engine coolant JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 994 of 2490

Engine Cooling - Thermostat4.0L SC V8 - AJ26

Remo

val and Installation

Remov

a

l

Installation

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. Drain the radiator. Refer to Ge neral Procedures. Retain the

coolant drain tray in position to catch any spillage when

removing the outlet pipe.

3. Disc

onnect the bottom hose

from the coolant outlet pipe.

1. Release and reposi tion the hose clip.

2. Disconnect the bottom hose.

4. Re

move the thermostat from the outlet pipe.

1. Remove the three bolts which secure the thermostat cover to the outlet pipe.

2. Remove the thermostat cover, the thermostat and

the seal from the outlet pipe. Discard the seal.

1. Installation is th e reverse of the re moval procedure.

Use new seali

ng rings on th

e coolant outlet pipe and

thermostat housing.

The t he

rmostat ball valve must

locate in the recess in the

cover.

2. Tighten the thermostat cover bolts to 8-10 Nm.

3. Refill the cooling system as de scribed in General Procedures.

Page 995 of 2490

Engine Co

oling - Thermostat Housing

Cover4.0L NA V8 - AJ27/3.2L NA V8

- AJ26

Re

moval and Installation

Remov

al

Installation

1. O

pen the engine compartment and fit paintwork protection

sheets.

2. Drain the radiator. Refer to Ge neral Procedures. Retain the

coolant drain tray in position to catch any spillage when

removing the thermostat cover.

3. Remove the engine cove r panels for access.

4. Di

sconnect the radiator bott

om hose from the thermostat

cover.

1. Release and reposition th e hose clip, and disconnect

the bottom hose from th e thermostat cover.

5. R

emove the thermostat cover.

1. Remove the three bolts which secure the thermostat cover to the housing.

2. Remove the thermostat cover from the housing.

6. R

emove the thermostat from the housing.

1. Remove the thermostat from the housing.

2. Remove (and discard) th e seal from the thermostat.

Fit a new seal to the

thermost

at. The seal may be fitted

either way round.

1. Installation is th e reverse of the re moval procedure.

2. Fit the thermostat so that the vent ball valve locates in the

recess in the cover.

3. Tighten the thermostat cover bolts to 8-10 Nm.

Page 997 of 2490

Engine Cooling - Thermostat Housing Cover4.

0L SC V8 - AJ26

Re

moval and Installation

Remov

al

Installation

1.

O

pen the engine compartment and fit paintwork protection

sheets.

2. Drain the radiator. Refer to Ge neral Procedures. Retain the

coolant drain tray in position to catch any spillage when

removing the outlet pipe.

3. Di

sconnect the bottom hose

from the coolant outlet pipe.

1. Release and reposi tion the hose clip.

2. Disconnect the bottom hose.

4. R

emove the thermostat from the outlet pipe.

1. Remove the three bolts which secure the thermostat cover to the outlet pipe.

2. Remove the thermostat cover, the thermostat and

the seal from the outlet pipe. Discard the seal.

1. Installation is th e reverse of the re moval procedure.

Use new

sealing rings on th

e coolant outlet pipe and

thermostat housing.

The t

hermostat ball valve must

locate in the recess in the

cover.

2. Tighten the thermostat cover bolts to 8-10 Nm.

3. Refill the cooling system as de scribed in General Procedures.

Page 998 of 2490

Engine Cooli

ng - Thermostat Housing

Cover Seal4.0L NA V8 - AJ27/3.2L

NA V8 - AJ26

Re mo

val and Installation

Remova

l

Installation

1. Op

en the engine compartment and fit paintwork protection

sheets.

2. Drain the radiator. Refer to Ge neral Procedures. Retain the

coolant drain tray in position to catch any spillage when

removing the thermostat cover.

3. Remove the engine cove r panels for access.

4. Disc

onnect the radiator bott

om hose from the thermostat

cover.

1. Release and reposition th e hose clip, and disconnect

the bottom hose from th e thermostat cover.

5. Re

move the thermostat cover.

1. Remove the three bolts which secure the thermostat cover to the housing.

2. Remove the thermostat cover from the housing.

6. Re

move the thermostat from the housing.

