filter JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1197 of 2490

Exhaus

t leak

Low e

xhaust temperature

Cat

alyst monitor sensor failure

P0151Le

ft-hand H02S sense circuit low

voltage

H02

S disconnected

H0

2S to ECM wiring open circuit

H0

2S short circuit to ground

H0

2S failure

F

or left-hand HO2S circuit tests, GO

to Pinpoint Test H.

.

P0152Le

ft-hand H02S sense circuit high

voltage

H02

S sensing circuit short circuit to

high voltage

H0

2S ground braided shield open

circuit

H0

2S failure

F

or left-hand HO2S circuit tests,GO to

Pinpoint Test H.

.

P0153Le

ft-hand H02S sense circuit slow

response

Engine

misfire

H02

S disconnected

H0

2S mechanical damage

H0

2S to ECM wiring intermittent

open circuit

H02

S sensing circuit short circuit to

high voltage

H0

2S short circuit to ground

H0

2S ground braided shield open

circuit

H0

2S heater circuit fault

Exhaus

t leak

Low e

xhaust temperature

Injector fl

ow partially blocked

Catal

yst efficiency decrease

H0

2S failure

Chec

k for 'engine misfire detected'

DTCs. For HO2S circ uit tests, GO to

Pinpoint Test H.

. Check for exhaust

leak

s,

REFER to Section 309

-00

Exhaust

Sy

stem

.

Chec

k injectors,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0155Left-hand H02S heater

circuit

malfunction

H02

S disconnected

H0

2S heater power supply open

circuit

H0

2S heater to ECM wiring short

circuit or open circuit

H0

2S heater failure

F

or left-hand HO2S heater circuit

tests,GO to Pinpoint Test I.

.

P0157Le

ft-hand catalyst monitor sensor

sense circuit low voltage

Catal

yst monitor sensor

disconnected

Catal

yst monitor sensor to ECM

wiring open circuit

Catal

yst monitor sensor short

circuit to ground

Cat

alyst monitor sensor failure

F

or left-hand catalyst monitor sensor

circuit tests,GO to Pinpoint Test J.

.

P0158Le

ft-hand catalyst monitor sensor

sense circuit high voltage

Catal

yst monitor sensor sensing

circuit short circuit to high voltage

Catalyst

monitor sensor ground

braided shield open circuit

Cat

alyst monitor sensor failure

F

or left-hand catalyst monitor sensor

circuit tests,GO to Pinpoint Test J.

.

P0160Le

ft-hand catalyst monitor sensor

sense circuit no activity

Catal

yst monitor sensor

disconnected

Catal

yst monitor sensor

mechanical damage

Catal

yst monitor sensor to ECM

wiring open circuit

Catal

yst monitor sensor sensing

circuit short circuit to high voltage

Catal

yst monitor sensor short

circuit to ground

Catalyst

monitor sensor ground

braided shield open circuit

Exhaus

t leak

Low e

xhaust temperature

Cat

alyst monitor sensor failure

F

or left-hand catalyst monitor sensor

circuit tests,GO to Pinpoint Test J.

.

Check f

or exhaust leaks,

REFER to Section 309

-00

Exhaust

Sy

stem

.

P0171Right

-hand cylinders combustion

too lean

Air

intake leak between MAF senso

r and th

rottle

F

uel filter system blockage

F

uel injector blockage

F

uel pressure regulator failure (low

fuel pressure)

Low f

uel pump output

Check ai

r intake system for leaks,

REFER to Section 303

-1

2 Intake Air

Distribu

tion and Filtering

.

Check the fuel fi

lter,

REFER to Section 310

-01

Fuel Tank

and Lines.

Chec

k the fuel injectors and fuel

Page 1198 of 2490

H02S harness wiri

ng fault

E

x

haust leak (before catalyst)

ECM receivi

n

g incorrect signal from

one or more of the following

sensors - ECT, MAF, IAT, TP

pr essure regulator,

REF

ER to Section 303

-04

Fu

el

Charging and Con

t

rols

.

Chec k the

fuel pressure. Check the

exhaust system for leaks,

REFER to Section 309

-00 Ex

haust

Sy

ste

m

.

R e

fer to pinpoint tests for sensors

listed.

P0172Right -

hand cylinders combustion

too rich

Engine m

isfire

Bl

ocked air

filter

F

u

el system return blockage

Leak

i

ng fuel injector(s)

F

u

el pressure regulator failure

(high fuel pressure)

ECM receivi n

g incorrect signal from

one or more of the following

sensors - ECT, MAF, IAT, TP

Chec k for 'en

gine misfire detected'

DTCs. Check the air filter element,

REFER to Section 303

-1 2

Intake Air

Distribu

tion and Filterin

g

.

Chec k the

fuel lines,

REFER to Section 310

-01 Fu

el Tank

and Lines.

Chec k the

fuel injectors and fuel

pressure regulator,

REFER to Section 303

-04 Fu

el

Charging and Con

t

rols

.

