drain bolt JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1362 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Transmission Intern al Wiring Harness

In-vehicle Repair

Removal

• NOTE: The temperature sensor is integral with the internal harness.

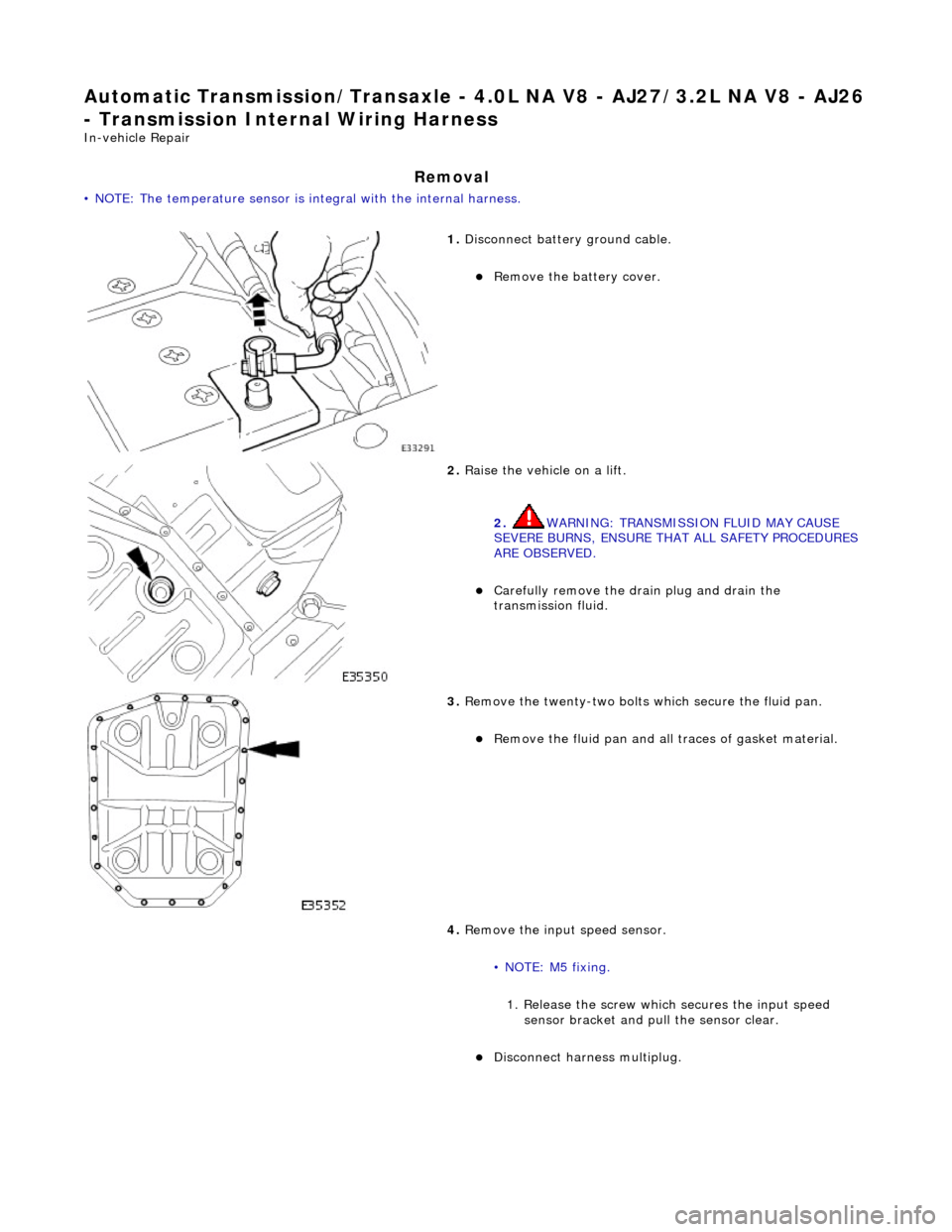

1. Disconnect battery ground cable.

Remove the battery cover.

2. Raise the vehicle on a lift.

2. WARNING: TRANSMISSION FLUID MAY CAUSE

SEVERE BURNS, ENSURE THAT ALL SAFETY PROCEDURES

ARE OBSERVED.

Carefully remove the drain plug and drain the

transmission fluid.

3. Remove the twenty-two bolts which secure the fluid pan.

Remove the fluid pan and all tr aces of gasket material.

4. Remove the input speed sensor.

• NOTE: M5 fixing. 1. Release the screw which secures the input speed sensor bracket and pull the sensor clear.

Disconnect harness multiplug.

Page 1373 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Turbine Shaft Speed (TSS) Sensor

In-vehicle Repair

Removal

1. Disconnect battery ground cable.

Remove the battery cover.

