Amp JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 456 of 2490

3.3. If an obvi

ous cause for an observed or

reported concern is found, correct th e cause (if possible) before proceeding

to the next step.

4. 4. Check the power steering fluid condit ion. For additional information, REFER to Power Steering Fluid Condition

Check in this section.

5. 5. If the concern is not visually evid ent, verify the symptom and REFER to Steering Fault Diagnosis by Symptom

Charts in this section.

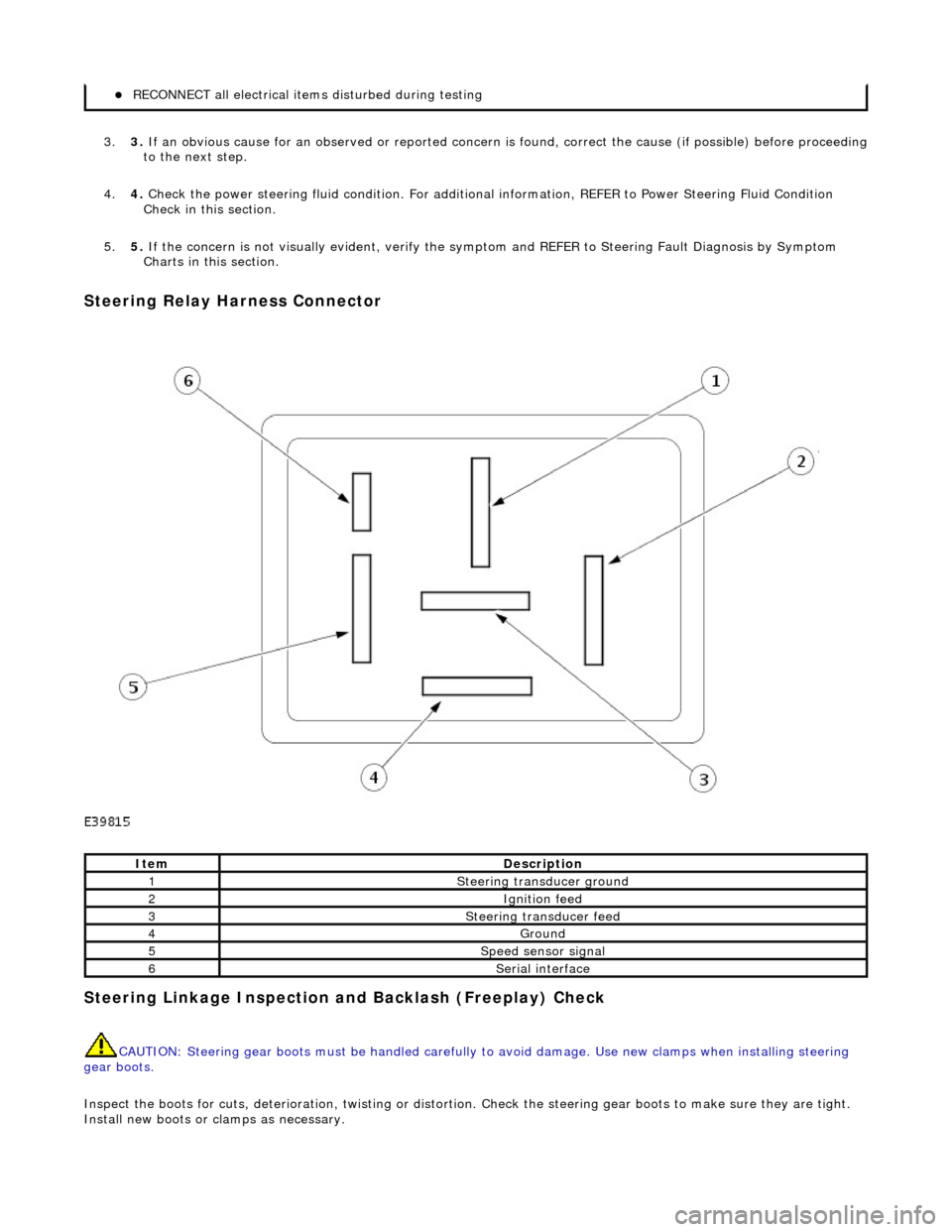

Steering Re

lay Harness Connector

Stee

ring Linkage In

spection and Backlash (Freeplay) Check

CAUTIO

N: Steering gear boots must be

handled carefully to avoid damage. Use new clamps when installing steering

gear boots.

