engine coolant JAGUAR X308 1998 2.G Manual PDF

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1087 of 2490

Engine Igni

tion - Ignition Coil-On-Plug LH

Re

moval and Installation

Remov

al

Installation

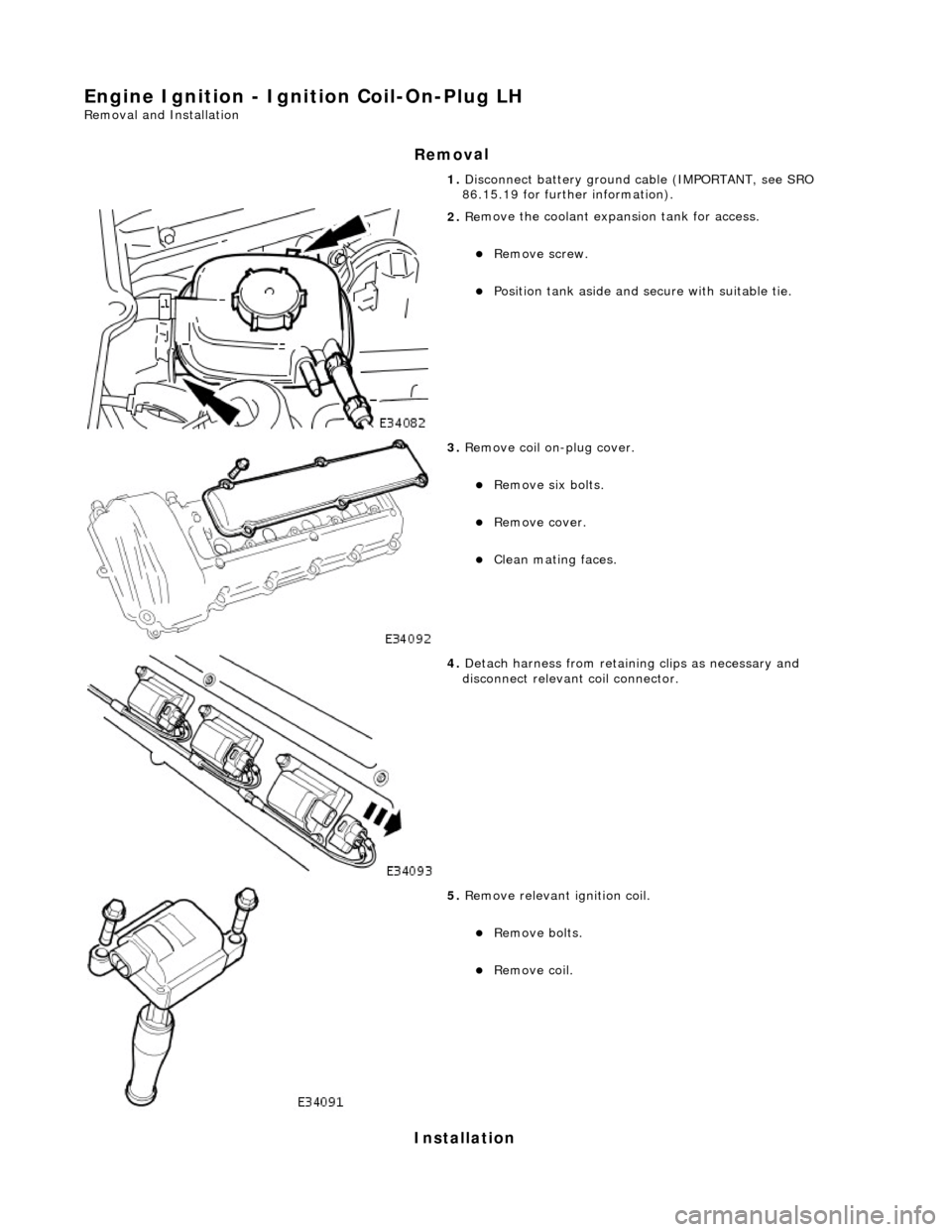

1. Disc

onnect battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. Re

move the coolant expansion tank for access.

R

emove screw.

Position tank aside an

d secu

re with suitable tie.

3. Re

move coil on-plug cover.

R

emove six bolts.

R

emove cover.

Cle

an mating faces.

4. D

etach harness from retain

ing clips as necessary and

disconnect relevant coil connector.

5. R

emove relevant ignition coil.

Re

move bolts.

Re

move coil.

Page 1094 of 2490

Engine Emission

Control - Engine Emission Control

D

iagn

osis and Testing

I

n

spection and Verification

1.

1. Veri fy the customer concern.

2. 2. Vis

ually inspect for obvious signs of mechanical

or electrical damage, correct fitment, etc.

