engine ignition JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1089 of 2490

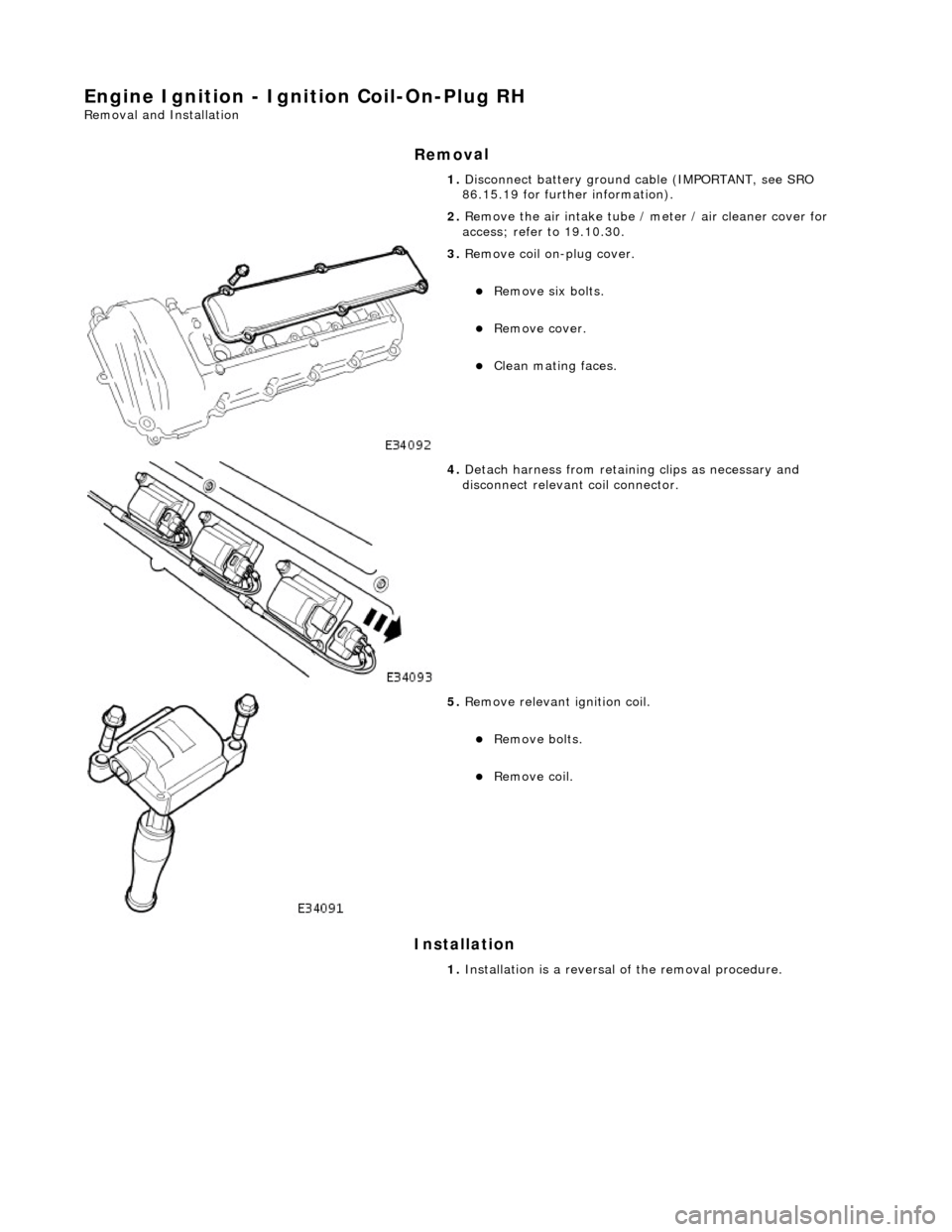

Engine Igni

tion - Ignition Coil-On-Plug RH

Re

moval and Installation

Remov

al

Installation

1. Disc

onnect battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. Remove the air intake tube / meter / air cleaner cover for

access; refer to 19.10.30.

3. Re

move coil on-plug cover.

R

emove six bolts.

R

emove cover.

Cle

an mating faces.

4. D

etach harness from retain

ing clips as necessary and

disconnect relevant coil connector.

5. R

emove relevant ignition coil.

Re

move bolts.

Re

move coil.