Inspect the boots for cuts, deterioration, tw isting or distortion. Check the steering gear boots to make sure they are tight.

Install new boots or clamps as necessary.

REC O

NNECT all electrical item

s disturbed during testing

Ite

m

De

scr

iption

1Ste

e

rin

g tran

sduc

er

ground

2Igni

ti

on feed

3Steeri

ng transducer feed

4Ground

5Speed s

ensor signal

6Seri

a

l interface

Page 458 of 2490

The

measurement of the maximum system pressure, (which is

governed by the pressure relief valve) is achieved by

inserting the Service Tool (pressure gauge and adaptors) into th e fluid circuit of the power steering system. Run the engine

at idle speed, turn the st eering from lock to lock and read the ma ximum pressure recorded on the gauge.

Installin

g Test Equipment

To

in

stall the pressure test equipment:

Pla

c

e a suitable drain tray be

low the power steering pump.

Install a hose clamp on

the re

servoir to pump hose prior to disconnecting any hoses, to avoid unnecessary loss of

fluid.

Disc

onnect the hose from the power st

eering pump high pressure outlet.

Install the pu

mp outlet to hose adaptor (5

). Do not omit the 'O' ring seal (9).

Connect the power steering

pump

adaptor to control valve hose (6) of the test equipment.

Install th e adaptor (4) in th

e high

pressure hose previously removed from the power steering pump outlet.

Conn

ect the connector (3) of the test equipment hose (2) to the adaptor (4).

R

e

move the hose clamp fro

m the reservoir hose.

Start th

e engine.

With the control valve (7) OPEN and the engine idli ng, the following system pressures may be checked:

Du

ring turning.

W

h

en the steering is

held on full lock.

With

the steeri

ng at rest.

• CAUTIONS:

To avoid excessive heating of the po wer steering pump, do not close the valve for longer than 5 seconds maximum.

Do not drive the vehicle with the test equipment installed.

With the control valve (7) CLOSED the power steering pump maximum ou tput pressure can be checked.

Removing Test Equipment

To

remove the test equipment:

Install a hose clamp

on

the reservoir to power steering pump hose.

Re

movi

ng the test equipmen

t is a reversal of the in stallation instructions.

Install a new '

O

' ring seal (9) to the power steering pump high pressu

re outlet to hose connection.

Instal

l the original hose to

the power steering pump.

Re

move the clamp from the reservoir to

the power steering pump hose.

Top-up the reservoir flui

d.

Ble

e

d the power steerin

g system. For additional information,

REFER to Power Steering System Bleeding

- in thi

s section.

Stee

ring Fault Diagnosis by Sympt

om Charts

Leakage

52

11-0

11-03/1

Pump High Pressure Ou

tlet

to Hose Adaptor

621

1

-011-02

Pump Adaptor

to Contro

l Valve Hose

721

1

-011-01

Control Valve

82

11-

011

Pressure Gauge

9-'O

'

Ring Seal

Cond

iti

on

Possib

l

e Sources

Acti

o

n

Co

nfirm

the position of the fluid

leak.

CLEAN th

e area of the leak.

In

s

pect the area and confirm the exact position of leak.

Make sure the fluid

is not from anoth

er system on

the vehicle.

Page 468 of 2490

Hiss (Swish)

Hiss or Val

ve Hiss is a high-frequency so

und coming from the steering gear when the system is loaded. It is a rushing or

"swish" noise that doesn't change frequency with RPM. Hiss is the general noise generated by the flow of hydraulic fluid

through restrictions in the steer ing system. Restrictions include the rotary stee ring valve, power steering tubes, connectors,

tuning orifices, etc. Hiss can be air- borne and structure-borne, but the structure-borne path through the steering

intermediate shaft is usually dominant.

Moan (Groan)

Moan is the general structu r

e-borne noise of the steering system. Moan is primarily transmitted to the driver via the body

structure through the pump mount, engine mounts, power steering lines and power steering brackets. On some vehicles,

moan is a load humming noise, often present when the wheel is turned and the system is loaded. It may change frequency

with engine RPM and if the sy stem is loaded or unloaded.

