coolant JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 926 of 2490

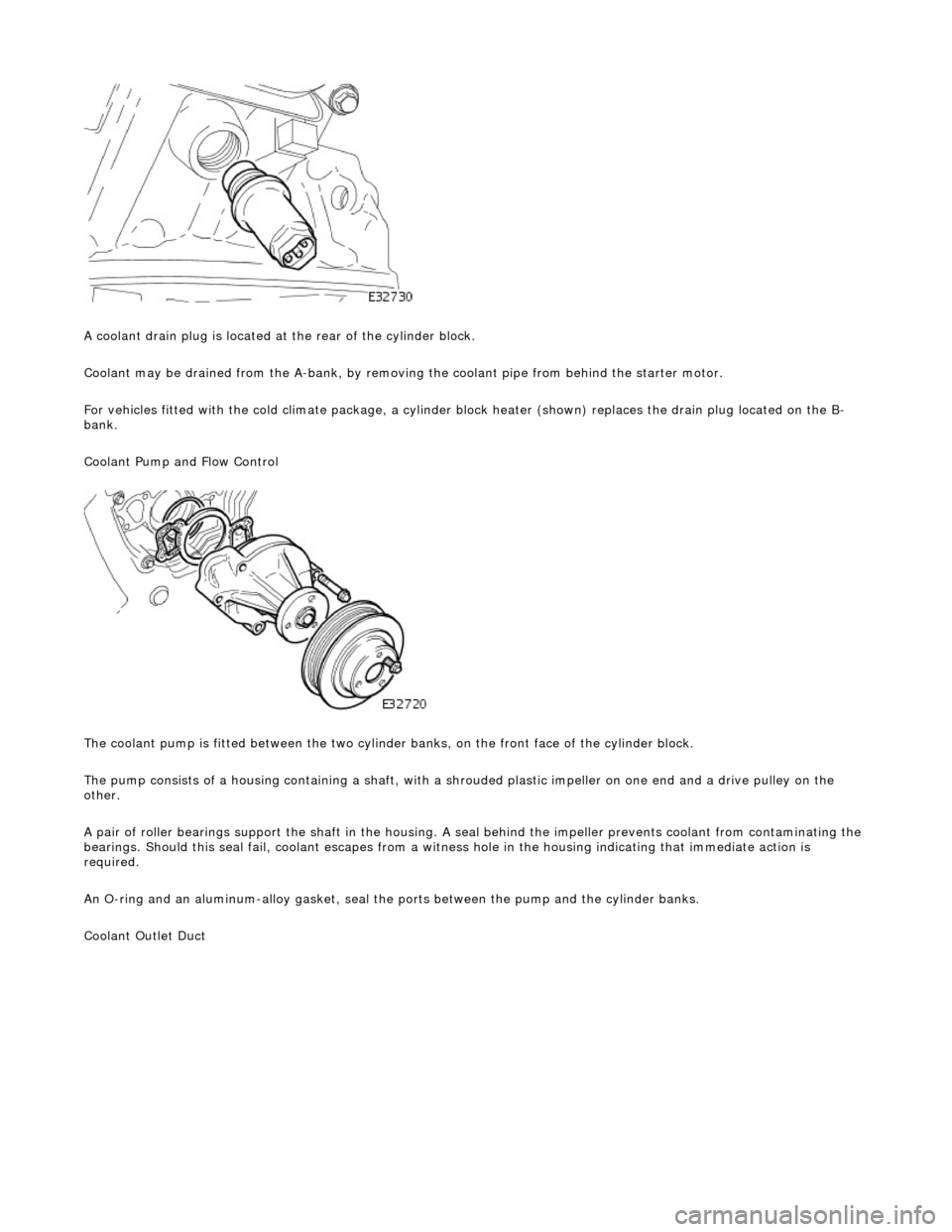

A coola n

t drain plug is located at the rear of the cylinder block.

Coolant may be drained from the A-bank, by removing the coolant pipe from behind the starter motor.

For vehicles fitted with the cold climate package, a cylinder block heater (shown) replaces the drain plug located on the B-

bank.

