egr JAGUAR X308 1998 2.G Manual Online

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1271 of 2490

Controller Area Network (CAN)

The TCM is an integral part of the CAN system which facilitates the interchange of real-time data between control modules

and sensors. Please see section 303- 14 for a full description of CAN.

OBDII Interface

Data concerning OBDII related transmission failures is stored in the ECM for access via the J1962 socket.

System Functions

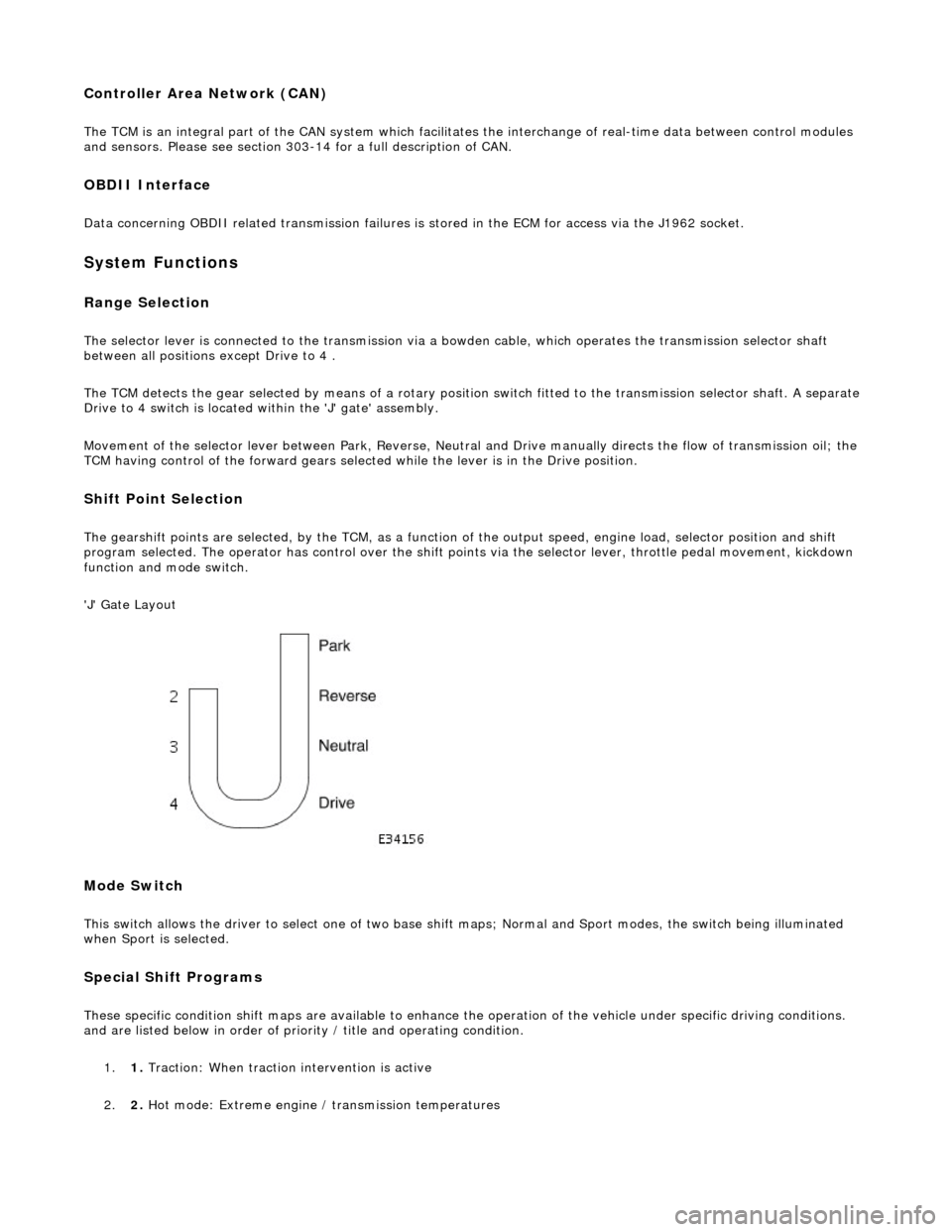

Range Selection

The selector lever is connected to the transmission via a bowden cable, which operates the transmission selector shaft

between all positions except Drive to 4 .

