of the brake disc to provide the required ventilation to keep the disc cool under operating conditions.

The caliper carrier, which is se cured to the vertical link by two bolts, carries the single-pis ton caliper housing. The caliper

housing is secured to the caliper carrier by two guide-pins and an anti-rattle spring. When the brakes are applied the

caliper-housing piston pushes th e brake pad in front of it, towards the brake di sc. This movement forces the caliper housing

to move along the guide-pins, in the oppo site direction of the piston, to apply the second brake pad. The brake disc is

therefore gripped between the two pads. As brake pressure is increased the grip on the brake disc is increased to slow-down

the rotation of the road wheel.

The disc brakes requ ire no adjustment.

It

e

m

Par

t

Number

De

scr

iption

1—B

r

ake Disc

2—Caliper Housin

g

3—Caliper Carrier

4—Brake Pads

5—Guide P i

ns

6—Du

st

Covers

7—An

ti

-rattle Spring

8—Du

st

Shield

9—Brake Hos

e

10—Bleed Nipp

le

Page 341 of 2490

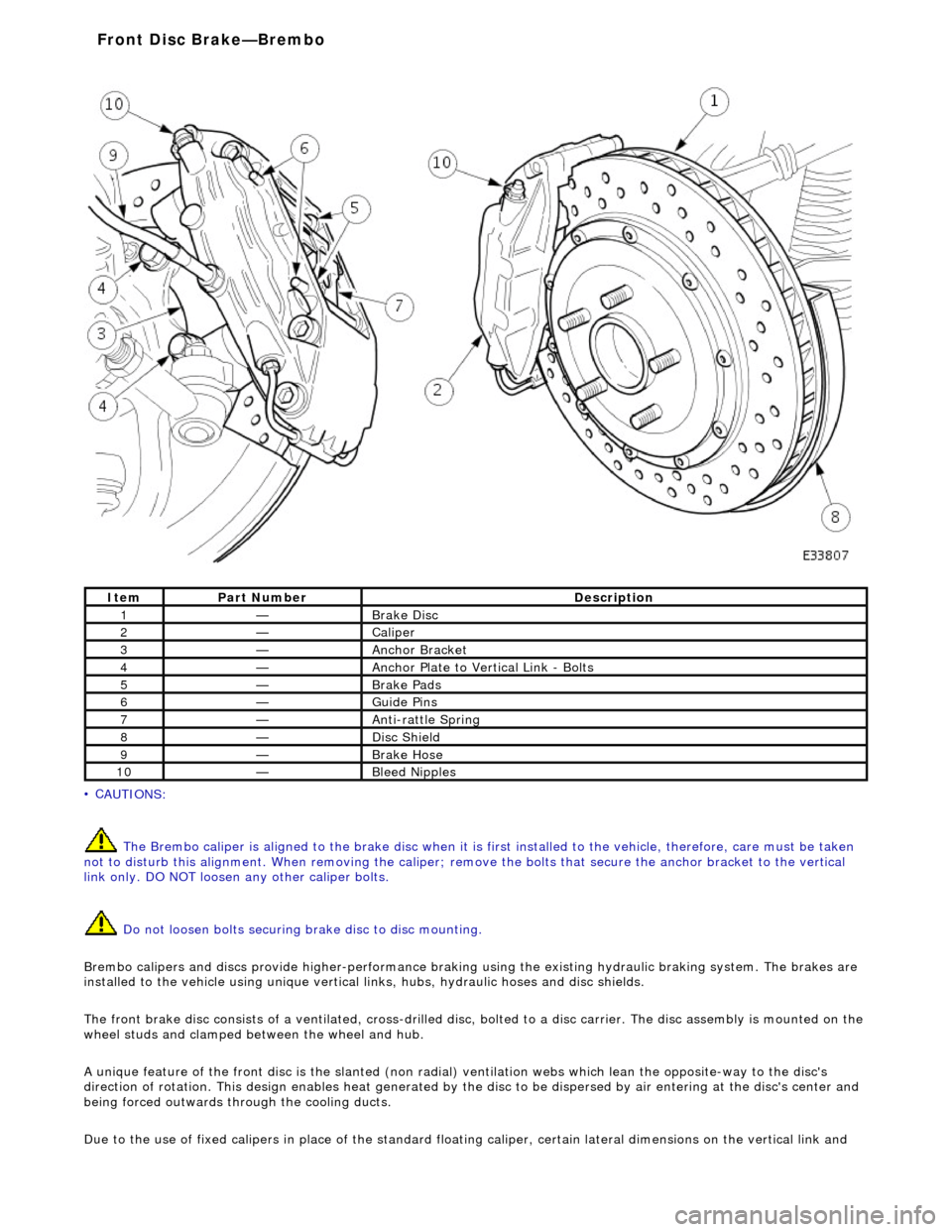

• C

AUTIONS:

The Brembo caliper is aligned to the brak e disc when it is first installed to the vehicle, therefore, care must be taken

not to disturb this alignment. When removi ng the caliper; remove the bolts that secure the anchor bracket to the vertical

link only. DO NOT loosen any other caliper bolts.

Do not loosen bolts securing brake disc to disc mounting.

Brembo calipers and discs provide higher -performance braking using the existing hydraulic braking system. The brakes are

installed to the vehicle using unique vertical links, hubs, hydraulic hoses and disc shields.

The front brake disc consists of a ventilated, cross-drilled disc, bolted to a disc carrier. The disc assemb ly is mounted on the

wheel studs and clamped be tween the wheel and hub.

A unique feature of the front disc is th e slanted (non radial) ventilation webs which lean the opposite-way to the disc's

direction of rotation. This design enables he at generated by the disc to be dispersed by air entering at the disc's center and

being forced outwards through the cooling ducts.

Due to the use of fixed calipers in place of the standard floating caliper, certain lateral dimensions on the vertical link and

