engine coolant JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1462 of 2490

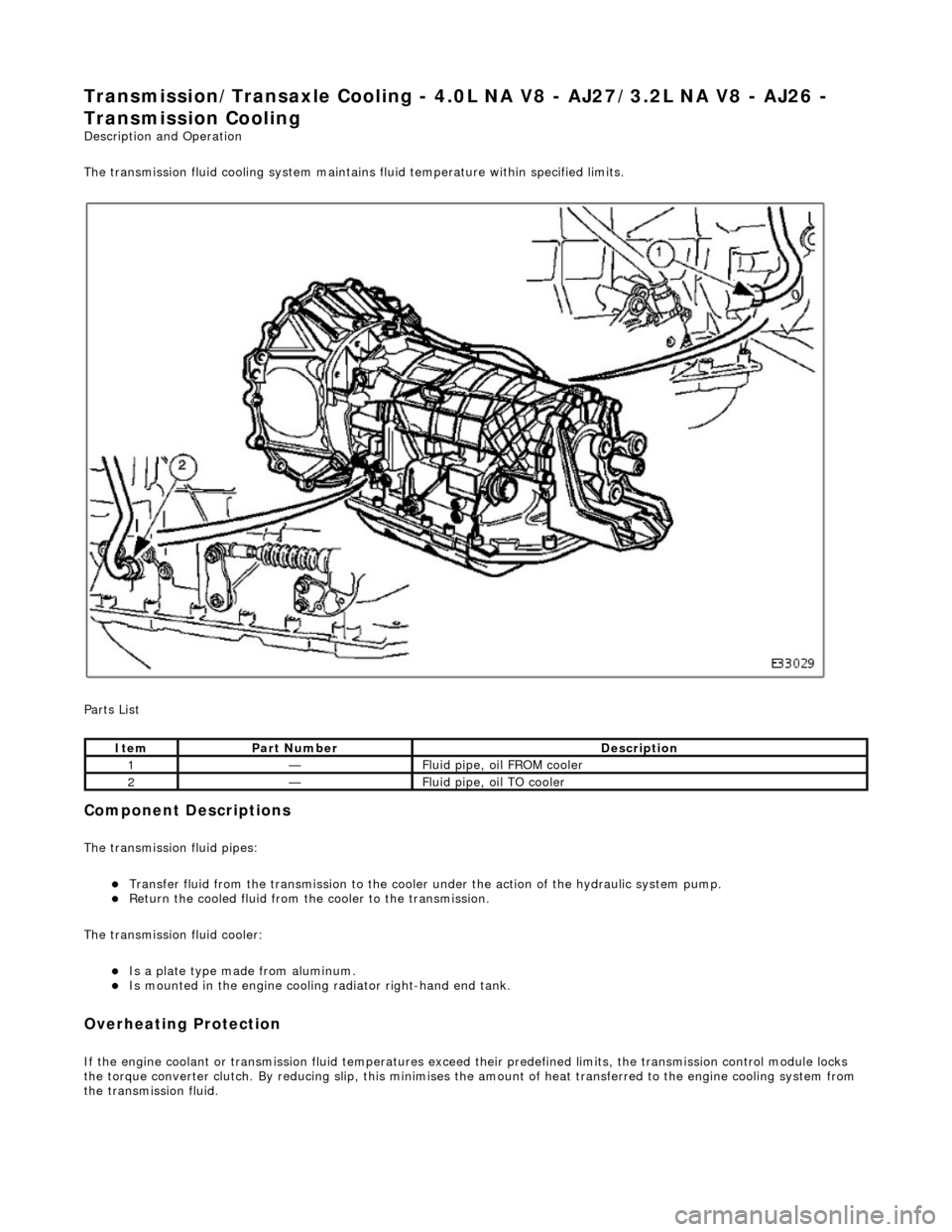

Transmission/Transaxle Cooling - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26 -

Transmission Cooling

Description and Operation

The transmission fluid cooling system maintains fluid temperature within specified limits.

Parts List

Component Descriptions

The transmission fluid pipes:

Transfer fluid from the transmission to the cooler under the action of the hydraulic system pump. Return the cooled fluid from th e cooler to the transmission.