R e

fer to pinpoint tests for sensors

listed.

P0174L e

ft-hand cylinders combustion

too lean

Air in

take leak between MAF senso

r and th

ro

ttle

F

u

el filter system blockage

F

u

el injector blockage

F

u

el pressure regulator failure (low

fuel pressure)

Low fu

el pump output

H0

2S harness wiri

ng fault

E

x

haust leak (before catalyst)

ECM receivi

n

g incorrect signal from

one or more of the following

sensors - ECT, MAF, IAT, TP

Check the ai r intak

e system for leaks,

REFER to Section 303

-1 2

Intake Air

Distribu

tion and Filterin

g

.

Check the fuel fi lter,

REF

ER to Section 310

-01

Fu

el Tank

and Lines.

Chec k the

fuel injectors and fuel

pressure regulator,

REFER to Section 303

-04 Fu

el

Charging and Con

t

rols

.

Chec k the

fuel pressure. For HO2S

circuit tests,GO to Pinpoint Test H.

,

a n

dGO to Pinpoint Test

I.

. Check

the

exhaust system for leaks,

REFER to Section 309

-00 Ex

haust

Sy

ste

m

.

R e

fer to pinpoint tests for sensors

listed.

P0175L e

ft-hand cylinders combustion

too rich

Engine m

isfire

Bl

ocked air

filter

F

u

el system return blockage

Leak

i

ng fuel injector(s)

F

u

el pressure regulator failure

(high fuel pressure)

ECM receivi n

g incorrect signal from

one or more of the following

sensors - ECT, MAF, IAT, TP

Chec k for 'en

gine misfire detected'

DTCs. Check air filter element,

REFER to Section 303

-1 2

Intake Air

Distribu

tion and Filterin

g

.

Chec k the

fuel lines,

REFER to Section 310

-01 Fu

el Tank

and Lines.

Chec k the

fuel injectors and fuel

pressure regulator,

REFER to Section 303

-04 Fu

el

Charging and Cont

rols

.

Re

fer to pinpoint tests for sensors

listed.

P0201 Fu

el injector circuit malfunction,

cyl 1

Injector discon n

ected

Inject

or wir

ing open or short circuit

Injector fail

ure

F

o

r fuel injector

circuit tests,

REFER to Section 303

-04 Fu

el

Charging and Con

t

rols

. P0202F

u

el injector circuit malfunction,

cyl 3

P0203F u

el injector circuit malfunction,

cyl 5

P0204F u

el injector circuit malfunction,

cyl 7

P0205F u

el injector circuit malfunction,

cyl 2

P0206F u

el injector circuit malfunction,

cyl 4

P0207F u

el injector circuit malfunction,

cyl 6

P0208F u

el injector circuit malfunction,

Page 1201 of 2490

leak

/blockage

EVAP valve failure

P0444Evaporati

ve emissions system

(EVAP) valve circuit open circuit

EVAP t

o ECM drive circuit open

circuit or high resistance

EVAP failu

re

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0445Evaporati

ve emissions system

(EVAP) valve circuit short circuit

E

VAP to ECM drive circuit short

circuit to ground

EVAP failu

re

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0447Cani

ster close valve (CCV) circuit

open circuit

CCV to ECM

drive circuit open

circuit, high resi stance or short

circuit to ground

EVAP failu

re

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0448Cani

ster close valve (CCV) circuit

short circuit

CCV to

ECM drive circuit short

circuit to high voltage

CCV failure

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0452F

uel tank pressure (FTP) sensor

circuit low voltage

FTP

sensor disconnected

FTP

sensor to ECM sense circuit

open circuit or short circuit to

ground

FTP sen

sor to ECM power supply

circuit open circuit or short circuit

to ground

F

TP sensor failure

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0453F

uel tank pressure (FTP) sensor

circuit high voltage

FTP

sensor to ECM signal ground

circuit open circuit

F

TP sensor to ECM wiring (supply,

sense, signal, ground) short circuit

to each other

FTP

sensor to ECM sense circuit

short circuit to high voltage

F

TP sensor failure

F

or evaporative emissions pinpoint

tests,

REFER to Section 303

-1

3 Evaporative

Emiss

ions

.

P0460Fue

l level sense signal

performance

Fue

l level sensor

to instrument

cluster circuits in termittent short or

open circuit

F

uel level sensor failure

Instrument cluster

faul

t (incorrect

fuel level data)

F

or fuel level sensor

circuit tests,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0506Idl

e rpm lower than expected

Ai

r intake blockage

Acce

ssory drive overload

(defective/siezed component)

Thr

ottle valve stuck closed

Throttl

e assembly failure

Chec

k the air intake system.

REFER to Section 303

-1

2 Intake Air

Distribu

tion and Filtering

.

Check t

he accessory drive

components,

REFER to Section 303

-0

5 Accessory

Dr

ive

.

