Suspension JAGUAR X308 1998 2.G Service Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 122 of 2490

Front Suspension - Front Stabilizer B

ar Bushing

Re

mo

val and Installation

Materials

S p

ecification

Cas

t

rol NTR

Remov

a

l

Na

m

e

R

u

bber Suspension Insulator Lube

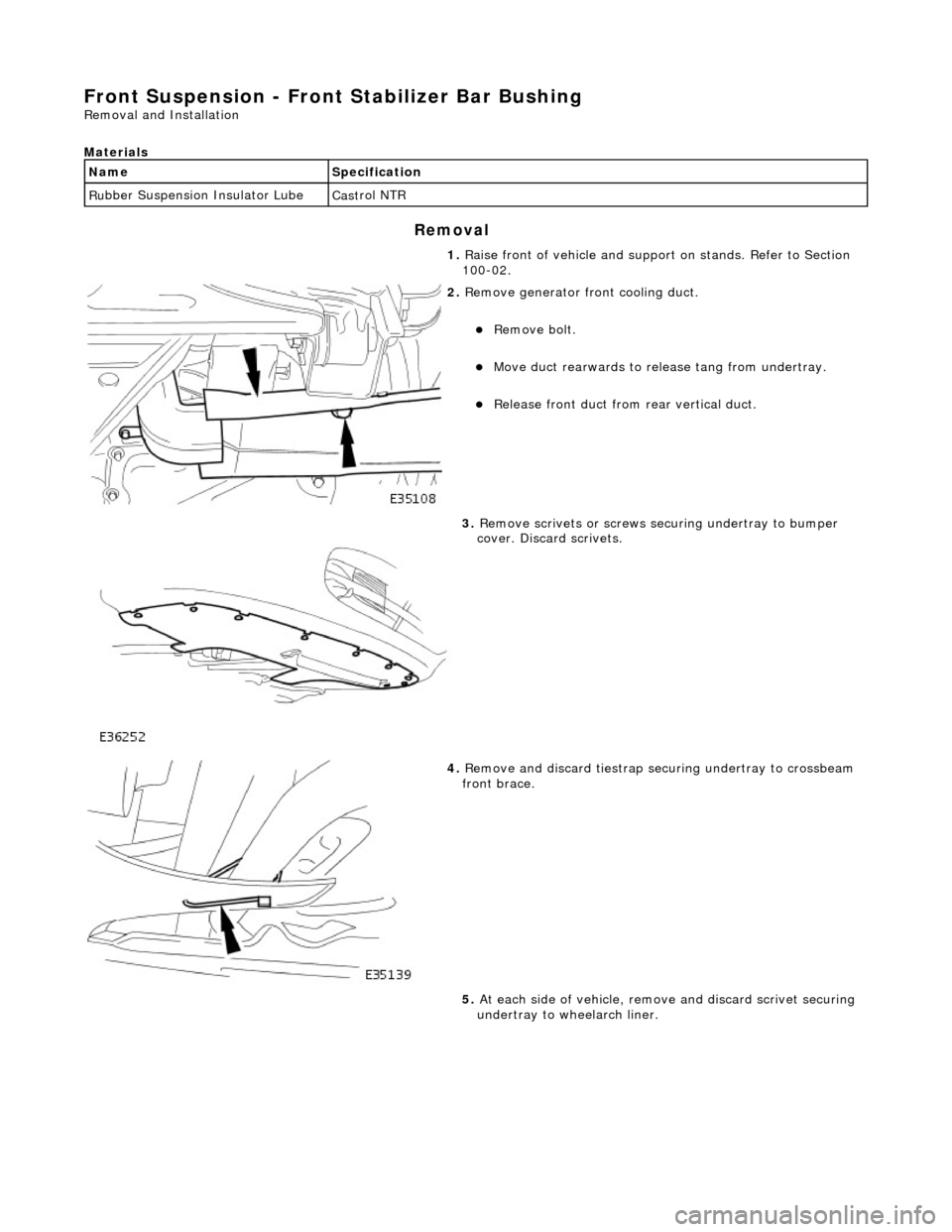

1. Raise front of vehicle and support on stands. Refer to Section

100-02.

2. Re

move generator front cooling duct.

Re

mo

ve bolt.

Move duct rea

r

wards to rele

ase tang from undertray.

Re

lease front duct from rear vertical duct.

