lock JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 244 of 2490

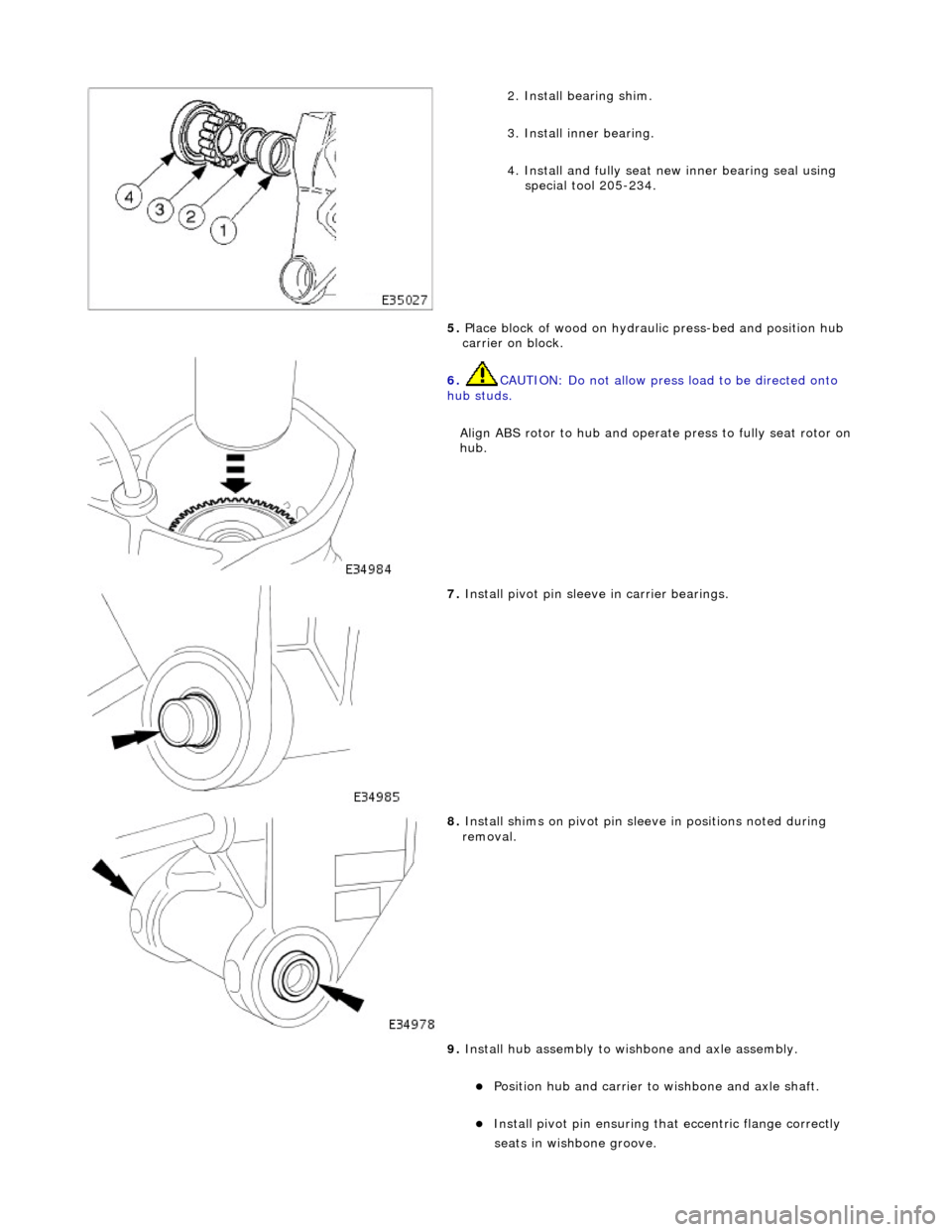

2.

Install bearing shim.