F

or throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0507Idle rpm

higher than expected

Inta

ke air leak between MAF

sensor and throttle

Inta

ke air leak between throttle

and engine

Engine

breather leak

Cruis

e (speed) control vacuum

failure

Thr

ottle valve stuck open

Throttl

e assembly failure

Chec

k the air intake system.

REFER to Section 303

-1

2 Intake Air

Distribu

tion and Filtering

.

Chec

k the engine breather system,

REFER to Section 303

-08

Engine

Emissi

on Control

.

F

or cruise (speed) control information,

REFER to Section 310

-03

Speed

Control.

F

or throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P0560Vehicle voltage

malfunction

ECM battery

power supply open

circuit, high resistance

F

or ECM power supply circuit tests,

GO to Pinpoint Test AD.

.

P0566Cruise (speed) contr

ol

CANCEL

switch ON fault

Cru

ise (speed) control switches

internal steering wheel short circuit

to ground

For cru

ise (speed) control circuit tests,

REFER to Section 310

-03

Speed

Page 1204 of 2490

op

en circuit

ECM ground circuit faul

t (relay coil

drive)

P1235Vacuu m

switching valve (VSV) 1

circuit range/ performance

(mechanical guard position)

Vac u

um leak/blockage between the

throttle elbow and the throttle

vacuum actuator

Vacuu m

actuator failure

Mechanica

l

guard actuator

seized/spring broken

Carr y out mechanical checks

for

vacuum leak/blockag e, failed vacuum

actuator, and broken /siezed actuator

spring.

P1236Vacuu m

switching valve (VSV) 1

(vacuum) circuit failure

VSV 1 disconne cted

VSV 1 to ECM drive circu

i

t high

resistance, open circuit or short

circuit

VSV 1 powe r supply open

circuit

VSV 1 failu

r

e

For VSV tests,

REF

ER to Section 310

-03

Sp

eed

Control.

P1237Vacuu

m

switching valve (VSV) 2

(atmosphere) circuit failure

VSV 2 disconne cted

VSV 2 to ECM drive circu

i

t high

resistance, open circuit or short

circuit

VSV 2 power supply open

circuit

VSV 2 failu

r

e

For VSV tests,

REF

ER to Section 310

-03

Sp

eed

Control.

P1238Vacuu

m

switching valve (VSV) 3

(release) circuit failure

VSV 3 disconne cted

VSV 3 to ECM drive circu

i

t high

resistance, open circuit or short

circuit

VSV 3 powe r supply open

circuit

VSV 3 failu

r

e

For VSV tests,

REF

ER to Section 310

-03

Sp

eed

Control.

P1240Sensor r

e

fere

nce voltage

malfunction (throttle sensors, fuel

tank pressure se nsor) (ECM pins

EM10-21; EM11-8)

ECM t o

sensors reference voltage

short circuit to ground, short circuit

to high voltage, op en circuit, high

resistance

TP sensor , pedal position and

mechan

ical guard sensor(s), fuel

tank pressure sens or failure(s)

Fo

r sensor reference voltage circuit

tests,GO to Pinpoint Test V.

.

P1241Sensor re

ferenc

e voltage low

(throttle sensors, fuel tank

pressure sensor) (ECM pins EM10-

21; EM11-8)

ECM t o

sensors reference voltage

short circuit to ground

TP sensor , APP

and mechanical

guard sensor(s), fuel tank pressure

sensor failure(s)

F o

r sensor reference voltage circuit

tests,GO to Pinpoint Test V.

.

P1242Sensor re

ferenc

e voltage high

(throttle sensors, fuel tank

pressure sensor) (ECM pins EM10-

21; EM11-8)

ECM t o

sensors reference voltage

circuit open circuit, high resistance,

short circuit to high voltage

TP sensor , APP

and mechanical

guard sensor(s), fuel tank pressure

sensor failure(s)

F o

r sensor reference voltage circuit

tests,GO to Pinpoint Test V.

.

P1243Sensor re

ference ground

malfunction (throttle sensors, fuel

tank pressure sensor, ECT sensor,

IAT sensor, IAT sensor 2) (ECM

pins EM10-20; EM11-12)

ECM t o

sensors reference ground

circuit open circuit, high resistance

Throttle sensors, fuel

tank pressure

sensor, ECT sensor, IAT sensor,

IAT sensor 2 failures

F o

r sensor reference ground circuit

tests,GO to Pinpoint Test W.

.

P1245Engine crank signal low voltage Starter relay coi

l to ECM/BPM

circuit open circuit

For en gin

e crank circuit tests,GO to

Pinpoint Test X.

.

P1246Engine crank signal high voltage Starter relay coi

l to ECM/BPM

circuit short circuit to B+ voltage

B P

M failure

For en

gin

e crank circuit tests,GO to

Pinpoint Test X.

.