3. Re

move scrivets or screws se

curing undertray to bumper

cover. Discard scrivets.

4. Re

move and discard tiestrap securing undertray to crossbeam

front brace.

5. At each side of vehicle, remo ve and discard scrivet securing

undertray to wheelarch liner.

Page 127 of 2490

Front Suspension - Front Stabiliz

er Bar Link

Re

moval and Installation

Remov

al

Installation

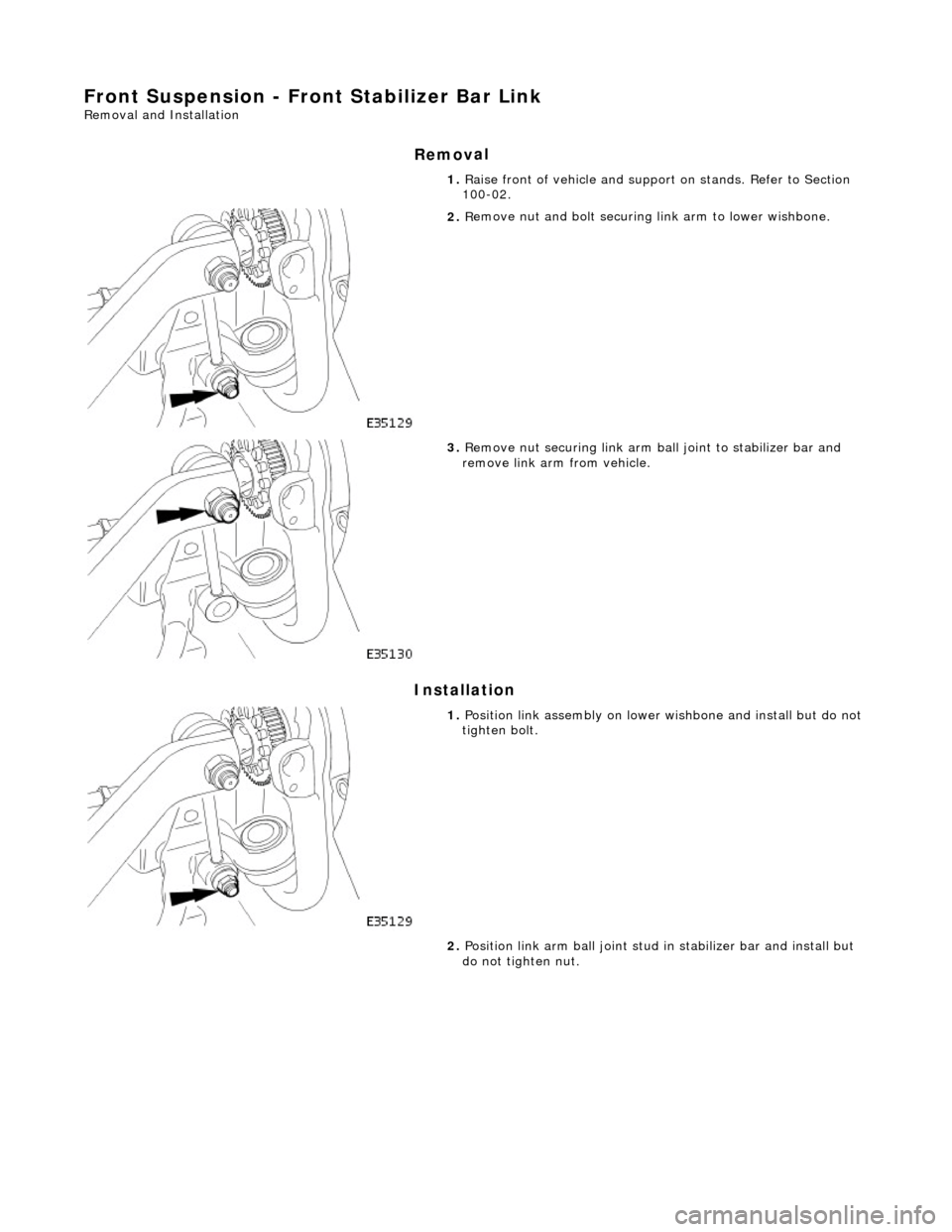

1. R

aise front of vehicle and support on stands. Refer to Section

100-02.

2. R

emove nut and bolt securing

link arm to lower wishbone.