2. Raise the vehicle on a lift.

2. WARNING: TRANSMISSION FLUID MAY CAUSE

SEVERE BURNS, ENSURE THAT ALL SAFETY PROCEDURES

ARE OBSERVED.

Carefully remove the drain plug and drain the

transmission fluid.

3. Remove the twenty-two bolts which secure the fluid pan.

Remove the fluid pan and all tr aces of gasket material.

4. Remove the input speed sensor.

• NOTE: M5 fixing.

1. Release the screw which secures the input speed sensor bracket and pull the sensor clear.

5. Disconnect the multiplug from the speed sensor.

Page 1388 of 2490

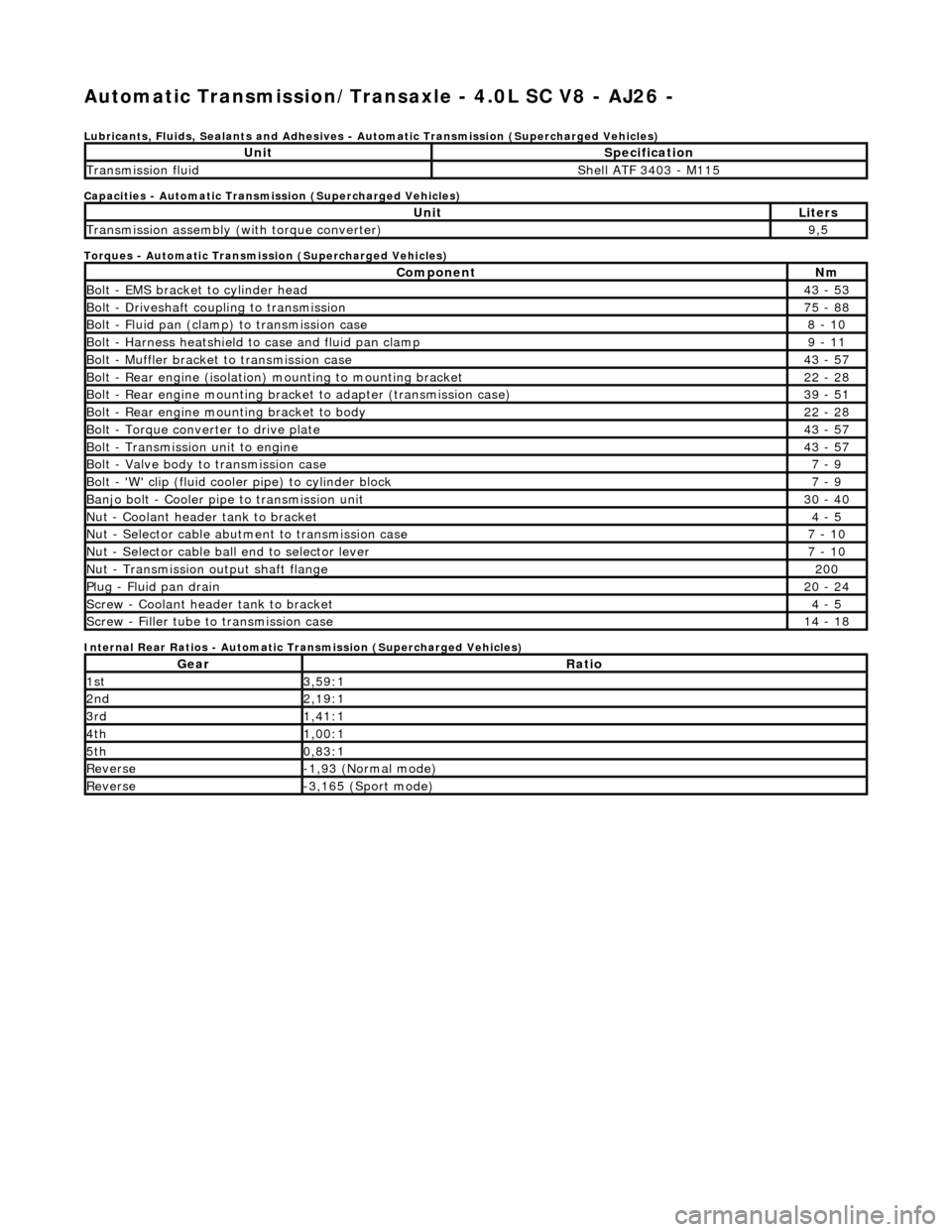

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 -

Lubricants, Fluids, Sealants and Adhesives - Automatic Transmission (Supercharged Vehicles)

Capacities - Automatic Transmission (Supercharged Vehicles)

Torques - Automatic Transmission (Supercharged Vehicles)

Internal Rear Ratios - Automatic Transmission (Supercharged Vehicles)

