clock JAGUAR X308 1998 2.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 883 of 2490

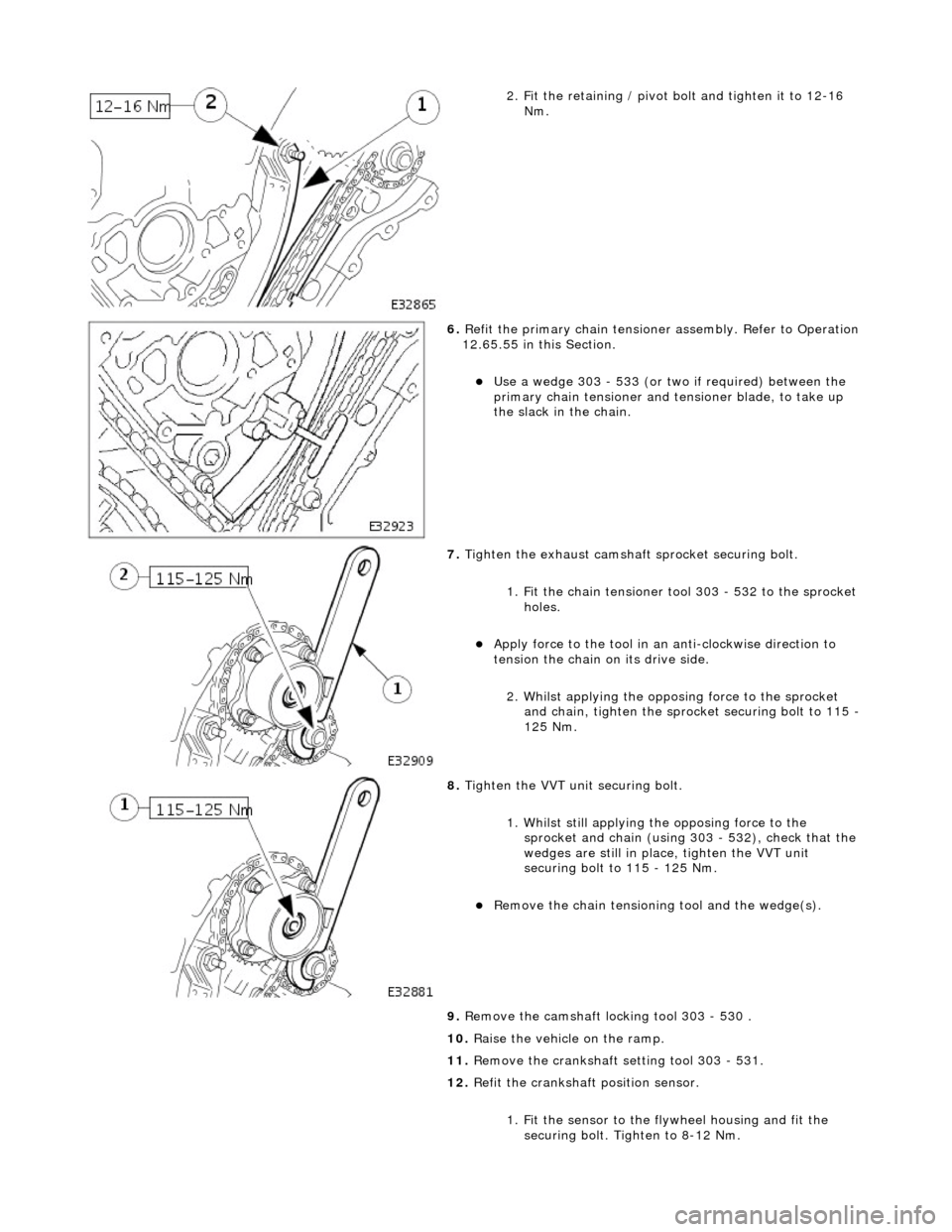

2. Fit the retaining / pivot bolt and tighten it to 12-16 Nm.

6. Refit the primary chain tensione r assembly. Refer to Operation

12.65.55 in this Section.

Use a wedge 303 - 533 (or two if required) between the

primary chain tensioner and te nsioner blade, to take up

the slack in the chain.

7. Tighten the exhaust camshaft sprocket securing bolt.

1. Fit the chain tensioner tool 303 - 532 to the sprocket holes.

Apply force to the tool in an anti-clockwise direction to

tension the chain on its drive side.

2. Whilst applying the opposing force to the sprocket and chain, tighten the sprock et securing bolt to 115 -

125 Nm.

8. Tighten the VVT unit securing bolt.

1. Whilst still applying the opposing force to the

sprocket and chain (using 303 - 532), check that the

wedges are still in place, tighten the VVT unit

securing bolt to 115 - 125 Nm.

Remove the chain tensioning tool and the wedge(s).

9. Remove the camshaft locking tool 303 - 530 .

10. Raise the vehicle on the ramp.

11. Remove the crankshaft setting tool 303 - 531.

12. Refit the crankshaft position sensor.

1. Fit the sensor to the fl ywheel housing and fit the

securing bolt. Tighten to 8-12 Nm.