3. R

emove nut securing link arm ba

ll joint to stabilizer bar and

remove link arm from vehicle.

1. Position li

nk assembly on lower

wishbone and install but do not

tighten bolt.

2. Position link arm ball joint stud in stabilizer bar and install but

do not tighten nut.

Page 129 of 2490

Front Suspension - Upper Arm Bushing

Re

moval and Installation

Remov

al

CAUTI

ON: Replacement of

nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

S

pecial Tool(s)

Ball

Joint Taper Separator

204-192 (JD 219)

Front Camber Tie-do

wn Link

204-114 (JD 133)

1. R

aise front of vehicle.

Refer to Section 100-02.

2. P

osition camber tie down spec

ial tool 204-114 on suspension.

Fully s

lacken tool adjuster nut.

Position too

l in road spring and pass upper dowel through

slot in suspen sion turret.

3. Lower front of vehicle.

4. R

otate stem of special tool 204-114 to locate dowel in

suspension turret slot.

5. WARNING: WHEN TIGHTENING TOOL NUT, USE LOWER

DOWEL AS A GUIDE TO ENSURE THAT THE TOOL STEM DOES

NOT ROTATE AND DISTURB POSITION OF DOWEL IN

SUSPENSION TURRET.

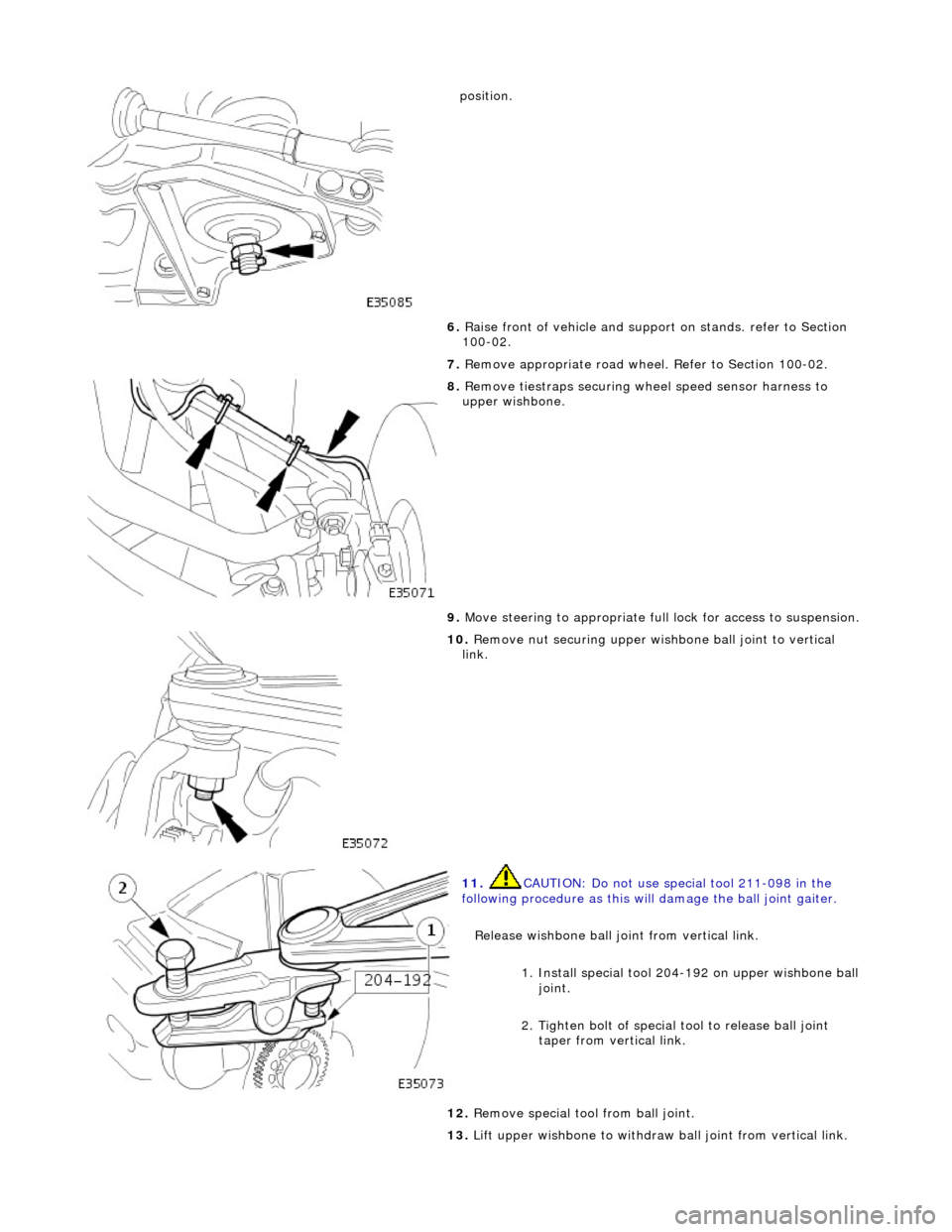

Fully tighten nut of special tool to achieve suspension mid-laden

Page 130 of 2490

positio

n.

6. Raise front of vehicle and support on stands. refer to Section

100-02.

7. Remove appropriate road wheel. Refer to Section 100-02.

8. Remove t

iestraps securing wheel speed sensor harness to

upper wishbone.

9. Move steering to appropriate full lock for access to suspension.