UnitSpecification

Transmission fluidShell ATF 3403 - M115

UnitLiters

Transmission assembly (with torque converter)9,5

ComponentNm

Bolt - EMS bracket to cylinder head43 - 53

Bolt - Driveshaft coupling to transmission75 - 88

Bolt - Fluid pan (clamp) to transmission case8 - 10

Bolt - Harness heatshield to case and fluid pan clamp9 - 11

Bolt - Muffler bracket to transmission case43 - 57

Bolt - Rear engine (isolation) mounting to mounting bracket22 - 28

Bolt - Rear engine mounting brac ket to adapter (transmission case)39 - 51

Bolt - Rear engine mounting bracket to body22 - 28

Bolt - Torque converter to drive plate43 - 57

Bolt - Transmission unit to engine43 - 57

Bolt - Valve body to transmission case7 - 9

Bolt - 'W' clip (fluid cooler pipe) to cylinder block7 - 9

Banjo bolt - Cooler pipe to transmission unit30 - 40

Nut - Coolant header tank to bracket4 - 5

Nut - Selector cable abutment to transmission case7 - 10

Nut - Selector cable ball end to selector lever7 - 10

Nut - Transmission output shaft flange200

Plug - Fluid pan drain20 - 24

Screw - Coolant header tank to bracket4 - 5

Screw - Filler tube to transmission case14 - 18

GearRatio

1st3,59:1

2nd2,19:1

3rd1,41:1

4th1,00:1

5th0,83:1

Reverse-1,93 (Normal mode)

Reverse-3,165 (Sport mode)