The TCM detects the gear selected by means of a rotary position switch fitted to the transmission selector shaft. A separate

Drive to 4 switch is located within the 'J' gate' assembly.

Movement of the selector lever between Park, Reverse, Neutral and Drive manually directs th e flow of transmission oil; the

TCM having control of the forward gears selected while the lever is in the Drive position.

Shift Point Selection

The gearshift points are selected, by the TCM, as a function of the output speed, engine load, selector position and shift

program selected. The operator has control over the shift points via the selector lever, throttle pedal movement, kickdown

function and mode switch.

'J' Gate Layout

Mode Switch

This switch allows the driver to select one of two base shift maps; Normal and Sport modes, the switch being illuminated

when Sport is selected.

Special Shift Programs

These specific condition shift maps are available to enhance the operation of the vehicle under specific driving conditions.

and are listed below in order of priority / title and operating condition.

1. 1. Traction: When traction intervention is active

2. 2. Hot mode: Extreme engine / transmission temperatures

Page 1362 of 2490

Automatic Transmission/Transaxle - 4.0L NA V8 - AJ27/3.2L NA V8 - AJ26

- Transmission Intern al Wiring Harness

In-vehicle Repair

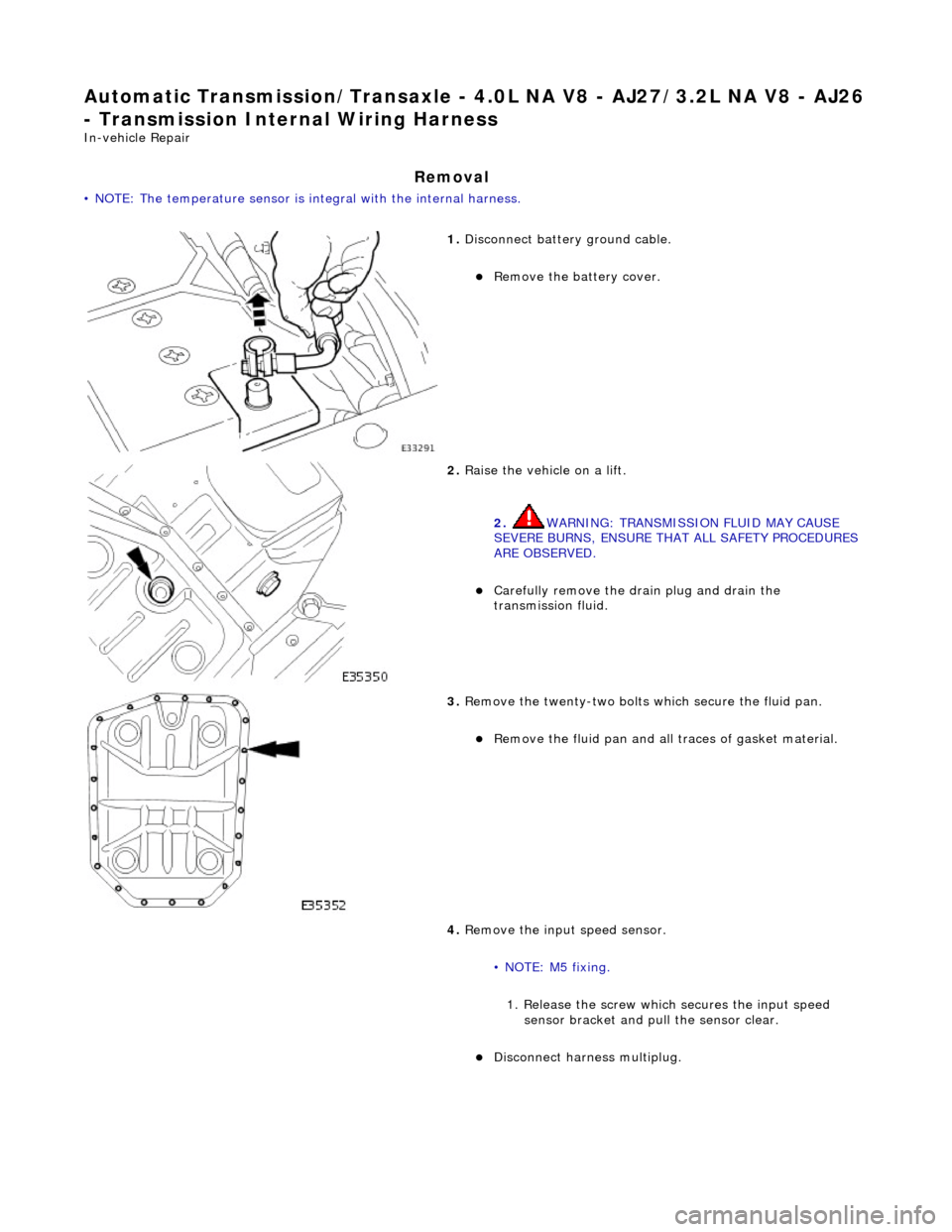

Removal

• NOTE: The temperature sensor is integral with the internal harness.

1. Disconnect battery ground cable.

Remove the battery cover.

2. Raise the vehicle on a lift.

2. WARNING: TRANSMISSION FLUID MAY CAUSE

SEVERE BURNS, ENSURE THAT ALL SAFETY PROCEDURES

ARE OBSERVED.

Carefully remove the drain plug and drain the

transmission fluid.

3. Remove the twenty-two bolts which secure the fluid pan.

Remove the fluid pan and all tr aces of gasket material.

4. Remove the input speed sensor.

• NOTE: M5 fixing. 1. Release the screw which secures the input speed sensor bracket and pull the sensor clear.

Disconnect harness multiplug.

Page 1393 of 2490

2.2. Switch OFF the ignition.

3. 3. Wait 10 seconds.

4. 4. Start the engine.

5. 5. Select R (reverse will be selected).

6. 6. Select D ( 2 will be selected).