10. R

emove nut securing upper wish

bone ball joint to vertical

link.

11 . CAUTI

ON: Do not use special tool 211-098 in the

following procedure as this will damage the ball joint gaiter.

Release wishbone ball joint from vertical link.

1. Install special tool 204-192 on upper wishbone ball joint.

2. Tighten bolt of special tool to release ball joint

taper from vertical link.

12 . Re

move special tool from ball joint.

13. Lift upper wishbone to withdraw ball joint from vertical link.

Page 134 of 2490

17.

R

elease dowel of special tool 204-114 from suspension turret

slot.

18. Raise vehicle for access an d remove special tool from

suspension.

19. Fully lower vehicle.

20. Carry out steering geometry an d wheel alignment checks and

if necessary adjust. Refer to 57.65.01.

Page 135 of 2490

Front Suspension - Front Wheel Bearing

Re

moval and Installation

S

pecial Tool(s)

Hub Remover

204-193 (JD 224)

Hub Removal Collets

2

04-194 (JD 225)

Hub Holdin

g Tool

204-195 (JD 227)

Hub Replacer

2

04-196 (JD 236)

Wh

eel Bearing Remover

204-197 (JD 237)

Wh

eel Bearing Replacer

204-198 (JD 238)

ABS Rotor Nut Socket

20

6-066A

Ci

rclip Pliers

Page 147 of 2490

Front Suspension - Wheel Knuckle

Re

moval and Installation

S

pecial Tool(s)

Hub Remover

204-193 (JD 224)

Hub Removal Collets

2

04-194 (JD 225)

Hub Holdin

g Tool

204-195 (JD 227)

Hub Replacer

2

04-196 (JD 236)

Wh

eel Bearing Remover

204-197 (JD 237)

Wh

eel Bearing Replacer

204-198 (JD 238)