1. Installation is a reversal of the removal procedure.

Page 1091 of 2490

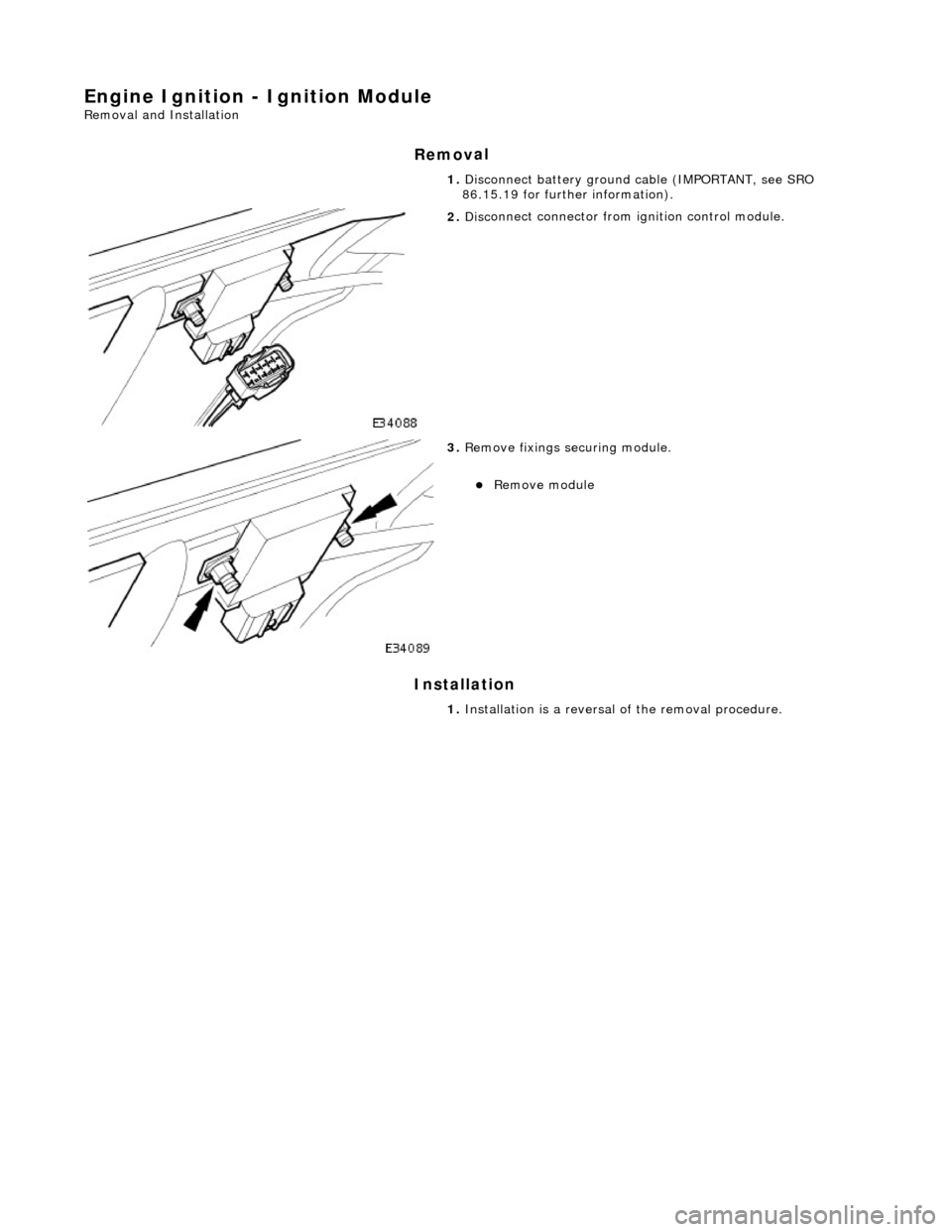

Engine Igni

tion - Ignition Module

Re

moval and Installation

Remov

al

Installation

1.

Disc

onnect battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. Disc

onnect connector from ignition control module.

3. Re

move fixings securing module.

Re

move module

1. Installation is a reversal of the removal procedure.

Page 1092 of 2490

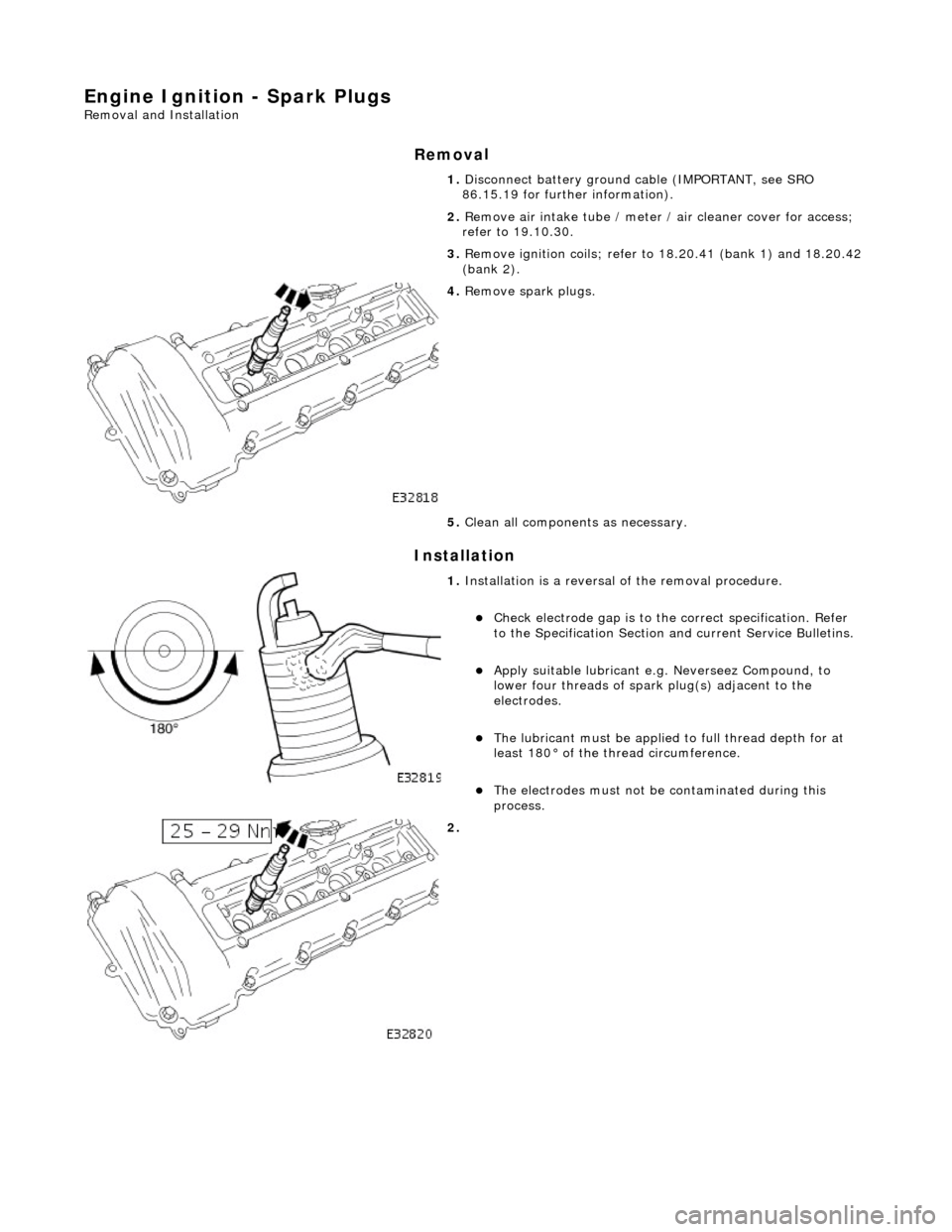

Engine Ignition - Spark

Plugs

Re

mo

val and Installation

Remov

a

l

Installation

1.

Disc onne

ct battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. Remove air intake tube / meter / air cleaner cover for access;

refer to 19.10.30.

3. Remove ignition coils; refer to 18.20.41 (bank 1) and 18.20.42

(bank 2).

4. Re

move spark plugs.

5. Clean all components as necessary.

1. Installation

is a reversal

of the removal procedure.

Check ele

ctrode gap is to the

correct specification. Refer

to the Specification Section and current Service Bulletins.

Apply su

itable lubricant e.

g. Neverseez Compound, to

lower four threads of spark plug(s) adjacent to the

electrodes.

The lubrican t must be applied

to full thread depth for at

least 180° of the thread circumference.

T h

e electrodes must not be

contaminated during this

process.

2.

