rear axle JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1674 of 2490

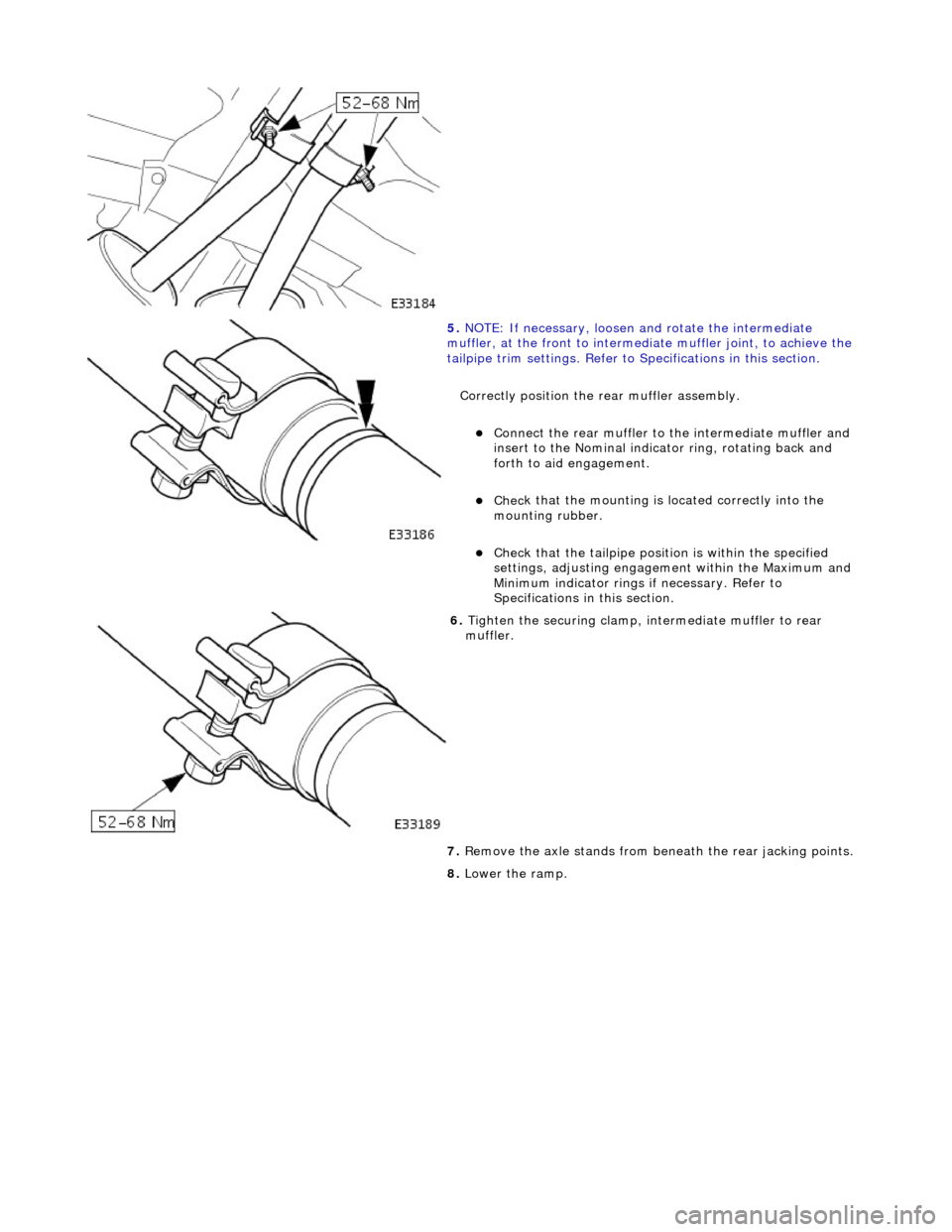

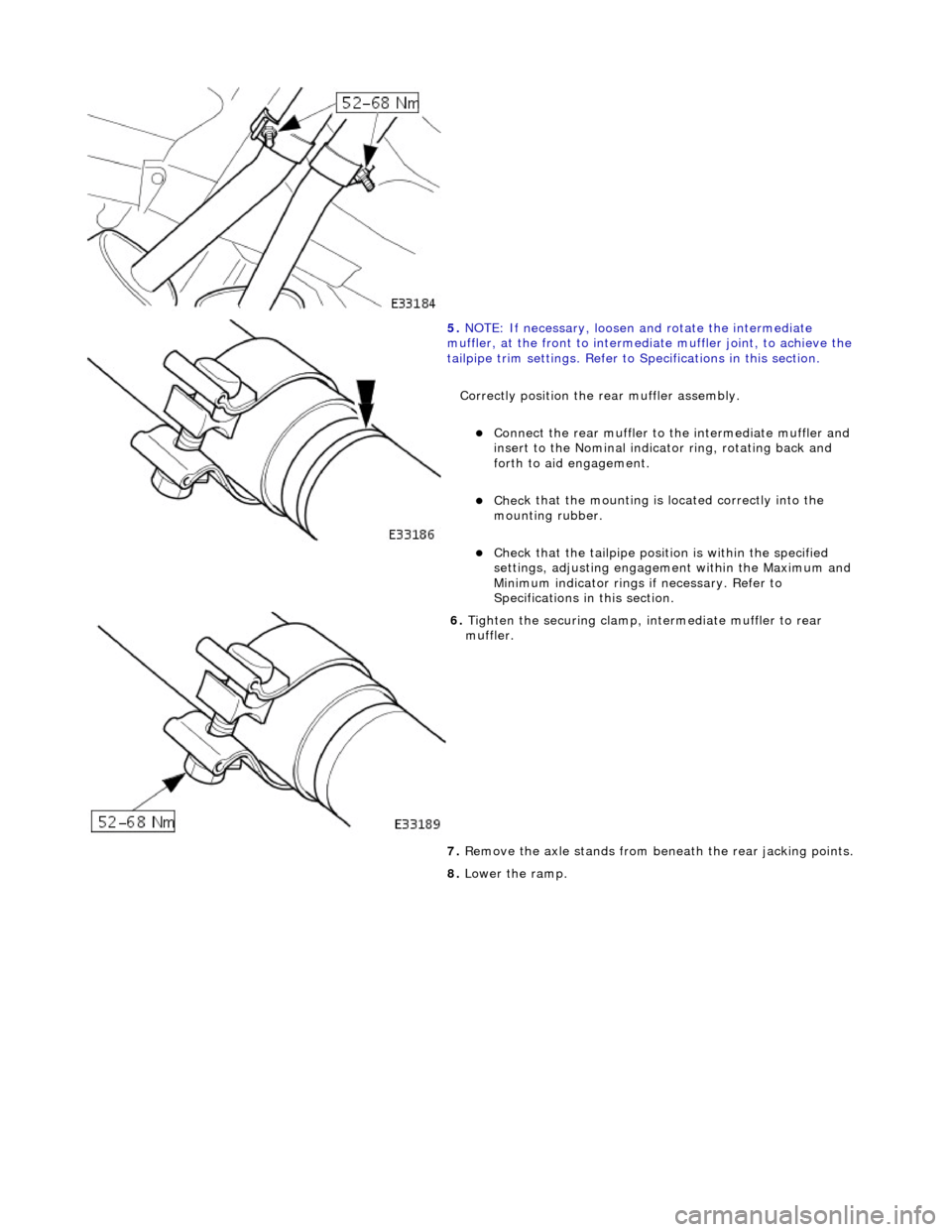

5.

NO TE

: If necessary, loosen and rotate the intermediate

muffler, at the front to intermediate muffler joint, to achieve the

tailpipe trim settings. Refer to Specifications in this section.

Correctly position the rear muffler assembly.

Connect the rear muffl

er to the intermediate muffler and

insert to the Nominal indicator ring, rotating back and

forth to aid engagement.

Chec k

that the mounting is located correctly into the

mounting rubber.

Chec k

that the tailpi

pe position is wi thin the specified

settings, adjusting engageme nt within the Maximum and

Minimum indicator rings if necessary. Refer to

Specifications in this section.

6. Tigh te

n the securing clamp, in

termediate muffler to rear

muffler.