Rack Knock (R

ack Slap)

CAU

T

ION: DO NOT attempt to adjust the stee

ring gear yoke. Failure to follow this instruction will result in the steering

gear warranty to become invalid.

Rack Knock is a rattle sound an d steering wheel vibration caused by separation of the steering gear and pinion while driving

over bumps. It is a structure-borne noise transmitted throug h the intermediate shaft and column. Rack knock can also be

heard as a "thump" or impact noise that occurs with the vehicle stationary when the steering wheel is released from a

loaded position and allowed to return to rest . Noise occurs with the engine on or off.

Rattles

Ra

ttles are noises caused by knocking or hitting with components in the steering system. Steering rattles can occur in the

engine compartment, the suspension, or the passenger compartment . Rattles can be caused by loose parts, movable and

flexible parts, and improper clearances.

Squea k

s/Scrapes

Squeaks/Scrapes are noises due

to fri

ction or component rubbi

ng anywhere in the steering system. Squeaks/Scrapes have

appeared in steering linkages and jo ints, in column components and in co lumn and steering wheel trim parts.

Weep

We

ep is an air-borne noise, occasionally

generated when turning the steering across lock at a constant rate. When present

on a vehicle the noise, once initiated can often be maintained across a large proportion of the available steering movement.

Whistle

Wh

istle is similar to hiss but is louder and of a higher frequency. It is also more

of a pure tone noise than hiss. Whistle is

air-borne and is generated by a high flow rate of hydraulic fluid through a small restriction.

Zip

Zip n

o

ise is the air-borne noise

generated by power steerin g pump cavitation when power steering fluid does not flow freely

through the suction hose from the rese rvoir to the pump. Zip primarily occurs during cold weather at start-up.

Steering System Vibrations and Harshne

ss

Buzz

Buzz is a tactile rotary vi

bration felt in

the steering wheel for slow steering inputs. Buzz can also be called a grinding feel

and it is closely related to grunt and is caused by high system gain with low damping. Buzz is generally excited during

parking manoeuvres with low to medium speed steering input.

Page 469 of 2490

Buzz (E

lectrical)

A

different steering buzz can be caused by

pulse width modulated (PWM) electric actuators used in variable assist steering

systems. This buzz is felt by turning the ignition key to run without starting the engine and holding onto the steering wheel.

In extreme cases, the buzz can be felt with the engine running also.

Column/Steering Wheel

Shake

Column shake is a low f

requenc

y vertical vibration excited by primary engine vibrations.

Nibble (Shimm

y)

Steeri

ng nibble is a rotary oscillation or

vibration of the steering wheel, which can be excited at a specific vehicle speed.

Nibble is driven by wheel and tire imbalance exciting a suspensi on recession mode, which then translates into steering gear

travel and finally steering wheel nibble.

Shudder (Judd

er)

Shudder i

s a low frequency oscillation of th

e entire steering system (tire, wheels, st eering gear and linkage, etc.) when the

vehicle is steered during static-park or at low sp eeds. Shudder is very dependent on road surface.

Torque Ri

pple

Torque rippl

e is a concern with Electric Power Steering (EPS) sy

stems. Torque ripple is most evident at static-park steering

the wheel very slowly from lock to lock. Torque ripple is primarily caused by motor commutation.

Torque/Veloc

ity Variation

(Phasing/Effort Cycling)

Steeri

ng wheel torque variation oc

curring twice in one revolution is normally as a result of problems with the lower steering

column (intermediate shaft), but foul cond itions generally result in either constant stiffnes s or single point stiffness.

Depending upon the orientation of the joints, the steering can fe el asymmetric (torque falling off in one direction and rising

in the other) or else it can simply have pronounced peaks and troughs as the steering moves from lock to lock.

Wheel Fight

(Kick Back)

W

heel fight is excess feedback of sudden road forces through th

e steering system and back to the driver. It is evaluated at

all vehicle speeds over cobblestones, rough roads, and potholes . The tires, wheels, and suspension generate forces into the

steering systems. Steering friction, hydraulic damping, hydr aulic compliance, mechanical compliance, steering ratio, and

assist gain all affect how much is transmitted to the driver.

Stee

ring Linkage

CAUTI

ON: Steering gear boots must be

handled carefully to avoid damage. Use new clamps when installing steering

gear boots.

Inspect the boots for cuts, deterioration, tw isting or distortion. Check the steering gear boots to make sure they are tight.