Page 1094 of 2490

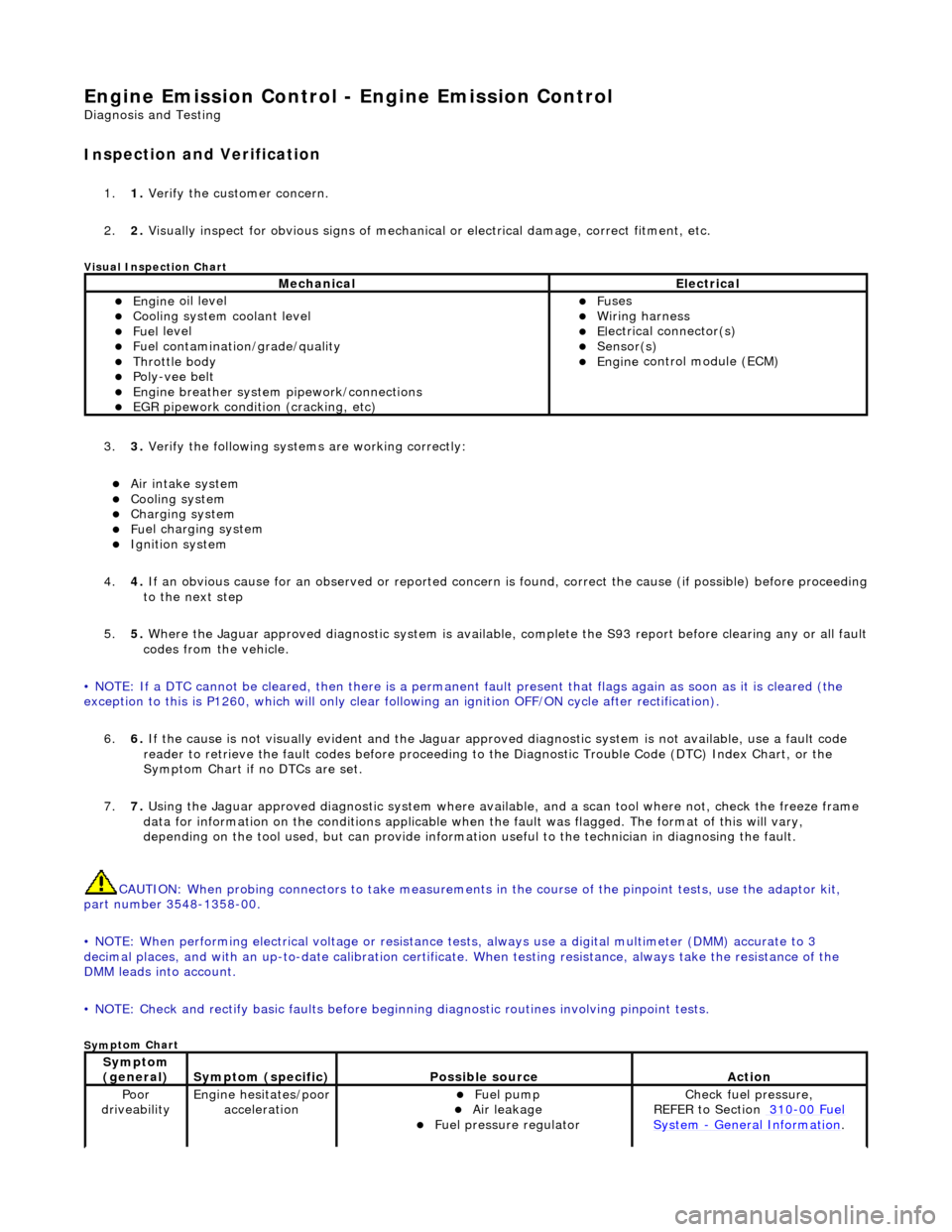

Engine Emission

Control - Engine Emission Control

D

iagn

osis and Testing

I

n

spection and Verification

1.

1. Veri fy the customer concern.

2. 2. Vis

ually inspect for obvious signs of mechanical

or electrical damage, correct fitment, etc.

Vi

sual Inspection Chart

3.

3. Veri fy the foll

owing syst

ems are working correctly:

Air intake

system

Coo

ling system

Charging system

Fu

el charging system

Ignition sys

t

em

4. 4. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding

to the next step

5. 5. Where the Jaguar approved diagnostic sy stem is available, complete the S93 report before clearing any or all fault

codes from the vehicle.

• NOTE: If a DTC cannot be cleared, then there is a permanent fault present that flag s again as soon as it is cleared (the

exception to this is P1260, which will only clear following an ignition OFF/ON cycle after rectification).

6. 6. If the cause is not visually evident and the Jaguar approv ed diagnostic system is not available, use a fault code

reader to retrieve the fault codes be fore proceeding to the Diagnostic Trou ble Code (DTC) Index Chart, or the

Symptom Chart if no DTCs are set.

7. 7. Using the Jaguar approved diagnostic system where available, and a scan tool where not, check the freeze frame

data for information on the conditions applicable when the fault was flagged. The format of this will vary,

depending on the tool used, but can pr ovide information useful to the technician in diagnosing the fault.

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit,

part number 3548-1358-00.

• NOTE: When performing electrical voltag e or resistance tests, always use a digital multimeter (DMM) accurate to 3

decimal places, and with an up-t o-date calibration certificate. When testing resistance, always take the resistance of the

DMM leads into account.

• NOTE: Check and rectify basic faults before beginning diagnostic ro utines involving pinpoint tests.

Sym

ptom Chart

MechanicalElectrical

Engi

ne

oil level

Coo

ling system coolant level

Fue

l

level

Fuel contaminatio

n

/

grade/quality

Throttle body Poly

-ve

e belt

Engine breath

er

system

pipework/connections

EGR pipework

condition (cracking, etc)

F

u

ses

W

i

ring harness

E

l

ectrical connector(s)

Sens

o

r(s)

Engine

control module (E

CM)

Sy

m

ptom

(general)

S y

mptom (specific)

Possib

l

e source

Acti

o

n

Poor

dr iveabilityEngine h e

sitates/poor

acceleration

Fue l

pump

Air leakage F

u

el pressure regulator

Chec

k fu

el pressure,

REFER to Section 310

-00 Fu

el

Sy

ste

m

- General Informati

on.