1. Remove the thermostat from the housing.

2. Remove (and discard) th e seal from the thermostat.

Fit a new seal to the

thermostat. Th

e seal may be fitted

either way round.

1. Installation is th e reverse of the re moval procedure.

2. Fit the thermostat so that the vent ball valve locates in the

recess in the cover.

3. Tighten the thermostat cover bolts to 8-10 Nm.

Page 1000 of 2490

Engine Cooli

ng - Thermostat Housin

g Cover Seal4.0L SC V8 - AJ26

Remo

val and Installation

Remov

a

l

Installation

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. Drain the radiator. Refer to Ge neral Procedures. Retain the

coolant drain tray in position to catch any spillage when

removing the outlet pipe.

3. Disc

onnect the bottom hose

from the coolant outlet pipe.

1. Release and reposi tion the hose clip.

2. Disconnect the bottom hose.

4. Re

move the thermostat from the outlet pipe.

1. Remove the three bolts which secure the thermostat cover to the outlet pipe.

2. Remove the thermostat cover, the thermostat and

the seal from the outlet pipe. Discard the seal.

1. Installation is th e reverse of the re moval procedure.

Use new seali

ng rings on th

e coolant outlet pipe and

thermostat housing.

The t he

rmostat ball valve must

locate in the recess in the

cover.

2. Tighten the thermostat cover bolts to 8-10 Nm.

3. Refill the cooling system as de scribed in General Procedures.

Page 1002 of 2490

In

stallation

2.