7. Remove the axle stands from be neath the rear jacking points.

8. Lower the ramp.

Page 1675 of 2490

Exhaust System - Intermediate Muffler LH4

.0L SC V8 - AJ26

Re

moval and Installation

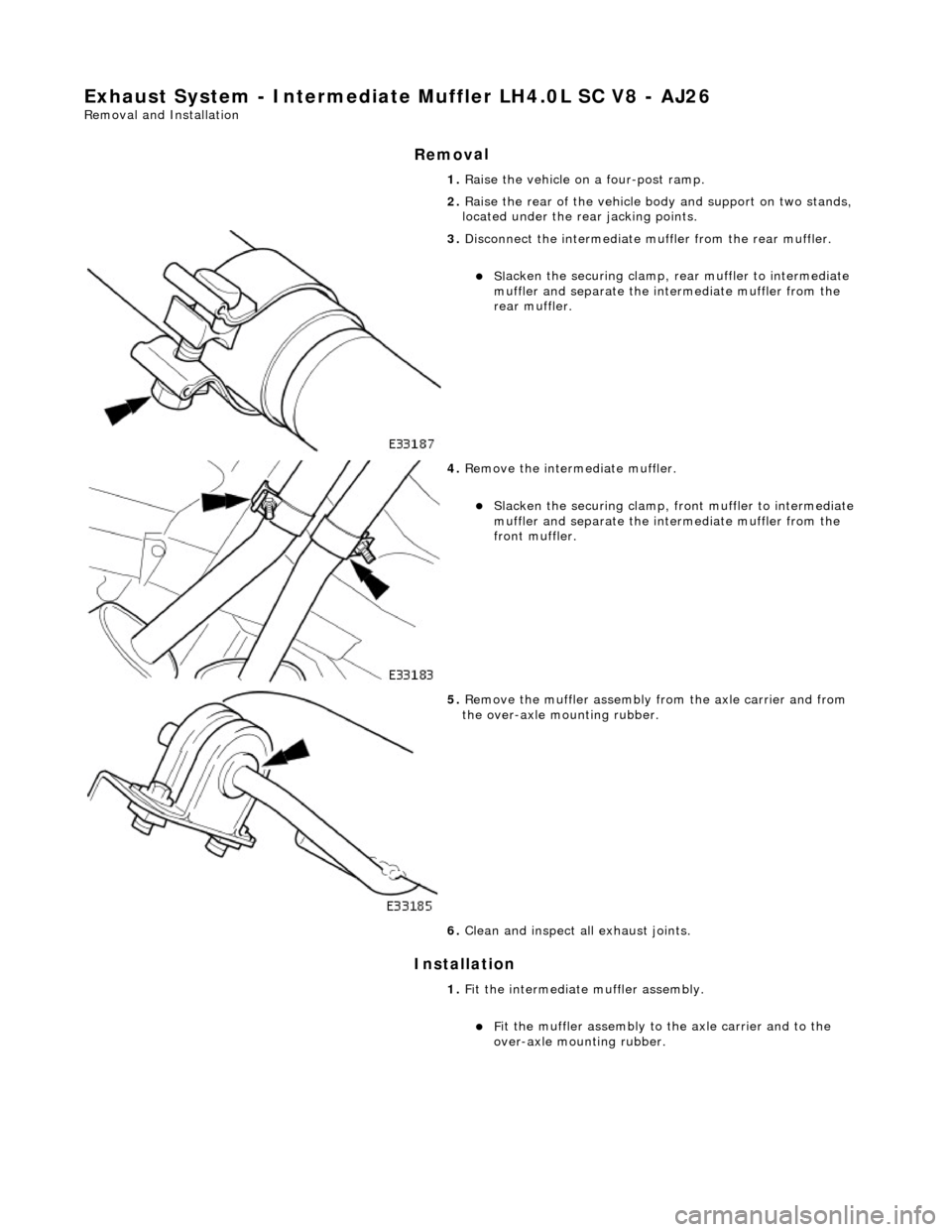

Remov

al

Installation

1. R

aise the vehicle on a four-post ramp.

2. Raise the rear of the vehicle bo dy and support on two stands,

located under the re ar jacking points.

3. Di

sconnect the intermediate

muffler from the rear muffler.

Sl

acken the securing clamp, re

ar muffler to intermediate

muffler and separate the in termediate muffler from the

rear muffler.

4. R

emove the intermediate muffler.

Sl

acken the securing clamp, front muffler to intermediate

muffler and separate the in termediate muffler from the

front muffler.

5. R

emove the muffler assembly

from the axle carrier and from

the over-axle mounting rubber.

6. Clean and inspect al l exhaust joints.

1. Fit the intermediate muffler assembly.

F

it the muffler assembly to the axle carrier and to the

over-axle mounting rubber.