P1250Engine load

malfunction

Air in

take leak

Engine breath

er leak

TP sens

or circuit fault (DTC P0121)

Throttle

valve spring failure

Check air i

ntake system for leaks,

REFER to Section 303

-12

Intake Air

Distribution and Filterin

g

.

Check engi

ne breather system for

leaks,

REFER to Section 303

-08 En

gine

Emissi

on Control.

Se e

pinpoint test for P0121. For

throttle body information,

REFER to Section 303

-04 Fu

el

Charging and Con

t

rols

.

P1251Thr

o

ttle position malfunction

(engine off)

TP sensor to ECM wiri

ng open

circuit or high resistance

F o

r TP sensor circ

uit tests,GO to

Pinpoint Test D.

, andGO to Pinpoint

Page 1207 of 2490

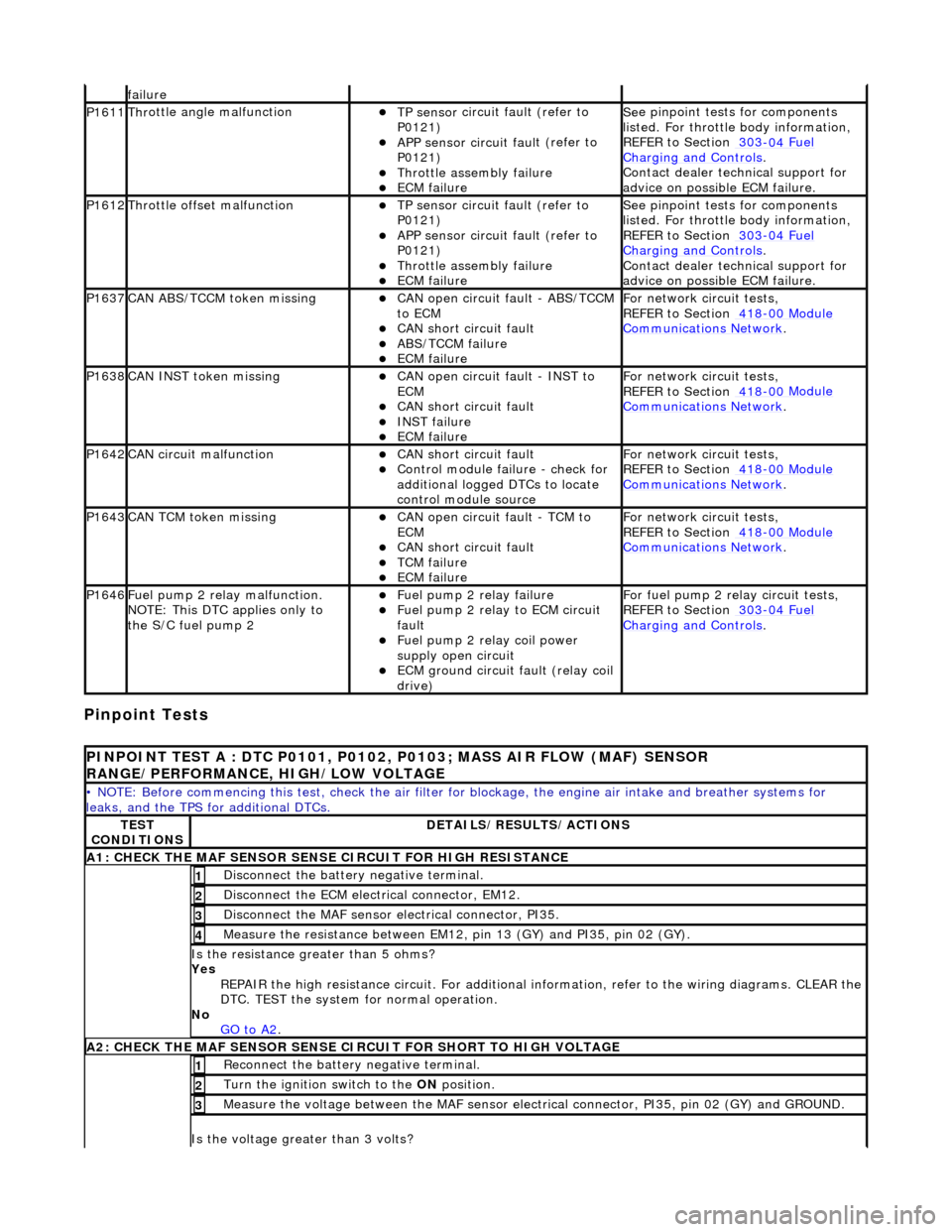

Pinpoint Tests

f

ailure

P1611Thr

ottle angle malfunction

TP sensor

circuit fault (refer to

P0121)

APP sensor circuit faul

t (refer to

P0121)

Throttl

e assembly failure

ECM failu

re

Se

e pinpoint tests for components

listed. For throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

Contact deal

er technical support for

advice on possible ECM failure.