Page 1441 of 2490

Automatic Transmission/Transaxle - 4.0L SC V8 - AJ26 - Transmission

Fluid Pan Gasket

In-vehicle Repair

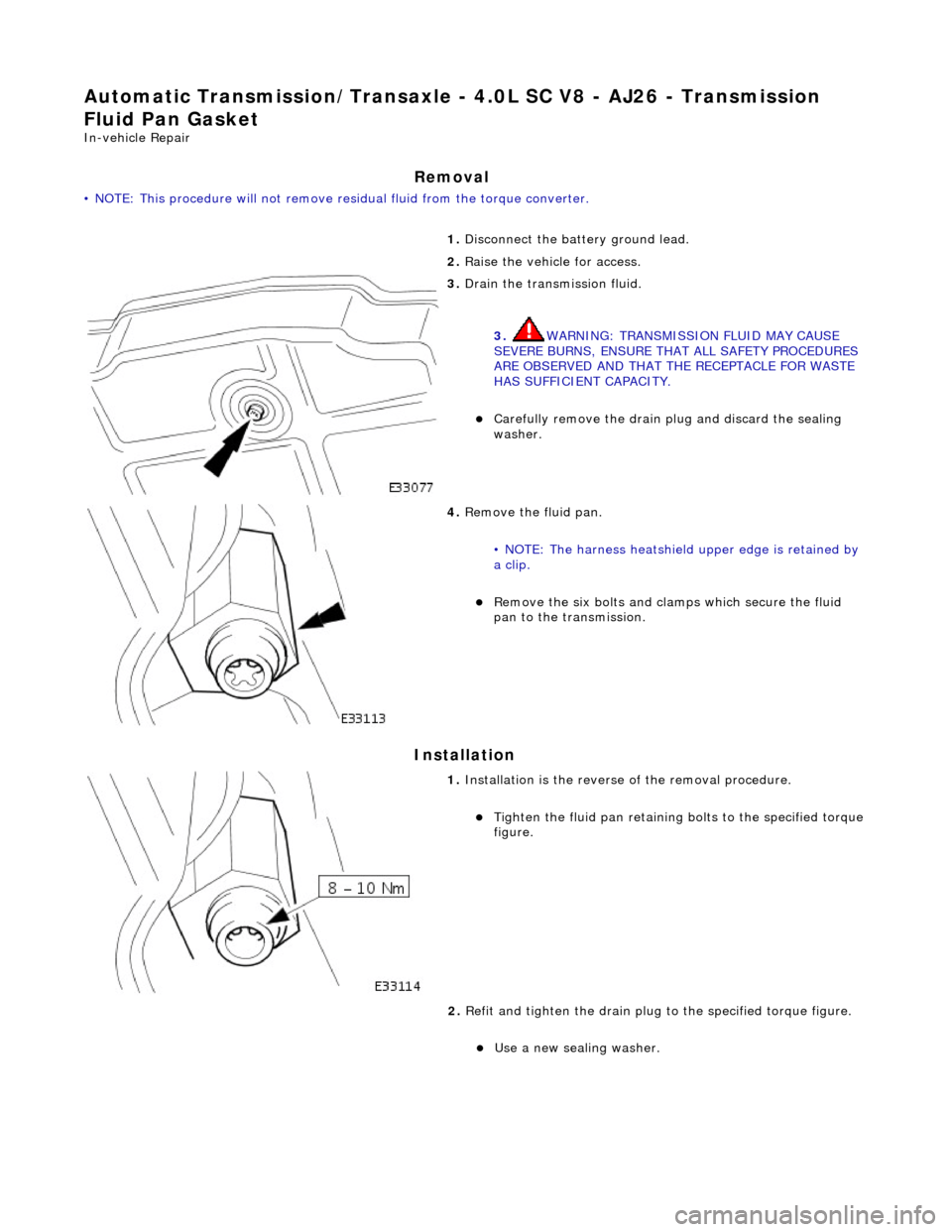

Removal

• NOTE: This procedure will not remove re sidual fluid from the torque converter.

Installation

1. Disconnect the battery ground lead.

2. Raise the vehicle for access.

3. Drain the transmission fluid.

3. WARNING: TRANSMISSION FLUID MAY CAUSE

SEVERE BURNS, ENSURE THAT ALL SAFETY PROCEDURES

ARE OBSERVED AND THAT THE RECEPTACLE FOR WASTE

HAS SUFFICIENT CAPACITY.

Carefully remove the drain pl ug and discard the sealing

washer.

4. Remove the fluid pan.

• NOTE: The harness heatshield upper edge is retained by

a clip.

Remove the six bolts and clam ps which secure the fluid

pan to the transmission.

1. Installation is th e reverse of the re moval procedure.

Tighten the fluid pan retaining bolts to the specified torque figure.

2. Refit and tighten the drain plug to the specified torque figure.

Use a new sealing washer.

Page 1450 of 2490

brackets.

3. Tighten the support hook adjusters to take the weight of the engine.

12. Raise the vehicle for access.

13. Remove the LH downpipe catalytic converter. Refer to

Operation 17.50.09.

14. Remove the front muffler. Re fer to Operation 30.10.18.

15. Remove the RH downpipe catalytic converter. Refer to

Operation 17.50.09 and 17.50.10.

16. Drain the transmission fluid. Refer to Operation 44.24.02.

17. Locate an Epco V-100, or sim ilar lift, under the transmission

unit.

Adjust the angle of the lift to suit the transmission.

Secure the side clamps.

Pass the safety chain over the transmission unit and

tighten the clamp to secure the assembly.

18. Remove the rear engine mounting bracket.

1. Remove the centre bolt from the engine/transmission

mounting.

2. Remove the four bolts which secure the mounting

bracket to the body.

19. Detach the driveshaft (prop- shaft) from the transmission

drive flange.

If the transmission is to be refitted, mark the position of

the coupling relative to the drive flange.

19. CAUTION: Under no circ umstances remove the

driveshaft to flexible coupling fixings.

1. Remove the transmission drive flange to flexible

coupling fixings.

Page 1733 of 2490

Fuel Tank and Li

nes - Fuel Pump

Re

moval and Installation

Remov

al

Installation

1.

WARNING: B

EFORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND

UNDERSTOOD.

Remove the battery. For additional information, refer to Section

414

-0

1 Battery, Mounting and Cables

.

2.

Drain th

e fuel tank using a suitab

le suction pump/tanker. If the

On-board Refueling Vapour Recove ry (ORVR) system is fitted,

refer to Section 310

-00

Fuel System

- General

Information

.

3. R

emove the fuel tank. For addi

tional information, refer to Fuel

Tank

in this section.

4. Remove the fuel tank evaporativ e loss flange sealing ring. For

additional information, refer to Section 303

-13

.

5. R

emove fuel feed hose from tank.

U

sing special tool JD175, slacken fuel feed hose to tank

stub securing clip.

Di

sconnect hose from tank stub.

6. Remove fuel pump assembly.

R

elease bolt securing fuel

pump mounting bracket and

place assembly to front.

Slac

ken securing clip and disc

onnect hose from fuel pump.

R

emove link lead from fuel pump.

Re

move pump.

1. NOTE: Install new sealing ring to evaporative loss flange. For

additional information, refer to Section 303

-13

.

In

stallation is th

e reverse of the removal procedure.