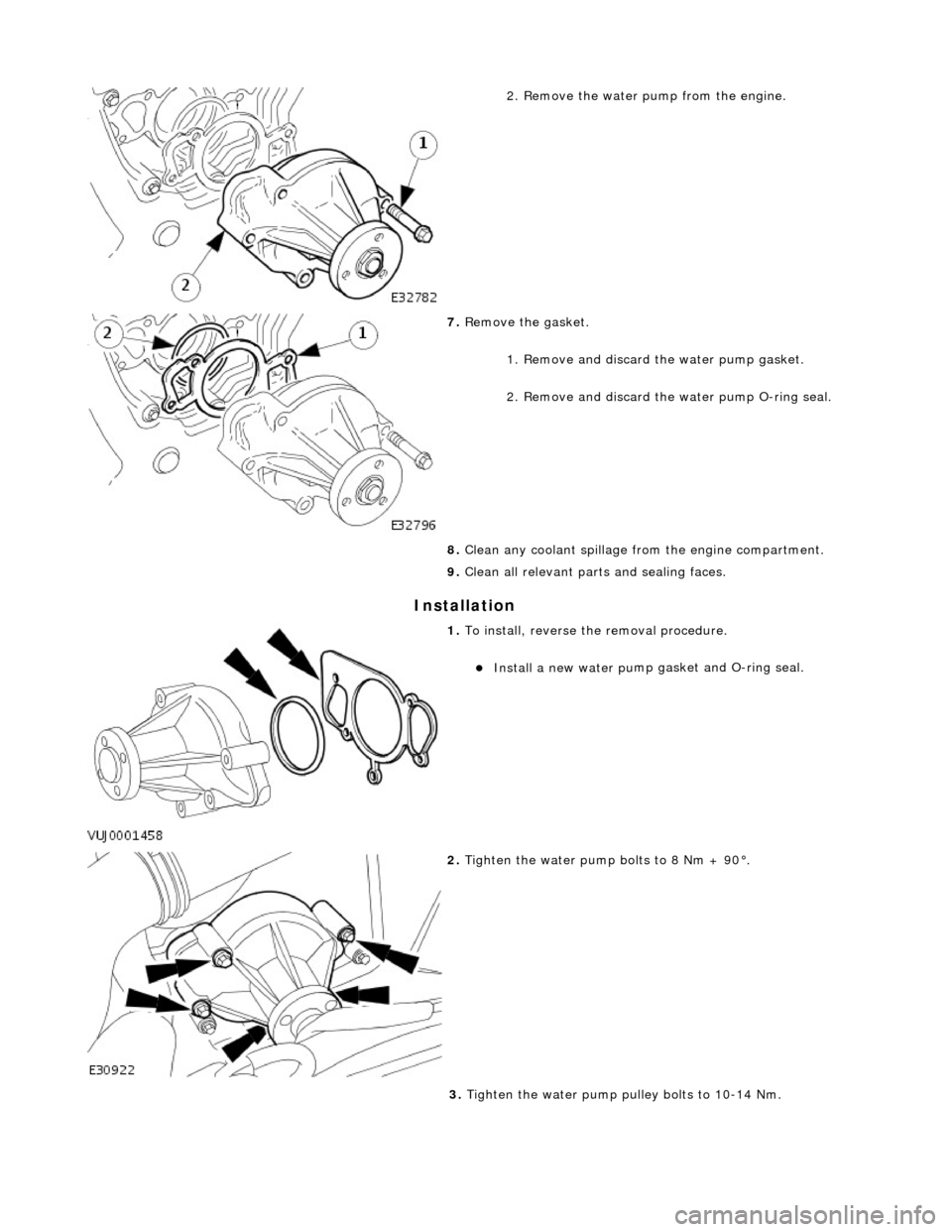

Remove the water pump from the engine.

7. Remo

ve the gasket.

1. Remove and discard the water pump gasket.

2. Remove and discard the water pump O-ring seal.

8. Clean any coolant spillage fro m the engine compartment.

9. Clean all relevant part s and sealing faces.

1. To i

nstall, reverse the removal procedure.

Install a new water

pu

mp gasket and O-ring seal.

2. Tigh ten th

e water pump bolts to 8 Nm + 90°.

3. Tighten the water pump pulley bolts to 10-14 Nm.

Page 1005 of 2490

I

nstallation

1

. Remove the five bolts wh

ich secure the water pump.

2. Remove the water pump from the engine.

8. Re

move the gasket.

1. Remove and discard the water pump gasket.

2. Remove and discard the water pump O-ring seal.

9. Clean any coolant spillage fro m the engine compartment.

10. Clean all relevant part s and sealing faces.

1. To

install, reverse the removal procedure.

Install a new water

pump gasket and O-ring seal.

2. Tigh

ten the water pu

mp securing bolts to 8 Nm + 90°.