3. Install inner bearing.

4. Install and fully seat new inner bearing seal using special tool 205-234.

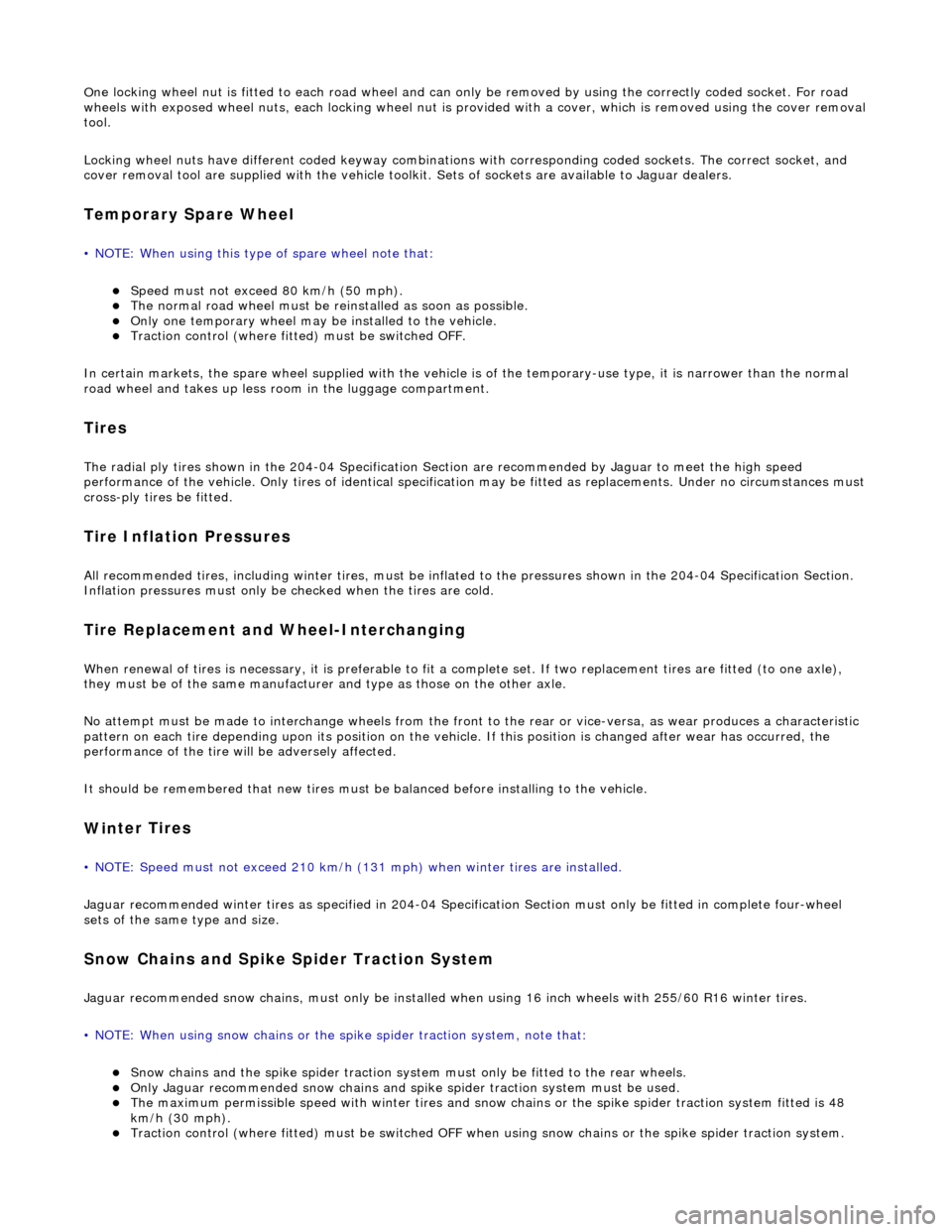

5. Place block of wood on hydrau lic press-bed and position hub

carrier on block.

6. CAUTIO

N: Do not allow press

load to be directed onto

hub studs.

Align ABS rotor to hub and operat e press to fully seat rotor on

hub.

7. Install piv o

t pin sleeve in carrier bearings.

8. Inst al

l shims on pivot pin slee

ve in positions noted during

removal.

9. Install hub assembly to wi shbone and axle assembly.

Position hub and carr

ier to wishbone and axle shaft.

Install pivo

t pin ensuring that

eccentric flange correctly

seats i

n wishbone groove.

Page 248 of 2490

Rear Su

spension - Wh

eel Knuckle Bushing

Remo

val and Installation

Remov

a

l

S

p

ecial Tool(s)

Hub Holdin

g Tool

2

04-195 (JD227)

Hub Pu

ller

204-011 (JD 1D)

D rive

r Handle

100-013 (18G-134)

Bearing Cu p Replacer Adaptor

2

04-120 (JD 550-6)

1. CAUTION: Replacement of nuts and bolts: Various

thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt

can be used. See section 100-00 for information.

Release parking brake.

2. Ra

ise the vehicle on a four-post lift.

3. Fully slacken bu

t do not remove parking brake cable adjuster

nut.

4. Release appropriate side parkin g brake cable from connecting

Page 262 of 2490

Wheel C

hanging

For wheel

chan

ging proced

ure refer to 74.20.05.

CAUTION: Do not allow grease to contaminate the wheel stud threads and wheel nut to wheel mating surface, as this

may cause the nuts to loosen.

• NOTE: When installing the wheel, smear a thin layer of grease onto the hub mounting face and spigot; and wheel

mounting face and spigot hole, to prev ent the wheel corroding on to the hub.

Locking Wheel Nuts

Locking wheel nuts are fitted as standard to UK vehicles.

1—Stee

l Wheel Trim 7J x 16

2—St

arbur

st Alloy 7J x 16

3—Cro

w

n Alloy 7J x 16

4—Sol

a

r Alloy 7.5J x 17

5—Ce

lt

ic Alloy 8J x 17

6—Lunar All

oy 7J

x 16

7—As

te

roid Alloy 8J x 18

8—Cor

ona Al

loy 7J x 16

9—Ecli

pse Alloy 8J x 16

10—Mi

lan All

oy 8.5J x 18

11—R

K

Winter Wheel 8.5J x 18

It

e

m

Par

t

Number

De

scr

iption

1—Lockin

g whe

el nut

2—Cov

e

r

3—Cov

e

r removal tool

4—Wre

n

ch socket

It

e

m

Par

t

Number

De

scr

iption

Page 263 of 2490

O

ne locking wheel nut is fitted to each road wheel and can on

ly be removed by using the correctly coded socket. For road

wheels with exposed wheel nuts, each locking wheel nut is provided with a cover, which is removed using the cover removal

tool.

Locking wheel nuts have different coded keyway combinations with corresponding coded sockets. The correct socket, and

cover removal tool are supplied with the vehicle toolkit. Sets of sockets are available to Jaguar dealers.

Temporary Spare Wheel

•

NOTE: When using this type of spare wheel note that:

Speed

must not exceed 80 km/h (50 mph).

The normal ro

ad wheel must be reinstalled as soon as possible.

On

ly one temporary wheel may be installed to the vehicle.

Tracti

on control (where fitted

) must be switched OFF.

In certain markets, the spare wheel supplied with the vehicle is of the temporary-use type, it is narrower than the normal

road wheel and takes up less room in the luggage compartment.

Tire

s

The

radial ply tires shown in the 204-04

Specification Section are recommended by Jaguar to meet the high speed

performance of the vehicle. Only tires of identical specification may be fitted as replacements. Unde r no circumstances must

cross-ply tires be fitted.

Tire Inflation Pressures

Al

l recommended tires, including winter tire

s, must be inflated to the pressures shown in the 204-04 Specification Section.

Inflation pressures must only be checked when the tires are cold.

Tire Replac

ement and Wheel-Interchanging

W

hen renewal of tires is necessary, it is

preferable to fit a complete set. If two replacement tires are fitted (to one axle),

they must be of the same manufacturer and type as those on the other axle.