The limp-home mode will be retained until the fault is remedied or the fault code has been erased. Intermittent faults may

be cleared by cycling the ignition OFF/ON. In certain cases the component may need to be operated before the fault code is

cleared eg. a shift solenoid.

Emergency Running (mechanica l/hydraulic limp-home mode)

Should slip be detected, due to a mechanical failure or loss of pressure, the transmission will either shift to, and hold 3 or

shift to, and hold, the last gear which was known to be alright. This condition may be cleared by cycling the ignition OFF/ON

following mechanical repair.

The operator will be made aware of certain faults by a warning message on th e instrument cluster.

Data concerning OBDII related transmission failures is stored in the ECM for access via the J1962 socket.

Safety Functions

These functions are designed to safeguard against inappropriate actions by the operator as well as system malfunctions.

The electrical and diagnostic system has been designed such that system integrity is protected at all times, the safety

concept being based on th e following three points.

1. 1. The hydraulic system has 'fail-safe' characteristics regardin g its electrical operation, such that should the power

supply be lost to the electro-hydraulic actuators the transmission will initiate a limp-home mode.

2. 2. Recognition of critical shift operation by monitoring the last element in the signal path, ie the solenoid valve, and

checking by means of redundant me asured variables relative to engine, transmission and road speeds.

3. 3. Each time the vehicle is started there is a check on the entire safety hardware and the associated program parts

and signal paths. A malfunction in this part of the system, or triggering of the safety circuit, is communicated to

the operator by a warning messag e on the instrument cluster.

CAUTION: Do not engage R or P with the vehicle in motion.

Should R be engaged with the vehicle in forward motion, the transmission will default to neutral until either the vehicle

speed decreases to 4 mph or D is selected.

Towing

The vehicle may be towed provided that:

Selector in position N Speed < 50 kph Distance < 50 km

System Functions

'J' Gate Layout

Page 1395 of 2490

and/or increased performance as appropriate.