Page 1095 of 2490

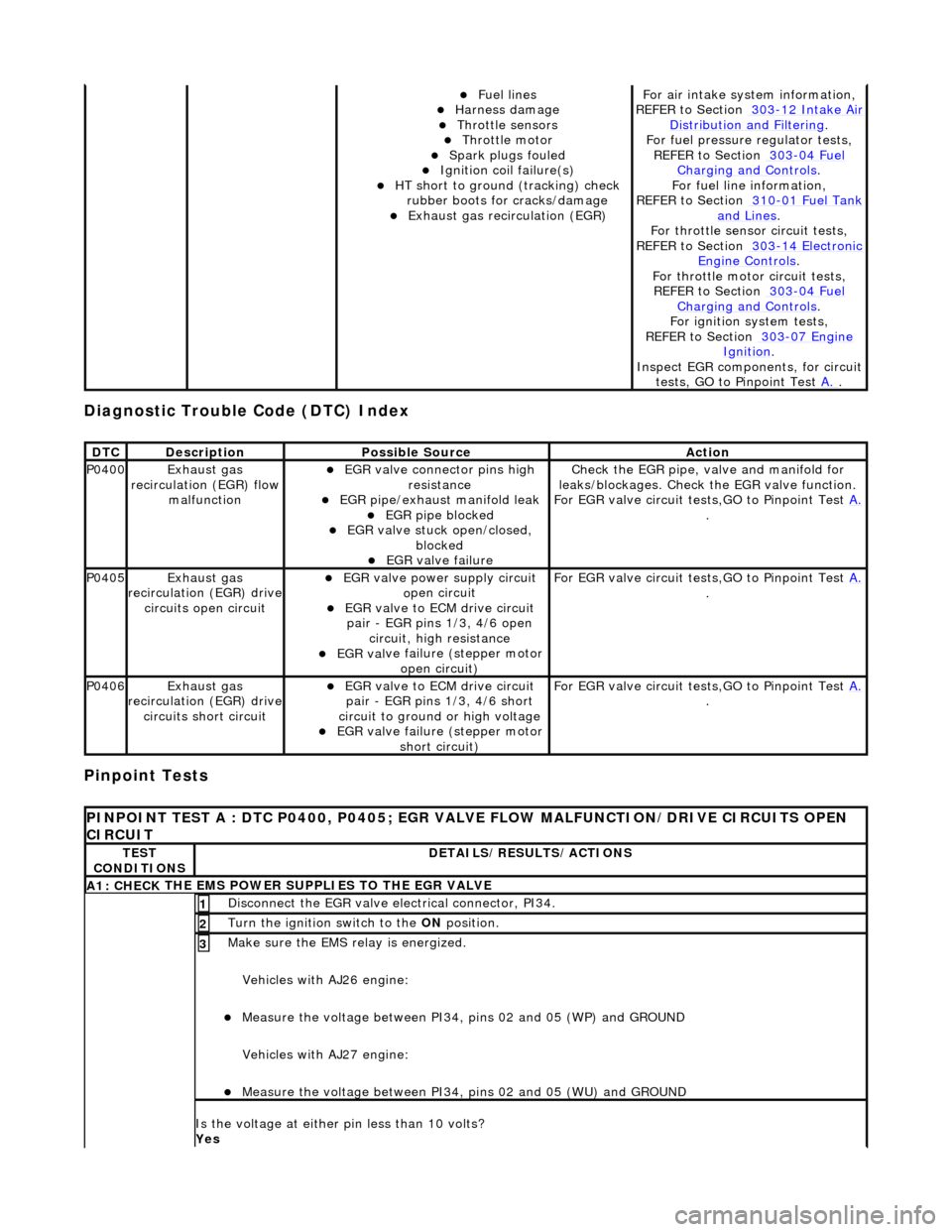

Diagnostic Trouble Code (D

TC) Index

Pinpoint Tests

Fue

l lines

Harness damage

Throttl

e sensors

Throttl

e motor

Spark plugs

fouled

Ignition coil

failure(s)

HT sho

rt to ground (tracking) check

rubber boots for cracks/damage

Exhaus

t gas recirculation (EGR)

F

or air intake syst

em information,

REFER to Section 303

-12

Intake Air

Distribu

tion and Filtering

.

F

or fuel pressure

regulator tests,

REF

ER to Section 303

-04

Fuel

Charging and Con

trols

.

F

or fuel line information,

REFER to Section 310

-01

Fuel Tank

and Lines.

F

or throttle sensor

circuit tests,

REFER to Section 303

-14

Electronic

Engine

Controls

.

Fo

r throttle motor

circuit tests,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

For ign

ition system tests,

REFER to Section 303

-07

Engine

Ignition.

Inspe

ct EGR components, for circuit

tests, GO to Pinpoint Test A.

.

DT

C

De

scription

Possib

le Source

Acti

on

P0400Exhaus

t gas

recirculation (EGR) flow malfunction

EGR

valve connector pins high

resistance

EGR pipe/exhaust manifold leak EGR pipe block

ed

EGR val

ve stuck open/closed,

blocked

EGR

valve failure

Check the EGR pi

pe, valve and manifold for

leaks/blockages. Check the EGR valve function.

For EGR valve circuit tests,GO to Pinpoint Test A.

.

P0405Exhaus

t gas

recirculation (EGR) drive

circuits open circuit

EGR valve power supply circuit o

pen circuit

EGR valve t

o ECM drive circuit

pair - EGR pins 1/3, 4/6 open circuit, high resistance

EGR val

ve failure (stepper motor

open circuit)

F

or EGR valve circuit tests,GO to Pinpoint Test

A.

.

P0406Exhaus

t gas

recirculation (EGR) drive

circuits short circuit

EGR valve t

o ECM drive circuit

pair - EGR pins 1/3, 4/6 short

circuit to ground or high voltage

EGR val

ve failure (stepper motor

short circuit)

F

or EGR valve circuit tests,GO to Pinpoint Test

A.

.

P

INPOINT TEST A : DTC P0400, P0405; EGR VALV

E FLOW MALFUNCTION/DRIVE CIRCUITS OPEN

CIRCUIT

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

A1: CHECK

THE EMS POWER SU

PPLIES TO THE EGR VALVE

D

isconnect the EGR valve electrical connector, PI34.

1

Turn the ignition swi

tch to the ON

position.

2

Make sure the EMS re lay i

s energized.

Vehicles with AJ26 engine:

Me

asure the voltage between PI34, pins 02 and 05 (WP) and GROUND

Vehicles with AJ27 engine:

Me

asure the voltage between PI34, pins 02 and 05 (WU) and GROUND

3

Is th

e voltage at either pin less than 10 volts?