No attempt must be made to interchange wh eels from the front to the rear or vice-versa, as wear produc es a characteristic

pattern on each tire depending upon its po sition on the vehicle. If this position is changed after wear has occurred, the

performance of the tire w ill be adversely affected.

It should be remembered that new tires must be balanced befo re installing to the vehicle.

Win

ter Tires

•

NOTE: Speed must not exceed 210 km/h (131 mph) when winter tires are installed.

Jaguar recommended winter tires as specified in 204-04 Specification Section must only be fitted in complete four-wheel

sets of the same type and size.

Snow Chains and Spike Spider Traction System

Jagu

ar recommended snow chains, must on

ly be installed when using 16 inch wheels with 255/60 R16 winter tires.

• NOTE: When using snow chains or the spike spider traction system, note that:

Snow ch

ains and the spike spider

traction system must only be fitted to the rear wheels.

O

nly Jaguar recommended snow chains and spik

e spider traction system must be used.

The m

aximum permissible speed with winter tires and snow chains or the spike spider traction system fitted is 48

km/h (30 mph).

Tracti

on control (where fitted) must be

switched OFF when using snow chains or the spike spider traction system.

Page 284 of 2490

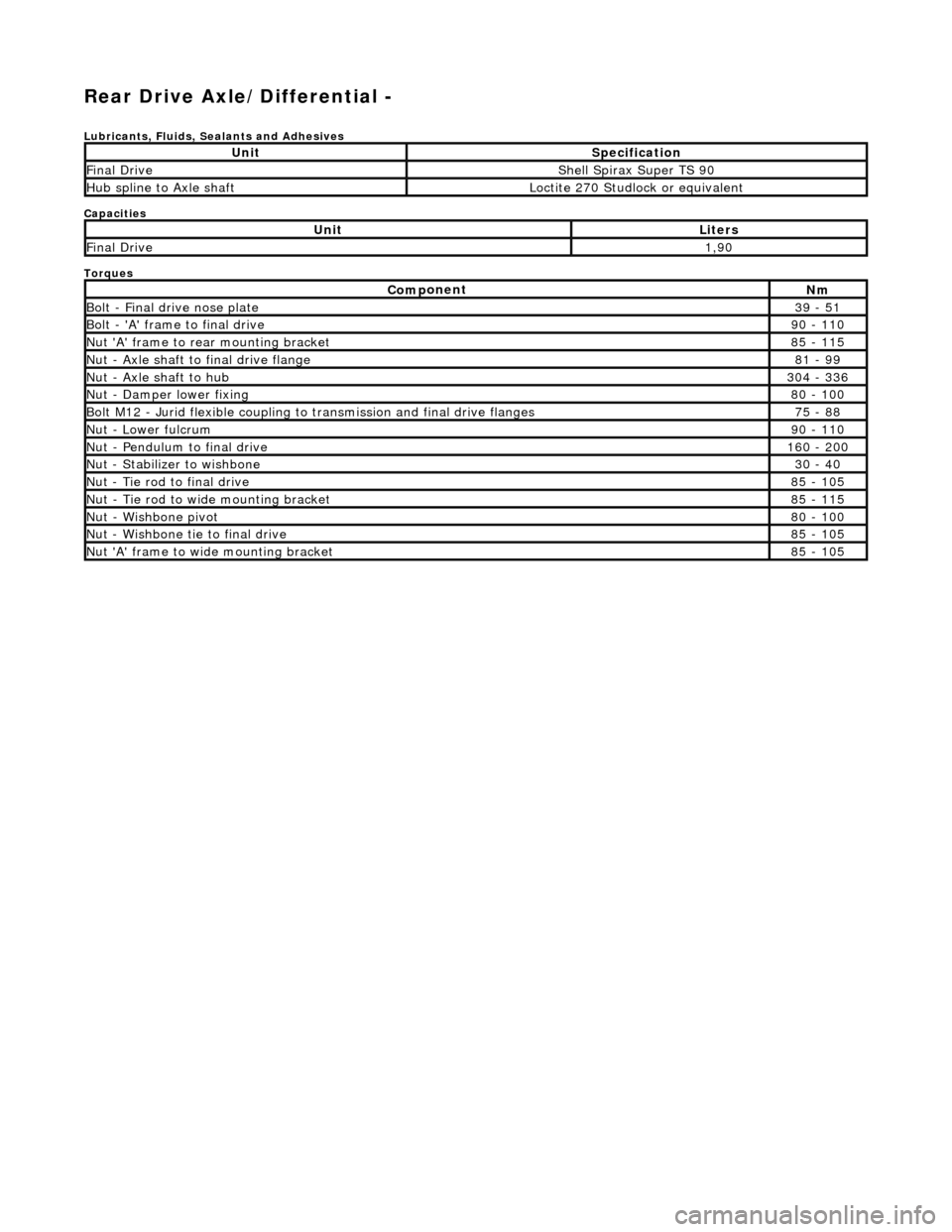

Re

ar Drive Axle/Differential -

Lubric

ants, Fluids, Sealants and Adhesives

Capacities

Torques

UnitSp

ecification

F

i

nal Drive

Shell Sp

irax Supe