The transmission fluid cooler:

Is a plate type made from aluminum. Is mounted in the engi ne cooling radiator right-hand end tank.

Overheating Protection

If the engine coolant or transm ission fluid temperatures exceed their predefined limits, th e transmission control module locks

the torque converter clutch. By reducing slip, this minimises th e amount of heat transferred to the engine cooling system from

the transmission fluid.

ItemPart NumberDescription

1—Fluid pipe, oil FROM cooler

2—Fluid pipe, oil TO cooler

Page 1463 of 2490

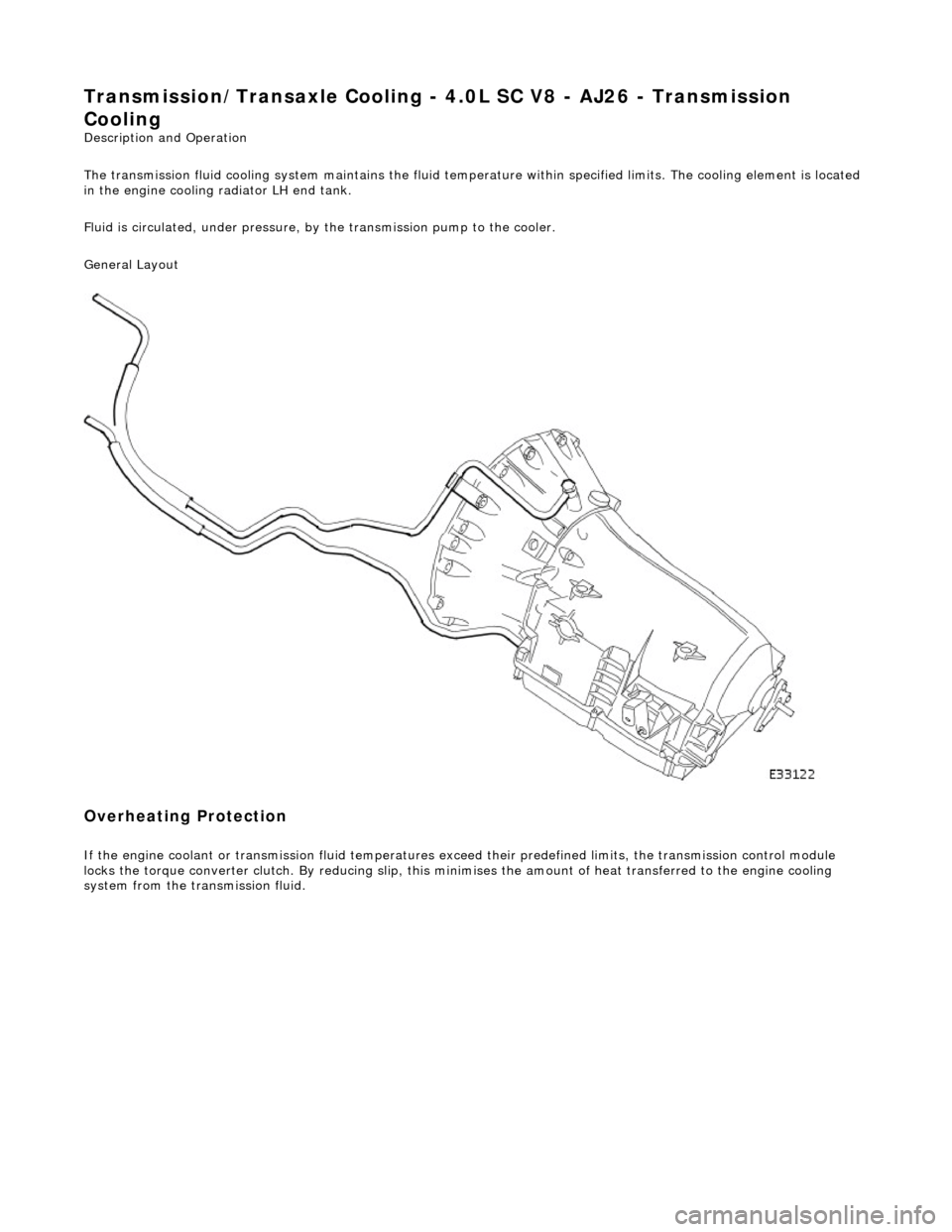

Transmission/Transaxle Cooling - 4.0L SC V8 - AJ26 - Transmission

Cooling

Description and Operation

The transmission fluid cooling system maintains the fluid temperature within specified limits. The cooling element is located

in the engine cooling radiator LH end tank.