Page 1738 of 2490

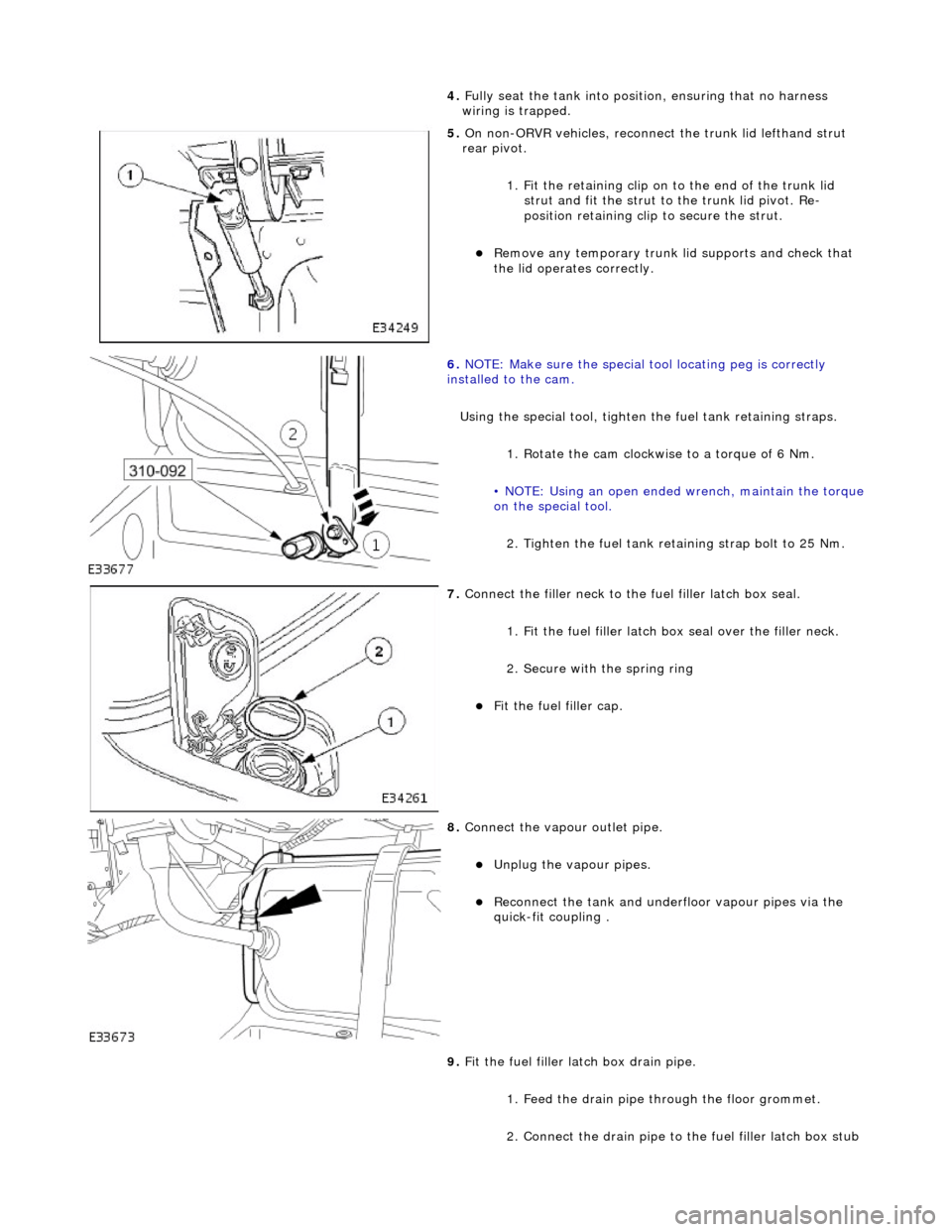

4. Full

y seat the tank into positi

on, ensuring that no harness

wiring is trapped.

5. On non-

ORVR vehicles, reconnec

t the trunk lid lefthand strut

rear pivot.

1. Fit the retaining clip on to the end of the trunk lid strut and fit the strut to the trunk lid pivot. Re-

position retaining clip to secure the strut.

Re

move any temporary trunk lid supports and check that

the lid operates correctly.

6. NOTE

: Make sure the special tool locating peg is correctly

installed to the cam.

Using the special tool, tighten the fuel tank retaining straps.

1. Rotate the cam clockwise to a torque of 6 Nm.

• NOTE: Using an open ended wrench, maintain the torque

on the special tool.

2. Tighten the fuel tank reta ining strap bolt to 25 Nm.

7. Connect the fi

ller neck to the fuel filler latch box seal.

1. Fit the fuel filler latch box seal over the filler neck.

2. Secure with the spring ring

F i

t the fuel filler cap.

8. Connect the vapour outlet pip

e.

Unplug the v

a

pour pipes.

Reconn

ect th

e tank and underfloor vapour pipes via the

quick-fit coupling .