Serial Communications Interfaces

Controller Area Network (CAN)

The TCM is an integral part of the CAN system which facilita tes the interchange of real-time data between control modules

and sensors; refer to 303-14 fo r a full description of CAN.

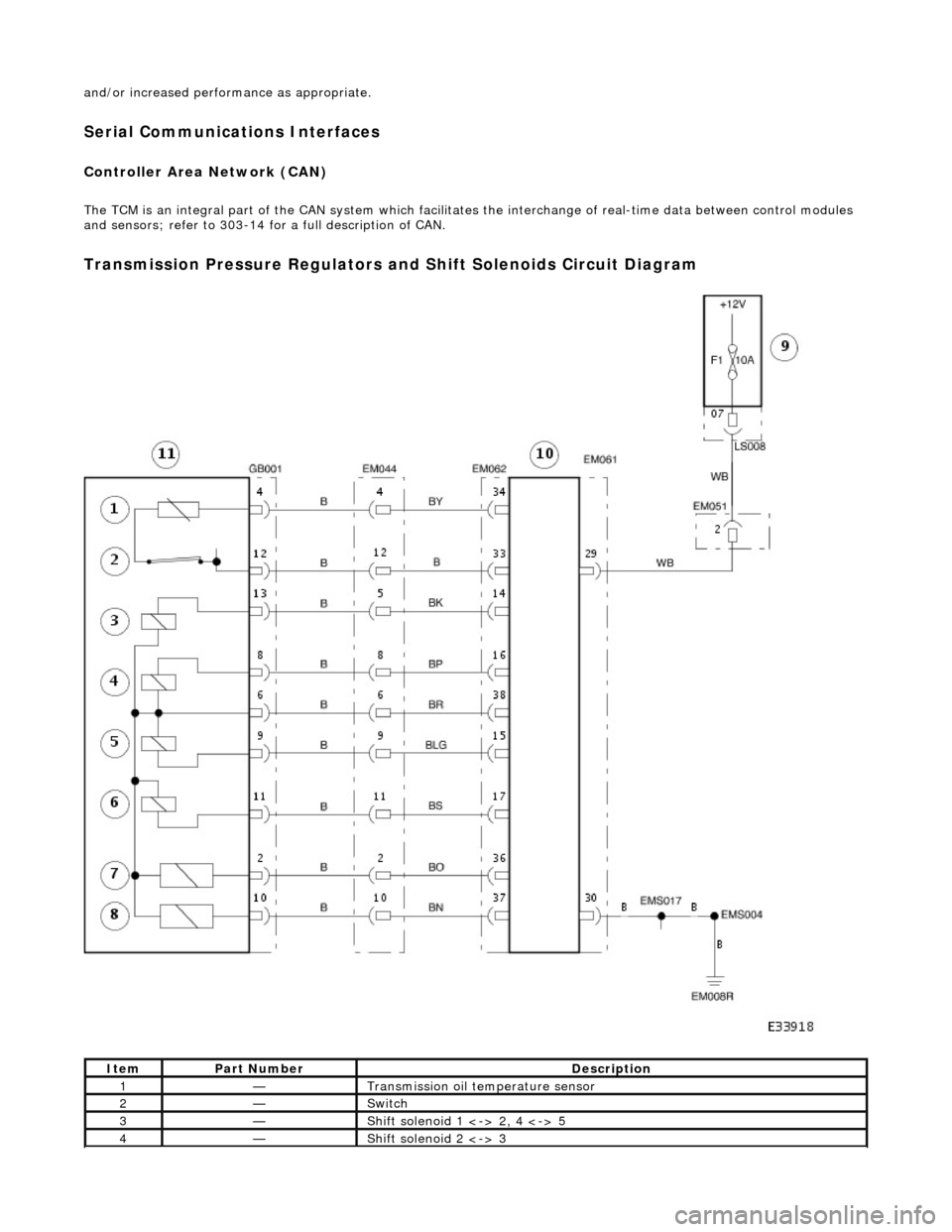

Transmission Pressure Regulators and Shift Solenoids Circuit Diagram

ItemPart NumberDescription

1—Transmission oil temperature sensor

2—Switch

3—Shift solenoid 1 <-> 2, 4 <-> 5

4—Shift solenoid 2 <-> 3

Page 1527 of 2490

Rear Muffler Assembly

The left-hand and right-hand rear muffler assemblies comprise:

Absorption type muffler. Inlet pipe and tailpipe welded to the muffler. Tailpipe bright finisher integral with the tailpipe.