ABS Rotor Nut Socket

20

6-066A

Ci

rclip Pliers

Page 153 of 2490

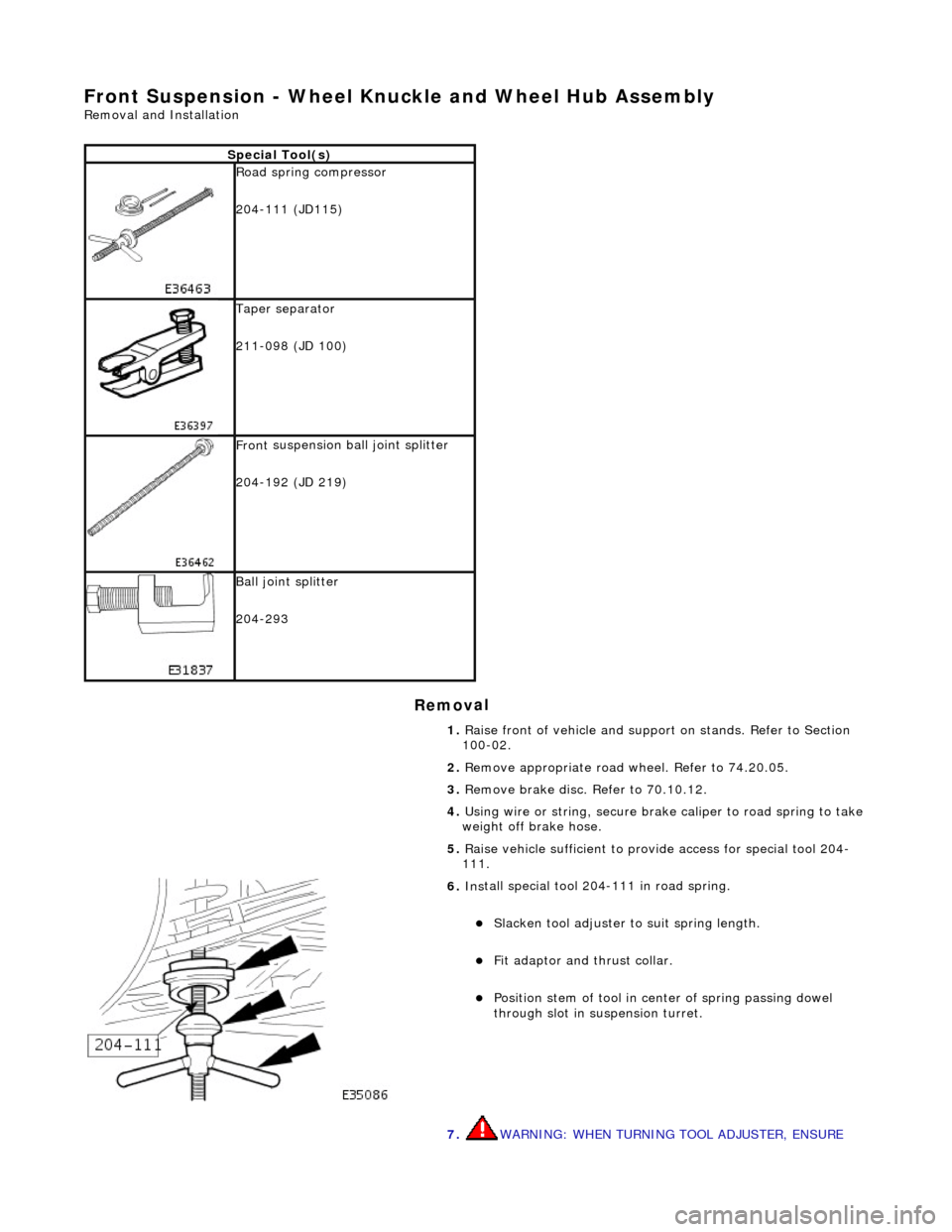

Front Susp

ension - Wheel Knuckle and Wheel Hub Assembly

Re

moval and Installation

Remov

al

S

pecial Tool(s)

R

oad spring compressor

204-111 (JD115)

Taper separator

211-098 (JD 100)

Front

suspension ball joint splitter

204-192 (JD 219)

Bal

l joint splitter

204-293

1. Raise front of vehicle and support on stands. Refer to Section

100-02.

2. Remove appropriate road wheel. Refer to 74.20.05.

3. Remove brake disc. Refer to 70.10.12.

4. Using wire or string, secure brak e caliper to road spring to take

weight off brake hose.

5. Raise vehicle sufficient to provide access for special tool 204-

111.

6. Ins

tall special tool 204-111 in road spring.

Sl

acken tool adjuster to suit spring length.

Fit adaptor and th

rust collar.

Posit

ion stem of tool in center of spring passing dowel

through slot in su spension turret.

7. WARNING: WHEN TURNING TOOL ADJUSTER, ENSURE

Page 154 of 2490

THAT TOOL STEM

DOES NOT ROTATE AND DISTURB POSITION

OF DOWEL IN SUSPENSION TURRET.

Engage dowel of special tool 204-111 in suspension turret and

rotate to position across slot.

8. Lower vehicle onto stands.

9. Ro

tate tool adjuster to tension spring.

10 . R

emove wheel speed sensor se

curing screw and withdraw

sensor from vertical link.

11 . R

emove nut securing tie rod oute

r ball joint to steering arm.

12. Release ball joint from vertical link.

1. Install special tool 211-098 on tie rod outer ball joint.

2. Tighten tool bolt to rele ase taper pin from vertical

link.