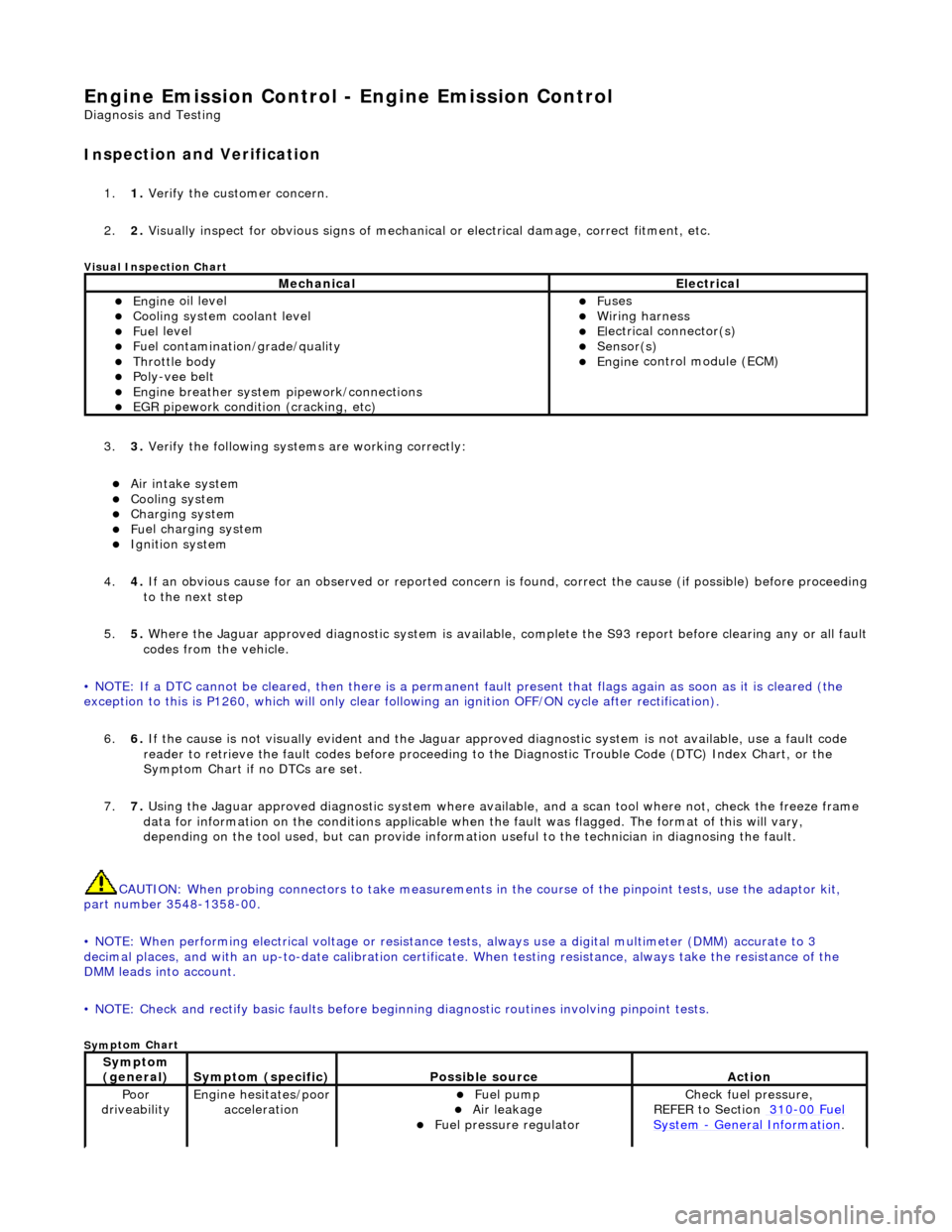

Vi

sual Inspection Chart

3.

3. Veri fy the foll

owing syst

ems are working correctly:

Air intake

system

Coo

ling system

Charging system

Fu

el charging system

Ignition sys

t

em

4. 4. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding

to the next step

5. 5. Where the Jaguar approved diagnostic sy stem is available, complete the S93 report before clearing any or all fault

codes from the vehicle.

• NOTE: If a DTC cannot be cleared, then there is a permanent fault present that flag s again as soon as it is cleared (the

exception to this is P1260, which will only clear following an ignition OFF/ON cycle after rectification).

6. 6. If the cause is not visually evident and the Jaguar approv ed diagnostic system is not available, use a fault code

reader to retrieve the fault codes be fore proceeding to the Diagnostic Trou ble Code (DTC) Index Chart, or the

Symptom Chart if no DTCs are set.

7. 7. Using the Jaguar approved diagnostic system where available, and a scan tool where not, check the freeze frame

data for information on the conditions applicable when the fault was flagged. The format of this will vary,

depending on the tool used, but can pr ovide information useful to the technician in diagnosing the fault.

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit,

part number 3548-1358-00.

• NOTE: When performing electrical voltag e or resistance tests, always use a digital multimeter (DMM) accurate to 3

decimal places, and with an up-t o-date calibration certificate. When testing resistance, always take the resistance of the

DMM leads into account.

• NOTE: Check and rectify basic faults before beginning diagnostic ro utines involving pinpoint tests.

Sym

ptom Chart

MechanicalElectrical

Engi

ne

oil level

Coo

ling system coolant level

Fue

l

level

Fuel contaminatio

n

/

grade/quality

Throttle body Poly

-ve

e belt

Engine breath

er

system

pipework/connections

EGR pipework

condition (cracking, etc)

F

u

ses

W

i

ring harness

E

l

ectrical connector(s)

Sens

o

r(s)

Engine

control module (E

CM)

Sy

m

ptom

(general)

S y

mptom (specific)

Possib

l

e source

Acti

o

n

Poor

dr iveabilityEngine h e

sitates/poor

acceleration

Fue l

pump

Air leakage F

u

el pressure regulator

Chec

k fu

el pressure,

REFER to Section 310

-00 Fu

el

Sy

ste

m

- General Informati

on.

Page 1098 of 2490

Engine Emission

Control - Exhaus

t Gas Recirculation (EGR) Valve

Remo

val and Installation

Remov

a

l

1.

Re

move the engine cover.

For additional informat ion, refer to Section 501

-05

Interior

Trim and Ornamen

t

ation

.

2. Disc

onnect the evaporative emission canister purge valve

electrical connector.

3. Detac

h and reposition the evaporative emission canister purge

valve.

4. NOTE : Cap the coolan

t hose

to minimize coolant loss.

Disconnect the coolant hose.

5. Disconnect the exhaust gas recirc ulation (EGR) valve electrical

connector.