9. Fit the fuel filler latch box drain pipe.

1. Feed the drain pipe th rough the floor grommet.

2. Connect the drain pipe to the fuel filler latch box stub

Page 1788 of 2490

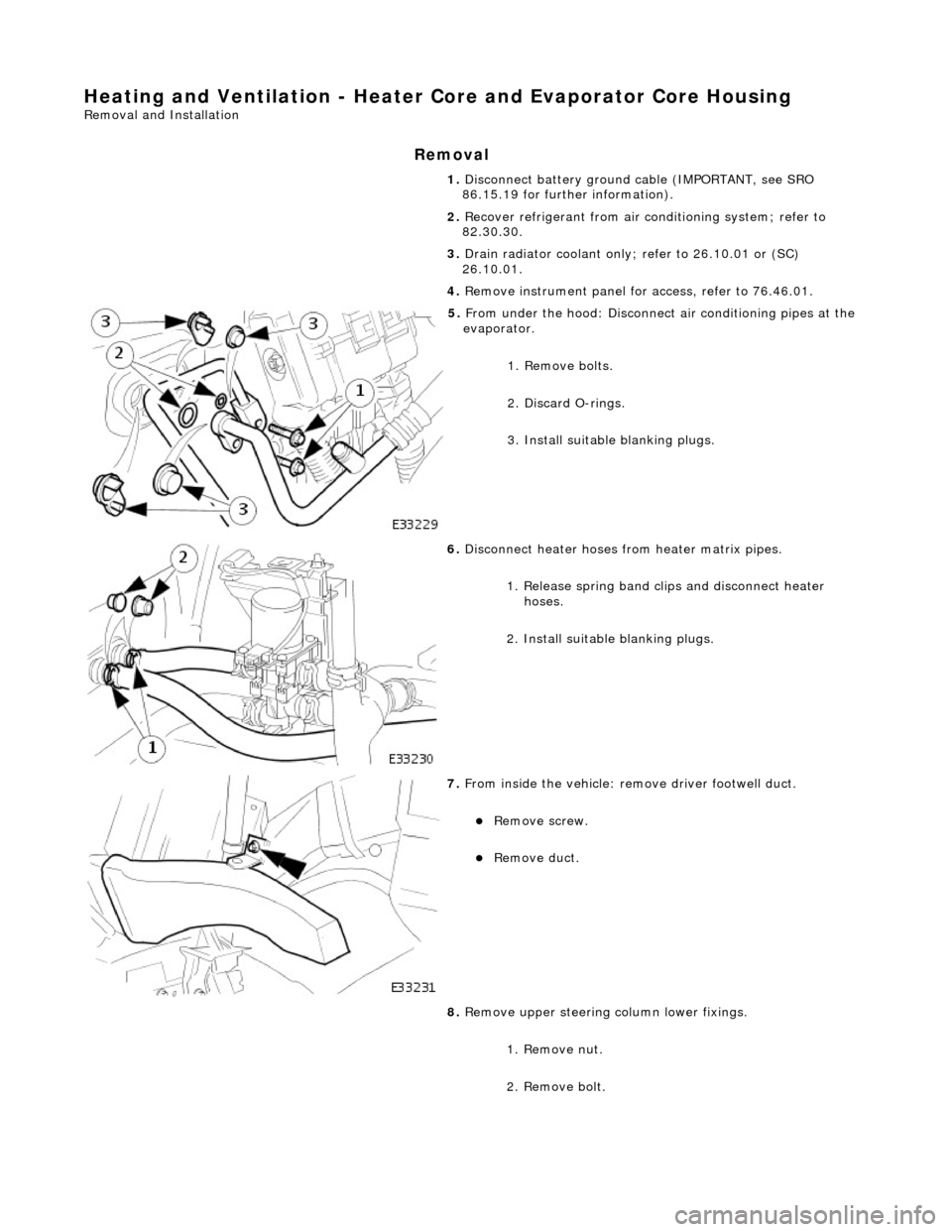

Heating and Ventilation - Heater Core and Evaporator Core Housing

Removal and Installation

Removal

1. Disconnect battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. Recover refrigerant from air co nditioning system; refer to

82.30.30.

3. Drain radiator coolant only; refer to 26.10.01 or (SC)

26.10.01.

4. Remove instrument panel for access, refer to 76.46.01.

5. From under the hood: Disconnect air conditioning pipes at the

evaporator.

1. Remove bolts.

2. Discard O-rings.

3. Install suitable blanking plugs.

6. Disconnect heater hoses from heater matrix pipes.

1. Release spring band clips and disconnect heater hoses.

2. Install suitable blanking plugs.

7. From inside the vehicle: re move driver footwell duct.

Remove screw.

Remove duct.

8. Remove upper steering column lower fixings.

1. Remove nut.

2. Remove bolt.

Page 2022 of 2490

Body closures

Each front and rear door consists of a welded, mild steel inner frame and an outer panel. The outer panel is welded to the

waist rail and cheater of the inner frame, then bonded and clinched to fo rm the door assembly. Cosmetic PVC bead is

applied to all clinch joints. Sp onge rubber seals are mounted on the doors. Inte rnal insulation is provided by a foam water

shedder attached to the door by double-sided adhesive tape.