Install new boots or clamps as necessary.

• NOTE: The following steps must be carried out with assistance.

1. 1. With the wheels in the straight ahead po sition, gently turn the steering wheel to the left and the right to check for

free play.

2. 2. Free play should be between 0 and 6 mm (0 and 0.24 in) at the steering wheel rim. If the free play exceeds this

limit, either the ball joints are worn, the lower steering column joints are worn or the backlash of the steering gear

is excessive.

Page 478 of 2490

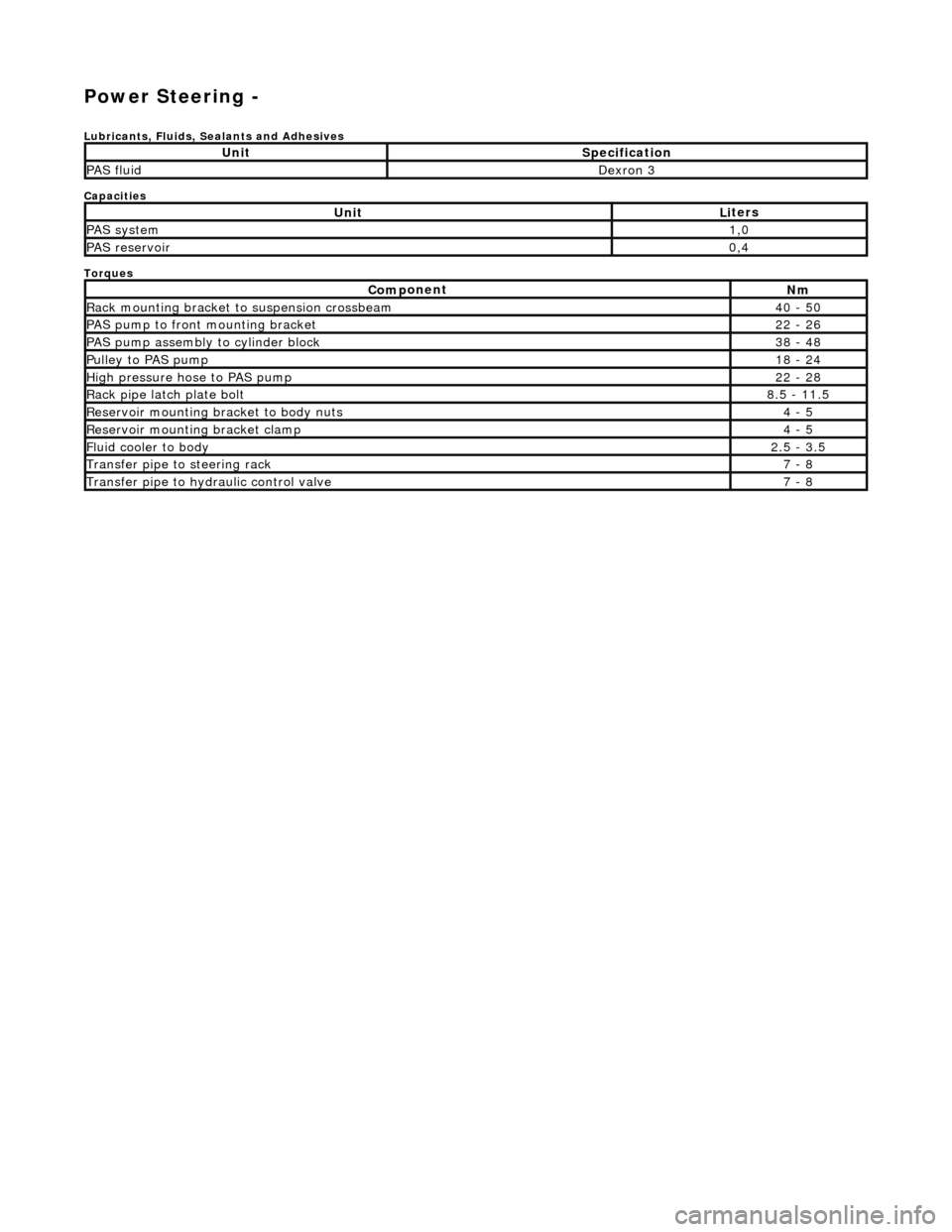

Power Steering -

Lubric

ants, Fluids, Sealants and Adhesives

Capacities

Torques

UnitSp

ecification

PAS flu

i

d

De

xr

on 3

UnitLi

t

ers

PAS syste

m1,0

PAS reservoi

r0,4

Com p

onent