Yes

Page 1161 of 2490

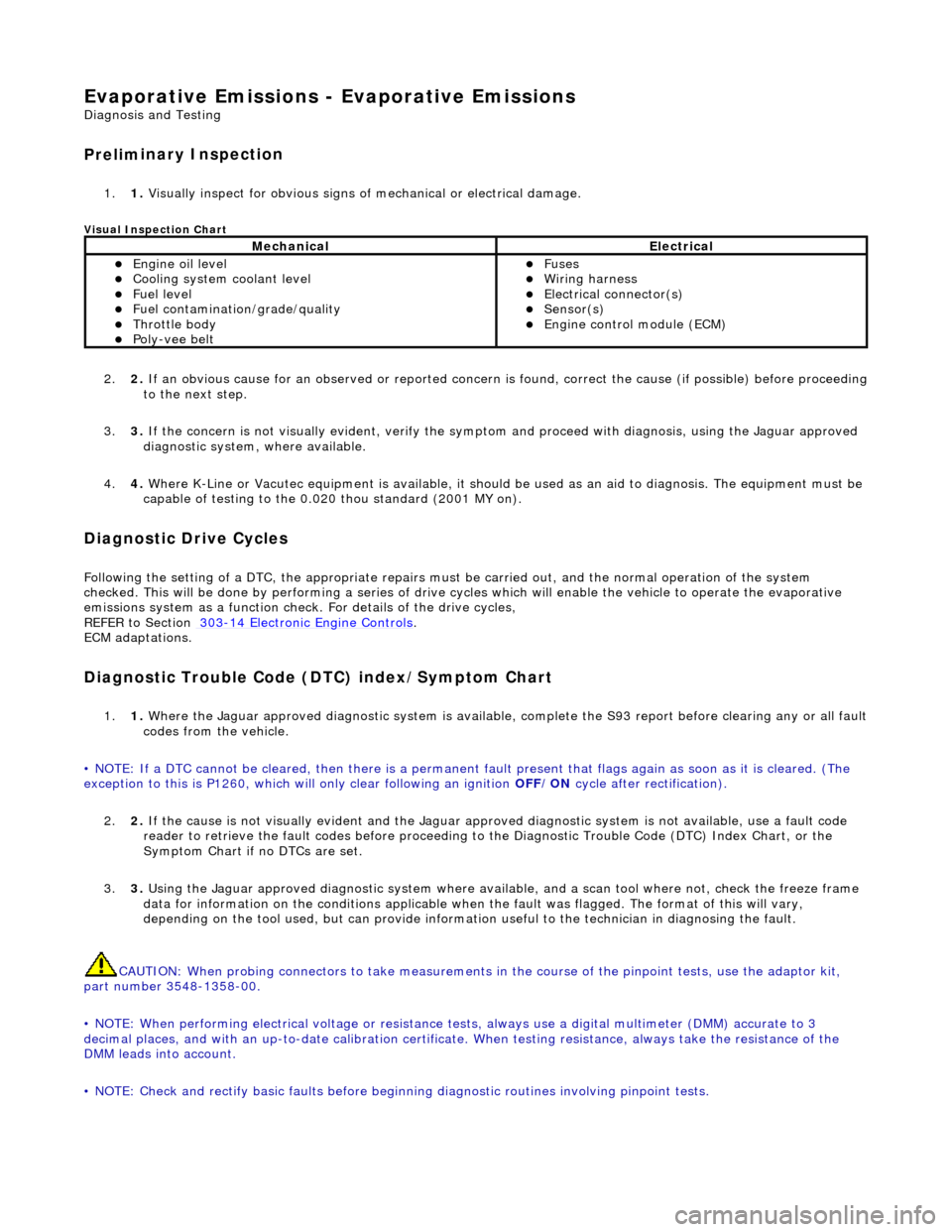

E

vaporative Emissions - Evaporative Emissions

D

iagnosis and Testing

Prelim

inary Inspection

1.

1. Vis

ually inspect for obvious signs of mechanical or electrical damage.

V

isual Inspection Chart

2.

2. If

an obvious cause for an observed or

reported concern is found, correct th e cause (if possible) before proceeding

to the next step.

3. 3. If the concern is not visually evident, verify the symptom and proceed with diagnosis, using the Jaguar approved

diagnostic system, where available.

4. 4. Where K-Line or Vacutec equipment is available, it should be used as an aid to diagnosis. The equipment must be

capable of testing to the 0.020 thou standard (2001 MY on).

Diagnostic Drive Cycles

Following th

e setting of a DTC, the appropriate repairs must

be carried out, and the normal operation of the system

checked. This will be done by performing a series of drive cycles which will enable the vehicle to operate the evaporative

emissions system as a function check. For details of the drive cycles,

REFER to Section 303

-1

4 Electronic Engine Controls

.

ECM adapt

ations.

Diagnostic Trouble Code

(D

TC) index/Symptom Chart

1.

1. Wh

ere the Jaguar approved diagnostic sy

stem is available, complete the S93 report before clearing any or all fault

codes from the vehicle.

• NOTE: If a DTC cannot be cleared, then there is a permanent fault present that flag s again as soon as it is cleared. (The

exception to this is P1260, which will only clear following an ignition OFF/ON cycle after rectification).

2. 2. If the cause is not visually evident and the Jaguar approv ed diagnostic system is not available, use a fault code

reader to retrieve the fault codes be fore proceeding to the Diagnostic Trou ble Code (DTC) Index Chart, or the

Symptom Chart if no DTCs are set.

3. 3. Using the Jaguar approved diagnostic system where available, and a scan tool where not, check the freeze frame

data for information on the conditions applicable when the fault was flagged. The format of this will vary,

depending on the tool used, but can pr ovide information useful to the technician in diagnosing the fault.

CAUTION: When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit,

part number 3548-1358-00.

• NOTE: When performing electrical voltag e or resistance tests, always use a digital multimeter (DMM) accurate to 3

decimal places, and with an up-t o-date calibration certificate. When testing resistance, always take the resistance of the

DMM leads into account.

• NOTE: Check and rectify basic faults before beginning diagnostic ro utines involving pinpoint tests.

MechanicalElectrical

Engi

ne oil level

Coo

ling system coolant level

Fue

l level

Fuel contaminatio

n

/grade/quality

Throttle body Poly

-vee belt

F

uses

W

iring harness

E

lectrical connector(s)

Sens

or(s)

Engine

control module (ECM)