P1612Throttl

e offset malfunction

TP sensor

circuit fault (refer to

P0121)

APP sensor circuit faul

t (refer to

P0121)

Throttl

e assembly failure

ECM failu

re

Se

e pinpoint tests for components

listed. For throttle body information,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

Contact deal

er technical support for

advice on possible ECM failure.

P1637CAN AB

S/TCCM token missing

CAN

open circuit fault - ABS/TCCM

to ECM

CAN s

hort circuit fault

ABS/TCCM failu

re

ECM failu

re

F

or network circuit tests,

REFER to Section 418

-00

Module

Comm

unications Network

.

P1638CAN INST token missingCAN

open circuit fault - INST to

ECM

CAN s

hort circuit fault

INST

failure

ECM failu

re

F

or network circuit tests,

REFER to Section 418

-00

Module

Comm

unications Network

.

P1642CAN c

ircuit malfunction

CAN s

hort circuit fault

Control modul

e failure - check for

additional logged DTCs to locate

control module source

F

or network circuit tests,

REFER to Section 418

-00

Module

Comm

unications Network

.

P1643CAN TC

M token missing

CAN

open circuit fault - TCM to

ECM

CAN s

hort circuit fault

TCM failure

ECM failu

re

F

or network circuit tests,

REFER to Section 418

-00

Module

Comm

unications Network

.

P1646F

uel pump 2 relay malfunction.

NOTE: This DTC applies only to

the S/C fuel pump 2

F

uel pump 2 relay failure

F

uel pump 2 relay to ECM circuit

fault

F

uel pump 2 relay coil power

supply open circuit

ECM ground circuit faul

t (relay coil

drive)

F

or fuel pump 2 relay circuit tests,

REFER to Section 303

-04

Fuel

Charging and Con

trols

.

P

INPOINT TEST A : DTC P0101, P0102, P0103; MASS AIR FLOW (MAF) SENSOR

RANGE/PERFORMANCE, HIGH/LOW VOLTAGE

•

NOTE: Before commencing this

test, check the air filter for blockage, the engine air inta ke and breather systems for

leaks, and the TPS for additional DTCs.

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

A1: CHECK

THE MAF SENSOR SENS

E CIRCUIT FOR HIGH RESISTANCE

Di

sconnect the battery negative terminal.

1

D

isconnect the ECM electrical connector, EM12.

2

Di

sconnect the MAF sensor electrical connector, PI35.

3

Meas

ure the resistance between EM12, pin 13 (GY) and PI35, pin 02 (GY).

4

Is th

e resistance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No GO to A2

.

A2: CHECK

THE MAF SENSOR SENSE CI

RCUIT FOR SHORT TO HIGH VOLTAGE

R

econnect the battery negative terminal.

1

Turn the ignition swi

tch to the ON

position.

2

M

easure the voltage between the MAF sensor electrical connector, PI35, pin 02 (GY) and GROUND.

3

Is th

e voltage greater than 3 volts?

