SOLENOID JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1275 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Diagnostic Strategy

Diagnosis and Testing

Quick Reference Fault Chart

Quick Reference Fault Chart

Special Tool(s)

Digital multimeter

Generic scantool

SymptomPossible SourcesAction

Normal transmission

operation but fault codes

stored• NOTE: If P0706 is logged ignore P0742

Output speed sensor circuit fault

TCM faulty

ABS system fault (this code may log er roneously following an ABS problem)

Position switch and D to 4 switch circuit fault

P R 4 circuit fault

*

*

*

*

*

GO to

P0721 GO to

P1603 GO to

P0742

*

*

*

Sport mode will not selectMode switch circuit fault

*GO to

P0790

*

Mode switch state lamp not

workingMode switch supply

Mode switch circuit fault

*

*GO to

P0790

*

Poor, or reduced shift

qualityPresence of EMS faults

(may affect the accuracy of the torque signal)

*GO to EMS *

Transmission temperature sensor circuit

*GO to

P0710

*

Out of sequence shiftOutput / input speed sensor circuit fault

Mechanical fault (check all other operations)

*

*GO to

P1731

*

No torque converter lock-

upP R 4 circuit fault

*GO to

P0743

*

Mechanical fault, should P R 4 be OK

*GO to

P0741

*

Harsh shifts, engine stalling (torque converter stuck on)P R 4 circuit fault

Mechanical fault, should P R 4 be OK

*

*GO to

P0742

*

Default to 4th gearSolenoid / pressure regulator supply from TCM

*GO to

P0702

*

• NOTE: If the code logs wh

en 3rd is selected, then the D to 4 switch is the most probable cause If the code logs when D is selected fro m the LH side of the gate,

then check selector cable adjustment

'J gate' or selector ca ble out of adjustment

D to 4th switch

Rotary position switch circuit

*

*

*GO to

P0706

*

Input speed sensor circuit fault

Input speed sensor faulty

*

*GO to

P0715

*

Solenoid #1 circuit fault

*GO to

P0753

*

Solenoid #2 circuit fault

*GO to

*

Page 1276 of 2490

Symptom Chart

Symptom Chart

P0758

Solenoid #3 circuit fault

*GO to

P0763

*

TCM faulty

*GO to

P1605 and

P1608

*

ABS fault

CAN circuit fault between ABS/TCCM and TCM

Output speed sensor circuit fault

*

*

*GO to

P1720

*

Mechanical fault (check all other operations)

*GO to

P1726

*

Pressure regulator, solenoid

or speed sensor circuit fault

Mechanical fault - transmission defaulted to 5th?

*

*GO to

P1734

*

Pressure regulator #1 circuit fault

*GO to

P1745

*

Pressure regulator #2 circuit fault

*GO to

P1746

*

Pressure regulator #3 circuit fault

*GO to

P1747

*

Pressure regulator #4 circuit fault

*GO to

P0743

*

Pressure regulator #5 circuit fault

*GO to

P1748

*

Mechanical fault - transmission defaul

ted during 2nd to 3rd or 3rd to 4th

shift?

*GO to

P1779

*

Power (ignition) supply fault to TCM

Vehicle battery charging system fault

*

*GO to

P1789 and

P1793

*

Incompatible ECM, ABS/TCCM, TCM or INST - check part number

*GO to

P1795

*

CAN circuit fault

Check fault code(s) in ECM, ABS/TCCM or INST and rectify as required

*

*GO to

P1796

*

Faulty ECM

CAN circuit fault between ECM and TCM

*

*GO to

P1797

*

Default to 5th gearOutput speed sensor circuit fault

Mechanical fault (check pulling

away from standstill performance)

*

*GO to

P1722

*

Output / input speed sensor circuit fault

Mechanical fault (check operation of tr

ansmission in 2nd, 3rd and 4th gears)

*

*GO to

P1730

*

SymptomPossible SourcesAction

DTC P0741 Torque converter clutch system

performance or stuck offTorque converter clutch slipping or stuck off

*GO to Pinpoint

Test A

*

DTC P0742 Torque converter clutch system stuck onTorque converter clutch stuck on