Page 889 of 2490

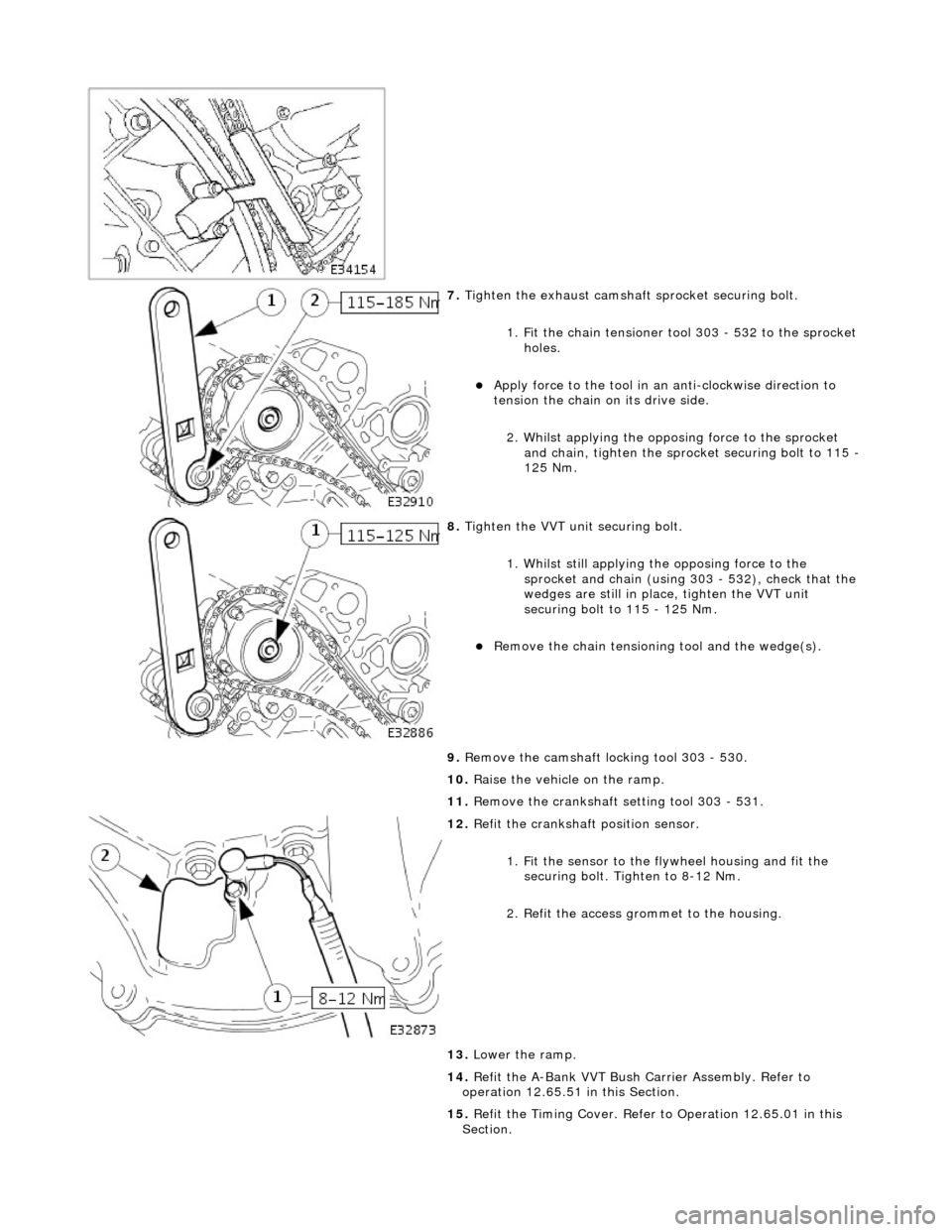

7. Tighten the exhaust camshaft sprocket securing bolt.

1. Fit the chain tensioner tool 303 - 532 to the sprocket holes.

Apply force to the tool in an anti-clockwise direction to

tension the chain on its drive side.

2. Whilst applying the opposing force to the sprocket and chain, tighten the sprock et securing bolt to 115 -

125 Nm.

8. Tighten the VVT unit securing bolt.

1. Whilst still applying the opposing force to the

sprocket and chain (using 303 - 532), check that the

wedges are still in place, tighten the VVT unit

securing bolt to 115 - 125 Nm.

Remove the chain tensioning tool and the wedge(s).

9. Remove the camshaft locking tool 303 - 530.

10. Raise the vehicle on the ramp.

11. Remove the crankshaft setting tool 303 - 531.

12. Refit the crankshaft position sensor.

1. Fit the sensor to the fl ywheel housing and fit the

securing bolt. Tighten to 8-12 Nm.