Nm

Rac

k

mountin

g brac

ke

t to suspension crossbeam

40

- 50

PAS pump to front mounti

ng bracket

22

-

26

P

AS pu

mp assembly to cylinder block

38

-

48

Pul

l

ey to PAS pump

18

-

24

Hi

gh pressure hose to PAS pump22 -

28

Rack

pipe latch plate bolt8.5 -

11.5

R

e

servoir mounting bracket to body nuts

4 -

5

R

e

servoir mounting bracket clamp

4 -

5

Fluid cooler to body2.

5 -

3.5

Transfer pipe

to steering rack7 -

8

Transfer pipe

to hydraulic con

trol valve

7 -

8

Page 490 of 2490

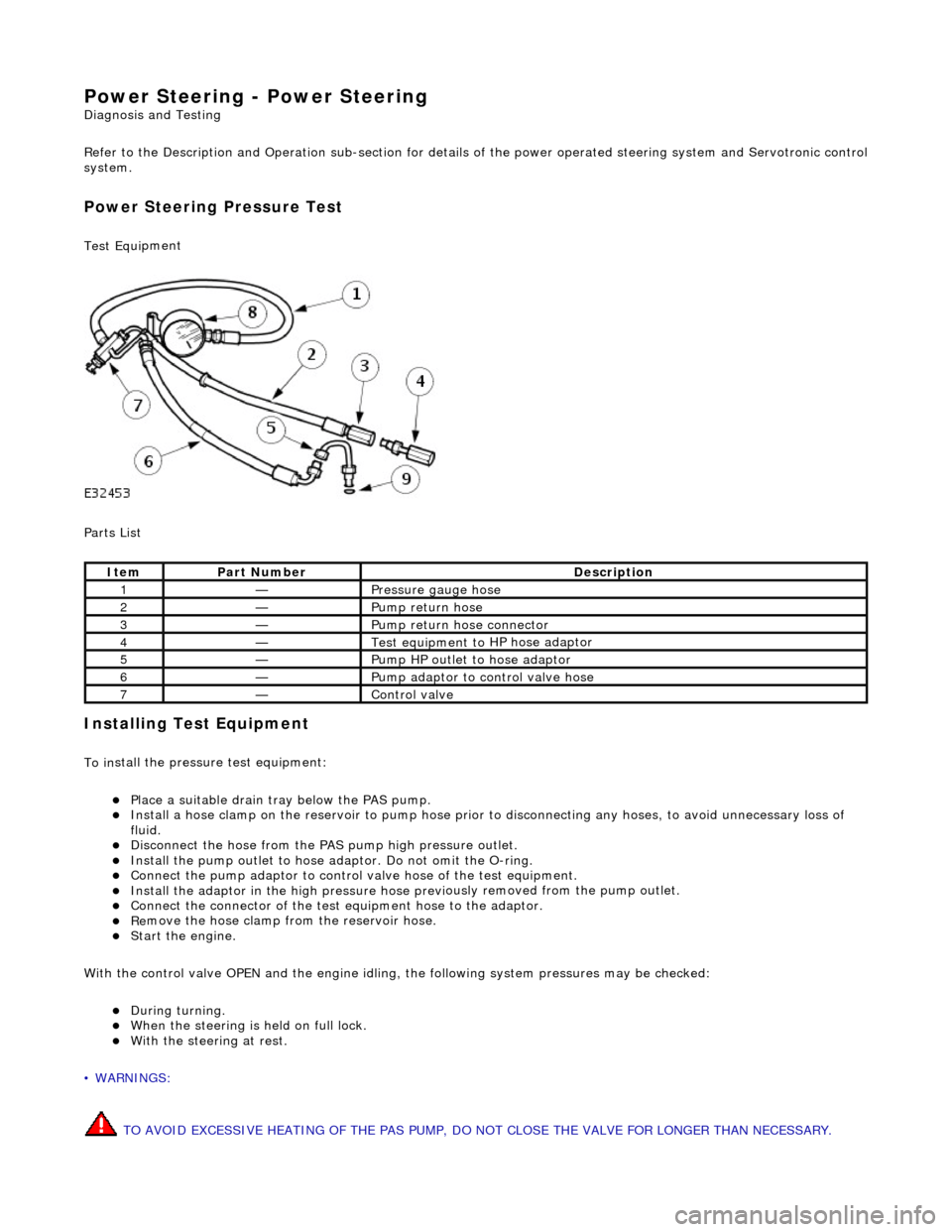

Power Steering - Power Steering

Diagn

osis and Testing

Refer to the Description and Operation sub-section for details of the power operated steering system and Servotronic control

system.