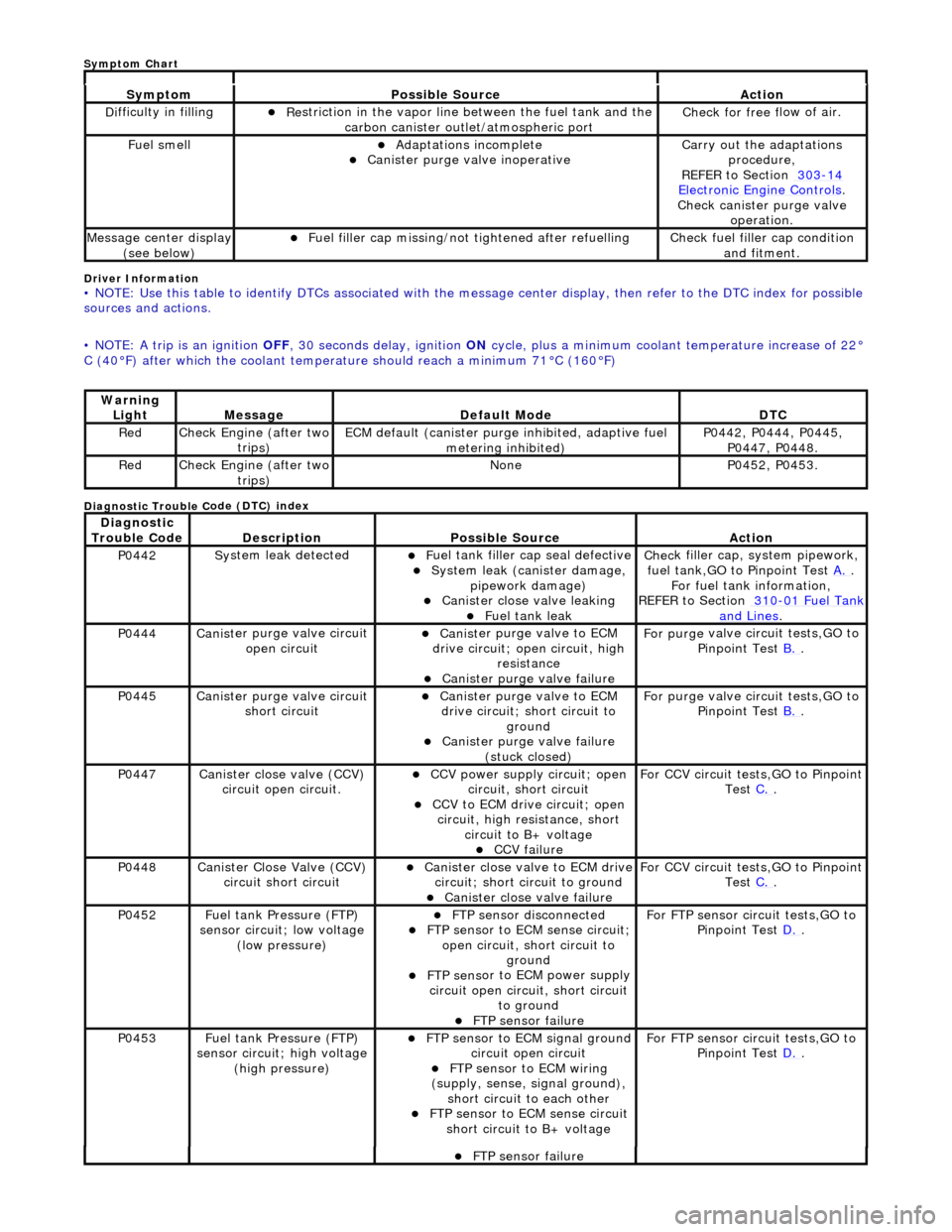

Page 1162 of 2490

Driver Info

rmation

•

NOTE: Use this table to identify DTCs associated with the me

ssage center display, then refer to the DTC index for possible

sources and actions.

• NOTE: A trip is an ignition OFF, 30 seconds delay, ignition ON cycle, plus a minimum coolant temperature increase of 22°

C (40°F) after which the coolant temperat ure should reach a minimum 71°C (160°F)

Diagnostic Trouble C

ode (DTC) index

Sy

m

ptom

Possib

l

e Source

Acti

o

n

D

i

fficulty in filling

R

e

striction in the vapor line between the fuel tank and the

carbon canister outlet/atmospheric port

Check f or free f

low of air.

F

u

el smell

Adaptat

i

ons incomplete

Cani

st

er purge valve inoperative

Carry

o

ut the adaptations

procedure,

REFER to Section 303

-14 Ele c

tronic Engine Controls

.

Chec k cani

ster purge valve

operation.

M e

ssage center display

(see below)

Fue l

filler cap missing/not

tightened after refuelling

Check fu

el filler cap condition

and fitment.

Warning Li

ght

Mess

age Defaul

t Mode

DT

C

RedCheck Engine (after two

trip

s)

ECM de

fa

ult (canister purge inhibited, adaptive fuel

metering inhibited)

P0442,

P0444, P0445,

P0447, P0448.

Re dCheck Engine (after two

trip

s)

No

neP04 52,

P0453.

Di

agno

stic

Trouble Code

De scr

iption

Possib

l

e Source

Acti

o

n

P0442Sy

st

em leak detected

F

u

el tank filler cap seal defective

Sy

ste

m leak (c

anister damage,

pipework damage)

Cani st

er close valve leaking

F

u

el tank leak

Chec

k fi

ller cap,

system pipework,

fuel tank,GO to Pinpoint Test A.

.

F o

r fuel tank information,

REFER to Section 310

-01 Fu

el Tank

and Lines.

P0444Canist

er purge valve circuit

open circuit

Cani st

er purge valve to ECM

drive circuit; open circuit, high

resistance

Cani st

er purge valve failure

F

or purge

valve circuit tests,GO to

Pinpoint Test B.

.

P0445Canist

er purge valve circuit

short circuit

Cani st

er purge valve to ECM

drive circuit; short circuit to ground

Canist

er purge valve failure

(stuck closed)

F or purge

valve circuit tests,GO to

Pinpoint Test B.

.

P0447Canist

er close valve (CCV)

circuit open circuit.

CCV power su pply ci

rcuit; open

circuit, short circuit

CCV to ECM drive circuit;

open

circuit, high resistance, short circuit to B+ voltage

CCV failure

Fo

r CCV circuit tests,GO to Pinpoint

Test C.

.

P0448Canist

er Close Valve (CCV)

circuit short circuit

Cani st

er close valve to ECM drive

circuit; short circuit to ground

Cani st

er close valve failure

F

o

r CCV circuit tests,GO to Pinpoint

Test C.

.

P0452 Fu

el tank Pressure (FTP)

sensor circuit; low voltage (low pressure)

FTP sen

sor disconnected

FTP sen

sor to ECM sense circuit;

open circuit, short circuit to ground

FTP sens

or to ECM power supply

circuit open circuit, short circuit to ground

FT

P sensor failure

For FT

P se

nsor circuit tests,GO to

Pinpoint Test D.

.

P0453Fu

el tank Pressure (FTP)

sensor circuit; high voltage

(high pressure)

FTP sen

sor to ECM signal ground

circuit open circuit

F T

P sensor to ECM wiring

(supply, sense, signal ground),

short circuit to each other

FTP sen

sor to ECM sense circuit

short circuit to B+ voltage

For FT P se

nsor circuit tests,GO to

Pinpoint Test D.

.