It

em

Par

t Number

De

scription

1—B

rake Disc

2—Caliper

3—Anch

or Bracket

4—Anchor Pl

ate to Vertical Link - Bolts

5—Brake Pad

s

6—Guide P

ins

7—Anti-r

attle Spring

8—Di

sc Shield

9—Brake Hos

e

10—Bleed Nipp

les

Front Disc Brake—

Brembo

Page 365 of 2490

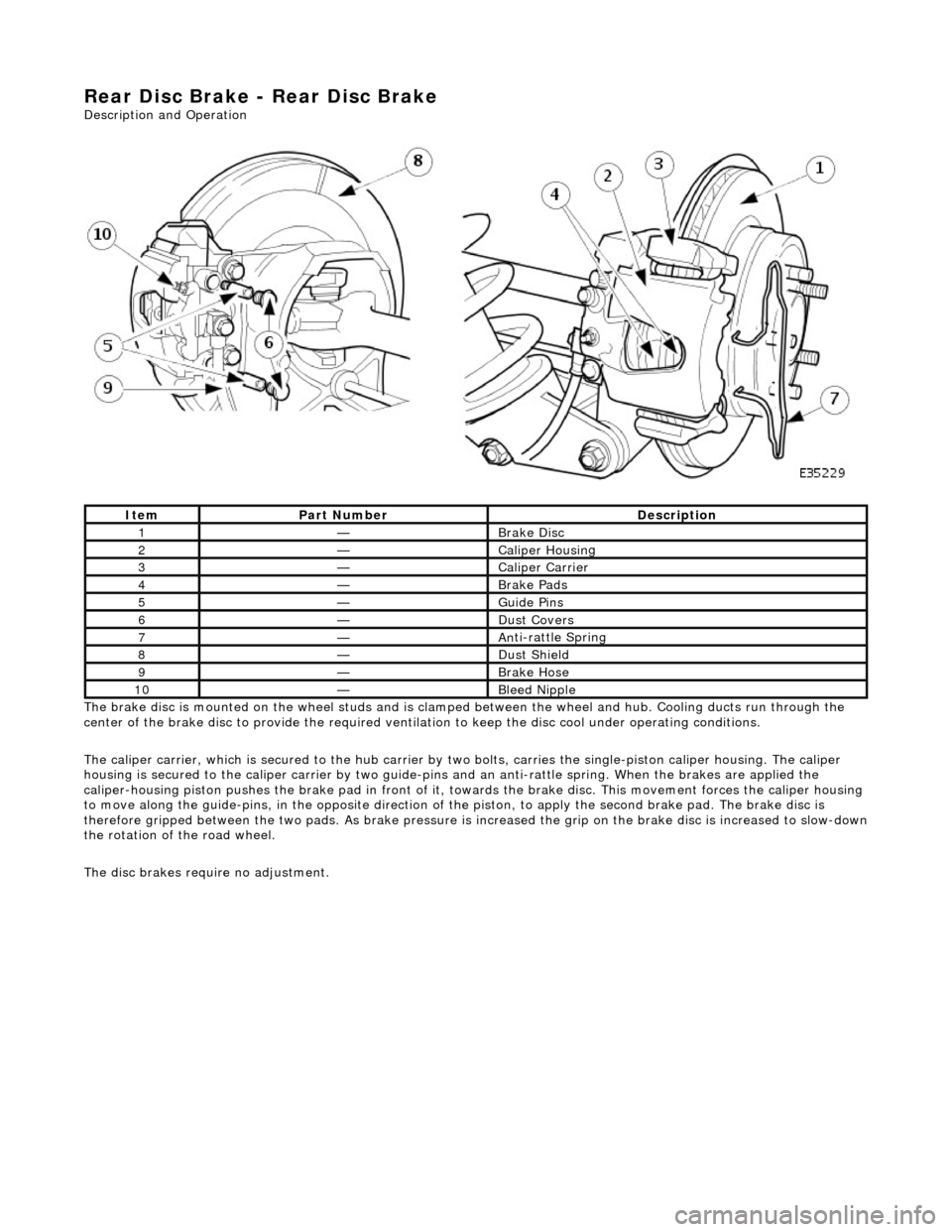

Rear

Disc Brake - Rear Disc Brake

Description an

d Operation

The brake disc is mounted on the wheel studs and is clamped between the wheel and hub. Cooling ducts run through the

center of the brake disc to provide the required ventilation to keep the disc cool under operating conditions.

The caliper carrier, which is se cured to the hub carrier by two bolts, carries the single-piston caliper housing. The caliper

housing is secured to the caliper carrier by two guide-pins and an anti-rattle spring. When the brakes are applied the

caliper-housing piston pushes th e brake pad in front of it, towards the brake di sc. This movement forces the caliper housing

to move along the guide-pins, in the oppo site direction of the piston, to apply the second brake pad. The brake disc is

therefore gripped between the two pads. As brake pressure is increased the grip on the brake disc is increased to slow-down

the rotation of the road wheel.

The disc brakes requ ire no adjustment.