Power Steer ing Pressure Test

Test Equ

i

pment

Parts List

In

stalling Test Equipment

To

in

stall the pressure test equipment:

Pla

c

e a suitable drain tray below the PAS pump.

Install a hose clamp

on

the re

servoir to pump hose prior to disconnecting any hoses, to avoid unnecessary loss of

fluid.

Di sc

onnect the hose from the PAS pump high pres

sure outlet.

Ins

tall the pump outlet to hose ad

aptor. Do not omit the O-ring.

Conn

ect the pump adaptor to control valve hose of the test equipment.

Install th

e adaptor in the high pressure hose previ

ously re

moved from the pump outlet.

Conne

ct the connector of the test equipment hose to the adaptor.

R

e

move the hose clamp fro

m the reservoir hose.

Start th

e engine.

With the control valve OPEN and the engine idling , the following system pressures may be checked:

Du

ring turning.

W

h

en the steering is

held on full lock.

With

the steeri

ng at rest.

• WARNINGS:

TO AVOID EXCESSIVE HEATING OF THE PAS PUMP, DO NOT CLOSE THE VALVE FOR LONGER THAN NECESSARY.

Ite

m

Par

t

Number

De

scr

iption

1—Pressure

gauge hose

2—Pump return hose

3—Pump return hose connector

4—Test equi

pment to

HP hose adaptor

5—Pump HP outlet to hose adaptor

6—Pump adaptor

to control valve hose

7—Control valve

Page 491 of 2490

DO NOT DRIVE THE VEHICLE WITH THE TEST EQUIPMENT INSTALLED.

With the control valve CLOSED the pump maximum output pressure can be checked.

Remov

ing Test Equipment

T

o remove the test equipment:

Install a hose clamp

on the

reservoir to pump hose.

Re

moving the test equipmen

t is a reversal of the installation instructions.

Install a new O-r

ing to the PAS pump high

pressure outlet to hose connection.

Inst

all the original hose to the PAS pump.

R

emove the clamp from the reservoir to pump hose.

Top-up the reservoi

r fluid.

B

leed the PAS system; refe

r to this section.

Refer to PDU

User Guide

T

he PDU will diagnose all electrical components of the system.

Before changing a component, chec k fuse No. 12 (10A) in the left-hand heelboard fu se box. However, if this fuse is faulty a

number of other components wi ll also fail to function.

Page 492 of 2490

Power Steering - Steering Gear

Remo

val and Installation

Remov

a

l

All vehicles

S

p

ecial Tool(s)

Taper Sep

a

rator

211-098 (JD 100)

1. Centralize steeri ng the wheel.

2. Raise and support the vehicle on a four-post ramp.

3. Place a suitable drain pan under the stee ring gear.

4. Fr

om below the vehicle, check that

steering gear is centralized

by aligning the centralizing notc h on the dirt protection cover

with the location hole in the pinion housing casting.

5. NOTE : R

ight-hand shown, left-hand similar.

Remove and discard bo th tie rod end nuts.

6. NOTE : R

ight-hand shown, left-hand similar.

Detach both of the tie rod ends.

1. Fit the special tool to tie rod end.

2. Tighten the tool bolt to release the taper.

Re

move the tool.