Page 1113 of 2490

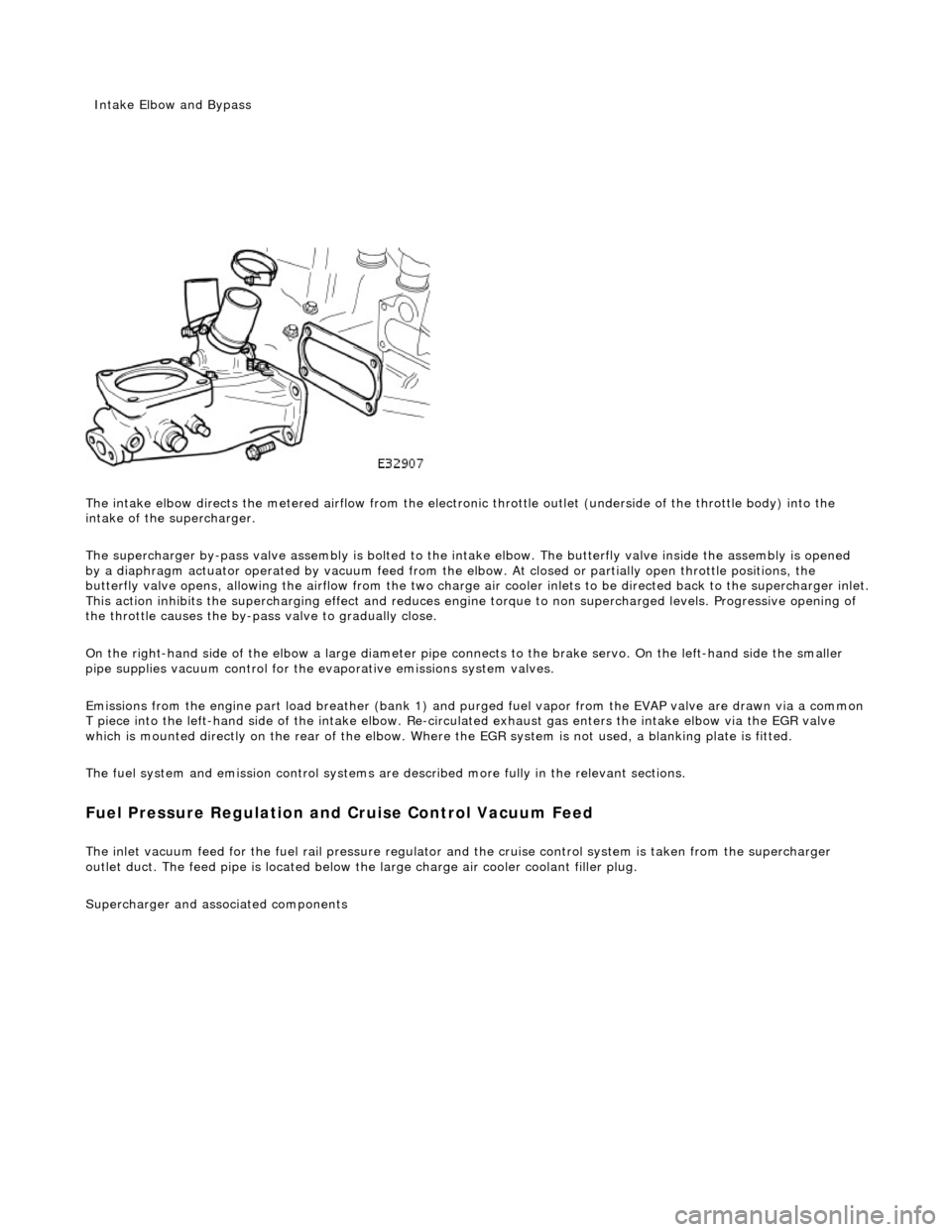

The intake elbow di

rects the metered airflow from the electronic throttle outlet (und

erside of the throttle body) into the

intake of the supercharger.

The supercharger by-pass valve assembly is bolted to the intake elbow. The butterfly valve inside the assembly is opened

by a diaphragm actuator operated by vacu um feed from the elbow. At closed or partially open throttle positions, the

butterfly valve opens, allowing th e airflow from the two charge air cooler inlets to be directed back to the supercharger inlet .

This action inhibits the supercharging e ffect and reduces engine torque to non supercharged levels. Progressive opening of

the throttle causes the by-pass valve to gradually close.

On the right-hand side of the elbow a la rge diameter pipe connects to the brake servo. On the left-hand side the smaller

pipe supplies vacuum control for the evaporative emissions system valves.

Emissions from the engine part load breather (bank 1) and pu rged fuel vapor from the EVAP valve are drawn via a common

T piece into the left-hand side of the intake elbow. Re-cir culated exhaust gas enters the intake elbow via the EGR valve

which is mounted directly on the rear of the elbow. Where the EGR system is not used, a blanking plate is fitted.

The fuel system and emission control systems are described more fully in the relevant sections.

Fuel Pressure Regula

tion and

Cruise Control Vacuum Feed

The inlet v

acuum feed fo

r the fuel rail pressure regula tor and the cruise control system is taken from the supercharger

outlet duct. The feed pipe is located below the large charge air cooler coolant filler plug.