Tailpipe Clearance to Moulded Bumper

Page 1597 of 2490

Pinpoint test F: P0153

With EM010 and EM015 disconnected, measure the

voltage between EM010/023 and EM015/001. 1

Is the voltage B+?

Yes Remove link lead and reconnect all connectors.

GO to E18

No Check integrity of EMS fuse F1 4, EMS control relay (relay

1) is energized and all connections are made.

GO to E18

E18: END

Perform appropriate service drive cycle and check for the

presence of DTC. 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST F : P0153

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

F1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Page 1609 of 2490

Pinpoint test G: P0157, P0158

With EM010 and EM015 disconnected, measure the

voltage between EM010/023 and EM015/002. 1

Is the voltage B+?

Yes Remove link lead and reconnect all connectors.

GO to F19

No Check integrity of EMS fuse F1 4, EMS control relay (relay

1) is energized and all connections made.

GO to F19

F19: END

Perform appropriate service drive cycle and check for the

presence of DTC. 1

Has the fault code cleared?

Yes STOP

No Contact Jaguar Service

PINPOINT TEST G : P0157, P0158

TEST CONDITIONSDETAILS/RESULTS/ACTIONS

G1: RETRIEVE DTCS

• NOTE: Battery and or ECM disconnection prior to scanning wi ll erase all data, ensure that the correct DTC is present.

Page 1692 of 2490

Fuel Tank and Lines - Fuel Tank and Li

nes

Description an

d Operation

Fuel Tank

Parts List

The steel fuel tank is located inside the trunk and mounted across the vehicle behind the passenger compartment bulkhead.

The fuel tank is held in posi tion by two retaining straps fi tted to body-mounted brackets.

The fuel tank has an integral non-adjustable fill er pipe and integral breather and vapor pipework.

A single fuel pump is mounted inside the tank on vehicles with normally aspirated engines. For vehicles with supercharged

engines, two pumps are fitted in the tank. Fuel is drawn by the pump(s) from the fuel tank and supplied via the fuel lines

and 70 micron filter to the fuel rails.

The fuel lines run from front-to-rear down the vehicle's left-hand-side.

Ite

m

Part

Number

Descr

iption

1—Fu

el filler latch box

2—Pressure reli

ef pipe, ORVR

(shown) / tank breather pipe on non-ORVR systems

3—Tank grounding

cable

4—Evaporative flan

ge assembly

(ORVR type shown)

5—Trunk elec

trical harne

ss (part of)

6—Fue

l

level sensor

flange/connector

7—Fu

el tank retaining straps

8—F

u

el tank retaining stra

ps adjustable clamps

9—Fu

el tank retaining straps lower brackets

10—Tank vapor outlet pipe to un

derflo

or pipe quick-fit connector

11—F

u

el filler latch bo

x water drain pipe

Page 1699 of 2490

Conne

ct the scan tool

1

Have the DTC(s) and fr

eeze

frame data been recorded?

Yes GO to A2

A2

: CHECK FUSE

•

NOTE: See further steps for poss

ible cause of fuse failure.

Chec

k fuse F7 integrity (located in the trunk).

1

OK

?

Yes GO to A3

No Renew fuse and test the syst em for normal operation.

A3:

CHECK SHORT TO SUPPLY

Page 1713 of 2490

Conne

ct the scan tool

1

Have the DTC(s) and fr

eeze

frame data been recorded?

Yes GO to B2

B2

: CHECK FUSE

•

NOTE: See further steps for poss

ible cause of fuse failure.

Chec

k fuse 15 integrity (located in the trunk)

1

OK

?

Yes GO to B3

No Renew fuse and test the syst em for normal operation.

B3:

CHECK SHORT TO SUPPLY