Page 498 of 2490

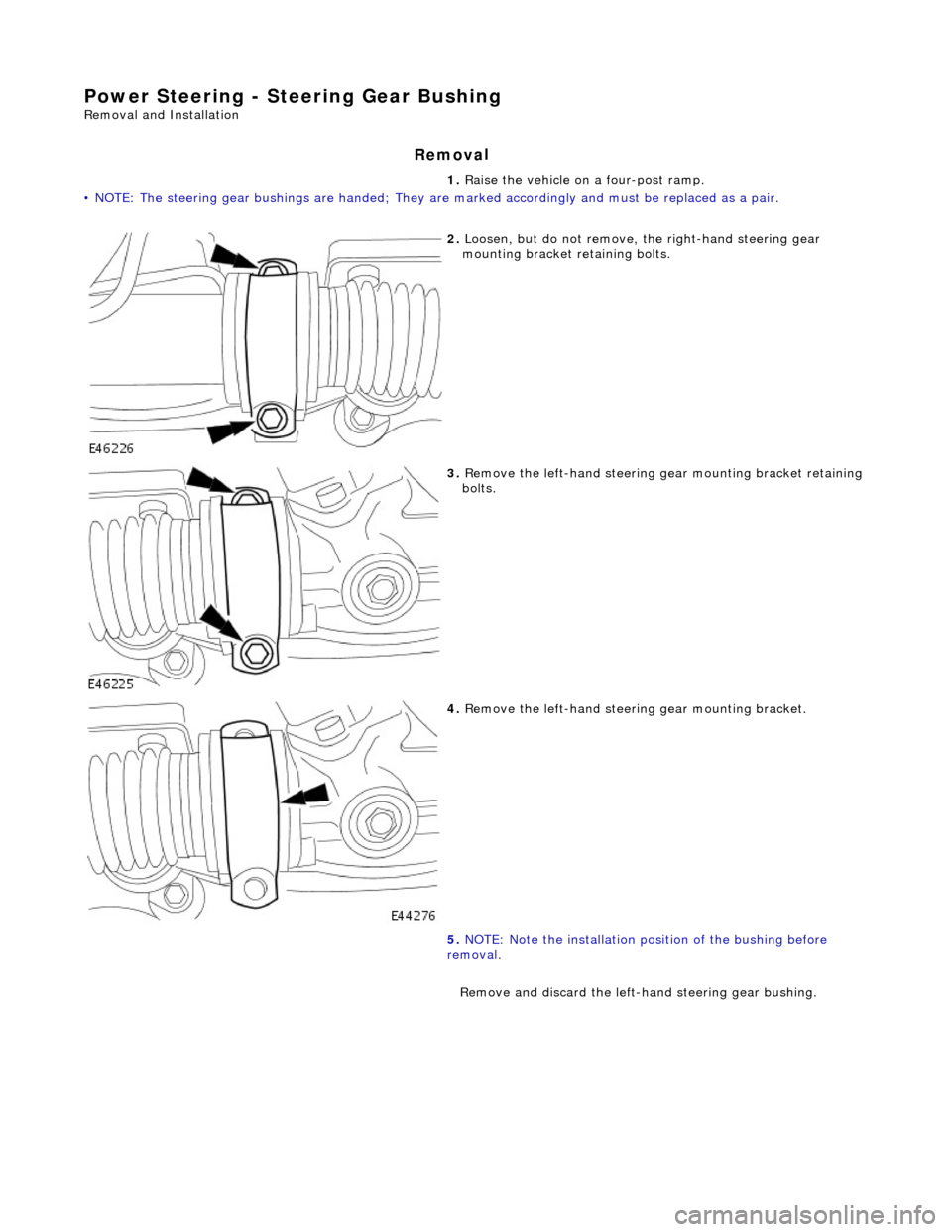

Power Steering - Steering Gear Bush

ing

Re

mo

val and Installation

Remov

a

l

•

NOTE

: The steering gear bushings are handed; They ar

e marked accordingly and must be replaced as a pair. 1.

Raise the vehicle on a four-post ramp.

2. Loosen , bu

t do not remove, th

e right-hand steering gear

mounting bracket retaining bolts.

3. Re

move the left-hand

steering gear mounting bracket retaining

bolts.

4. Re

move the left-han

d steering gear mounting bracket.

5. NOTE: Note the installation position of the bushing before

removal.

Remove and discard the left-h and steering gear bushing.