Superchar

ger

and associated components

Inta

ke Elbow and Bypass

Page 1120 of 2490

Intake Air Distribution and Filtering - Charge Air Cooler LH

Remo

val and Installation

Remov

a

l

Installation

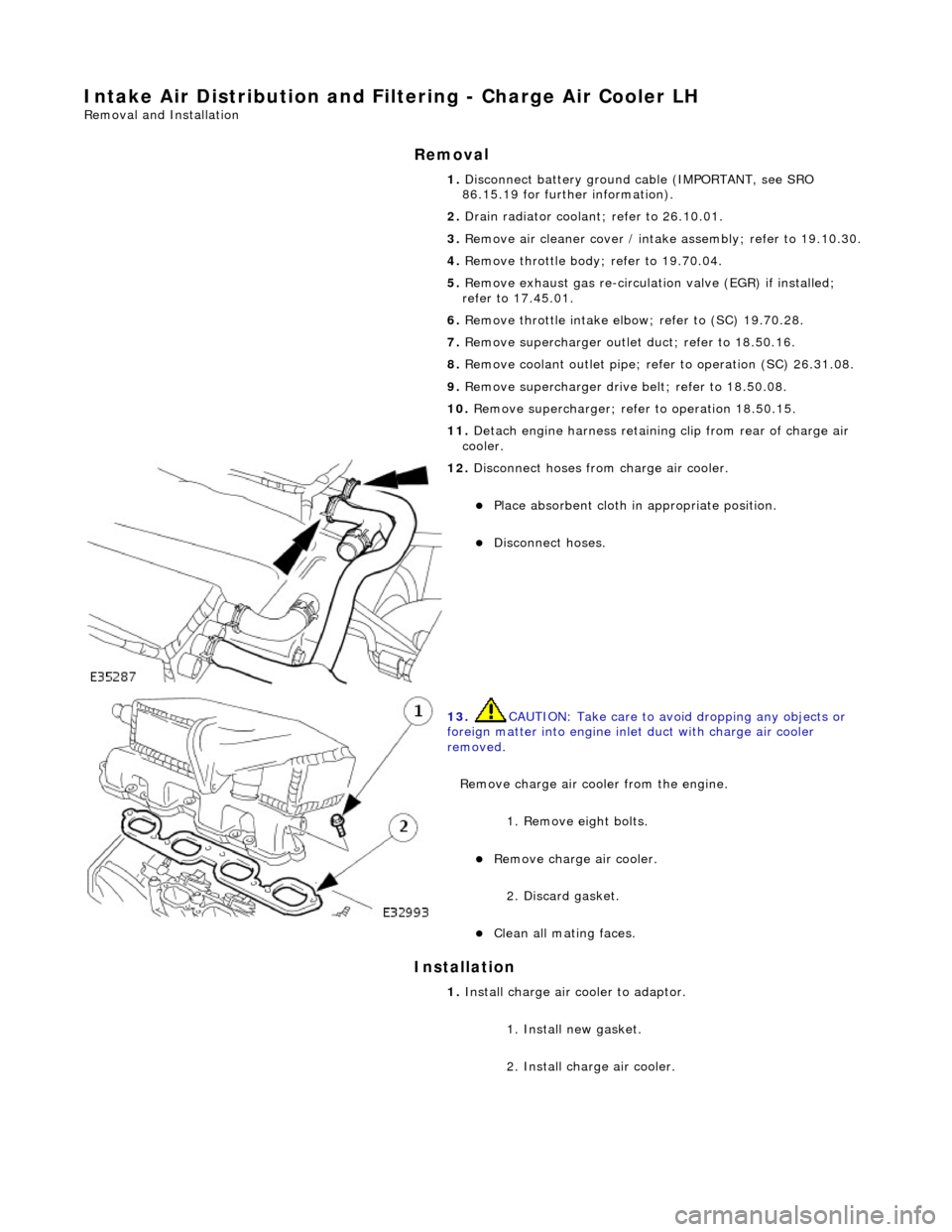

1. Disc onne

ct battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. Drain radiator coolant; refer to 26.10.01.

3. Remove air cleaner cover / intake assembly; refer to 19.10.30.

4. Remove throttle body; refer to 19.70.04.

5. Remove exhaust gas re-circulation valve (EGR) if installed;

refer to 17.45.01.

6. Remove throttle intake elbo w; refer to (SC) 19.70.28.

7. Remove supercharger outlet duct; refer to 18.50.16.

8. Remove coolant outlet pipe; refe r to operation (SC) 26.31.08.

9. Remove supercharger drive belt; refer to 18.50.08.

10. Remove supercharger; refer to operation 18.50.15.

11. Detach engine harness retaining clip from rear of charge air

cooler.

12. Di

sconnect hoses from charge air cooler.

Pla

ce absorbent cloth in appropriate position.

Di

sc

onnect hoses.

13 .

CAUTI

ON: Take care to avoi

d dropping any objects or

foreign matter into engine inle t duct with charge air cooler

removed.

Remove charge air cooler from the engine.

1. Remove eight bolts.

Remove charge air cooler.

2

. Discard gasket.

Cle

a

n all mating faces.

1.

Install ch

arge air

cooler to adaptor.