FT

P sensor failure

Sym

ptom Chart

Page 1163 of 2490

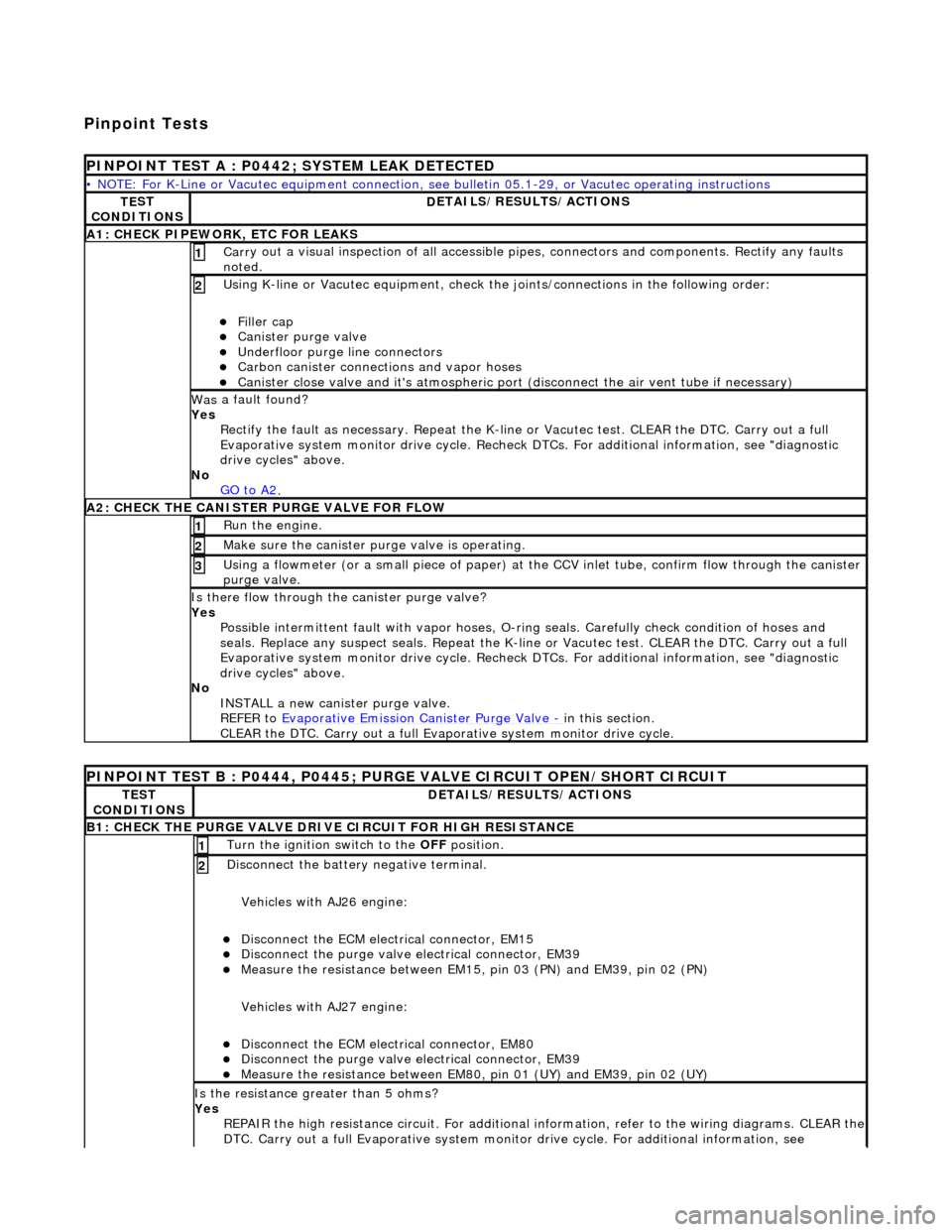

Pinpoint Tests

P

INPOINT TEST A : P0442; SYSTEM LEAK DETECTED

•

NOTE: For K-Line or Vacutec equipment connection, see bulletin 05.1-29, or Vacutec operating instructions

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

A

1: CHECK PIPEWORK, ETC FOR LEAKS

Carr

y out a visual inspection of all accessible pipes, connectors and components. Rectify any faults

noted.

1

U

sing K-line or Vacutec equipment, check the

joints/connections in the following order:

Fi

ller cap

Cani

ster purge valve

Underfl

oor purge line connectors

Carbon

canister connections and vapor hoses

Cani

ster close valve and it's atmospheric port (disconnect the air vent tube if necessary)

2

Was

a fault found?

Yes Rectify the fault as necessary. Re peat the K-line or Vacutec test. CLEAR the DTC. Carry out a full

Evaporative system monitor drive cycle. Recheck DT Cs. For additional information, see "diagnostic

drive cycles" above.

No GO to A2

.

A2: CHECK

THE CA

NISTER PURGE VALVE FOR FLOW

Ru

n the engine.

1

Make sure the canister purge

valve is operating.

2

Using a flowmeter

(or a small piece

of paper) at the CCV inlet tube, confirm flow through the canister

purge valve.

3

Is th

ere flow through the canister purge valve?

Yes Possible intermittent faul t with vapor hoses, O-ring seals. Carefully check condition of hoses and

seals. Replace any suspect seals. Repeat the K-line or Vacutec test. CLEAR the DTC. Carry out a full

Evaporative system monitor drive cycle. Recheck DT Cs. For additional information, see "diagnostic

drive cycles" above.

No INSTALL a new canister purge valve.

REFER to Evaporative Emission Canister Purge Valve

- in t

his section.

CLEAR the DTC. Carry out a full Evap orative system monitor drive cycle.

P

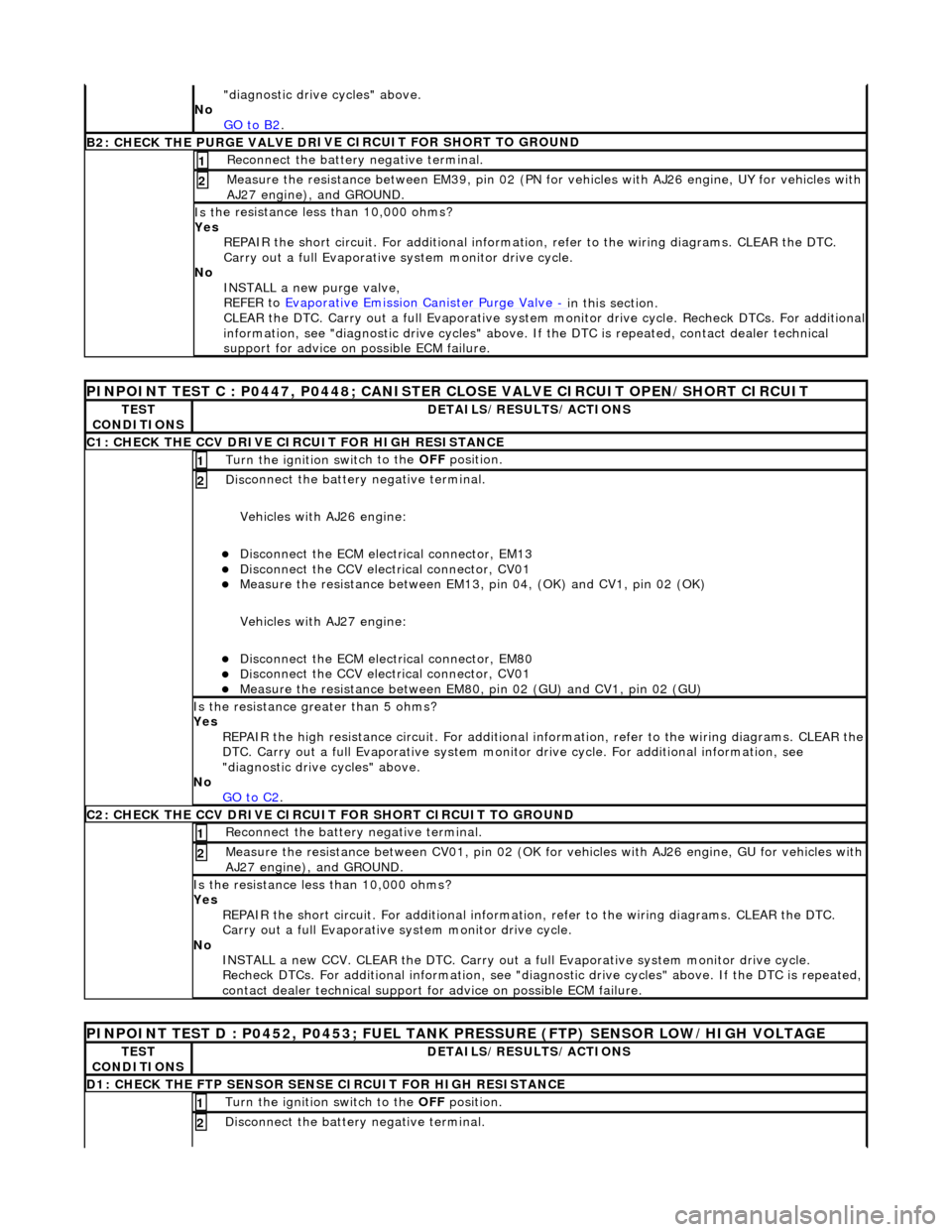

INPOINT TEST B : P0444, P0445; PURGE VALVE CIRCUIT OPEN/SHORT CIRCUIT

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

B1: CHECK

THE PURGE VALVE DRIV

E CIRCUIT FOR HIGH RESISTANCE

Turn the ignition swi

tch to the OFF

position.