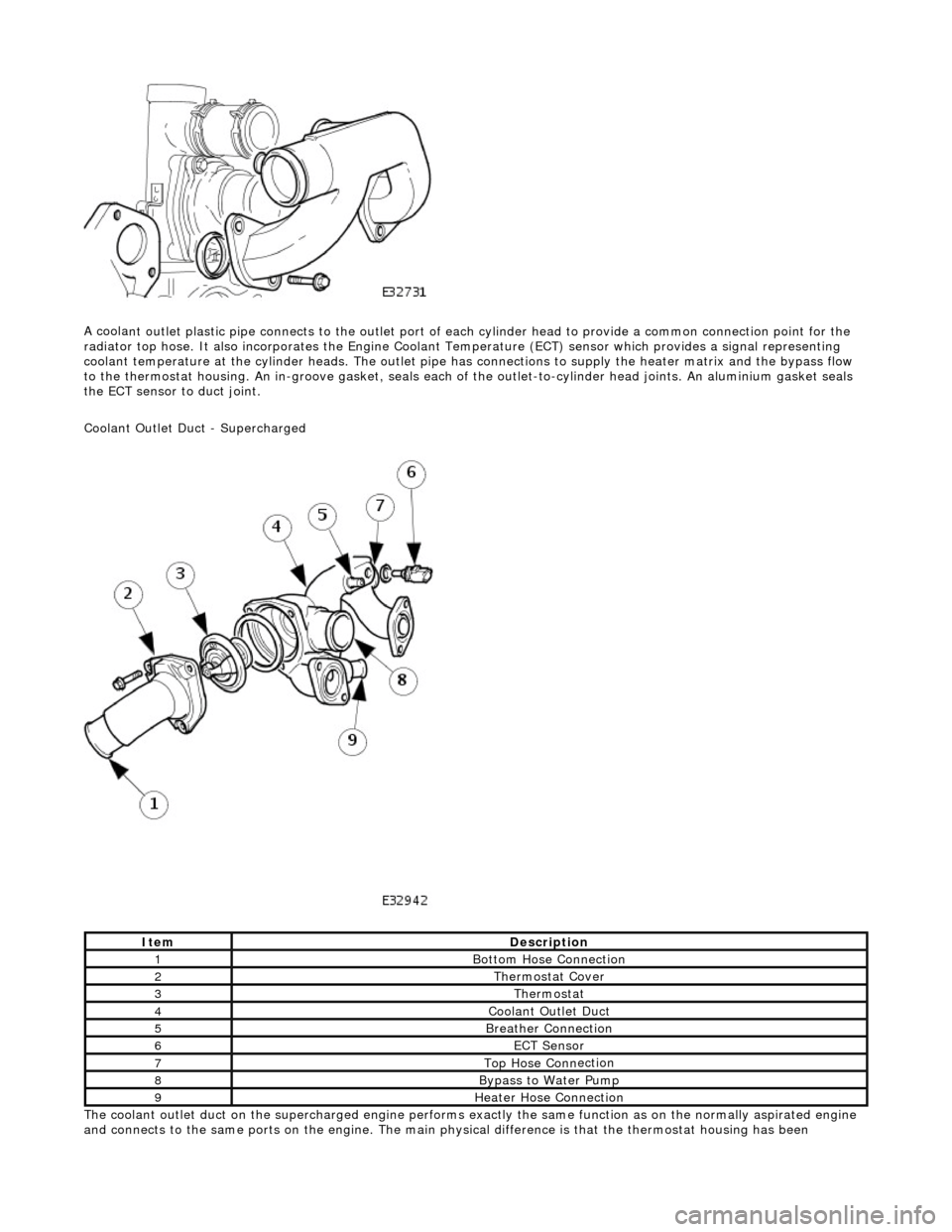

Coolant Pump and Flow Control

The coolant pump is fitted between the two cylinder banks, on the front face of the cylinder block.

The pump consists of a housing containing a shaft, with a sh rouded plastic impeller on one end and a drive pulley on the

other.

A pair of roller bearings support the shaft in the housing. A seal behind the impeller prevents coolant from contaminating the

bearings. Should this seal fail, coolant escapes from a witness hole in the housin g indicating that immediate action is

required.

An O-ring and an aluminum-alloy gasket, seal the ports between the pump and the cylinder banks.

Coolant Outlet Duct

Page 927 of 2490

A coola

nt outlet plastic pipe connects to the outlet port of ea

ch cylinder head to provide a common connection point for the

radiator top hose. It also incorporates the Engine Coolant Te mperature (ECT) sensor which provides a signal representing

coolant temperature at the cylinder heads. The outlet pipe has connections to supply the heater matrix and the bypass flow

to the thermostat housing. An in-groove ga sket, seals each of the outlet-to-cylinder head joints. An aluminium gasket seals

the ECT sensor to duct joint.