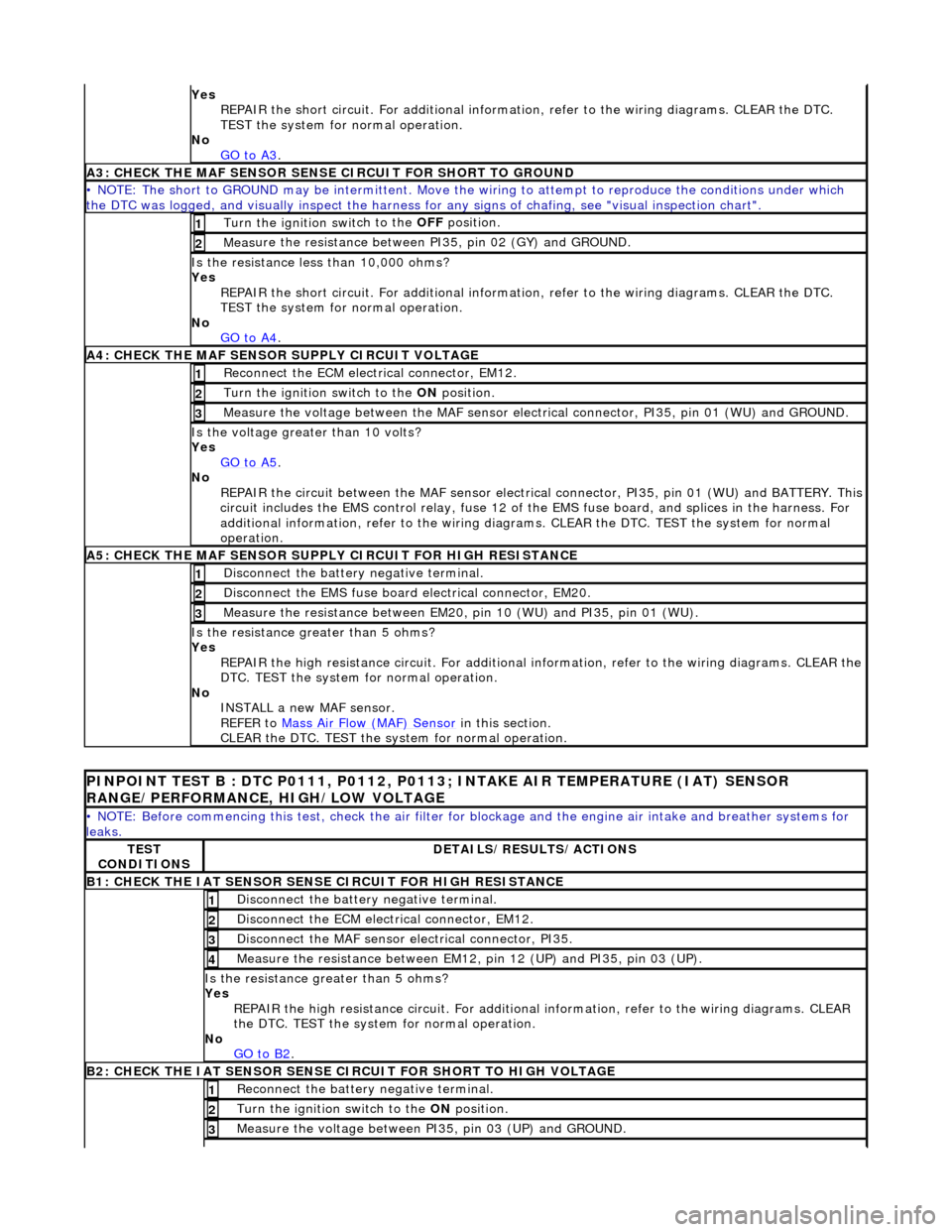

Page 1208 of 2490

Yes

R

EPAIR the short circuit. For addi

tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to A3

.

A3: CHECK THE MAF SENSO

R SENS

E CIRCUIT FOR SHORT TO GROUND

• NO

TE: The short to GROUND may be intermittent. Move the

wiring to attempt to reproduce the conditions under which

the DTC was logged, and visually inspect the harness for any signs of chafing, see "visual inspection chart".

Turn the ignition swit

ch to the OFF

position.

1

Measure t

he resistance between PI35, pin 02 (GY) and GROUND.

2

Is t

he resistance less than 10,000 ohms?

Yes REPAIR the short circuit. For addi tional information, refer to the wiring diagrams. CLEAR the DTC.

TEST the system for normal operation.

No GO to A4

.

A4: CHEC K THE MA

F SENSOR SUPPLY CIRCUIT VOLTAGE

Re

conn

ect the ECM electrical connector, EM12.

1

Turn the ignition swi

t

ch to the ON

position.

2

Me

asure the voltage between the MAF sensor electrical connector, PI35, pin 01 (WU) and GROUND.

3

Is the vol

t

age greater than 10 volts?

Yes GO to A5

.

No

REP

AIR the circuit between the MAF sensor electric

al connector, PI35, pin 01 (WU) and BATTERY. This

circuit includes the EMS control rela y, fuse 12 of the EMS fuse board, and splices in the harness. For

additional information, refer to the wiring diagrams. CLEAR the DT C. TEST the system for normal

operation.

A5: CHECK THE MAF SENSO

R SUPPLY CIRCUIT FOR HIGH RESISTANCE

Di

sc

onnect the battery negative terminal.

1

Di

sc

onnect the EMS fuse board electrical connector, EM20.

2

Meas

ure t

he resistance between EM20,

pin 10 (WU) and PI35, pin 01 (WU).

3

Is the res

istance greater than 5 ohms?

Yes REPAIR the high resistance circuit. For additional information, refer to the wiring diagrams. CLEAR the

DTC. TEST the system for normal operation.

No INSTALL a new MAF sensor.

REFER to Mass Air Flow (MAF) Sensor

in this

section.

CLEAR the DTC. TEST the system for normal operation.

P INPOINT TES

T B : DTC P0111, P0112, P0113;

INTAKE AIR TEMPERATURE (IAT) SENSOR

RANGE/PERFORMANCE, HIGH/LOW VOLTAGE

•

NOTE: Before commencing this

test, check the air filter for blockage and the engine air intake and breather systems for

leaks.

TE S

T

CONDITIONS

D E

TAILS/RESULTS/ACTIONS

B1: CHECK

THE IAT SENSOR

SENS

E CIRCUIT FOR HIGH RESISTANCE

Disc

onnect the battery negative terminal.

1

D

i

sconnect the ECM electrical connector, EM12.

2

Di

sc

onnect the MAF sensor electrical connector, PI35.

3

Me

asure

the resistance between EM12, pin 12 (UP) and PI35, pin 03 (UP).

4

Is th

e res

istance greater than 5 ohms?

Yes REPAIR the high resistance circui t. For additional information, refer to the wiring diagrams. CLEAR

the DTC. TEST the system for normal operation.

No GO to B2

.