r TS 90

Hub s

p

line to Axle shaft

Loct

it

e 270 Studlock or equivalent

UnitLi

t

ers

F

i

nal Drive

1,

90

Com p

onent

Nm

B

ol

t - Final drive nose plate

39

- 51

Bol t

- 'A' frame to final drive

9

0 -

110

Nu

t 'A' f

rame to rear mounting bracket

8

5 -

115

Nu

t -

Axle shaft to final drive flange

81

-

99

Nu

t -

Axle shaft to hub

3

04 -

336

N

u

t - Damper lower fixing

8

0 -

100

Bol

t

M12 - Jurid flexible coupling to

transmission and final drive flanges

75 -

88

N

u

t - Lower fulcrum

9

0 -

110

Nu

t -

Pendulum to final drive

1

60 -

200

N

u

t - Stabilizer to wishbone

30

-

40

N

u

t - Tie rod to final drive

8

5 -

105

Nu

t -

Tie rod to wide mounting bracket

8

5 -

115

Nu

t -

Wishbone pivot

8

0 -

100

N

u

t - Wishbone tie to final drive

8

5 -

105

N

u

t 'A' frame to wide mounting bracket

8

5 -

105

Page 290 of 2490

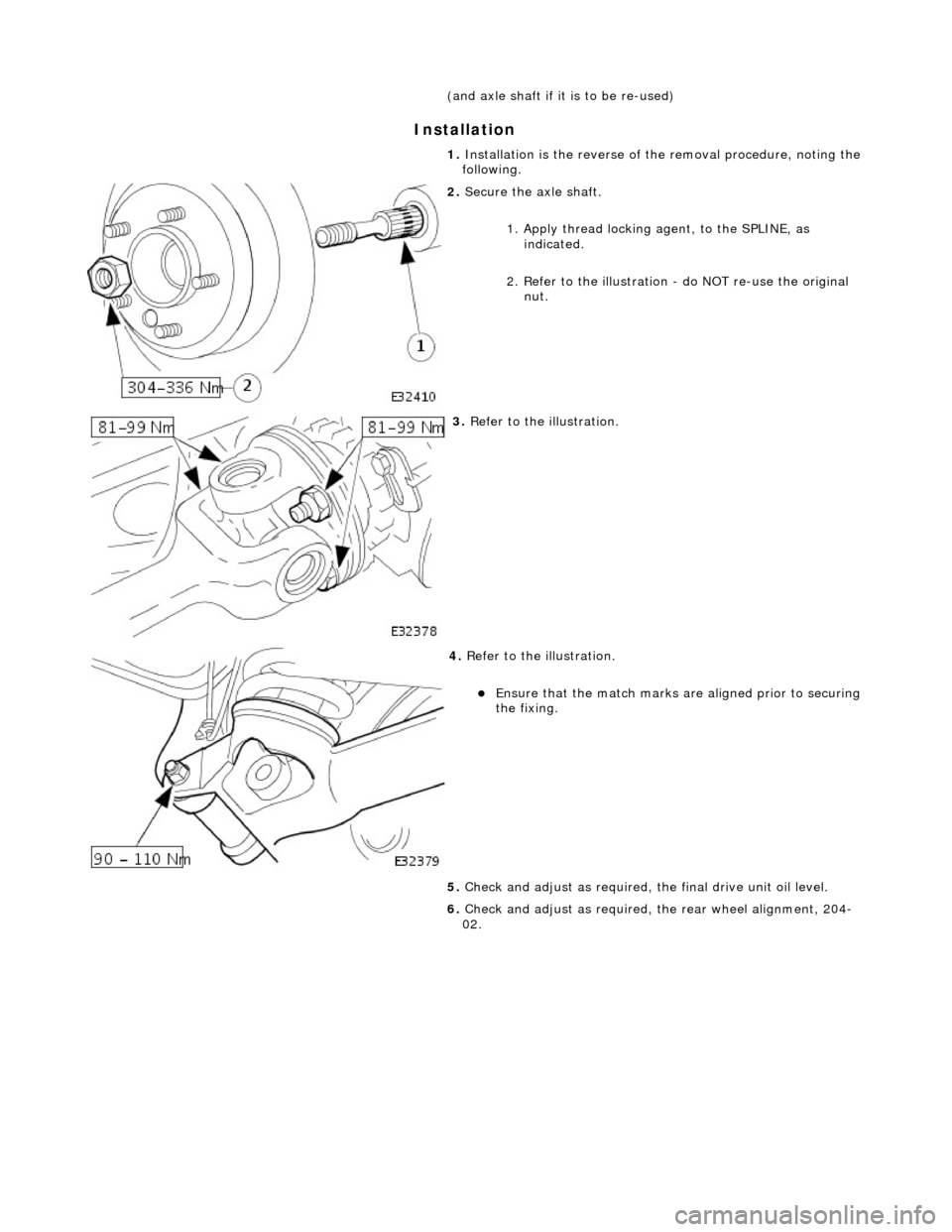

In

stallation

(and axle shaft if i

t

is to be re-used)

1. Installation is the re verse of the removal procedure, noting the

following.

2. Secure the axle shaft.

1.

Apply thread locking agent, to the SPLINE, as

indicated.

2. Refer to the illustration - do NOT re-use the original

nut.

3. Re

fer to the illustration.

4. Re

fer to the illustration.

E

n

sure that the match marks ar

e aligned prior to securing

the fixing.

5. Check and adjust as required, the final drive unit oil level.

6. Check and adjust as required, the rear wheel alignment, 204-

02.