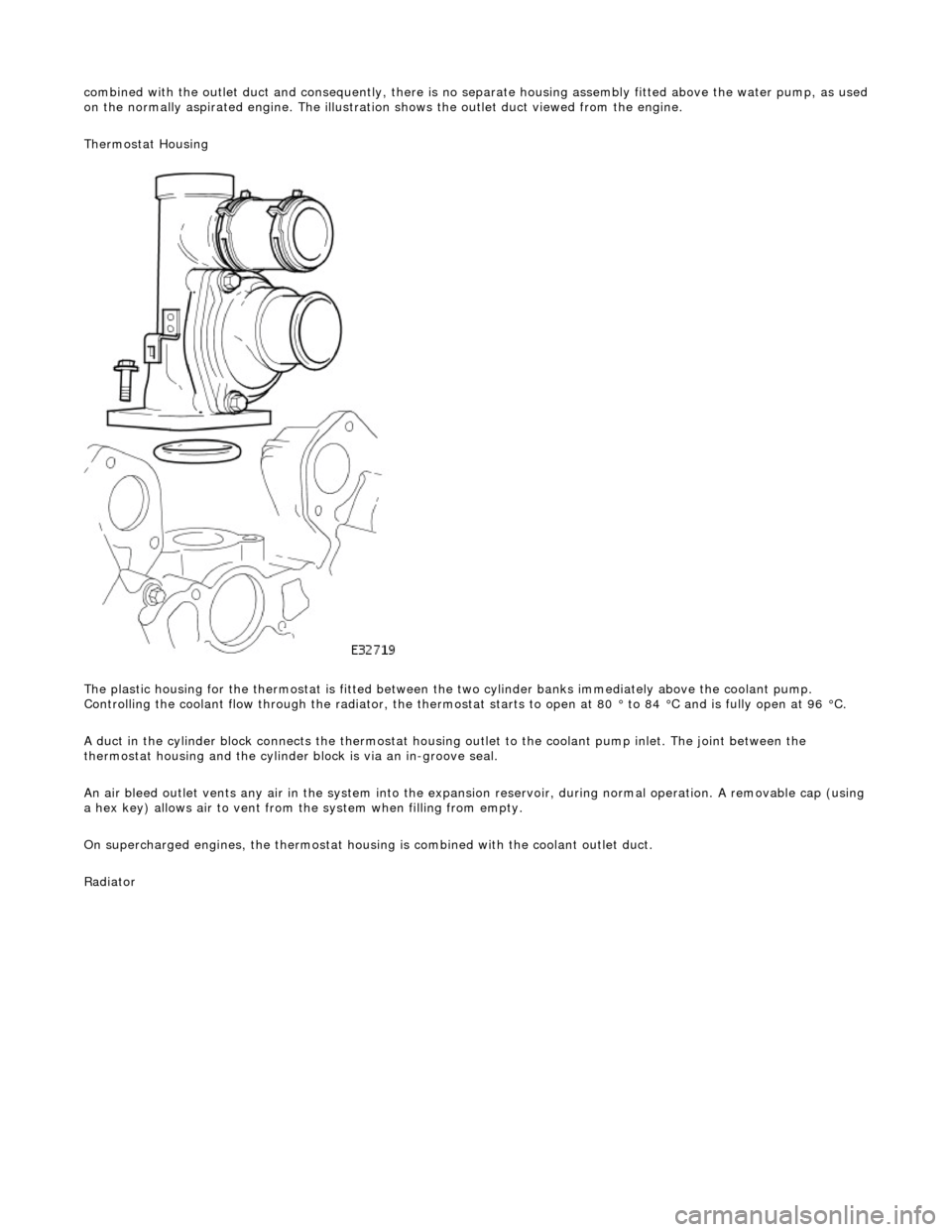

Coolant Outlet Duct - Supercharged

The coolant outlet duct on the supercharged engine performs exactly the same function as on the normally aspirated engine

and connects to the same ports on the engine. The main physical difference is that the thermostat housing has been

ItemDe

scription

1Bottom

Hose Connection

2The

rmostat Cover

3The

rmostat

4Coolan

t Outlet Duct

5B

reather Connection

6ECT Se

nsor

7Top Hose Conn

ection

8Bypa

ss to Water Pump

9Hea

ter Hose Connection

Page 928 of 2490

combin

ed with the outlet duct and consequently, there is no separate housin

g assembly fitted above the water pump, as used

on the normally aspirated engine. The illustration shows the outlet duct viewed from the engine.

Thermostat Housing

The plastic housing for the thermostat is fitted between th e two cylinder banks immediately above the coolant pump.

Controlling the coolant flow through the radiator, the thermostat starts to open at 80 ° to 84 °C and is fully open at 96 °C.

A duct in the cylinder block connects the thermostat housing outlet to the coolant pump inlet. The joint between the

thermostat housing and the cylinder block is via an in-groove seal.

An air bleed outlet vents an y air in the system into the expansion reservoir, durin

g normal operation. A removable cap (usin g

a hex key) allows air to vent from the system when filling from empty.

On supercharged engines, the thermostat housin g is combined with the coolant outlet duct.

Radiator

Page 929 of 2490

The cooling

pack incorporates the radiator a

ssembly with integral transmission oil cool er (located in the radiator outlet tank),

an air conditioning condenser, and the cooling fans and cowl assembly.

The cooling pack on supercharged vehicles is the same as described above, but with the addition of a charge air cooler

coolant radiator located in front of the condenser.

Radiator Mounti

ng/Retention

T

he radiator is mounted on four rubber mounts, one on each

end of the upper and lower horizontal face. The two lower

mountings are supported on two isolated brackets mounted on the body; the lower cradle assembly has subsequently been

deleted.

A closing panel made from polypropylene, which retains the radiat or assembly, fits over the top of the radiator and is bolted

to the vehicle top panel.