3. Tighten the water pump pulley bolts to 10-14 Nm.

Page 1020 of 2490

Fuel Char

ging and Controls - Fuel Charging and Controls

D

iagn

osis and Testing

I

n

spection and Verification

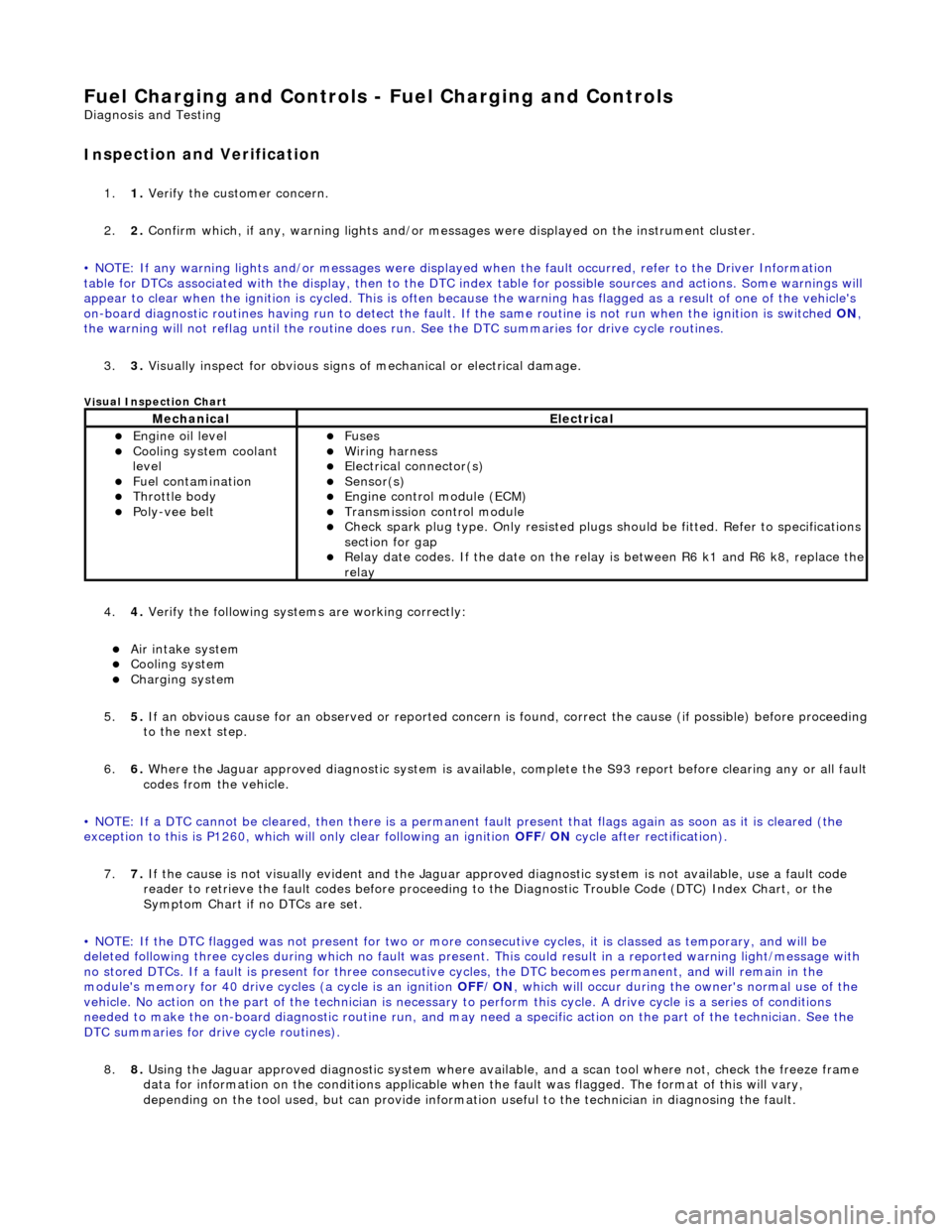

1.

1. Veri fy the customer concern.

2. 2. Confi

rm which, if any, warning li

ghts and/or messages were displayed on the instrument cluster.

• NOTE: If any warning lights and/or me ssages were displayed when the fault occurred, refer to the Driver Information

table for DTCs associated with the display, then to the DTC index table for possible sources and actions. Some warnings will

appear to clear when the ignition is cycl ed. This is often because the warning has flagged as a resu lt of one of the vehicle's

on-board diagnostic routines having run to detect the fault. If the same routine is not run when the ignition is switched ON,

the warning will not reflag until the routine does run. See the DTC summaries for drive cycle routines.

3. 3. Visually inspect for obvious signs of mechanical or electrical damage.

Vi

sual Inspection Chart

4.

4. Veri fy the foll

owing syst

ems are working correctly:

Air intake

system

Cooling system

Charging system

5. 5. If

an obvious cause for an observed or

reported concern is found, correct th e cause (if possible) before proceeding

to the next step.

6. 6. Where the Jaguar approved diagnostic sy stem is available, complete the S93 report before clearing any or all fault

codes from the vehicle.

• NOTE: If a DTC cannot be cleared, then there is a permanent fault present that flag s again as soon as it is cleared (the

exception to this is P1260, which will only clear following an ignition OFF/ON cycle after rectification).

7. 7. If the cause is not visually evident and the Jaguar approv ed diagnostic system is not available, use a fault code

reader to retrieve the fault codes be fore proceeding to the Diagnostic Trou ble Code (DTC) Index Chart, or the

Symptom Chart if no DTCs are set.

• NOTE: If the DTC flagged was not present for two or more co nsecutive cycles, it is classed as temporary, and will be

deleted following three cycl es during which no fault was present. This could result in a reported wa rning light/message with

no stored DTCs. If a fault is present for three consecutive cycles, the DTC becomes permanent, and will remain in the

module's memory for 40 drive cycl es (a cycle is an ignition OFF/ON, which will occur during the owner's normal use of the

vehicle. No action on the part of the technician is necessary to perform this cycle. A drive cycle is a series of conditions

needed to make the on-board diagnostic ro utine run, and may need a specific action on the part of the technician. See the

DTC summaries for drive cycle routines).

8. 8. Using the Jaguar approved diagnostic system where available, and a scan tool where not, check the freeze frame

data for information on the conditions applicable when the fault was flagged. The format of this will vary,

depending on the tool used, but can pr ovide information useful to the technician in diagnosing the fault.