The door aperture B/C posts are reinforced over their full height to fully satisfy all forthcoming European and Federal side

impact legislation. The hood consists of one piece inner and outer panels clinched and bonded together, with cosmetic bead

PVC sealant applied to all clinch joints. Th e hood pivots at the front on two hinges each secured by bolts to the hood front

underside and the BIW front upper crossmem ber. Two gas struts secured to the hood by pivot pins and snap-on couplings,

support the hood in the open position. A full width insulating pad is secured by screws to the underside of the hood. A

sponge rubber tubular seal is mounted tran sversely towards the front of the hood underside. The trunk lid is of similar

construction to the hood, consisting of inner and outer pa nels clinched and bonded together and PVC bead sealed.

Incorporating a removable moulded liner and two trunk illuminati on lights, the trunk lid is supported when open, by two gas

struts, each secured to the inner wheel arch and trunk hinge by snap fittin gs. For some markets, a warning triangle is

attached to a bracket on the trunk lid underside and is retained in the open position by a rubber block.

Fascia

One-piece slush-moulded fascia on inject ion moulded armature and steel cross-rail reinforcement. Fascia support brackets

set with BIW to achieve close tolerance fit of fascia to bo dy eliminate necessity for adjustment following removal and

installation..

Fuel Filler Flap

The fuel filler comprising a hinged flap attached to the body decking panel by tw o nuts, incorporates a rubber buffer, snap-

in striker, hinge spring and fuel cap stowage magnet. The rubber fuel bowl moulding is attached via a steel armature to the

body reinforcement panel by five M5 nuts and is retained at the filler neck by a clip. The mating drain tube is fitted with an

internal filter. The fuel filler flap latch mechanism attached to the fuel bowl armatu re by two M5 nuts, includes a locking pin

and actuator which are both se rviceable items. The latch actuator operates independently from the central locking system;

it is driven directly by the se curity and locking control module. Locking of the fuel filler flap is achi eved only by operation of

the key or by the remote rf transmitter.

Seating

All front seats are equipped with electric height adjustment. In addition, both seats are available with manual or power

forward and rearward adjustment, manual or power operated headrest adjustment, 12 way electric adjustment, memory

controlled 12 way seat adjustment and integral seat heating. A side air bag module is installe d in the outboard squab wing

of each front seat. Each front seat has a non-handed, one-piece frame incorporatin g cushion and squab frames, side air bag

support bracket and seat adjuster mechanis ms. Seat switchpacks are installed on the outboard side of driver and passenger

seats and control modules are installed in the base of each seat . The standard rear seat is of fixed, bench type with full

width removable cushion. For certain mark ets, two individual rear seats are available as an option on long wheelbase

models. Both type s of rear seat are available with th ermostatically controlled heating of the cushion and sq uab. Individual

rear seats are electrically adjustable fo r squab re cline (via cushion fore and af t movement), head restraint height and

lumbar support. Separate motors provide ad justment of each seat cushion and head restraint and an electrically driven air

compressor provides variation of lumbar support. Seat adjustment is controlled via switches installed on a panel in an

extension to the centre console.Both the driver and front pass enger seat are secured to the vehicle floor at four points.

Interior Trim

The one-piece door casings are trimmed in UEV to match the seating, with wood veneer at the waistline and a carpet insert

at the front lower corner. Each casing is secured to the door inner panel by fir tree fastener s along the lower section, two

armrest fixings at the centre and veneer panel dowels and fixings at the top. The armrests which are common to front and

rear doors, are trimmed in matc hing leather or UEV according to specification. Switchpacks dedicated to driver and front or

rear passenger, are incorporated in the ar mrests. A speaker is installed in the lower section of each door and a tweeter is

incorporated behind each interior door handle escutcheon. where premium ICE is fitted, the front tweeters are installed in

the upper A posts. On each side, a graine d UEV finisher trimmed to match the head lining is secured to the 'A' post and

cantrail by fir tree fasteners locating in BIW apertures. Th e upper 'D' post finisher is trimmed and secured in the same

manner. The single piece'B' post finishers, also finished in grained matching UEV, each have a front seat belt exit aperture

and are secured to the BIW by four spring clips and two fir tree fasteners. The one-piece headlining consists of a 6mm thick

polyurethane foam membrane covered with suede effect knitted polyester. The headlining is secured to the BIW roof by

body tangs, the roof console, sun visors, combined grab handles and coat hooks, th e cantrail finishers and where fitted, the