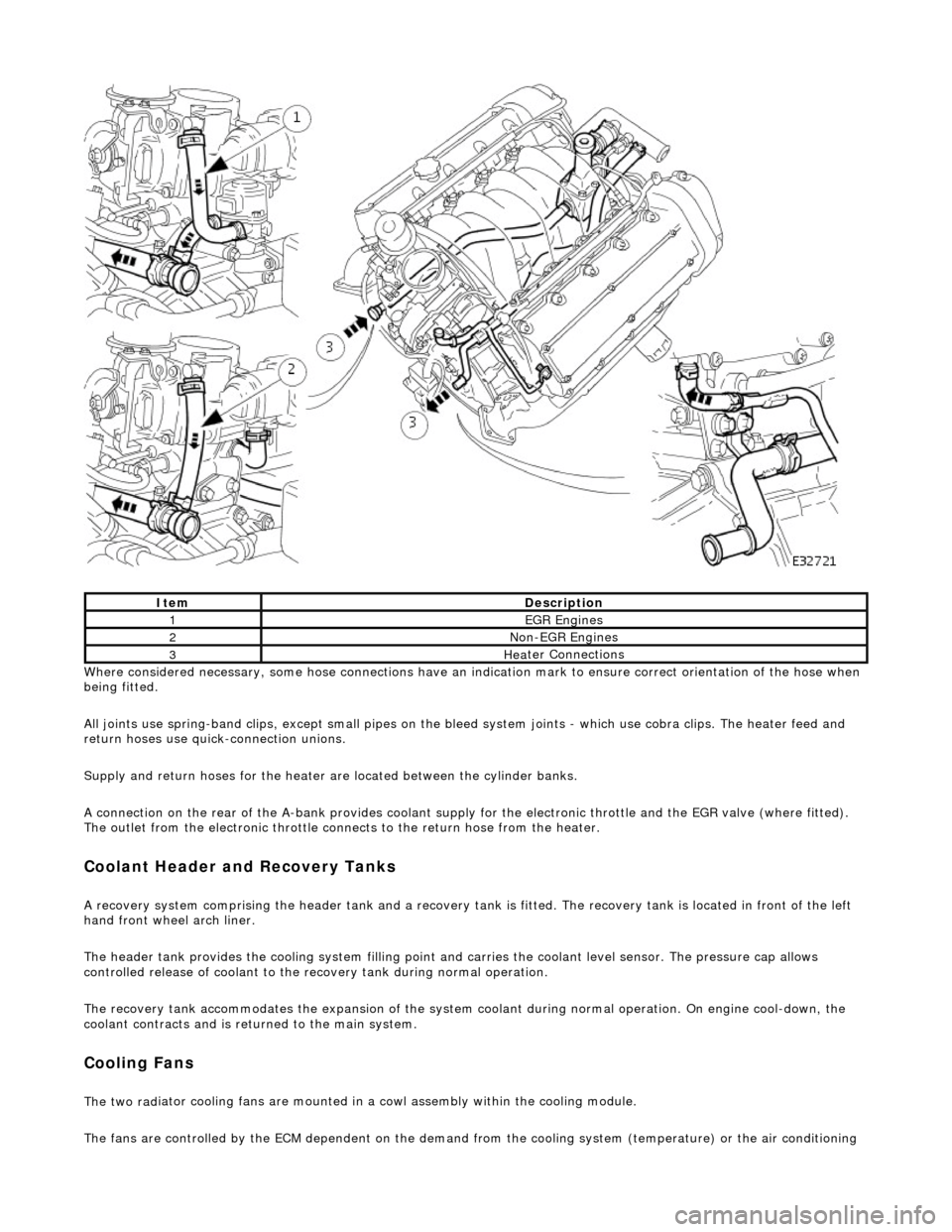

Coolant Hoses - Engine

Page 930 of 2490

Whe r

e considered necessary, some hose conn

ections have an indication mark to ensure correct orientation of the hose when

being fitted.

All joints use spring-band clips, except small pipes on the bleed system joints - which use cobra clips. The heater feed and

return hoses use quick-connection unions.

Supply and return hoses for the heater are located between the cylinder banks.

A connection on the rear of the A-bank provides coolant supply for the electronic throttle and the EGR valve (where fitted).

The outlet from the electronic throttle connects to the return hose from the heater.

Cool

ant Header and Recovery Tanks

A recovery system comp

rising the header tank

and a recovery tank is fitted. The recove ry tank is located in front of the left

hand front wheel arch liner.

The header tank provides the cooling system filling point and carries the coolant level sensor. The pressure cap allows

controlled release of coolant to the re covery tank during normal operation.

The recovery tank accommodates the expansion of the system coolant during normal operation. On engine cool-down, the

coolant contracts and is returned to the main system.

Coo lin

g Fans

The two

rad

iator cooling fans are mounted in

a cowl assembly within the cooling module.

The fans are controlled by the ECM dependent on the demand fr om the cooling system (temperature) or the air conditioning

ItemDescrip

tion

1EGR

E

ngines

2Non

-

EGR Engines

3Hea

ter Connections

Page 931 of 2490

s

ystem (pressure).

Outputs from the ECM control the radiator fans control module, located behind the left hand side of the bumper, to operate

the fans in the series mode (slow), paralle l mode (Fast) or Off modes. Hysteresis in the temperature and pressure switching

values prevents 'hun ting' between modes.

Under hot operating conditions, the fans may continue to operat e for some time after the engine has been switched off, but

will stop automatically when the coolant te mperature has been sufficiently reduced.