Page 508 of 2490

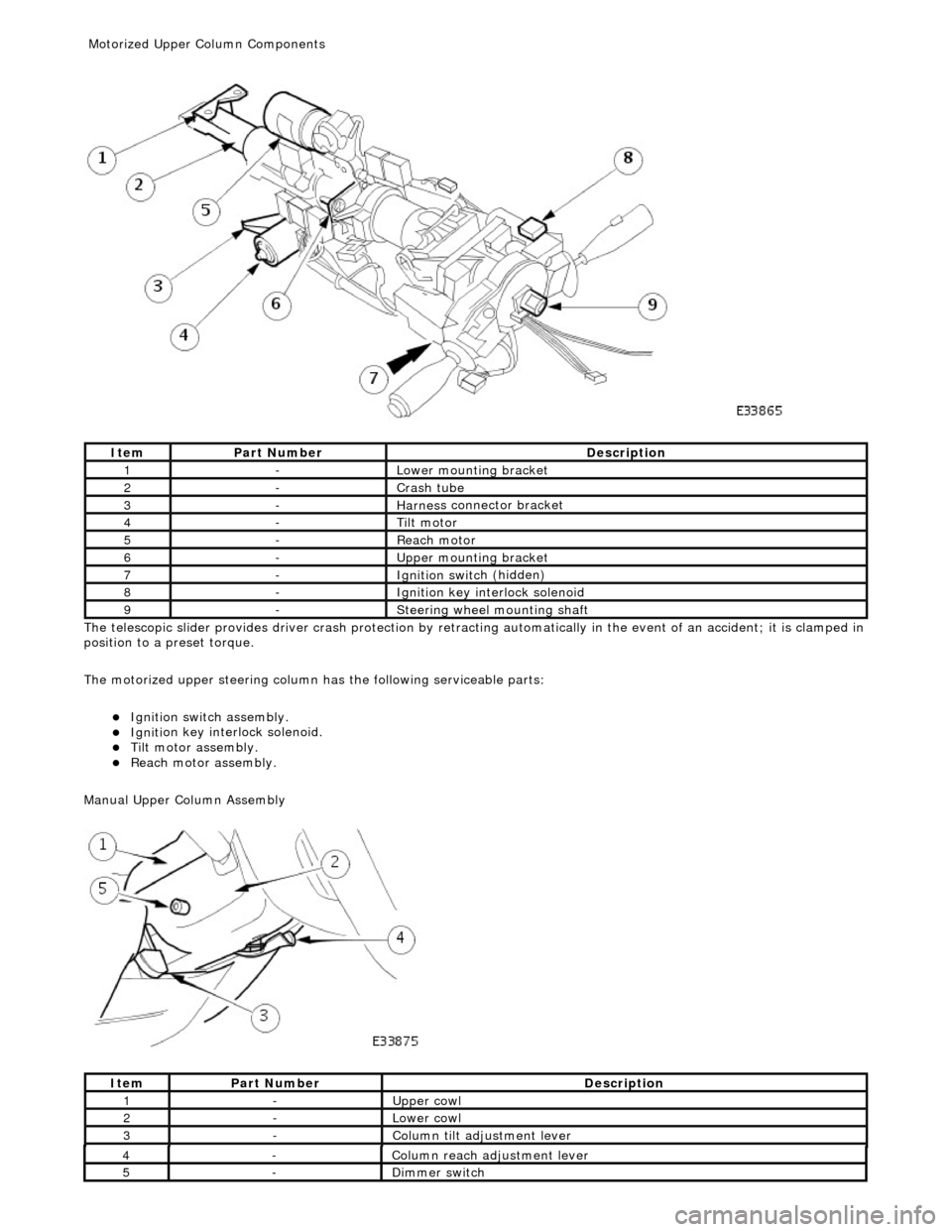

The te

lescopic slider provides driver crash

protection by retracting automatically in the event of an accident; it is clamped in

position to a preset torque.

The motorized upper steering column has the following serviceable parts:

Igniti

on switch assembly.

Igni

ti

on key interlock solenoid.

Ti

lt

motor assembly.

Reach motor assembly.

Manu al Upper Column Assembly

Ite

m

Par

t

Number

De

scr

iption

1-L

o

wer mounting bracket

2-Crash tube

3-Harnes

s c

onnector bracket

4-Tilt motor

5-Reach m

otor

6-Upper

moun

ting bracket

7-Ignition switc

h

(hidden)

8-Igni

ti

on key interlock solenoid

9-S

t

eering wheel mounting shaft

It

e

m

Par

t

Number

De

scr

iption

1-Upper

cowl

2-Lower cowl

3-Colu

mn tilt adjustment lever

4-Col

u

mn reach adjustment lever

5-Di

mm

er switch

Motorized Upper Co

lumn Components