Fluid is circulated, under pressure, by the transmission pump to the cooler.

General Layout

Overheating Protection

If the engine coolant or transmission fluid temperatures exceed their predefined limits, the transmission control module

locks the torque converter clutch . By reducing slip, this minimises the amount of heat transferred to the engine cooling

system from the transmission fluid.

Page 1638 of 2490

Exha

ust System - Catalyti

c Converter LH4.0L NA V8 - AJ27/3.2L NA V8 -

AJ26

Re mo

val and Installation

Remova

l

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. Remove the front muffler; refer to Operation 30.10.18 in this

section.

3. Re

move the centre trim panel

from the engine compartment.

1. Remove the left hand side enclosure panel.

2. Remove the centre trim panel.

4. Repo

sition the expansion tank from the mounting.

1. Disconnect the coolant level sensor connector.

2. Remove the nuts which secures the tank.

5. CAUT

ION: Note the position of the upstream and

downstream (where fitted) o xygen sensor multiplugs for

reassembly.

Disconnect the oxygen sensor multiplugs.

Di spl

ace the multiplugs from the engine mounting bracket.

Dis

connect the plug(s) from the oxygen sensor(s)

6.

Re

move the four nuts which se

cure the downpipe catalytic

converter to the exhaust manifold.

Page 1642 of 2490

Exha

ust System - Catalytic Conv

erter LH4.0L SC V8 - AJ26

Remo

val and Installation

Remov

a

l

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. Re

move the centre trim panel

from the engine compartment.

1. Remove the left hand side enclosure panel.

2. Remove the centre trim panel.

3. Repo

sition the expansion tank from the mounting.

1. Disconnect the coolant level sensor connector.

2. Remove the nuts which secures the tank.

4. CAUT

ION: Note the position of the upstream and

downstream (where fitted) o xygen sensor multiplugs for

reassembly.

Disconnect the oxygen sensor multiplugs.

Di spl

ace the multiplugs from the engine mounting bracket.

Dis

connect the plug(s) from the oxygen sensor(s)

5.

Re

move the four nuts which se

cure the downpipe catalytic

converter to the exhaust manifold.

Page 1645 of 2490

6. Connec

t the oxygen sensor multiplugs.

Con

nect the plug(s) to the respective (previously noted)

sensor(s).

Cor

rectly position the multiplu

gs on the mounting bracket.

7. F

it the coolant header tank.

1. Reposition the tank and fit the securing nuts.

2. Connect the harness connector

8. R

efit the centre trim panel and th

e left hand enclosure panel to

the engine compartment.

1. Refit the centre trim panel.

2. Refit the left hand enclosure panel.

9. Raise the vehicle on the ramp.

10. Tighten the mounting brac ket securing bolts.

Page 1654 of 2490

Exha

ust System - Catalyti

c Converter Gasket LH4. 0L NA V8 - AJ27/3.2L

NA V8 - AJ26

Re mo

val and Installation

Remova

l

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. Remove the front muffler; refer to Operation 30.10.18 in this

section.

3. Re

move the centre trim panel

from the engine compartment.

1. Remove the left hand side enclosure panel.

2. Remove the centre trim panel.

4. Repo

sition the expansion tank from the mounting.

1. Disconnect the coolant level sensor connector.

2. Remove the nuts which secures the tank.

5. CAUT

ION: Note the position of the upstream and

downstream (where fitted) o xygen sensor multiplugs for

reassembly.

Disconnect the oxygen sensor multiplugs.

Re

lease the multiplugs from th

e engine mounting bracket.

Dis

connect the plug(s) from the oxygen sensor(s)

6.

Re

move the four nuts which se

cure the downpipe catalytic

converter to the exhaust manifold.

Page 1656 of 2490

5. Connec t

the oxygen sensor multiplugs.