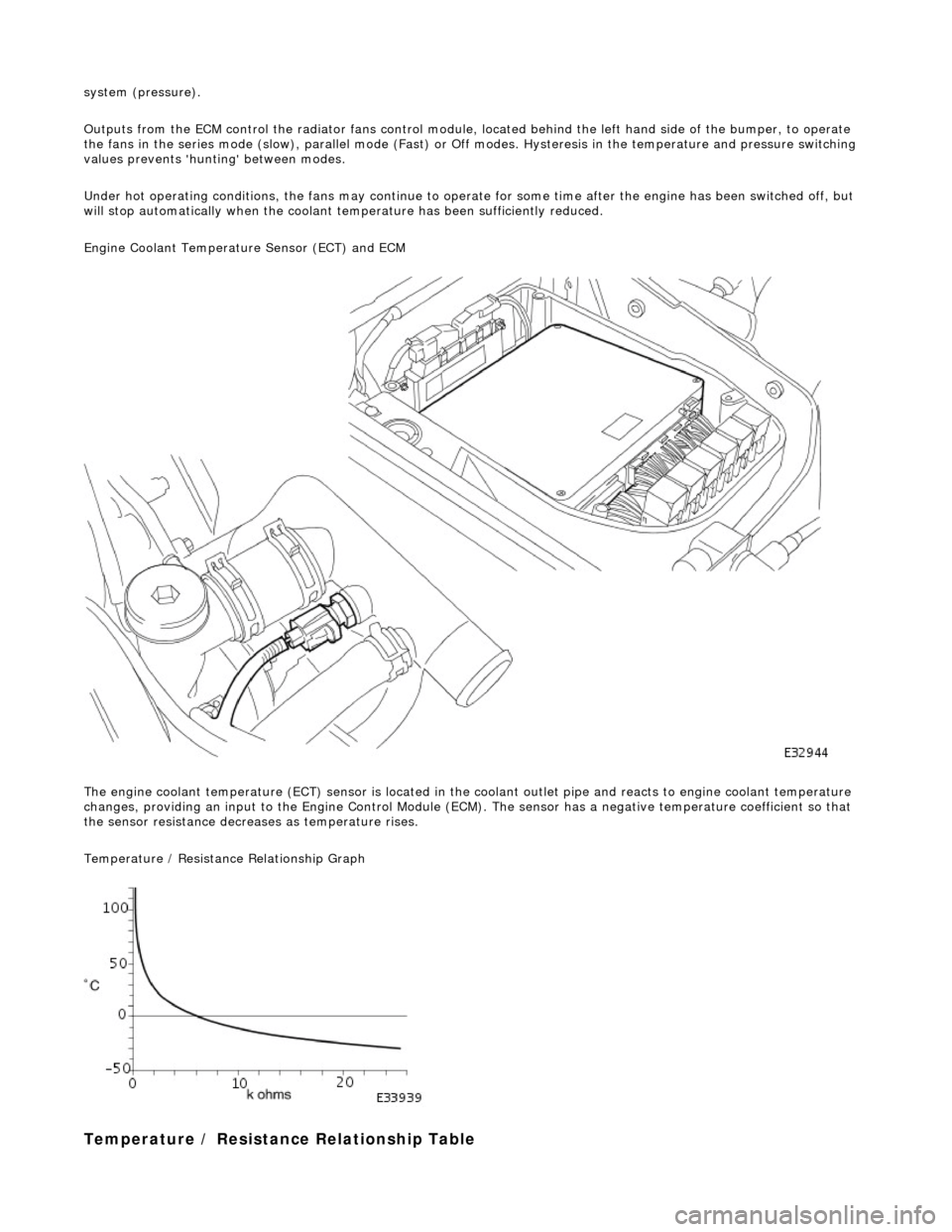

Engine Coolant Temperature Sensor (ECT) and ECM

The engine coolant temperature (ECT) sensor is located in the coolant outlet pipe and reacts to engine coolant temperature

changes, providing an input to the Engine Control Module (ECM). The sensor has a negative te mperature coefficient so that

the sensor resistance decrea ses as temperature rises.