1. Install new gasket.

2. Install charge air cooler.

Page 1121 of 2490

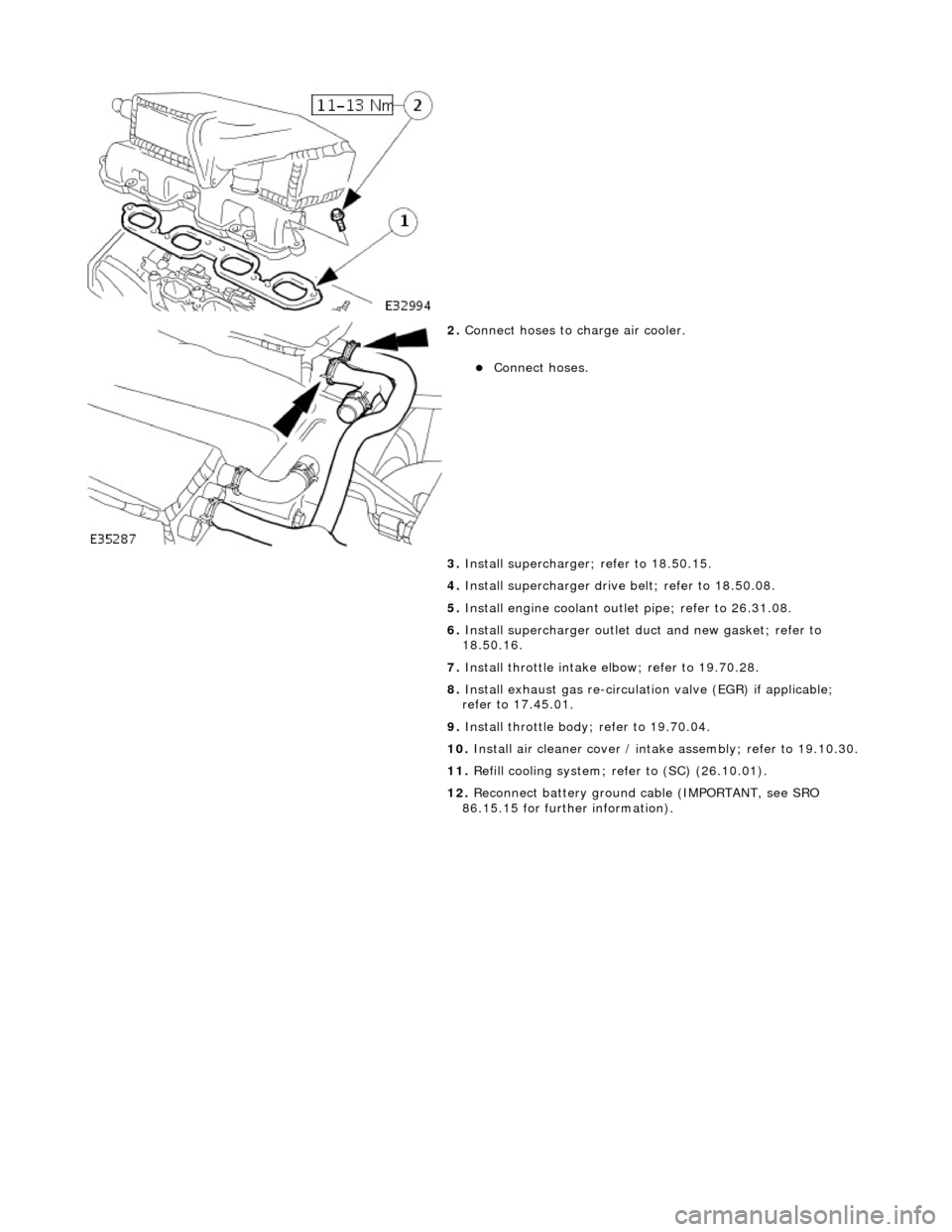

2.

Conne

ct hoses to charge air cooler.

Conne

ct hoses.

3. Install supercharger; refer to 18.50.15.

4. Install supercharger driv e belt; refer to 18.50.08.

5. Install engine coolant outlet pipe; refer to 26.31.08.

6. Install supercharger outlet du ct and new gasket; refer to

18.50.16.

7. Install throttle intake elbow; refer to 19.70.28.

8. Install exhaust gas re-circulation valve (EGR) if applicable;

refer to 17.45.01.

9. Install throttle body ; refer to 19.70.04.

10. Install air cleaner cover / intake assembly; re fer to 19.10.30.

11. Refill cooling system; refer to (SC) (26.10.01).

12. Reconnect battery ground cable (IMPORTANT, see SRO

86.15.15 for further information).