*GO to Pinpoint

Test A

*

DTC P0743 Torque converter clutch system

electrical#4 pressure regulator faulty

Harness fault

Connector pins(s) bent

, loose or corroded

*

*

*GO to Pinpoint

Test B

*

DTC P0702 Transmission control system

electricalHarness fault

High side switch (FET) fault

Connector pins(s) bent

, loose or corroded

*

*

*GO to Pinpoint

Test C or D

*

DTC P0753 Shift solenoid A electricalHarness fault

Solenoid open circuit

Solenoid short

Connector pins(s) bent

, loose or corroded

*

*

*

*GO to Pinpoint

Test C

*

DTC P0758 Shift solenoid B electricalHarness fault

Solenoid open circuit

Solenoid short

Connector pins(s) bent

, loose or corroded

*

*

*

*GO to Pinpoint

Test C

*

DTC P0763 Shift solenoid C electricalHarness fault

Solenoid open circuit

Solenoid short

Connector pins(s) bent

, loose or corroded

*

*

*

*GO to Pinpoint

Test C

*

Page 1289 of 2490

With EM007 and EM046 disconnected, measure the

resistance between EM007/052 and EM007/054 1

Repeat for EM007/053 and EM007/054 2

> 10 MOHM?

Yes GO to C7

No Inspect harness / connectors EM007 for damage, corrosion,

bent / pushed back pins. Repa ir as necessary and test the

system for normal operation.

C7: CHECK HARNESS CONTINUITY - SOLENOID

Page 1290 of 2490

With EM007 and EM046 disconnected, measure the

resistance in turn; 1

EM007/030 and EM046/008 2

EM007/033 and EM046/009 3

EM007/032 and EM046/004 4

Is the resistance < 0.5 OHM?

Yes GO to C8

No Inspect harness / connectors EM007 and EM046 for damage,

corrosion, bent / pushed back pins. Repair as necessary and

test the system for normal operation.

C8: CHECK FOR SOLENOID SHORT TO B+

Page 1292 of 2490

With EM007 and EM046 disconnected, measure the

resistance between EM007/030 and EM008R

Repeat for

1

EM007/033 and EM008R 2

EM007/032 and EM008R 3

Is the resistance > 10 MOHM?

Yes GO to C10

No

Inspect harness / connectors EM007 for damage, corrosion,

bent / pushed back pins. Repa ir as necessary and test the

system for normal operation.

C10: CHECK FOR SOLENOID SHORT TO IGNITION

Page 1293 of 2490

With EM007 and EM046 disconnected, measure the

resistance between EM007/030 and EM007/054

Repeat for

1

EM007/033 and EM007/054 2

EM007/032 and EM007/054 3

Is the resistance > 10 MOHM?

Yes Reconnect EM046

GO to C11

No Inspect harness / connectors EM007 for damage, corrosion,

bent / pushed back pins. Repa ir as necessary and test the

system for normal operation.