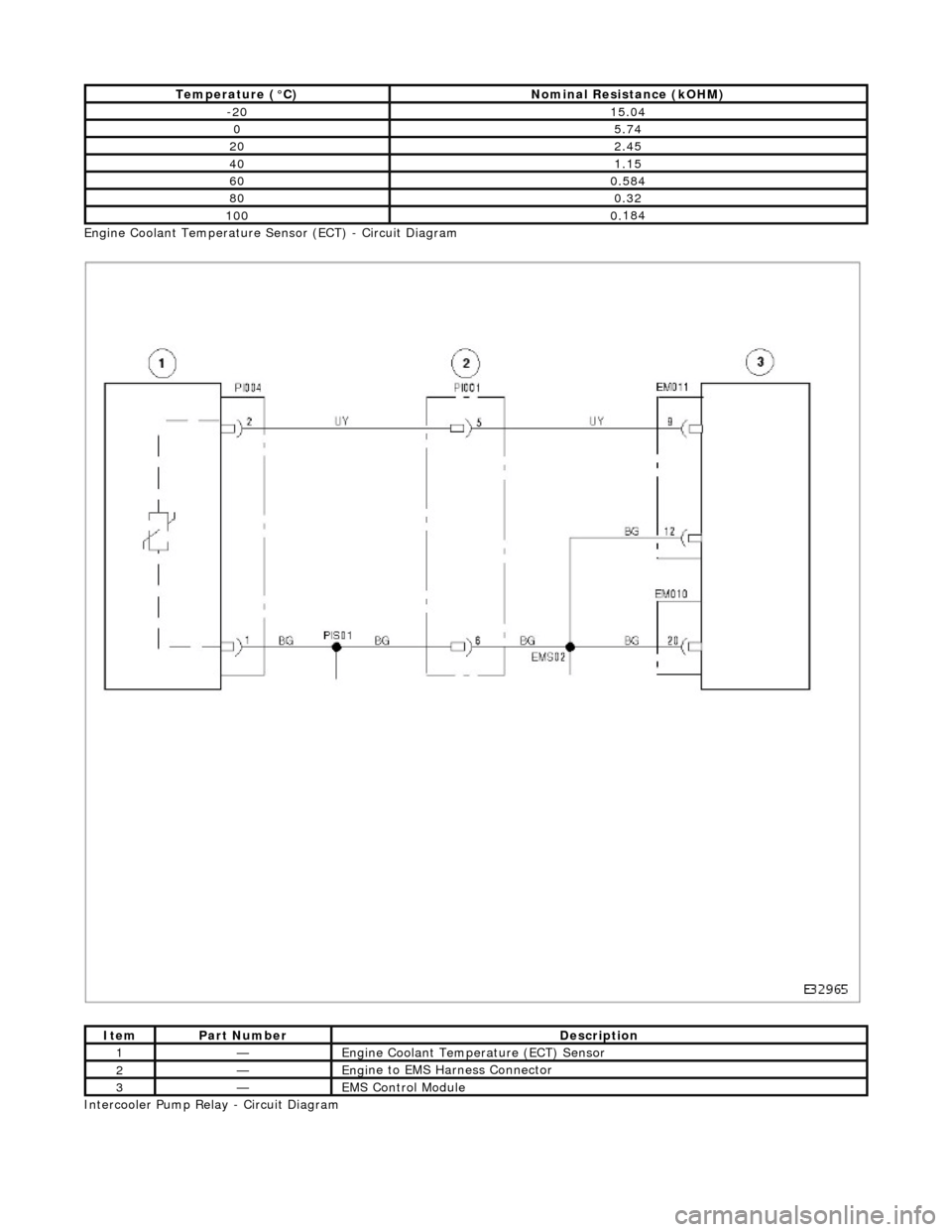

Temperature / Resistance Relationship Graph

T

emperature / Resistance

Relationship Table

Page 932 of 2490

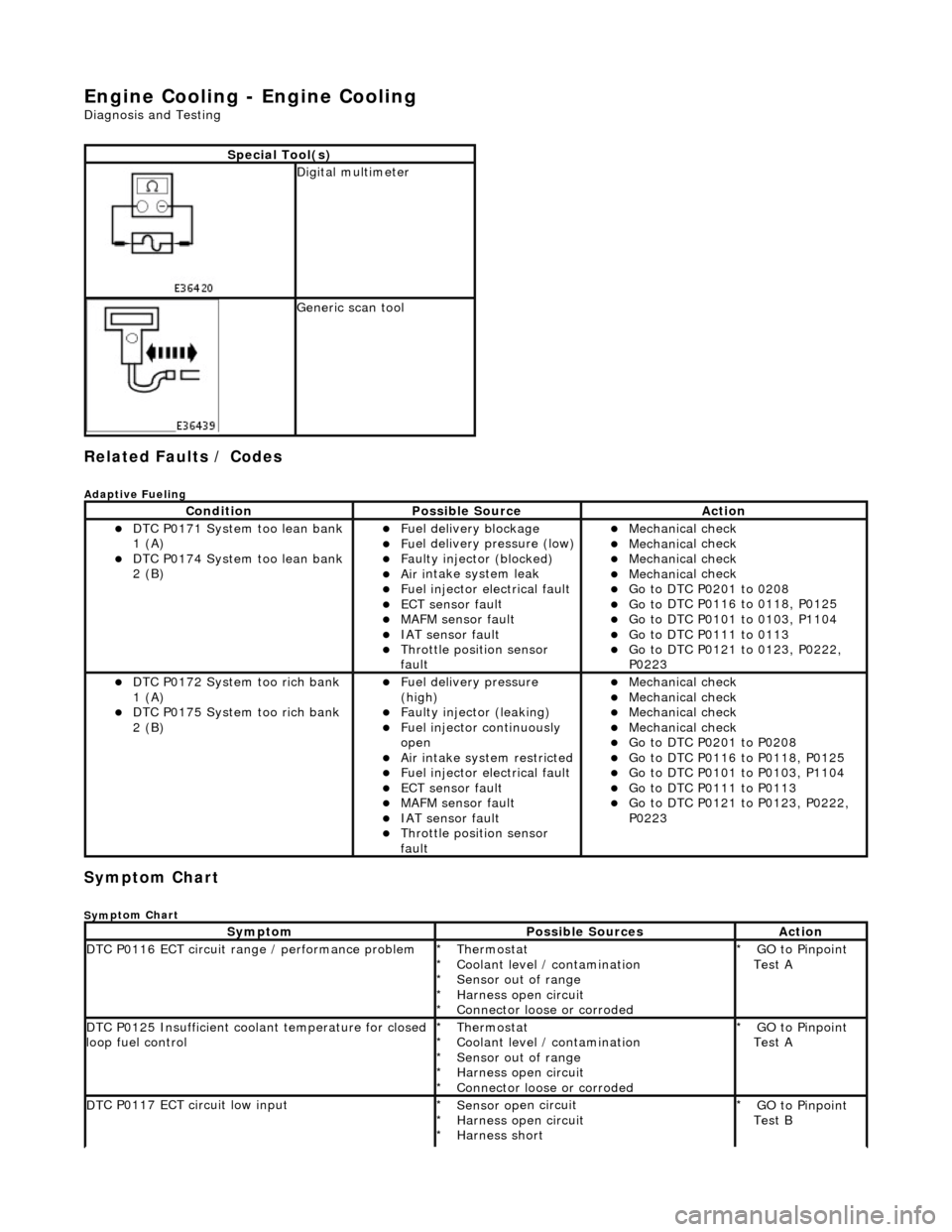

Engi

ne Coolant Temperature Sensor (ECT) - Circuit Diagram

Intercooler Pump Relay - Circuit Diagram

T emper

ature (°C)

No

mi

nal Resistance (kOHM)

-2

015 .0

4

05.7

4

202.45

401.15

600.

584

800.3

2

1000.

184

ItemPar

t

Number

De

scrip

tion

1—Eng

i

ne Coolant Temperature (ECT) Sensor

2—Eng

i

ne to EMS Harness Connector

3—EMS Con

trol Modu

le

Page 934 of 2490

Engine Cooling - Engine Cooling

Diagn

osis and Testing

Related Faults / Codes

Adaptive

Fue

ling

Sym

p

tom Chart

Sy

m

ptom Chart

S

p

ecial Tool(s)

D

i

gital multimeter

Generi

c scan tool

Conditi

on

Possib

l

e Source

Acti

o

n

D

T

C P0171 System too lean bank

1 (A)

D T

C P0174 System too lean bank

2 (B)

Fuel delivery blockage Fu

el delivery pressure (low)

F

a

ulty injector (blocked)

Ai

r i

ntake system leak

F

u

el injector electrical fault

ECT sensor

faul

t

MAFM sensor fault IAT se

nsor fault

Thro

tt

le position sensor

fault

Mec hanica

l check

Mec

hanica

l check

Mec

hanica

l check

Mec

hanica

l check

Go t

o DTC P020

1 to 0208

Go t

o

DTC P0116 to 0118, P0125

Go t

o

DTC P0101 to 0103, P1104

Go t

o DTC P011

1 to 0113

Go t

o

DTC P0121 to 0123, P0222,

P0223

D T

C P0172 System too rich bank

1 (A)