It

em

Par

t Number

De

scription

1—B

rake Disc

2—Caliper Housin

g

3—Caliper Carrier

4—Brake Pad

s

5—Guide P

ins

6—Du

st Covers

7—An

ti-rattle Spring

8—Du

st Shield

9—Brake Hos

e

10—Bleed Nipp

le

Page 366 of 2490

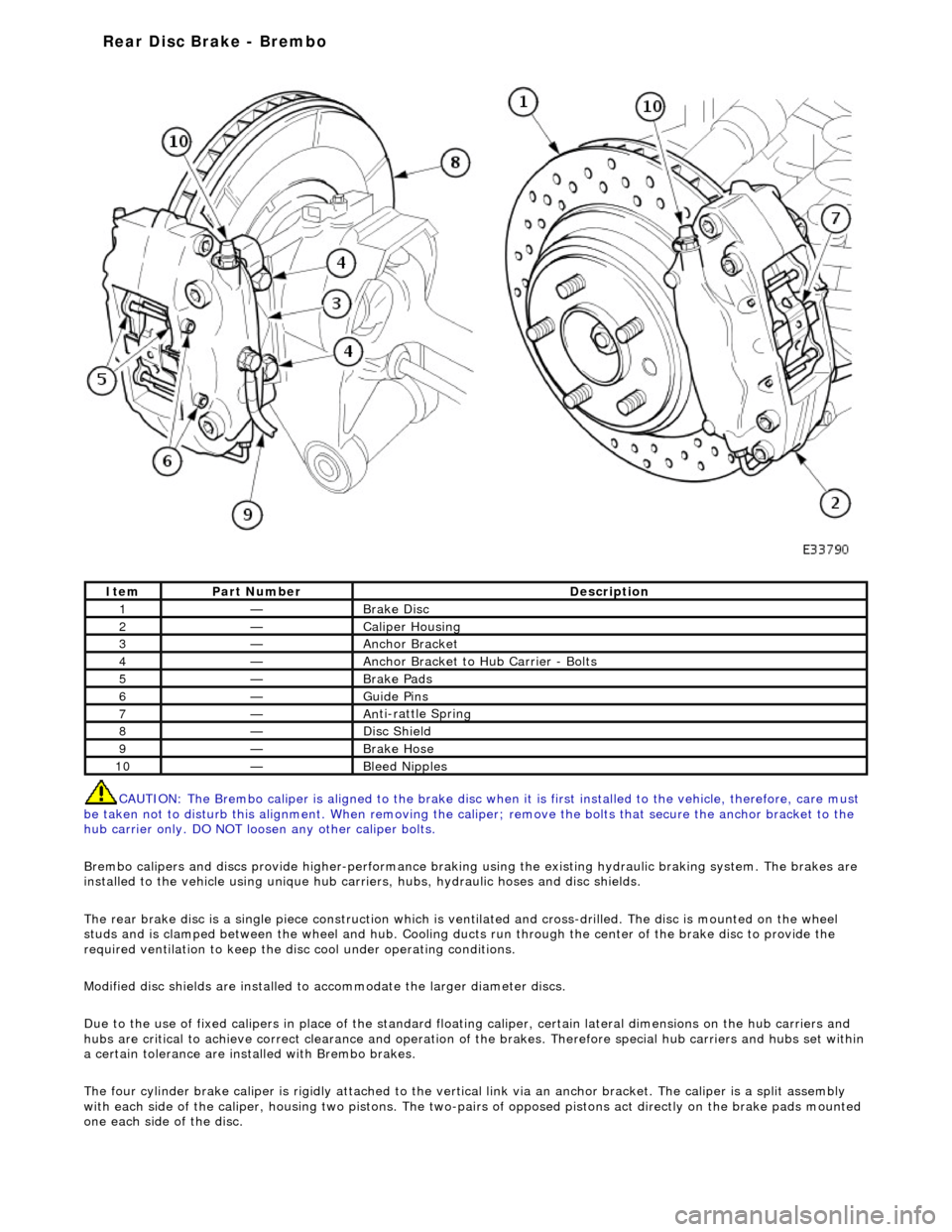

CAUTI O

N: The Brembo caliper is aligned to

the brake disc when it is first installed to the vehicle, therefore, care must

be taken not to disturb this alignment. When removing the ca liper; remove the bolts that secure the anchor bracket to the

hub carrier only. DO NOT loos en any other caliper bolts.

Brembo calipers and discs provide higher -performance braking using the existing hydraulic braking system. The brakes are

installed to the vehicle using unique hub carr iers, hubs, hydraulic hoses and disc shields.

The rear brake disc is a single piece co nstruction which is ventilated and cross-drilled. The disc is mounted on the wheel

studs and is clamped between the wheel and hub. Cooling ducts run through the ce nter of the brake disc to provide the

required ventilation to keep the disc cool under operating conditions.

Modified disc shields are installed to accommodate the larger diameter discs.

Due to the use of fixed calipers in place of the standard floating caliper, certain lateral dimensions on the hub carriers and

hubs are critical to achieve correct cleara nce and operation of the brakes. Therefore special hub carriers and hubs set within

a certain tolerance are inst alled with Brembo brakes.

The four cylinder brake caliper is rigidly attached to the vert ical link via an anchor bracket. The caliper is a split assembly

with each side of the caliper, housing two pistons. The two-pairs of opposed pistons act direct ly on the brake pads mounted

one each side of the disc.

It e

m

Par

t

Number

De

scr

iption

1—Brake D

i

sc

2—Caliper Housin

g

3—Anchor Bracke

t

4—Anchor Bracket to H

u

b Carrier - Bolts

5—Brake Pads

6—Guide Pi

ns

7—An

ti

-rattle Sprin

g

8—Di

sc

Shield

9—Brake Hos

e

10—Bleed Nipp

les

Rear Disc Brake - Brembo