Page 1677 of 2490

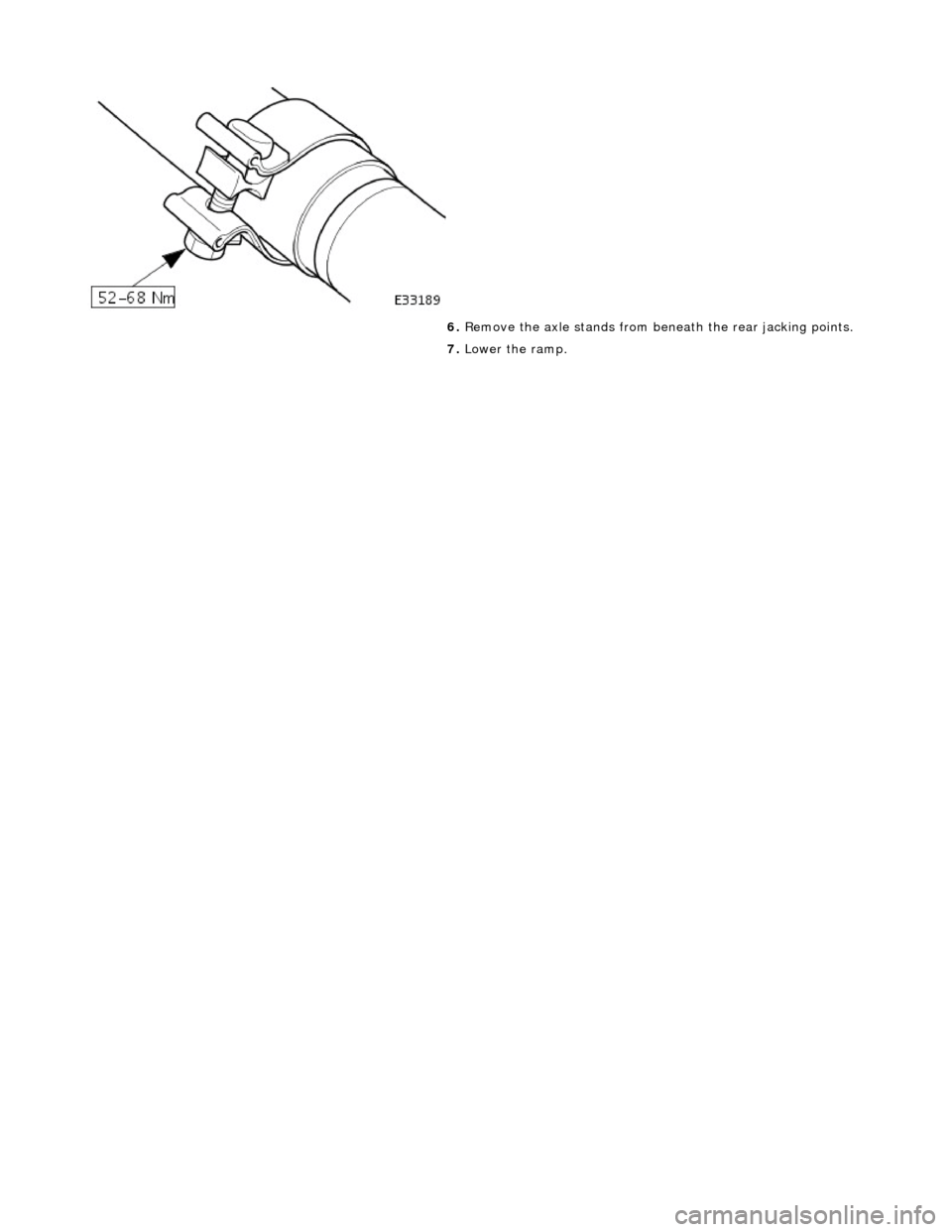

6.

R

emove the axle stands from be

neath the rear jacking points.