D T

C P0175 System too rich bank

2 (B)

F u

el delivery pressure

(high)

F a

ulty injector (leaking)

F

u

el injector continuously

open

Ai r i

ntake system restricted

Fu

el injector electrical fault

ECT sensor

faul

t

MAFM sensor fault IAT sensor fault

Thrott

le position sensor

fault

Mec hanica

l check

Mec

hanica

l check

Mec

hanica

l check

Mec

hanica

l check

Go t

o DTC P020

1 to P0208

Go t

o

DTC P0116 to P0118, P0125

Go t

o

DTC P0101 to P0103, P1104

Go t

o DTC P011

1 to P0113

Go t

o

DTC P0121 to P0123, P0222,

P0223

Sy m

ptom

Possib

l

e Sources

Acti

o

n

D

T

C P0116 ECT circuit range / performance problem

Thermostat

Coo

l

ant level / contamination

Sensor out of range

Harness open circuit

Connector loose or corroded

*

*

*

*

*

GO to Pinpoint

Test A

*

D

T

C P0125 Insufficient coolant temperature for closed

loop fuel control

Thermostat

Coo l

ant level / contamination

Sensor out of range

Harness open circuit

Connector loose or corroded

*

*

*

*

*

GO to Pinpoint

Test A

*

D

T

C P0117 ECT circuit low input

Sensor o

p

en circuit

Harness open circuit

Harness short

*

*

*

GO to Pinpoint

Test B

*

Page 935 of 2490

Pinpoint test

A: P0116, P0125

Connector

loose or corroded

*

D

TC P0118 ECT circuit high input

Sensor short

Harness open circui

t

Harness short

Connector loose or corroded

*

*

*

*

GO to Pinpoint

Test C

*

D