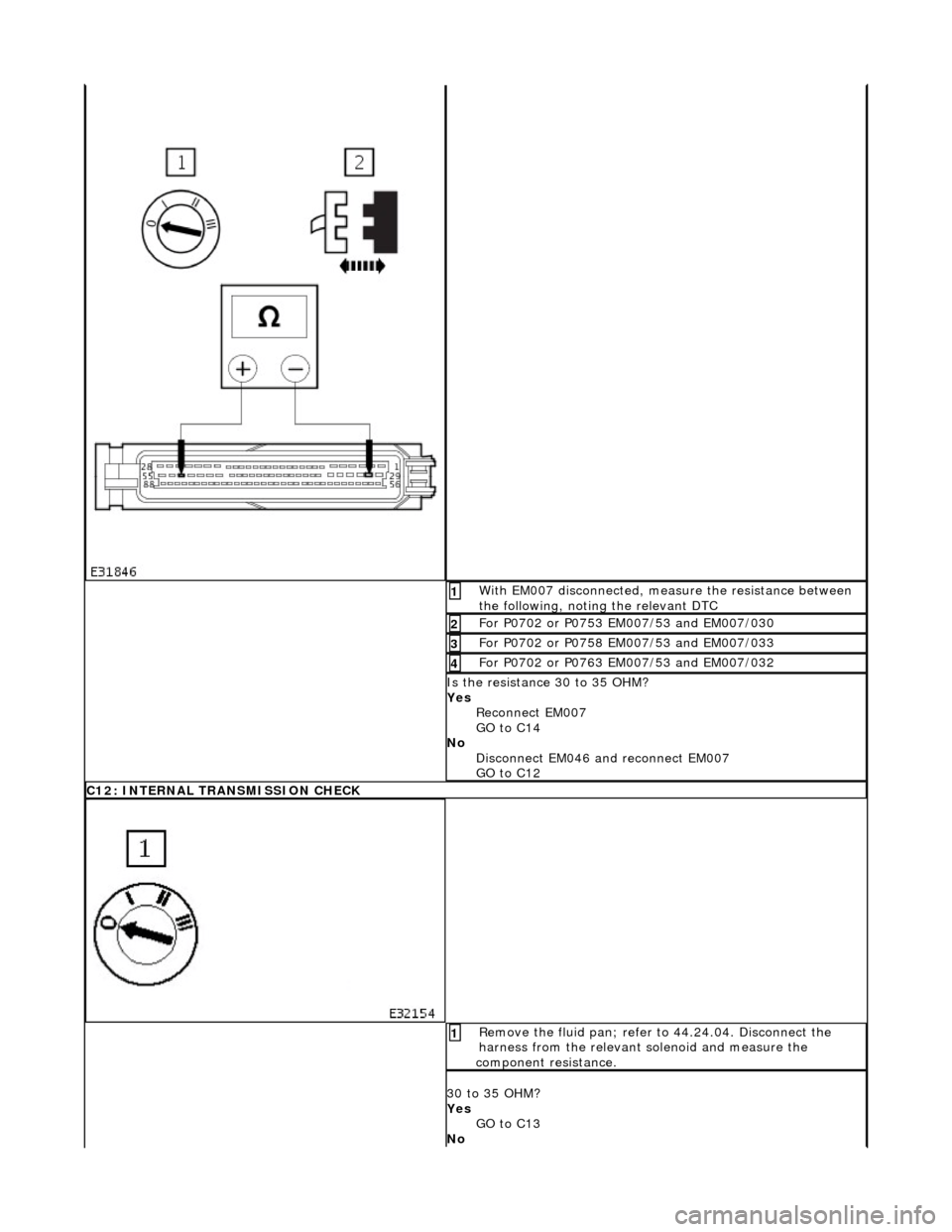

C11: CHECK INTERNAL HA RNESS AND COMPONENT CONTINUITY - SOLENOIDS

Page 1294 of 2490

With EM007 disconnected, measure the resistance between

the following, noting the relevant DTC 1

For P0702 or P0753 EM007/53 and EM007/030 2

For P0702 or P0758 EM007/53 and EM007/033 3

For P0702 or P0763 EM007/53 and EM007/032 4

Is the resistance 30 to 35 OHM?

Yes Reconnect EM007

GO to C14

No Disconnect EM046 and reconnect EM007

GO to C12

C12: INTERNAL TRANSMISSION CHECK

Remove the fluid pan; refer to 44.24.04. Disconnect the

harness from the relevant solenoid and measure the

component resistance. 1

30 to 35 OHM?

Yes GO to C13

No

Page 1295 of 2490

Pinpoint test D: P0702, P1745, P1746, P1747, P0743, P1748

Renew the solenoid; refer to 44.15.50.

C13: INTERNAL TRANSMISSION HARNESS CHECK

Measure the resistance from transmission internal harness

multiplug to the relevant solenoid connector 1

Is the resistance < 0.5 OHM?

Yes GO to C14

No Renew the internal harnes s; refer to 44.15.35.

C14: END

Cycle the ignition ON - (OFF for 2 minutes) - ON, start the

engine and run >1600 rpm 1

Has the fault code cleared?

Yes

STOP

No P0702 present?

Yes GO to D1

No P0753, P0758, P0763 present?

Yes Contact Jaguar Service

PINPOINT TEST D : P0702, P1745, P1746, P1747, P0743, P1748

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

D1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present

Connect the scan tool 1

Have the DTC(s) and freeze frame data been recorded?

Yes GO to D2

D2: CHECK HARNESS +VE CONTINUITY

Page 1339 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Electronic Pressure Control (EPC) Solenoid

In-vehicle Repair

Removal

1. Disconnect battery ground cable.

Remove the battery cover.

2. Raise the vehicle on a suitable lift.

2. WARNING: TRANSMISSION FLUID MAY CAUSE

SEVERE BURNS, ENSURE THAT ALL SAFETY PROCEDURES

ARE OBSERVED.

Carefully remove the drain plug and drain the

transmission fluid.

3. Remove the twenty-two fixings which secure the fluid pan .

Remove the fluid pan and all traces of gasket material.

4. Disconnect regulator / solenoid connectors.

5. Remove RH rear valve body securing screws.

Page 1340 of 2490

Installation

6. Remove the nine screws from th e pressure regulator / solenoid

retaining plate.

7. Remove the relevant pressure regulator.

1. Installation is the reverse of the removal procedure, noting

that a new pressure regulator 'O' ring MUST be used.

Fit the nine screws securing the pressure regulator /

solenoid retaining plate and ti ghten to the specified torque

figure.

2. Refit the RH rear valve body secu ring screws and tighten to the

specified torque figure.