7. Lower the ramp.

Page 1678 of 2490

Exhaust System - Intermediate Muffler RH4.0L NA V8 - AJ27/3.2L NA V8 -

AJ26

Re mo

val and Installation

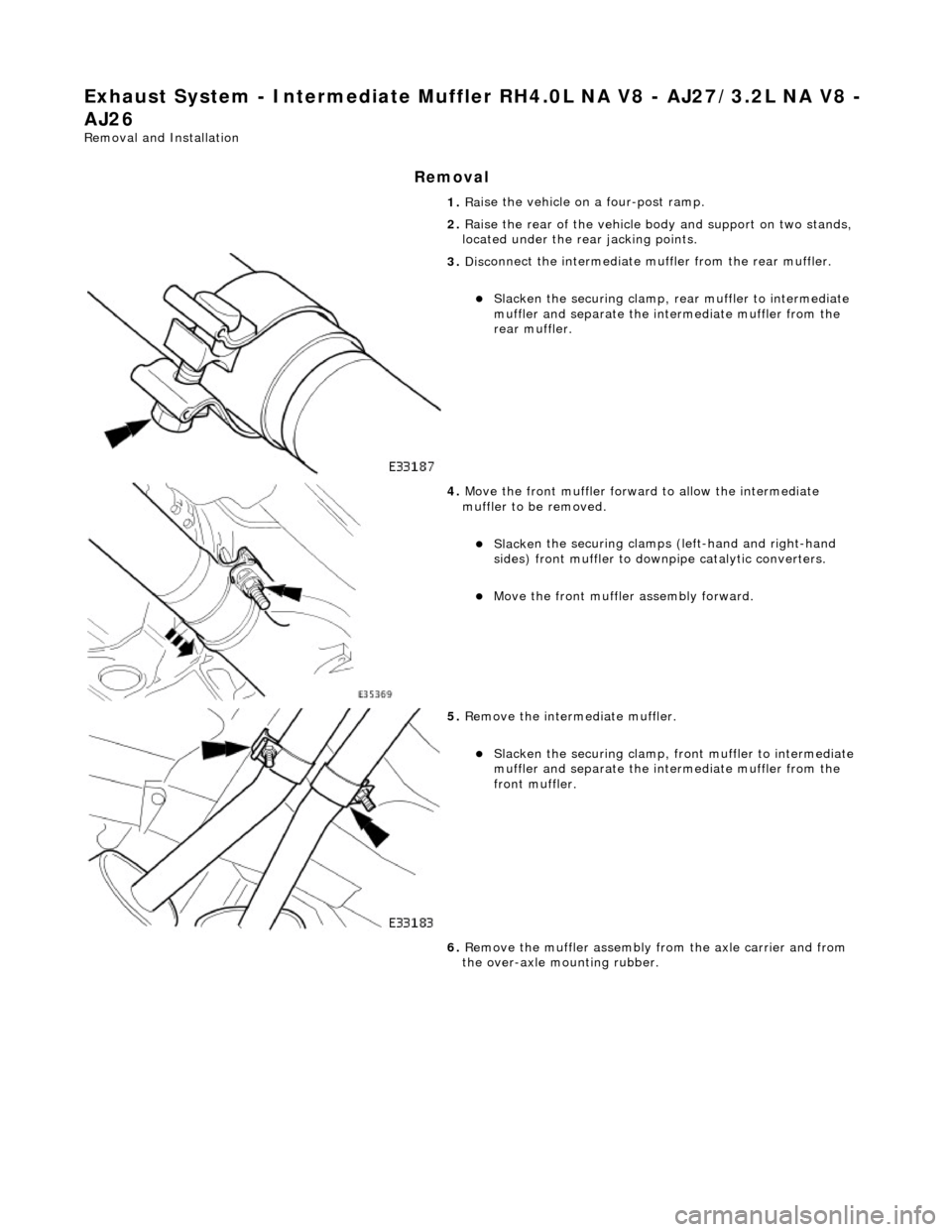

Remova

l

1.

Ra

ise the vehicle on a four-post ramp.

2. Raise the rear of the vehicle bo dy and support on two stands,

located under the re ar jacking points.

3. Disc

onnect the intermediate

muffler from the rear muffler.

Slacken the securi

ng clamp, re

ar muffler to intermediate

muffler and separate the in termediate muffler from the

rear muffler.

4. Move the front muf f

ler forwar

d to allow the intermediate

muffler to be removed.

Sl acke

n the securing clamps (left-hand and right-hand

sides) front muffler to downpipe catalytic converters.

Move the front muf f

ler

assembly forward.

5. Re

move the intermediate muffler.

Sl

acken the securi

ng clamp, front muffler to intermediate

muffler and separate the in termediate muffler from the

front muffler.

6. Remove the muffler assembly from the axle carrier and from

the over-axle mounting rubber.

Page 1680 of 2490

5.

NO TE

: If necessary, loosen and rotate the intermediate

muffler, at the front to intermediate muffler joint, to achieve the

tailpipe trim settings. Refer to Specifications in this section.

Correctly position the rear muffler assembly.

Connect the rear muffl

er to the intermediate muffler and

insert to the Nominal indicator ring, rotating back and

forth to aid engagement.

Chec k

that the mounting is located correctly into the

mounting rubber.

Chec k

that the tailpi

pe position is wi thin the specified

settings, adjusting engageme nt within the Maximum and

Minimum indicator rings if necessary. Refer to

Specifications in this section.

6. Tigh te

n the securing clamp, in

termediate muffler to rear

muffler.

7. Remove the axle stands from be neath the rear jacking points.

8. Lower the ramp.

Page 1681 of 2490

Exhaust System - Intermediate Muffler RH4

.0L SC V8 - AJ26

Re

moval and Installation

Remov

al

Installation

1. R

aise the vehicle on a four-post ramp.

2. Raise the rear of the vehicle bo dy and support on two stands,

located under the re ar jacking points.

3. Di

sconnect the intermediate

muffler from the rear muffler.

Sl

acken the securing clamp, re

ar muffler to intermediate

muffler and separate the in termediate muffler from the

rear muffler.