Page 2332 of 2490

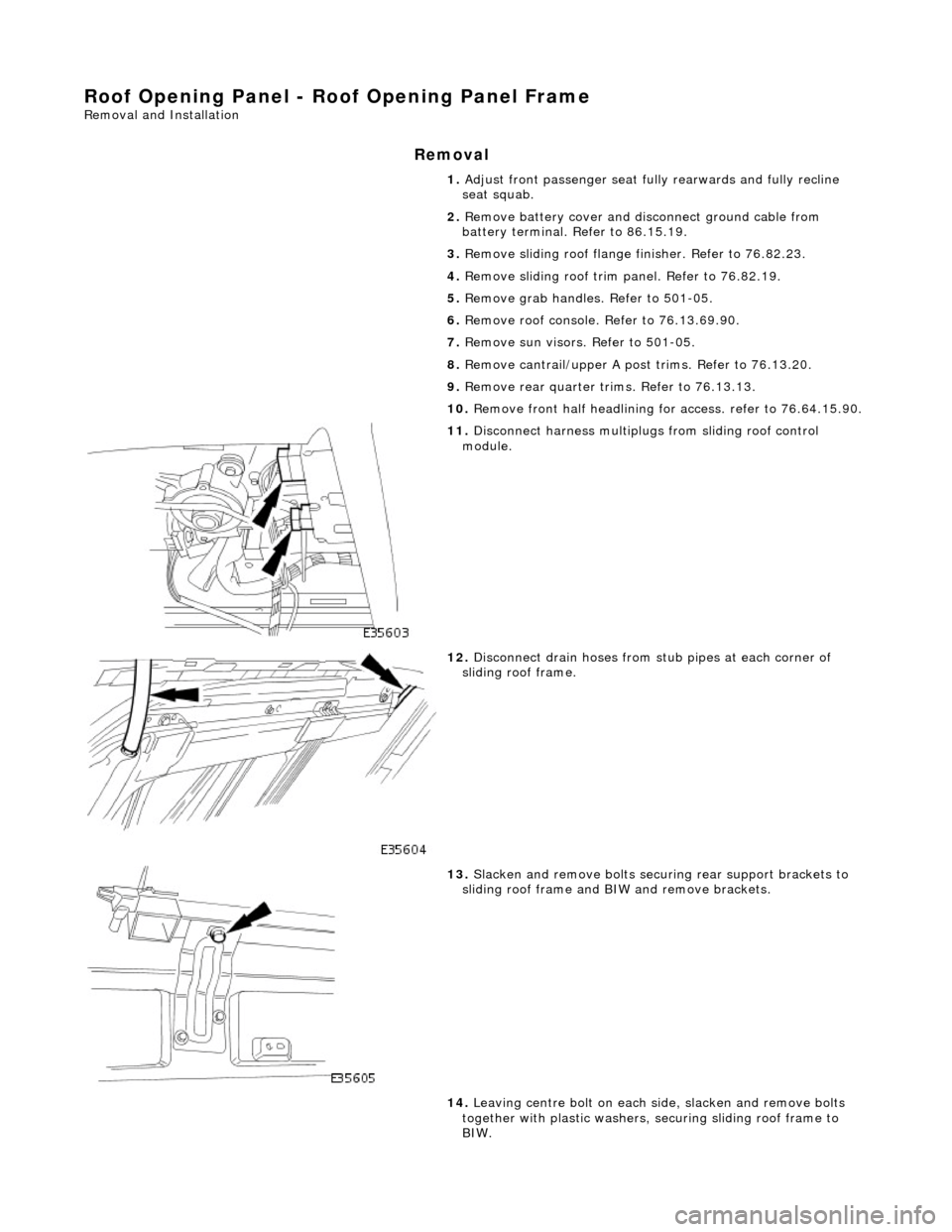

Roof Opening Panel - Roof Opening Panel Frame

Removal and Installation

Removal

1. Adjust front passenger seat fu lly rearwards and fully recline

seat squab.

2. Remove battery cover and disc onnect ground cable from

battery terminal. Refer to 86.15.19.

3. Remove sliding roof flange finisher. Refer to 76.82.23.

4. Remove sliding roof trim panel. Refer to 76.82.19.

5. Remove grab handles. Refer to 501-05.

6. Remove roof console. Refer to 76.13.69.90.

7. Remove sun visors. Refer to 501-05.

8. Remove cantrail/upper A post trims. Refer to 76.13.20.

9. Remove rear quarter trim s. Refer to 76.13.13.

10. Remove front half headlining for access. refer to 76.64.15.90.

11. Disconnect harness multiplugs from sliding roof control

module.

12. Disconnect drain hoses from stub pipes at each corner of

sliding roof frame.

13. Slacken and remove bolts securi ng rear support brackets to

sliding roof frame and BIW and remove brackets.

14. Leaving centre bolt on each side, slacken and remove bolts

together with plastic washers, securing sliding roof frame to

BIW.