Page 302 of 2490

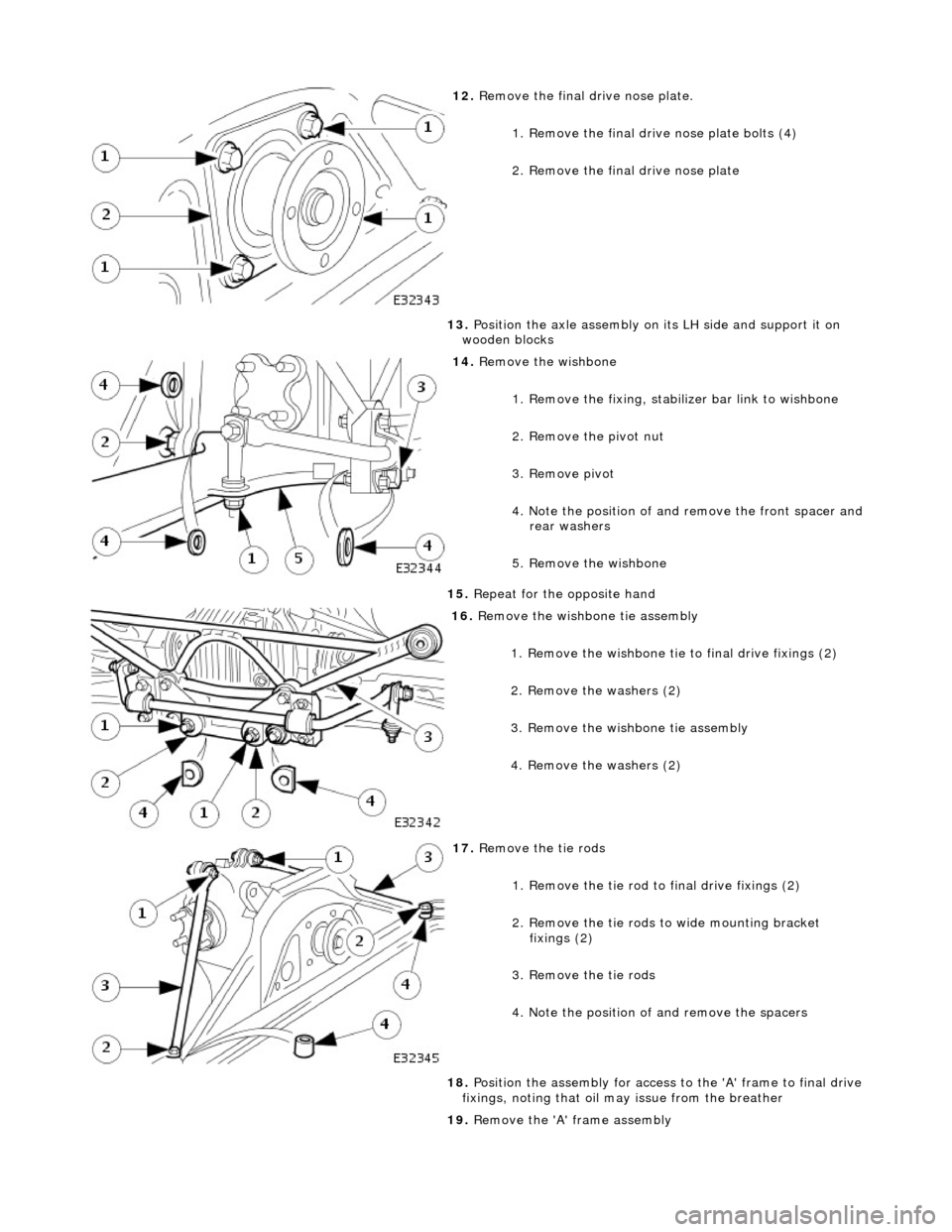

12. R

emove the final dr

ive nose plate.

1. Remove the final drive nose plate bolts (4)

2. Remove the final drive nose plate

13. Position the axle assembly on its LH side and support it on

wooden blocks

14 . Re

move the wishbone

1. Remove the fixing, stabilizer bar link to wishbone

2. Remove the pivot nut

3. Remove pivot

4. Note the position of and remove the front spacer and

rear washers

5. Remove the wishbone

15. Repeat for the opposite hand

16 . R

emove the wishbone tie assembly

1. Remove the wishbone tie to final drive fixings (2)

2. Remove the washers (2)

3. Remove the wishbone tie assembly

4. Remove the washers (2)

17. R

emove the tie rods

1. Remove the tie rod to final drive fixings (2)

2. Remove the tie rods to wide mounting bracket

fixings (2)

3. Remove the tie rods

4. Note the position of and remove the spacers

18. Position the assembly for access to the 'A' frame to final drive

fixings, noting that oil may issue from the breather

19. Remove the 'A' frame assembly

Page 310 of 2490

oc

curs only with the parking brake, th

e concern is in the rear brake system.

If the concern becomes evident during this check, verify it fits the description given before the road test. If the concern is

not evident, attempt to duplicate the condition using the information from the description.

If a concern exists, use the Symptom Chart in order to isolate it to a specific sub-system and condition description. From

this description, a list of possible sources can be used to further narrow the cause to a specific component or condition.