4. R

emove the intermediate muffler.

Sl

acken the securing clamp, front muffler to intermediate

muffler and separate the in termediate muffler from the

front muffler.

5. R

emove the muffler assembly

from the axle carrier and from

the over-axle mounting rubber.

6. Clean and inspect al l exhaust joints.

1. Fit the intermediate muffler assembly.

F

it the muffler assembly to the axle carrier and to the

over-axle mounting rubber.

Page 1683 of 2490

6.

R

emove the axle stands from be

neath the rear jacking points.

7. Lower the ramp.

Page 1734 of 2490

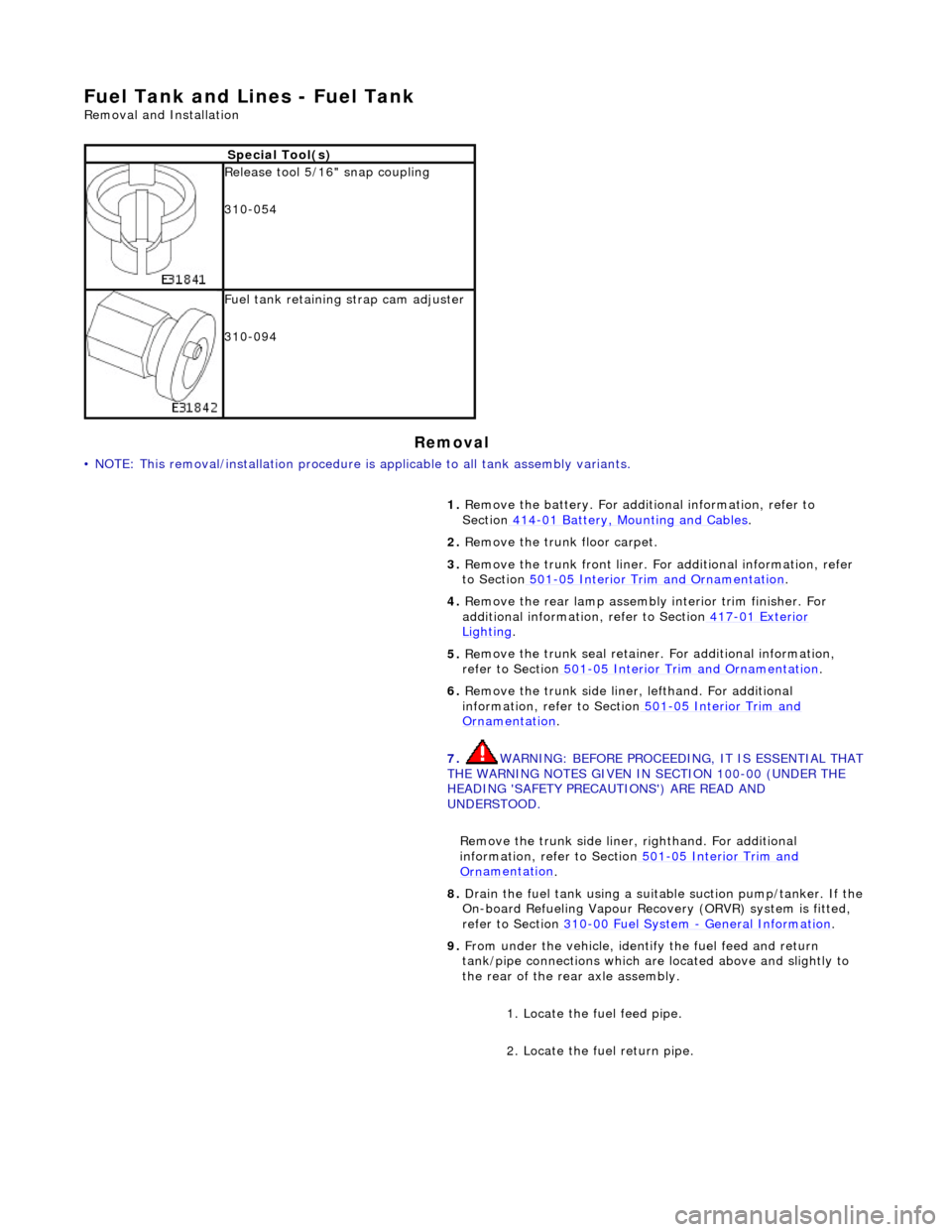

Fuel Tank and Lines - Fuel Tank

Re

mo

val and Installation

Remov

a

l

•

NO

TE: This removal/installation procedure is applicable to all tank assembly variants.