Con

n

ect the plug(s) to the respective (previously noted)

sensor(s).

Cor r

ectly position the multiplu

gs on the mounting bracket.

6. Fi

t the coolant header tank.

1. Reposition the tank and fit the securing nuts.

2. Connect the harness connector

7. Re

fit the centre trim panel and th

e left hand enclosure panel to

the engine compartment.

1. Refit the centre trim panel.

2. Refit the left hand enclosure panel.

8. Raise the ramp.

9. Tighten the mounting brac ket securing bolts.

Page 1658 of 2490

Exha

ust System - Cataly

tic Converter Gasket LH 4.0L SC V8 - AJ26

Remo

val and Installation

Remov

a

l

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. Re

move the centre trim panel

from the engine compartment.

1. Remove the left hand side enclosure panel.

2. Remove the centre trim panel.

3. Repo

sition the expansion tank from the mounting.

1. Disconnect the coolant level sensor connector.

2. Remove the nuts which secures the tank.

4. CAUT

ION: Note the position of the upstream and

downstream (where fitted) o xygen sensor multiplugs for

reassembly.

Disconnect the oxygen sensor multiplugs.

Di spl

ace the multiplugs from the engine mounting bracket.

Dis

connect the plug(s) from the oxygen sensor(s).

5.

Re

move the four nuts which se

cure the downpipe catalytic

converter to the exhaust manifold.

Page 1660 of 2490

In

stallation

1.

Fit a ne

w gasket to the mani

fold mating flange on the

downpipe.

2. Fit

the downpipe catalytic converter.

1. Fit the downpipe assembly to the manifold.

Fit,

but do not fully tighten, the mounting bracket securing

bolts. (Leave loose until the nu ts securing the downpipe to

the exhaust manifold are fitted.)

3. Lower the ramp.

4. Tigh te

n the nuts securing the downpipe flange to the manifold

flange.

5. Connec t

the oxygen sensor multiplugs.

Con

n

ect the plug(s) to the respective (previously noted)

sensor(s).

Cor r

ectly position the multiplu

gs on the mounting bracket.

6. Fi

t the coolant header tank.

1. Reposition the tank and fit the securing nuts.

2. Connect the harness connector

7. Refit the centre trim panel and th e left hand enclosure panel to

the engine compartment.

Page 1760 of 2490

Symp

tom #5

Sy

m

ptom #5

Low r

e

frigerant charge

*

Check f or 'hissi

ng' at expansion

valve; may be witnessed by low

HIGH side pressure. Recover / recharge

*

Moi

s

ture or air in the system

*

Chec k syst

em pressures

*

Heat er ci

rcuit air-lock

*

R e

fer section 303-03 for fill / bleed procedure

*

Suct ion

pipe touching bank 1 (A)

cylinder head (rubber isolator

missing)

*

Check the pi

pe cluster for correct fitti

ng

*

• NOTE: Electrical faults may be more rapidly traced using PDU

Sym

ptom

Possib

l

e Sources

Acti

o

n

Insuffi

ci

ent

heating

Coo l

ant flow valve stuck 'closed'

Coolant flow valve stuck 'open' allowing recirculation of

coolant at engine idle

*

*

Re

new v

alve

*

Motorized in-car aspirator sei zed

*R e

new aspirator

*

Coo l

air bypass damper stuck open

*

Re new,

check fault code #43

*

B l

ocked air inlet / pollen filter

*

Chec k / cl

ean / renew

*

B l

ower speed low

*

Check performance range

*

Low cool ant

level

*

Adjust as req u

ired (verify and correct

reason for loss)