MechanicalElectrical

Engine

oil level

Coo

ling system coolant

lev

el

Fuel contamination

Throttle body Poly-ve

e belt

Fu

ses

W

i

ring harness

E

l

ectrical connector(s)

Sens

o

r(s)

Engine

control module (E

CM)

Tran

s

mission control module

Check spark plu

g type. Only r

e

sisted plugs should be fitted. Refer to specifications

section for gap

Relay date codes. I

f the date on the rela

y is between R6 k1 and R6 k8, replace the

relay

Page 1049 of 2490

Accessory Drive - Accessory Drive

Description an

d Operation

Parts List

Cran

kshaft Pulley

The combined crankshaft

pulley and torsio

nal vibration damper drives a single, seve n ribbed vee belt. The belt drives all of

the engine-mounted accessories; the generator, the power assi sted steering pump, the air-conditioning compressor and the

coolant water pump.

I

dler Pulley

An i

dler pulley, on the right-hand

accessory mounting, increases the wrap-angle around the generator pulley.

Coolant Pump Drive

The coolan

t pump pulley is the

uppermost of the accessory drive pulleys. Th e coolant pump is fitted between the two

cylinder banks on the front face of the engine.

Air Conditioning Compressor Drive

Thi

s is positioned at the lowest poin

t of the front-end accessory-d rive on the left hand side accessory mounting.

It

em

Par

t Number

De

scription

1—Coo

lant Pump Drive

2—Ai

r-Conditioning Compressor Drive

3—Power Steer

ing Pump Drive

4—Au

tomatic Belt Tensioner

5—Crankshaft Pul

ley

6—Idle

r Pulley

7—Generator Dri

ve

Page 1077 of 2490

Engine Igni

tion -

Engine Ignition

D

iagnosis and Testing

I

nspection and Verification

1.