1

Di

sconnect the battery negative terminal.

Vehicles with AJ26 engine:

Disc

onnect the ECM electrical connector, EM15

Di

sconnect the purge valve electrical connector, EM39

Meas

ure the resistance between EM15,

pin 03 (PN) and EM39, pin 02 (PN)

Vehicles with AJ27 engine:

Disc

onnect the ECM electrical connector, EM80

Di

sconnect the purge valve electrical connector, EM39

Meas

ure the resistance between EM80, pin 01 (UY) and EM39, pin 02 (UY)

2

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. Carry out a full Evaporative system monitor drive cycle. For additional information, see

Page 1164 of 2490

"d

iagnostic drive cycles" above.

No GO to B2

.

B2: CHECK THE PURGE VALVE DR

IV

E CIRCUIT FOR SHORT TO GROUND

Re

connect the battery negative terminal.

1

Meas

ure t

he resistance between EM39, pin 02 (PN for vehicles with AJ26

engine, UY for vehicles with

AJ27 engine), and GROUND.

2

Is t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

Carry out a full Evaporative system monitor drive cycle.

No INSTALL a new purge valve,

REFER to Evaporative Emission Canister Purge Valve

- in thi

s section.

CLEAR the DTC. Carry out a full Evaporative system monitor drive cycle. Recheck DTCs. For additional

information, see "diagnostic drive cycles" above. If the DTC is repeated, contact dealer technical

support for advice on possible ECM failure.

PI

NPOINT TEST C : P0447, P0448; CANISTER CLOSE VALVE CIRCUIT OPEN/SHORT CIRCUIT

TE

S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

C1

: CH

ECK THE CCV DRIVE CIRCUIT FOR HIGH RESISTANCE

Turn the ignition swi

t

ch to the

OFF position.

1

Disc

onnect the battery negative terminal.

Vehicles with AJ26 engine:

Disc onne

ct the ECM electrical connector, EM13

Di

sc

onnect the CCV electrical connector, CV01

Meas

ure t

he resistance between EM13, pi

n 04, (OK) and CV1, pin 02 (OK)

Vehicles with AJ27 engine:

Disc onne

ct the ECM electrical connector, EM80

Di

sc

onnect the CCV electrical connector, CV01

Meas

ure t

he resistance between EM80,

pin 02 (GU) and CV1, pin 02 (GU)

2

Is the res

istance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. Carry out a full Evaporative system monitor drive cycle. For additional information, see

"diagnostic drive cycles" above.

No GO to C2

.

C2: CH

ECK THE CCV DRIVE CIRCUI

T FOR SHORT CIRCUIT TO GROUND

Re

connect the battery negative terminal.

1

Meas

ure t

he resistance between CV01,

pin 02 (OK for vehicles with AJ26 engine, GU for vehicles with

AJ27 engine), and GROUND.

2

Is t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

Carry out a full Evaporative system monitor drive cycle.

No INSTALL a new CCV. CLEAR the DTC. Carry out a fu ll Evaporative system monitor drive cycle.

Recheck DTCs. For additional inform ation, see "diagnostic drive cycles" above. If the DTC is repeated,

contact dealer technical support for advice on possible ECM failure.

P INPOINT TES

T D : P0452, P0453; FUEL TANK

PRESSURE (FTP) SENSOR LOW/HIGH VOLTAGE

TES

T

CONDITIONS

DE

TAILS/RESULTS/ACTIONS

D

1:

CHECK THE FTP SENSOR SENSE CIRCUIT FOR HIGH RESISTANCE

Turn the ignition swi

t

ch to the OFF

position.

1

Disc

onnect the battery negative terminal.

2

Page 1165 of 2490

Vehicles with AJ26 en

gine:

D

isconnect the ECM electrical connector, EM11

Di

sconnect the FTP sensor electrical connector, FP01

Meas

ure the resistance between EM11,

pin 07 (RG) and FP01, pin 02 (RG)

Vehicles with AJ27 engine:

D

isconnect the ECM electrical connector, EM81

Di

sconnect the FTP sensor electrical connector, FP01

Meas

ure the resistance between EM81,

pin 16 (RG) and FP01, pin 02 (RG)

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. Carry out a full Evaporative system monitor drive cycle. For additional information, see

"diagnostic drive cycles" above.

No GO to D2

.

D2: CHECK

THE FTP SENSOR SENSE CI

RCUIT FOR SHORT CIRCUIT TO GROUND

R

econnect the battery negative terminal.

1

Meas

ure the resistance between

FP01, pin 07 (RG) and GROUND.

2

Is

the resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

Carry out a full Evaporative system monitor drive cycle.

No GO to D4

.

D3: CHECK

THE FTP SENSOR SENSE CIRCUI

T FOR SHORT CIRCUIT TO HIGH VOLTAGE

Turn the ignition swi

tch to the ON

position.

1

Measure the

voltage between FP

01, pin 02 (RG) and GROUND.

2

Is th

e voltage greater than 3 volts?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

Carry out a full Evaporative system monitor drive cycle.

No GO to D4

.

D

4: CHECK THE FTP SENSOR SIGNAL GROUND CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

Vehicles with AJ26 engine:

D

isconnect the ECM electrical connector, EM10

Meas

ure the resistance between EM11, pin 12 (BG) and FP01, pin 01 (BG)

Meas

ure the resistance between EM10, pin 20 (BG) and FP01, pin 01 (BG)

Vehicles with AJ27 engine:

Re

connect the ECM electrical connector, EM81

D

isconnect the ECM electrical connector, EM82

D

isconnect the ECM electrical connector, EM83

Meas

ure the resistance between EM82, pin 07 (BG) and FP01, pin 01 (BG)

Meas

ure the resistance between EM83, pin 13 (BG) and FP01, pin 01 (BG)

1

Is either resi

stance

greater than 5 ohms?

Yes REPAIR the high resistance circui t. This circuit includes harness splice, EMS02. For additional

information, refer to the wiring diagrams. CLEAR the DTC. Carry out a full Evaporative system

monitor drive cycle. For additional informat ion, see "diagnostic drive cycles" above.

No GO to D5

.

D5:

CHECK THE FTP SENSOR SIGNAL GROUND

CIRCUIT FOR SHORT CIRCUIT TO GROUND

R

econnect the battery negative terminal.

1

Meas

ure the resistance between

FP01, pin 01 (BG) and GROUND.

2

Is

the resistance less than 10,000 ohms?