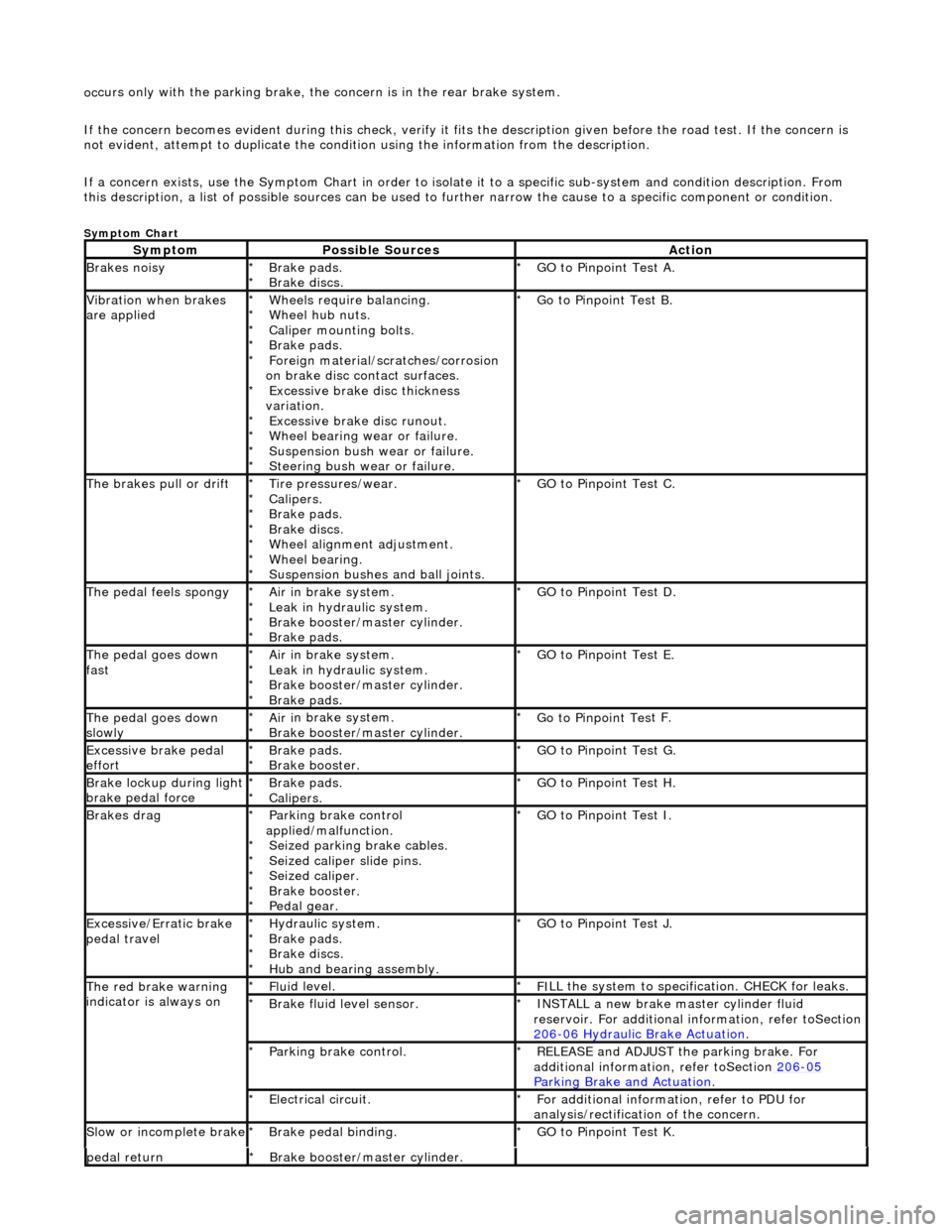

Sym

ptom Chart

Sy

m

ptom

Possib

l

e Sources

Acti

o

n

Brakes

n

oisy

Brake pads.

Brake di

scs

.

*

*

GO to Pinpoint

Tes

t A.

*

Vibration wh

en brakes

are applied

Wh eels require bala

ncing.

Wheel hub nuts.

Caliper mounting bolts.

Brake pads.

Foreign material/scr atches/corrosion

on brake disc contact surfaces. Excessive brake disc thickness

variation. Excessive brake disc runout.

Wheel bearing wear or failure.

Suspension bush wear or failure.

Steering bush wear or failure.

*

*

*

*

*

*

*

*

*

*

Go to Pinpoint

Tes

t B.

*

The brakes pull or drif tTire pressures/wear.

Calipers.

Brake pads.

Brake di

scs.

Wheel alignment adjustment.

Wheel bearing.

Suspension bushes and ball joints.

*

*

*

*

*

*

*

GO to Pinpoint

Tes

t C.

*

The pedal feels spongyAir i

n brake system.

Leak in hydraulic system.

Brake booster/master cylinder.

Brake pads.

*

*

*

*

GO to Pinpoint Tes

t D.

*

The pedal goes down

fa s

t

Ai

r i

n brake system.

Leak in hydraulic system.

Brake booster/master cylinder.

Brake pads.

*

*

*

*

GO to Pinpoint

Tes

t E.

*

The pedal goes down

slowl yAir i

n brake system.

Brake booster/master cylinder.

*

*

Go to Pinpoint

Tes

t F.

*

Excessive brake pedal

effor tBrake pads.

Brake booster.

*

*GO to Pinpoint

Tes

t G.

*

Brake lockup du ring ligh

t

brake pedal force

Brake pads.

Calipers.

*

*GO to Pinpoint

Tes

t H.

*

Brakes d r

ag

Parkin

g brake con

trol

applied/malfunction. Seized parking brake cables.

Seized caliper slide pins.

Seized caliper.

Brake booster.

Pedal gear.

*

*

*

*

*

*

GO to Pinpoint

Tes

t I.

*

Exce ssi

ve/Erratic brake

pedal travel

Hydrau li

c system.

Brake pads.

Brake discs.

Hub and bearing assembly.

*

*

*

*

GO to Pinpoint

Tes

t J.

*

The red brak e warning

indi

cator is always on

Fl

ui

d level.

*

F I

LL the system to specification. CHECK for leaks.

*

Brake flu i

d level sensor.

*

I N

STALL a new brake master cylinder fluid

reservoir. For additional in formation, refer toSection

206

-0 6

Hydraulic Brake Actuation

.

*

Parkin

g brake con

trol.

*

REL

E

ASE and ADJUST the parking brake. For

additional information, refer toSection 206

-05

Parkin g Brake an

d Actuation

.

*

E

l

ectrical circuit.

*

F or additional

information, refer to PDU for

analysis/rectification of the concern.

*

Sl

ow or i

ncomplete brake

Brake peda

l binding.

*

GO to Pinpoint Tes

t K.

*

pedal retu rnBr

ake booster/master cylinder.