Page 1122 of 2490

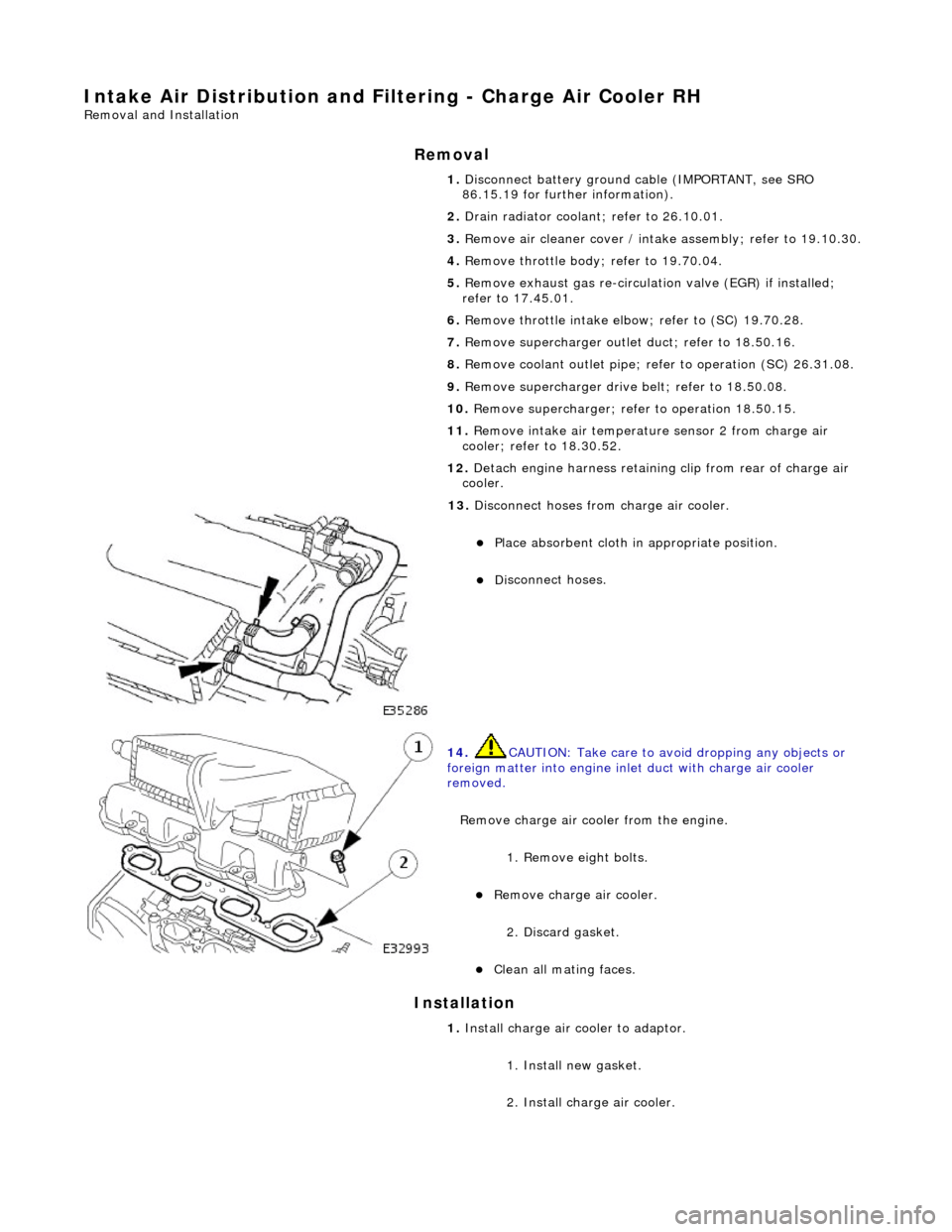

Intake Air Distribution and Filtering - Charge Air Cooler RH

Remo

val and Installation

Remov

a

l

Installation

1. Disc onne

ct battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. Drain radiator coolant; refer to 26.10.01.

3. Remove air cleaner cover / intake assembly; refer to 19.10.30.

4. Remove throttle body; refer to 19.70.04.

5. Remove exhaust gas re-circulation valve (EGR) if installed;

refer to 17.45.01.

6. Remove throttle intake elbo w; refer to (SC) 19.70.28.

7. Remove supercharger outlet duct; refer to 18.50.16.

8. Remove coolant outlet pipe; refe r to operation (SC) 26.31.08.

9. Remove supercharger drive belt; refer to 18.50.08.

10. Remove supercharger; refer to operation 18.50.15.

11. Remove intake air temperatur e sensor 2 from charge air

cooler; refer to 18.30.52.

12. Detach engine harness retaining clip from rear of charge air

cooler.

13. Di

sconnect hoses from charge air cooler.

Pla

ce absorbent cloth in appropriate position.

Di

sc

onnect hoses.

14 . CAUTI

ON: Take care to avoi

d dropping any objects or

foreign matter into engine inle t duct with charge air cooler

removed.

Remove charge air cooler from the engine. 1. Remove eight bolts.

Remove charge air cooler.

2

. Discard gasket.

Cle

a

n all mating faces.

1.

Install ch arge air

cooler to adaptor.