Page 156 of 2490

In

stallation

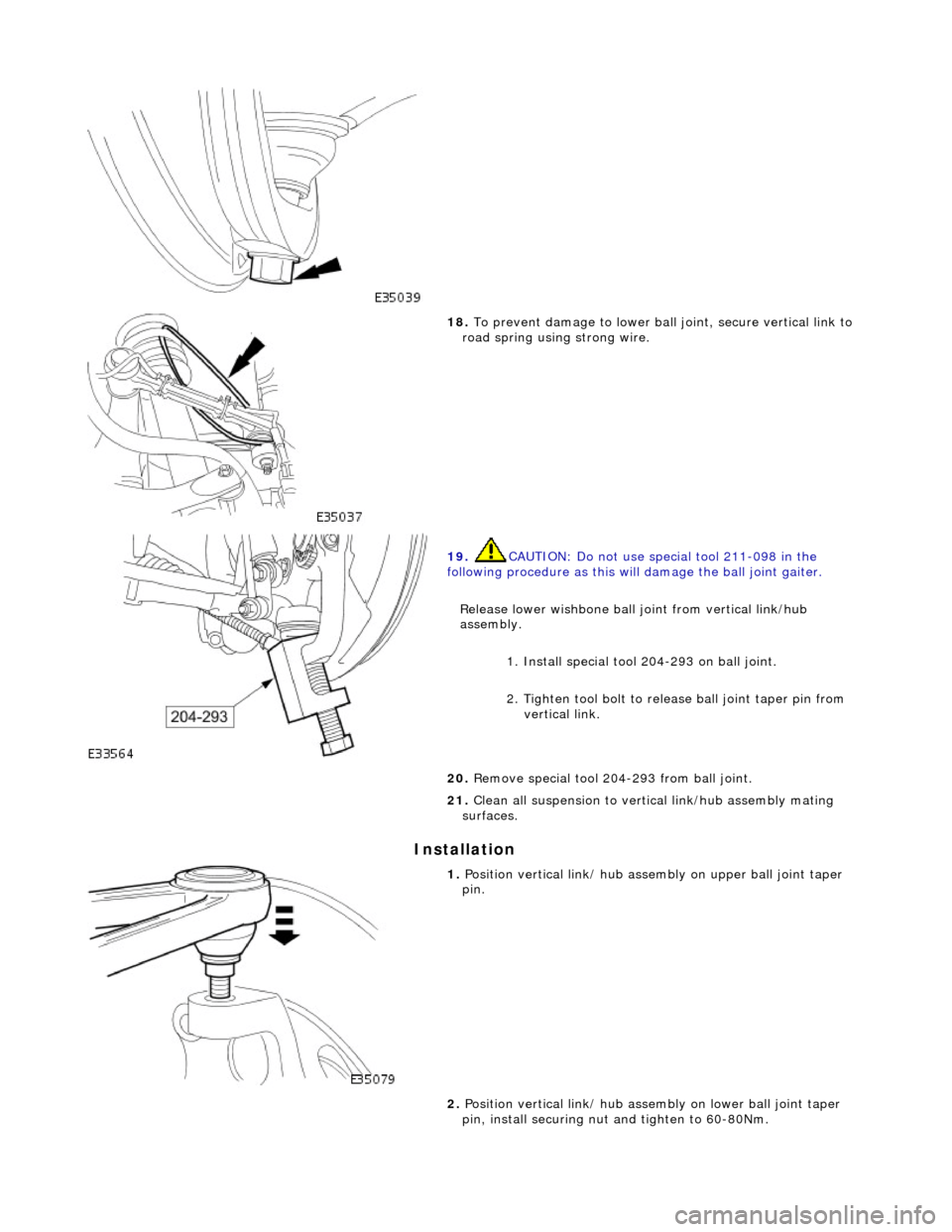

18

. To

prevent damage to lower ball

joint, secure vertical link to

road spring using strong wire.

19 . CAUTI

ON: Do not use special tool 211-098 in the

following procedure as this will damage the ball joint gaiter.

Release lower wishbone ball joint from vertical link/hub

assembly. 1. Install special tool 204-293 on ball joint.

2. Tighten tool bolt to rele ase ball joint taper pin from

vertical link.

20 .

R

emove special tool 204-293 from ball joint.

21. Clean all suspension to vertical link/hub assembly mating

surfaces.

1. Position verti c

al link/ hub asse

mbly on upper ball joint taper

pin.

2. Position vertical link/ hub asse mbly on lower ball joint taper

pin, install securing nut and tighten to 60-80Nm.