*

Page 315 of 2490

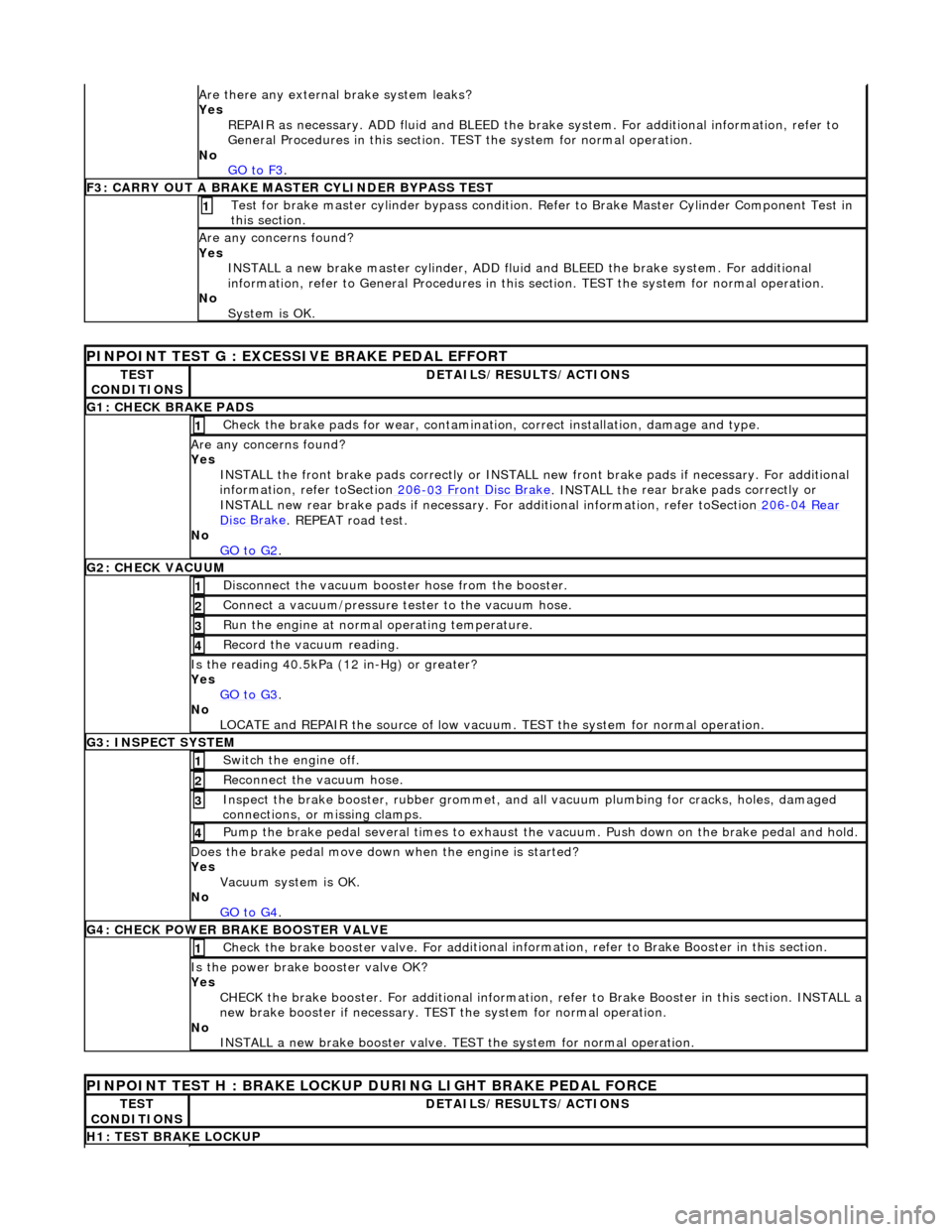

Are th

ere any external brake system leaks?

Yes REPAIR as necessary. ADD fluid and BLEED the brak e system. For additional information, refer to

General Procedures in this section. TEST the system for normal operation.

No GO to F3

.

F

3: CARRY OUT A BRAKE MASTER CYLINDER BYPASS TEST

Te

st for brake master cylinder bypass condition. Re

fer to Brake Master Cylinder Component Test in

this section.

1

A

re any concerns found?

Yes INSTALL a new brake master cylinder, ADD flui d and BLEED the brake system. For additional

information, refer to General Proc edures in this section. TEST the system for normal operation.

No System is OK.

PINPO

INT TEST G : EXCESSIVE BRAKE PEDAL EFFORT

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

G1

: CHECK BRAKE PADS

Check the brake pads for wear, contamin

atio

n, correct installation, damage and type.

1

A

re any concerns found?

Yes INSTALL the front brake pads correctly or INSTALL ne w front brake pads if necessary. For additional

information, refer toSection 206

-03

Front Disc Brake

. INSTALL the

rear brake pads correctly or

INSTALL new rear brake pads if necessary. For additional information, refer toSection 206

-04

Rear

Di

sc Brake

. REPEAT road test.

No

GO to G2

.

G2:

CHECK VACUUM

Di

sconnect the vacuum booster hose from the booster.

1

Conne

ct a vacuum/pressure tester to the vacuum hose.

2

Ru

n the engine at normal operating temperature.

3

Re

cord the vacuum reading.

4

Is

the reading 40.5kPa (1

2 in-Hg) or greater?

Yes GO to G3

.

No

LOCATE and REPAIR the source of low vacuum . TEST the system for normal operation.

G3

: INSPECT SYSTEM

Swi

tch the engine off.

1

Re

connect the vacuum hose.

2

Inspect th

e brake booster, rubber grommet, and al

l vacuum plumbing for cracks, holes, damaged

connections, or missing clamps.

3

Pump th

e brake pedal several time

s to exhaust the vacuum. Push down on the brake pedal and hold.

4

Does th

e brake pedal move down

when the engine is started?

Yes Vacuum system is OK.

No GO to G4

.

G4

: CHECK POWER BRAKE BOOSTER VALVE

Check the brake booster valve. For

add

itional information, refer to

Brake Booster in this section.

1

Is th

e power brake booster valve OK?

Yes CHECK the brake booster. Fo r additional information, refer to Brak e Booster in this section. INSTALL a

new brake booster if necessary. TEST the system for normal operation.

No INSTALL a new brake booster valve. TEST the system for normal operation.