1. Install new gasket.

2. Install charge air cooler.

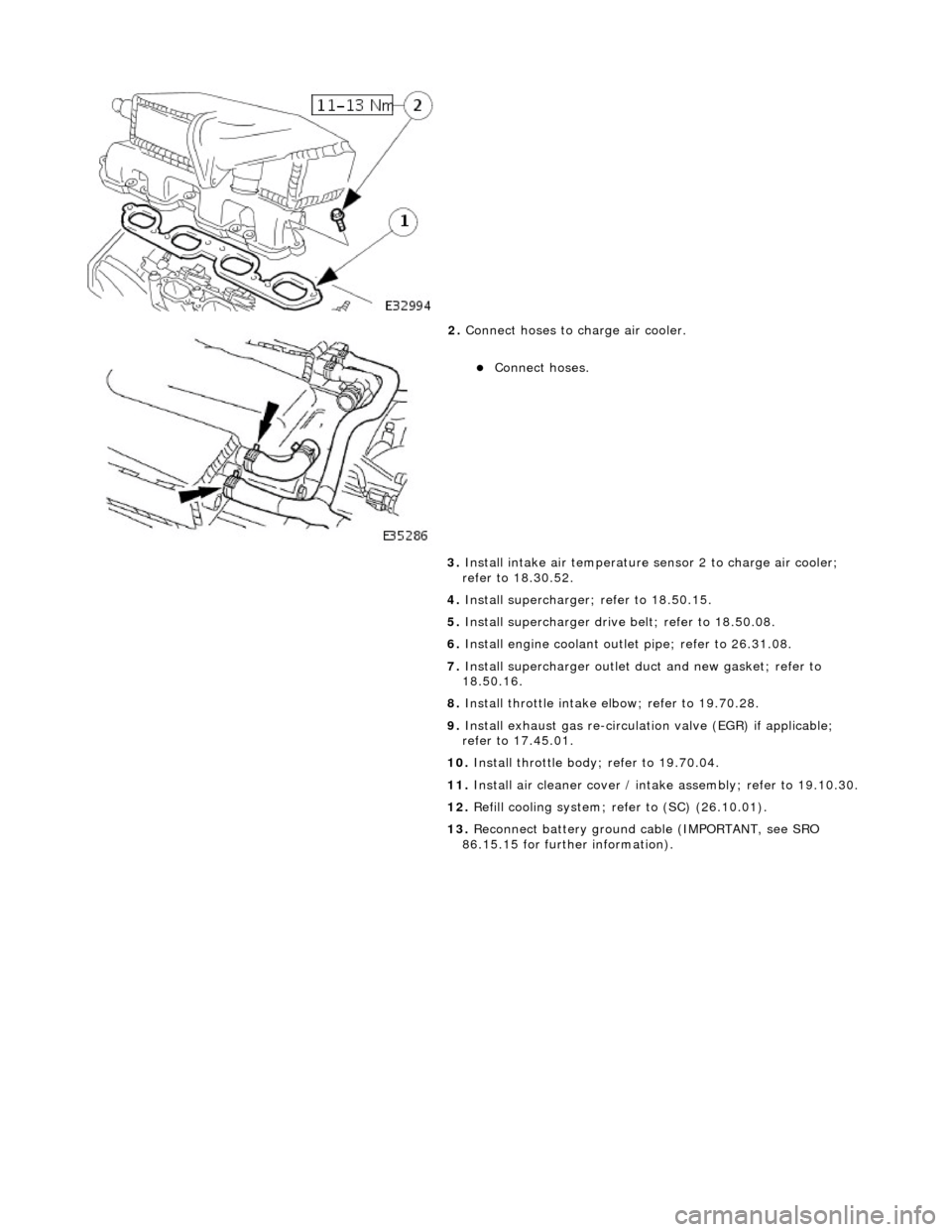

Page 1123 of 2490

2.

Conne

ct hoses to charge air cooler.

Conne

ct hoses.

3. Install intake air te mperature sensor 2 to charge air cooler;

refer to 18.30.52.

4. Install supercharger; refer to 18.50.15.

5. Install supercharger driv e belt; refer to 18.50.08.

6. Install engine coolant outlet pipe; refer to 26.31.08.

7. Install supercharger outlet du ct and new gasket; refer to

18.50.16.

8. Install throttle intake elbow; refer to 19.70.28.

9. Install exhaust gas re-circulation valve (EGR) if applicable;

refer to 17.45.01.

10. Install throttle body; refer to 19.70.04.

11. Install air cleaner cover / intake assembly; re fer to 19.10.30.

12. Refill cooling system; refer to (SC) (26.10.01).

13. Reconnect battery ground cable (IMPORTANT, see SRO

86.15.15 for further information).

Page 1126 of 2490

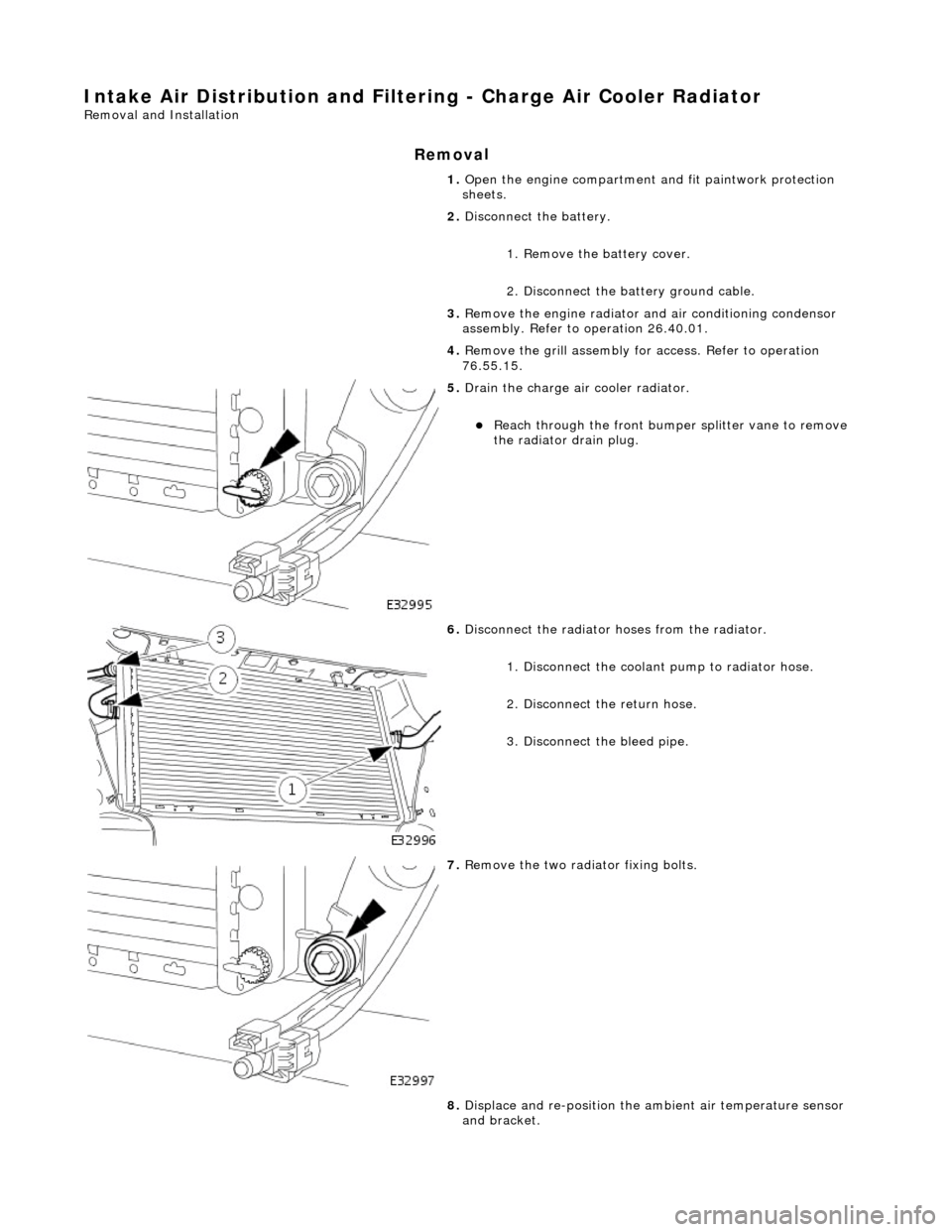

Intake Air Distribution and Filtering - Charge Air Cooler Radiator

Remo

val and Installation

Remov

a

l

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. Disconnect the battery.