*

Engine

t

hermostat faulty

*

Check engine r u

nning temperature

*

Heater water pump seized

*Chec k op

eration

*

Heater ma trix

blocked

*

Re new m

atrix

*

Heater circui t

air-lock

*

R e

fer section 303-03 for fill / bleed

procedure

*

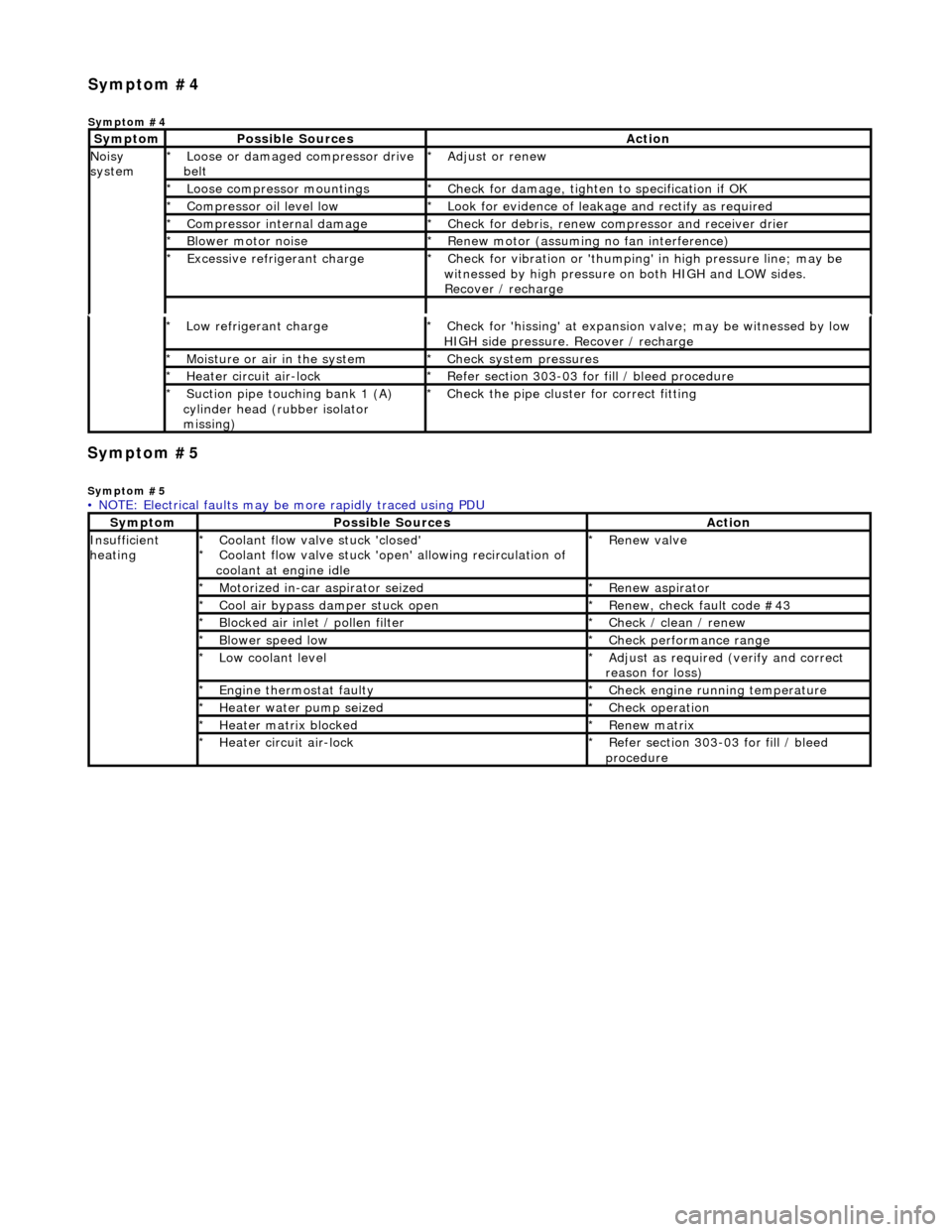

Sym

p

tom #4

Sym

ptom #4

Sy

m

ptom

Possib

l

e Sources

Acti

o

n

No

i

sy

system

Loose or damaged compressor drive

belt

*Adjust or r

e

new

*

Loose compressor mountings

*Check f o

r damage, tighten to specification if OK

*

Compressor oil level l

ow

*

Look for evidence of l

eakag

e and rectify as required

*

Compressor internal dama ge

*Check f o

r debris, renew compressor and receiver drier

*

B l

ower motor noise

*

Re new m

otor (assuming no fan interference)

*

Excessive refrige rant charge

*Check f o

r vibration or 'thumping'

in high pressure line; may be

witnessed by high pressure on both HIGH and LOW sides.

Recover / recharge

*