P

INPOINT TEST H : BRAKE LOCKUP

DURING LIGHT BRAKE PEDAL FORCE

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

H1

: TEST BRAKE LOCKUP

Page 316 of 2490

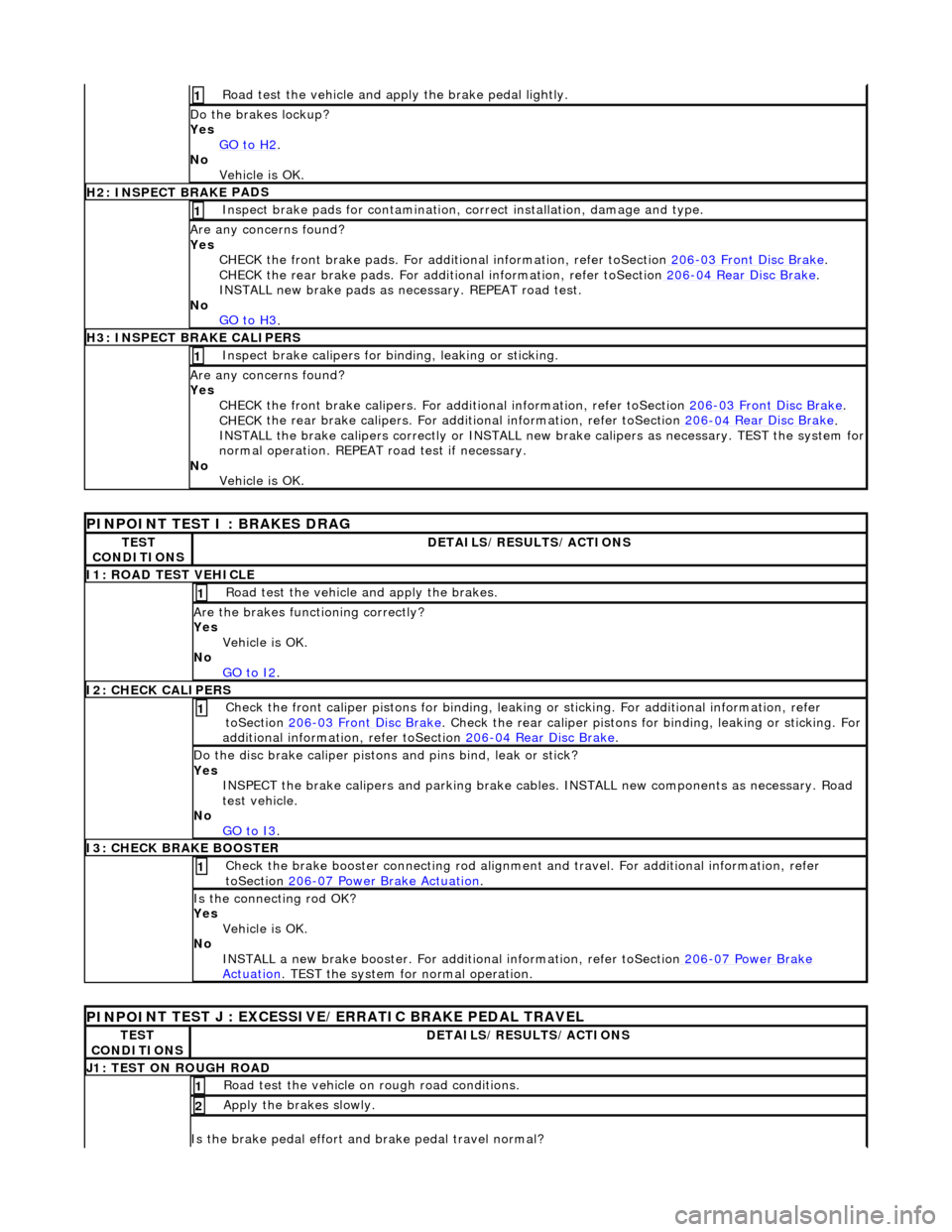

Road test the veh

icle and a

pply the brake pe dal lightly.

1

Do th

e brakes lockup?

Yes GO to H2

.

No

Vehicle is OK.

H2: INSPECT BRAKE PADS

Inspect brake pads for con

t

amination,

correct installation , damage and type.

1

Ar

e any concerns found?

Yes CHECK the front brake pads. For additi onal information, refer toSection 206

-03 Fr

ont Disc Brake

.

CHECK

the rear brake pads. For additi

onal information, refer toSection 206

-04

Rear Disc Brake

.

INST ALL new brake pads as ne ce

ssary. REPEAT

road test.

No GO to H3

.

H3: INSPECT BRAKE CALI

PERS

Inspect brake cali

pers for bindi

ng, leaking or sticking.

1

A

r

e any concerns found?

Yes CHECK the front brake calipers. For addi tional information, refer toSection 206

-03 Fr

ont Disc Brake

.

CHECK

the rear brake calipers. For addi

tional information, refer toSection 206

-04

Rear Disc Brake

.

IN ST

ALL the brake calipers correctly or INSTALL new

brake calipers as necessary. TEST the system for

normal operation. REPEAT road test if necessary.

No Vehicle is OK.

PI

NPOINT TEST I : BRAKES DRAG

TE

S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

I1

:

ROAD TEST VEHICLE

Ro

ad t

est the vehicle

and apply the brakes.

1

Are the brakes

functioning correctly?

Yes Vehicle is OK.

No GO to I2

.

I2

: CHECK CALIPERS

Check the fr

on

t caliper pistons for binding, leakin

g or sticking. For additional information, refer

toSection 206

-03 Fr

ont Disc Brake

. Check the rear cal

i

per pistons for

binding, leaking or sticking. For

additional information, refer toSection 206

-04

Rear Disc Brake

.

1

Do t

h

e disc brake caliper pistons

and pins bind, leak or stick?

Yes INSPECT the brake calipers and pa rking brake cables. INSTALL new co mponents as necessary. Road

test vehicle.

No GO to I3

.

I3

: CHECK BRAKE BOOSTER

Check the brake booster con

n

ecting rod alignment

and travel. For additional information, refer

toSection 206

-0 7

Power Brake Actuation

. 1

Is the co

nnecti

ng rod OK?

Yes Vehicle is OK.

No INSTALL a new brake booster. For addi tional information, refer toSection 206

-07

Power Brake

Actuation. TEST

the system for

normal operation.

PINPO

I

NT TEST J : EXCESSIVE/ERRATIC BRAKE PEDAL TRAVEL

TE

S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

J

1

: TEST ON ROUGH ROAD

R

oad test the vehi

cle on rough road conditions.

1

Apply the brakes slowly. 2

Is th

e brake pedal ef

fort an

d brake pedal travel normal?