1. Remove the battery cover.

2. Disconnect the battery ground cable.

3. Remove the engine radiator and air conditioning condensor

assembly. Refer to operation 26.40.01.

4. Remove the grill assembly fo r access. Refer to operation

76.55.15.

5. Drain th e charge air cooler radiator.

Reach t

hrough the front bumper

splitter vane to remove

the radiator drain plug.

6. Disc

onnect the radiator

hoses from the radiator.

1. Disconnect the coolant pump to radiator hose.

2. Disconnect the return hose.

3. Disconnect the bleed pipe.

7. Re

move the two radiator fixing bolts.

8. Displace and re-position the am bient air temperature sensor

and bracket.

Page 1127 of 2490

I

nstallation

9.

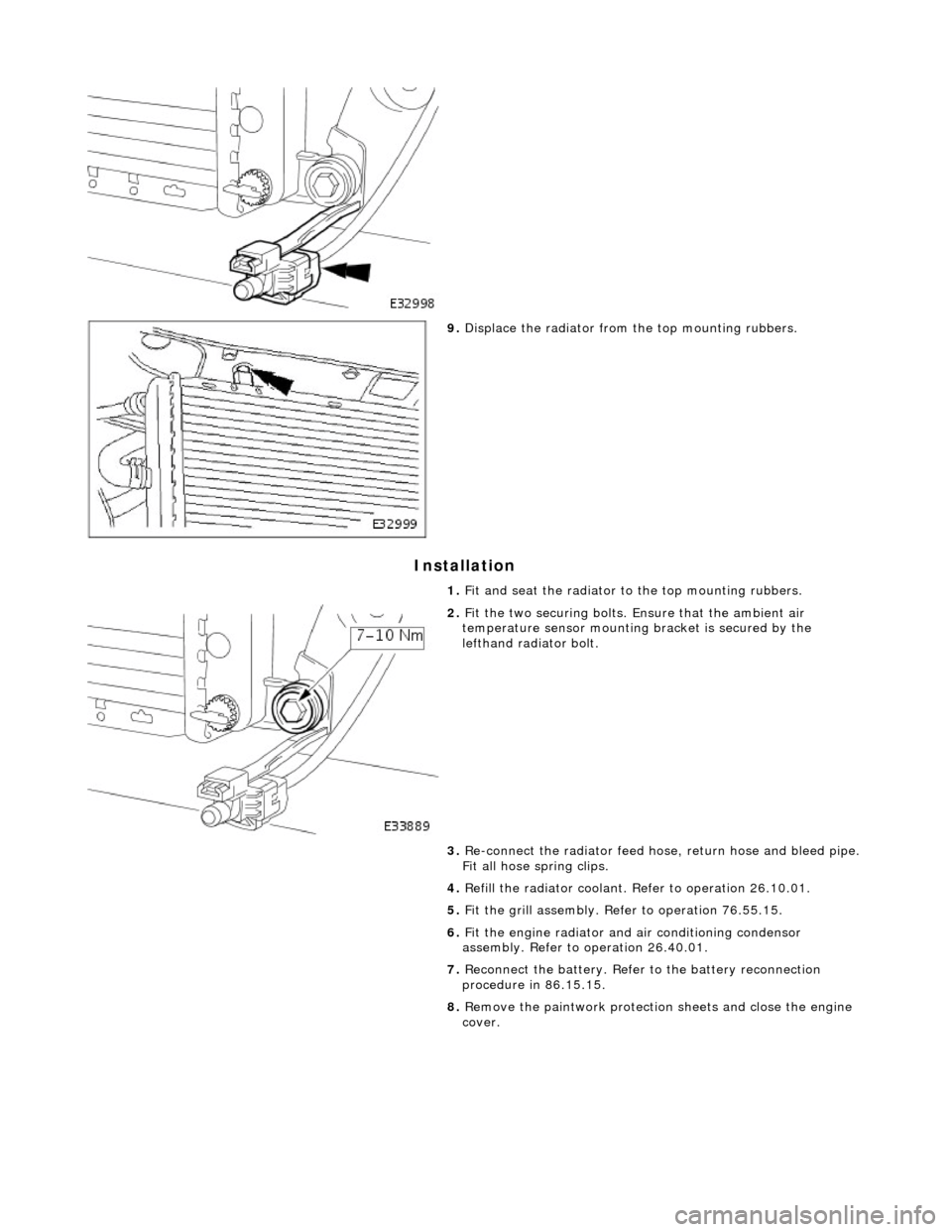

Di

splace the radiator from

the top mounting rubbers.

1. Fit and seat the radiator to the top mounting rubbers.

2. F

it the two securing bolts.

Ensure that the ambient air

temperature sensor mounting bracket is secured by the

lefthand radiator bolt.

3. Re-connect the radiator feed ho se, return hose and bleed pipe.

Fit all hose spring clips.

4. Refill the radiator coolant. Refer to operation 26.10.01.

5. Fit the grill assembly. Refer to operation 76.55.15.

6. Fit the engine radiator and air conditioning condensor

assembly. Refer to operation 26.40.01.

7. Reconnect the battery. Refer to the battery reconnection

procedure in 86.15.15.

8. Remove the paintwork protection sheets and close the engine

cover.