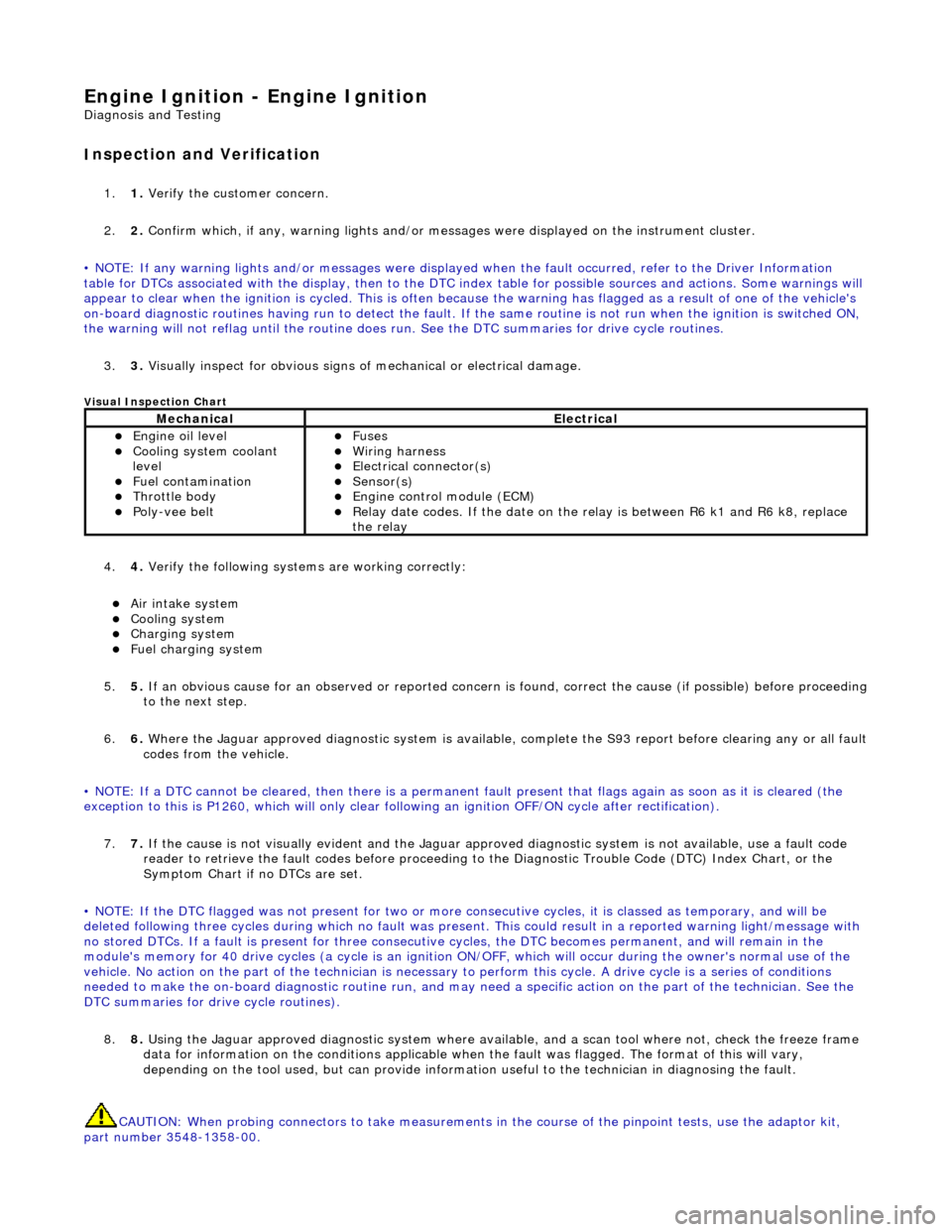

1. Veri

fy the customer concern.

2. 2. Confirm which, if any, warning li ghts and/or messages were displayed on the instrument cluster.

• NOTE: If any warning lights and/or me ssages were displayed when the fault occurred, refer to the Driver Information

table for DTCs associated with the display, then to the DTC index table for possible sources and actions. Some warnings will

appear to clear when the ignition is cycl ed. This is often because the warning has flagged as a resu lt of one of the vehicle's

on-board diagnostic routines having run to detect the fault. If the same routine is not run when the ignition is switched ON,

the warning will not reflag until the routine does run. See the DTC summaries for drive cycle routines.

3. 3. Visually inspect for obvious signs of mechanical or electrical damage.

V

isual Inspection Chart

4.

4. Veri

fy the following syst

ems are working correctly:

Air in

take system

Coo

ling system

Charging system

F

uel charging system

5. 5. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding

to the next step.

6. 6. Where the Jaguar approved diagnostic sy stem is available, complete the S93 report before clearing any or all fault

codes from the vehicle.

• NOTE: If a DTC cannot be cleared, then there is a permanent fault present that flag s again as soon as it is cleared (the

exception to this is P1260, which will only clear following an ignition OFF/ON cycle after rectification).

7. 7. If the cause is not visually evident and the Jaguar approv ed diagnostic system is not available, use a fault code

reader to retrieve the fault codes be fore proceeding to the Diagnostic Trou ble Code (DTC) Index Chart, or the

Symptom Chart if no DTCs are set.

• NOTE: If the DTC flagged was not present for two or more co nsecutive cycles, it is classed as temporary, and will be

deleted following three cycl es during which no fault was present. This could result in a reported wa rning light/message with

no stored DTCs. If a fault is present for three consecutive cycles, the DTC becomes permanent, and will remain in the

module's memory for 40 drive cycles (a cy cle is an ignition ON/OFF, which will occur during the owner's normal use of the

vehicle. No action on the part of the technician is necessary to perform this cycle. A drive cycle is a series of conditions

needed to make the on-board diagnostic ro utine run, and may need a specific action on the part of the technician. See the

DTC summaries for driv e cycle routines).

8. 8. Using the Jaguar approved diagnostic system where available, and a scan tool where not, check the freeze frame

data for information on the conditions applicable when the fault was flagged. The format of this will vary,

depending on the tool used, but can pr ovide information useful to the technician in diagnosing the fault.

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit,

part number 3548-1358-00.

MechanicalElectrical

Engi

ne oil level

Coo

ling system coolant

level

Fuel contamination

Throttle body Poly

-vee belt

F

uses

W

iring harness

E

lectrical connector(s)

Sens

or(s)

Engine

control module (ECM)

Relay date codes.

If the date on the relay is between R6 k1 and R6 k8, replace

the relay