S

p

ecial Tool(s)

R

e

lease tool 5/16" snap coupling

310-054

F u

el tank retaining strap cam adjuster

310-094

1. Remove the battery. For additi onal information, refer to

Section 414

-01

Battery, Mounting and Cables

.

2. Re

move the trunk floor carpet.

3. Remove the trunk front liner. Fo r additional information, refer

to Section 501

-05

Interior Trim and Ornamentation

.

4. Re

move the rear lamp assembly interior trim finisher. For

additional information, refer to Section 417

-01

Exterior

Ligh

ting.

5. Re

move the trunk seal retainer

. For additional information,

refer to Section 501

-0 5

Interior Trim and Ornamentation

.

6. Re

move the trunk side liner, lefthand. For additional

information, refer to Section 501

-05

Interior Trim and

Or

n

amentation

.

7. WARNING: B E

FORE PROCEEDING, IT IS ESSENTIAL THAT

THE WARNING NOTES GIVEN IN SECTION 100-00 (UNDER THE

HEADING 'SAFETY PRECAUTIONS') ARE READ AND

UNDERSTOOD.

Remove the trunk side liner, righthand. For additional

information, refer to Section 501

-05

Interior Trim and

Or

n

amentation

.

8.

Drain th e fue

l tank using a suitab

le suction pump/tanker. If the

On-board Refueling Vapour Recove ry (ORVR) system is fitted,

refer to Section 310

-00 Fu

el System

- General

Information

.

9. Fr

om under the vehicle, identify the fuel feed and return

tank/pipe connections which are located above and slightly to

the rear of the rear axle assembly.

1. Locate the fuel feed pipe.

2. Locate the fuel return pipe.

Page 1743 of 2490

Accelerati

on Control - Accelerator Cable Adjustment

Gen

eral Procedures

1.

Load the Approved Jaguar Diagno stic System with power train

data logger.

2. Connect the Approved Jaguar Diag nostic System to the vehicle.

3. W

ith 'Disable Network Integrity Test - YES/ NO' displayed on

the screen select YES.

4. With new menu displayed on the screen, select ' Engine

Management'.

5. Turn the ignition to ON.

R

emove any previously selected data logger parameters.

6. On data logger select PPS11 an d PPS2 (Pedal demand sensors

1 and 2).

7. On Sedan models only, remove the bulkhead covers on both

sides and the engine compartment rear cover.

8. Cut, remove and discard the ra tchet strap which retains the

throttle cable to the abutment bracket.

9. Ensure there is no tension on the throttle cable by releasing

the throttle cable adjustment nut from the abutment bracket.

10. Record the voltages for both sensors, PPS11 and PPS2.

11. Partially insert the throttle cable adjustment nut into the

abutment bracket.

12. Recheck the voltages for both sensors, PPS11 and PPS2.

13. Where the voltages at step 12 are higher than the voltages

taken at step 10, contin ue to step 15 below.

14. Where the voltages at step 12 are the same as the voltages

taken at step 10, contin ue to step 16 below.

15. Rotate the adjustment nut clockwise (as viewed from the

front of the vehicle) until the same voltages are indicated as in

step 10. Continue to turn thro ugh a part revolution until the

sides of the nut are vertical. Tu rn through a further 90 degrees,

then fully insert the nut into the abutment bracket.

16. Rotate the adjustment nut anti-clockwise (as viewed from the

front of the vehicle) until the indicated voltage starts to

increase. Then rotate the nut clockwise through a part

revolution until the sides are ve rtical. Turn through a further 90

degrees, then fully insert the nut into the abutment bracket.

17. Fit a new ratchet strap to secure the throttle cable adjusting

nut to the abutment bracket.

18. Operate the throttle pedal through 20 full cycles to settle the

cable. Check the voltages now shown, remain the same as in

steps 15 and 16.

19. Check and where necessary adjust the kickdown switch. For

additional information, refer to Section 307

-05A Automatic Transmissi

on/Transaxle External Controls

Sectio

n

307

-05

B

Au

tomatic Transmission/Tra

nsaxle External Controls

.

20

.

On Sedan models only, refit the engine compartment rear

cover and the bulkhead co vers on both sides.

21. Switch the ignition OFF and disconnect the Approved Jaguar

Diagnostic System.