B2: CHECK

THE IAT SENSOR SENSE CIRCUIT FOR SHORT TO HIGH VOLTAGE

R

e

connect the battery negative terminal.

1

Turn the ignition swi

t

ch to the ON

position.

2

Measure the voltage between PI 35,

pin 03 (UP) and GROUND.

3

Page 1260 of 2490

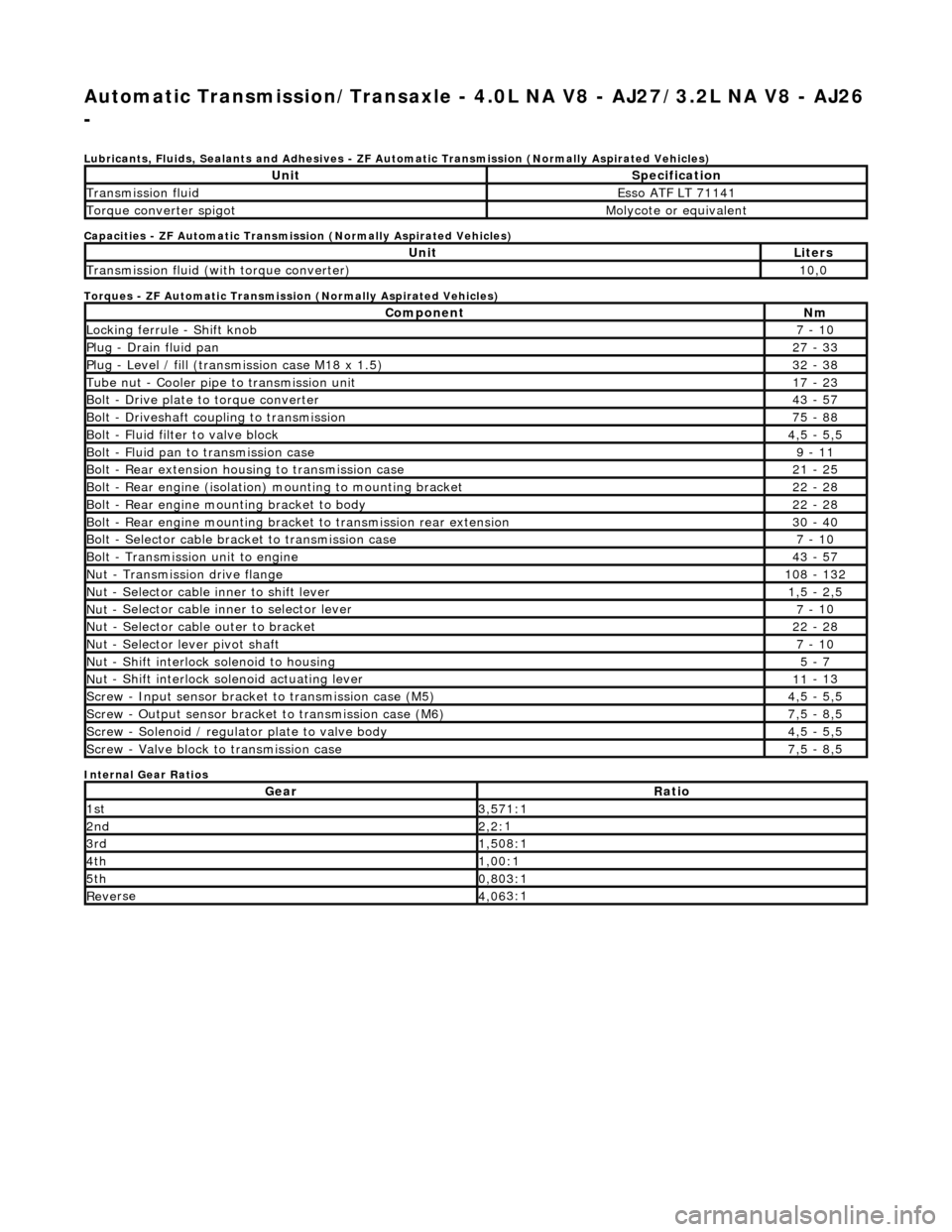

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

-

Lubri c

ants, Fluids, Sealants and Adhesives - ZF Au

tomatic Transmission (Normally Aspirated Vehicles)

Capacities - ZF Automatic Transmission (Normally Aspirated Vehicles)

Torques - ZF Automatic Transmission (Normally Aspirated Vehicles)

Internal Gear Ratios

UnitS p

ecification

Transmissi

on fluidEsso

ATF LT 71141

Torque converter spigotMolyc

o

te or equivalent

UnitLi

t

ers

Transmissi

on fluid (with

torque converter)

10

,0

Com p

onent

Nm

Locki

n

g ferrule - Shift knob

7 -

10

P

l

ug - Drain fluid pan

27

-

33

P

l

ug - Level / fill (transmission case M18 x 1.5)