TC P1474 Intercooler coolant pump relay malfunction

Intercooler pump relay

failure

Intercooler pump relay to ECM drive circuit

fault Intercooler pump relay coil ground circuit

fault Harness fault

Connector loose or corroded

Connector pins(s) bent or tracking between

connections ECM power supply fault

*

*

*

*

*

*

*

GO to Pinpoint

Test D

*

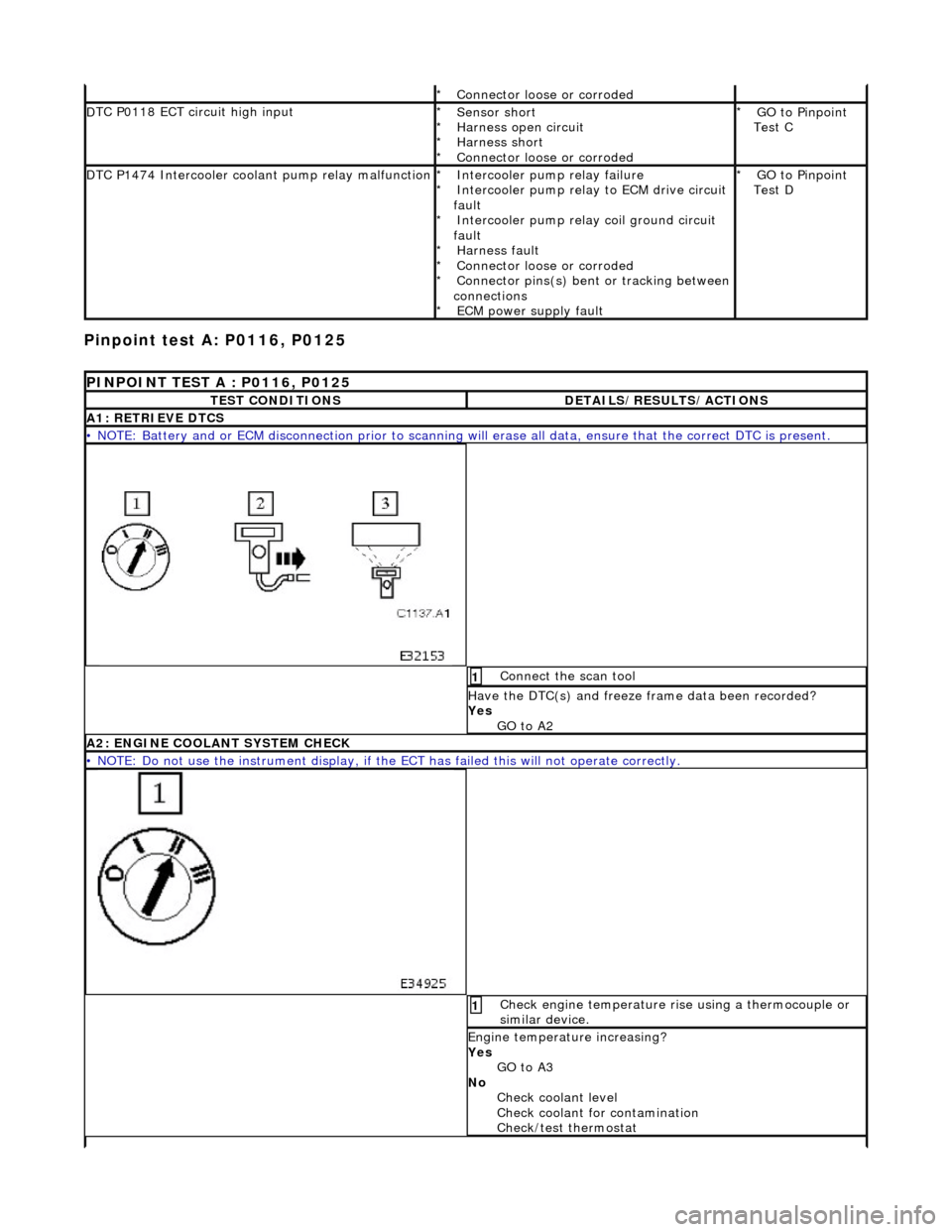

P

INPOINT TEST A : P0116, P0125

T

EST CONDITIONS

D

ETAILS/RESULTS/ACTIONS

A1

: RETRIEVE DTCS

•

NOTE: Battery and or ECM disconnection prior to scanning wi

ll erase all data, ensure that the correct DTC is present.

Conne

ct the scan tool

1

Have the DTC(s) and fr

eeze

frame data been recorded?

Yes GO to A2

A2: ENGINE

COOLANT SYSTEM CHECK

•

NOTE: Do not use the instrument display, if th

e ECT has failed this will not operate correctly.

Chec

k engine temperature rise using a thermocouple or

similar device.

1

Engine

temperature increasing?

Yes GO to A3

No Check coolant level

Check coolant for contamination

Check/test thermostat

Page 948 of 2490

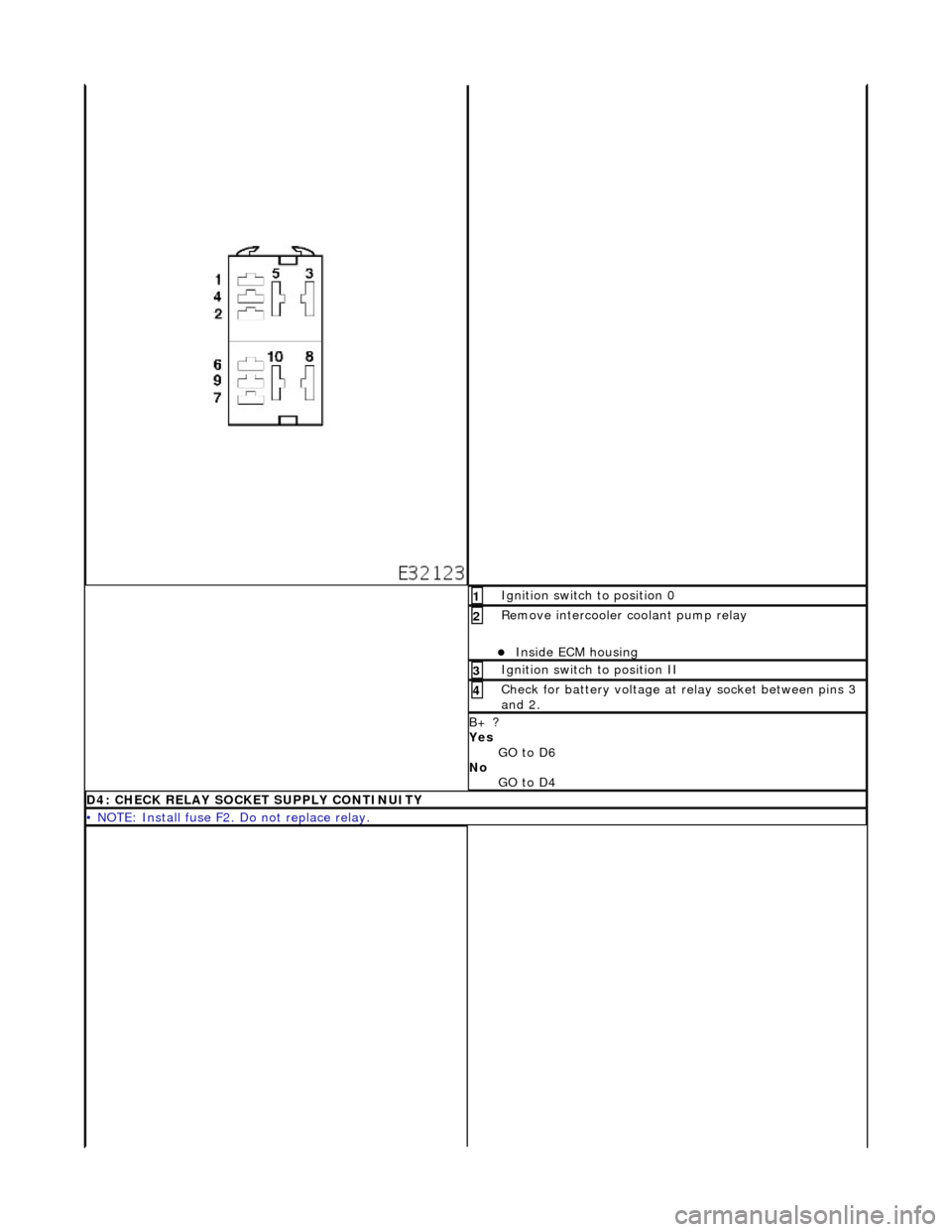

Ig

nition switch to position 0

1

R

e

move intercooler

coolant pump relay

Inside EC

M housing

2

Ignition switc

h

to position II

3

Ch

e

ck for battery voltage at relay socket between pins 3

and 2.

4

B+ ?

Yes

GO to D6

No GO to D4

D4: C H

ECK RELAY SOCKET SUPPLY CONTINUITY

•

NOTE: Install fuse F2.

Do not replace relay.