Page 1975 of 2490

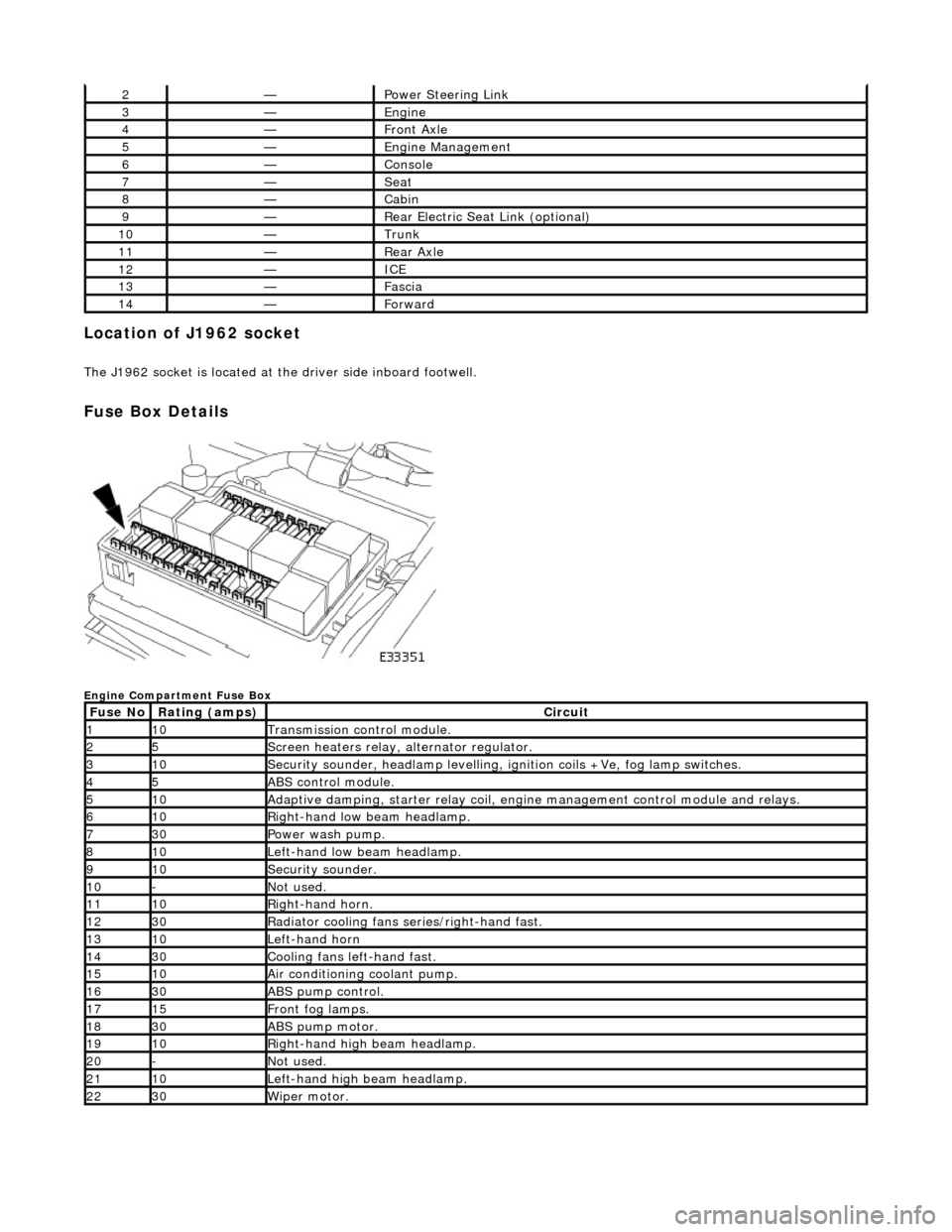

Location of J1962 socket

The J1962 socket is located at the driver side inboard footwell.

Fuse Box Details

Engine Compartment Fuse Box

2—Power Steering Link

3—Engine

4—Front Axle

5—Engine Management

6—Console

7—Seat

8—Cabin

9—Rear Electric Seat Link (optional)

10—Trunk

11—Rear Axle

12—ICE

13—Fascia

14—Forward

Fuse NoRating (amps)Circuit

110Transmission control module.

25Screen heaters relay, alternator regulator.

310Security sounder, headlamp levelling, ignition coils +Ve, fog lamp switches.

45ABS control module.

510Adaptive damping, starter relay coil, engine management control module and relays.

610Right-hand low beam headlamp.

730Power wash pump.

810Left-hand low beam headlamp.

910Security sounder.

10-Not used.

1110Right-hand horn.

1230Radiator cooling fans series/right-hand fast.

1310Left-hand horn

1430Cooling fans left-hand fast.

1510Air conditioning coolant pump.

1630ABS pump control.

1715Front fog lamps.

1830ABS pump motor.

1910Right-hand high beam headlamp.

20-Not used.

2110Left-hand high beam headlamp.

2230Wiper motor.