32

-

38

Tu

be

nut - Cooler pipe to transmission unit

17

-

23

B

o

lt - Drive plate to torque converter

43

-

57

B

o

lt - Driveshaft coupling to transmission

75

-

88

Bo

lt

- Fluid filter to valve block

4,

5 -

5,5

Bolt

-

Fluid pan to transmission case

9 -

11

B

o

lt - Rear extension housing to transmission case

21

-

25

Bolt

-

Rear engine (isolation) mounting to mounting bracket

22

-

28

Bolt -

Rear engine moun

ting bracket to body

22

-

28

Bolt

-

Rear engine mounting bracke

t to transmission rear extension

30 -

40

B

o

lt - Selector cable bracket to transmission case

7 -

10

Bolt

-

Transmission unit to engine

43

-

57

Nu

t -

Transmission drive flange

1

08 -

132

Nu

t -

Selector cable inner to shift lever

1,

5 -

2,5

Nu

t -

Selector cable inner to selector lever

7 -

10

Nu

t -

Selector cable outer to bracket

22

-

28

Nu

t

- Selector lever pivot shaft

7 -

10

Nu

t -

Shift interlock solenoid to housing

5 -

7

Nut -

Shift interlock solenoid actuating lever

11

-

13

Sc

re

w - Input sensor bracket to transmission case (M5)

4,

5 -

5,5

Screw

-

Output sensor bracket to transmission case (M6)

7,

5 -

8,5

Screw

-

Solenoid / regulator plate to valve body

4,

5 -

5,5

Sc

re

w - Valve block to transmission case

7,

5 -

8,5

GearRatio

1s

t3,57

1:1

2n

d2,2:

1

3r

d1,50

8:1

4t

h1,00

:1

5t

h0,80

3:1

Re

ve

rse

4,

06

3:1

Page 1262 of 2490

Contains th

e hydraulic system pump.

Contains

th

e fluid temperature sensor.

The epicyclic geartrain:

Provi des fi

ve forward gears and Reverse.

Has

h

ydraulically actuated, multi-disk clutches, to select the required gear ratios.

Feature

s clutch-to-clutch operation to permit

gear shifts for uninterrupted power flow.

The electro-hydraulic control unit:

Is lo c

ated in the lower part of

the unit, within the fluid pan.

Is controlled

by the TCM (transmissio

n control module), and the manual selector valve which is cable operated.

Re

gulates the flow of fluid to the ge

artrain clutches via three solenoid-operated valv es and the manual selector

valve.

Has fi ve pressure

regulators for controll

ing fluid pressures within the system.

Is con

nected to the TCM via a 16-way connector mounted on

the left-hand side of the transmission casing. Refer to

Connector Pins Identification, Section 307-01A.

The hydraulic system pump:

Is l o

cated at the front of the transmission casing.

Is dri

v

en from the impeller hub,

pressurising the fluid whenever the engine is running.

Supplie

s fluid under pressure to the torq

ue converter, geartrain, electro-hydr aulic control unit and the lubrication

circuit.

D r

aws fluid from the fluid pa

n below the transmission casing, through a filter.

The rear extension housing:

Is bolt

ed to the rear of the transmission casing.

Provides the rear engine / transmi

ssion mo

unting point; refer to section 303-01.

Carrie

s the transmission output shaft oil seal.

Filled-for-l

i

fe Fluid System

The

transm

ission is 'filled for life' and

does not require fluid changes, except where extreme driving conditions prevail.

Routine level checking is not required and a dipstick is not pr ovided. A level / filler plug is fitted for level checking and

replenishment, following service actions; see 303-01 General Procedures.

Transmission Torque Converter

Page 1348 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Main Control Valve Body

In-vehicle Repair

Removal

1. Disconnect battery ground cable.

Remove the battery cover.

2. Raise the vehicle for access.

2. WARNING: TRANSMISSION FLUID MAY CAUSE

SEVERE BURNS, ENSURE THAT ALL SAFETY PROCEDURES

ARE OBSERVED.

Carefully remove the drain plug and drain the

transmission fluid.

3. Remove the twenty-two bolts which secure the fluid pan.

Remove the fluid pan and all tr aces of gasket material.

4. Remove the fluid filter, (44.24.07).

5. Remove the input speed sensor.

• NOTE: M5 fixing.

1. Remove the screw from the input speed sensor securing bracket and pu ll the sensor clear.

Disconnect the harness multiplug.

Page 1359 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Transmission Fluid Filter

In-vehicle Repair

Removal

Installation

1.

Raise the vehicle for access.

2. Remove the fluid pan, 44.24.04.

3. Remove and discard the fluid filter.

Remove the two bolts which secure the filter.

Discard the 'O' ring.

Clean the fluid filter mating face.

1. Installation is th e reverse of the re moval procedure.

2. Renew the 'O' ring.

3. Tighten the two bolts to the spec ified torque figure, to secure

the filter .

4. Refill the transmission with flui d. Refer to Operation 44.24.02.