2. Refit the access grommet to the housing.

13. Lower the ramp.

14. Refit the A-Bank VVT Bush Carrier Assembly. Refer to

operation 12.65.51 in this Section.

15. Refit the Timing Cover. Refer to Operation 12.65.01 in this

Section.

Page 923 of 2490

be 'hun

g up' within the engine because it is not up to operating

temperature.

Should the oil level subsequently be topped-up, the level could

become too high, causing oil burning.

Typically, 0.875L is hung up.

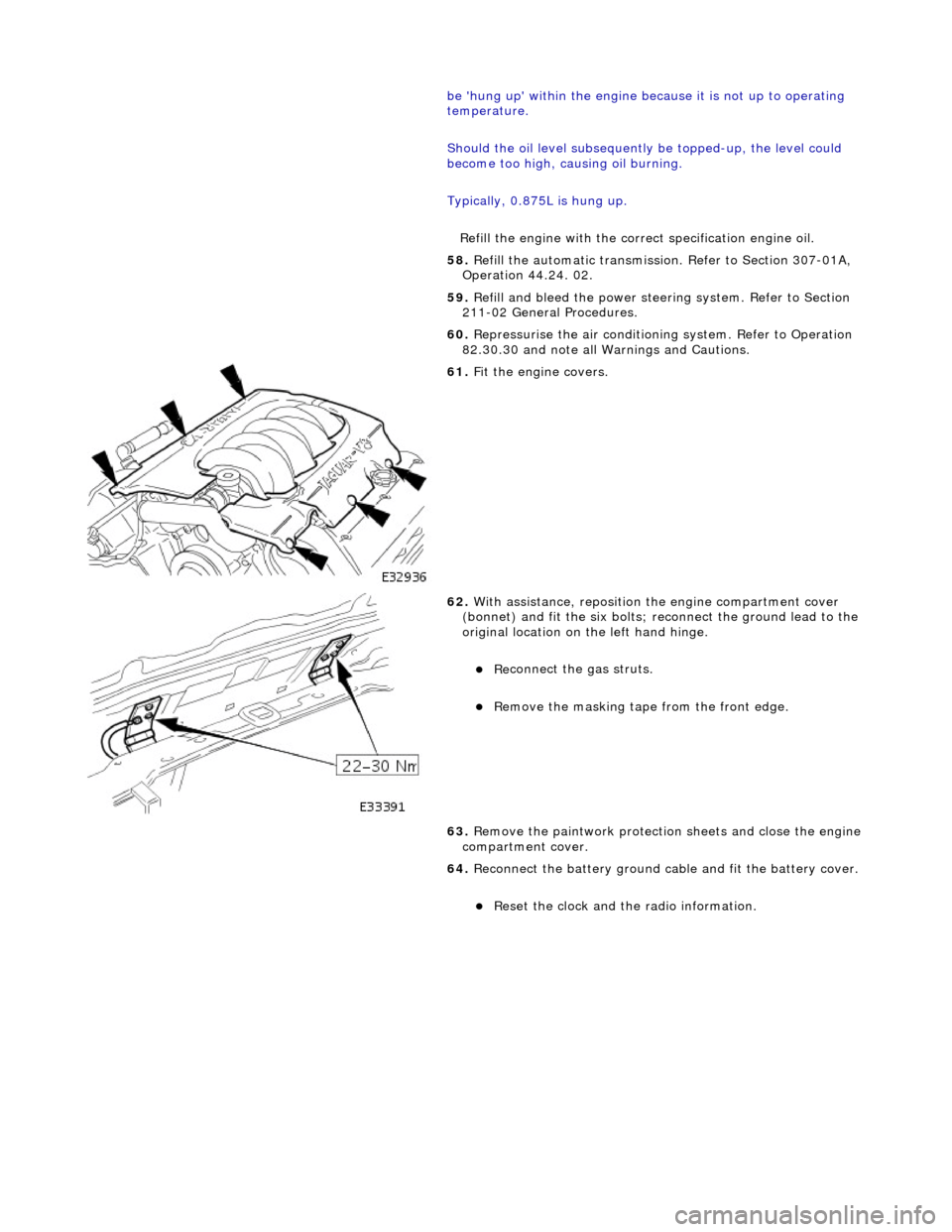

Refill the engine with the correct specification engine oil.

58. Refill the automatic transmission. Refer to Section 307-01A,

Operation 44.24. 02.

59. Refill and bleed the power stee ring system. Refer to Section

211-02 General Procedures.

60. Repressurise the air conditioni ng system. Refer to Operation

82.30.30 and note all Wa rnings and Cautions.

61

.

Fit the engine covers.

62

.

With assistance, reposition the engine compartment cover

(bonnet) and fit the si x bolts; reconnect the ground lead to the

original location on the left hand hinge.

Re

connect the gas struts.

R

emove the masking tape from the front edge.

63. Remove the paintwork protection sheets and close the engine

compartment cover.

64. Reconnect the battery ground cable and fit the battery cover.

Re

set the clock and the radio information.

Page 969 of 2490

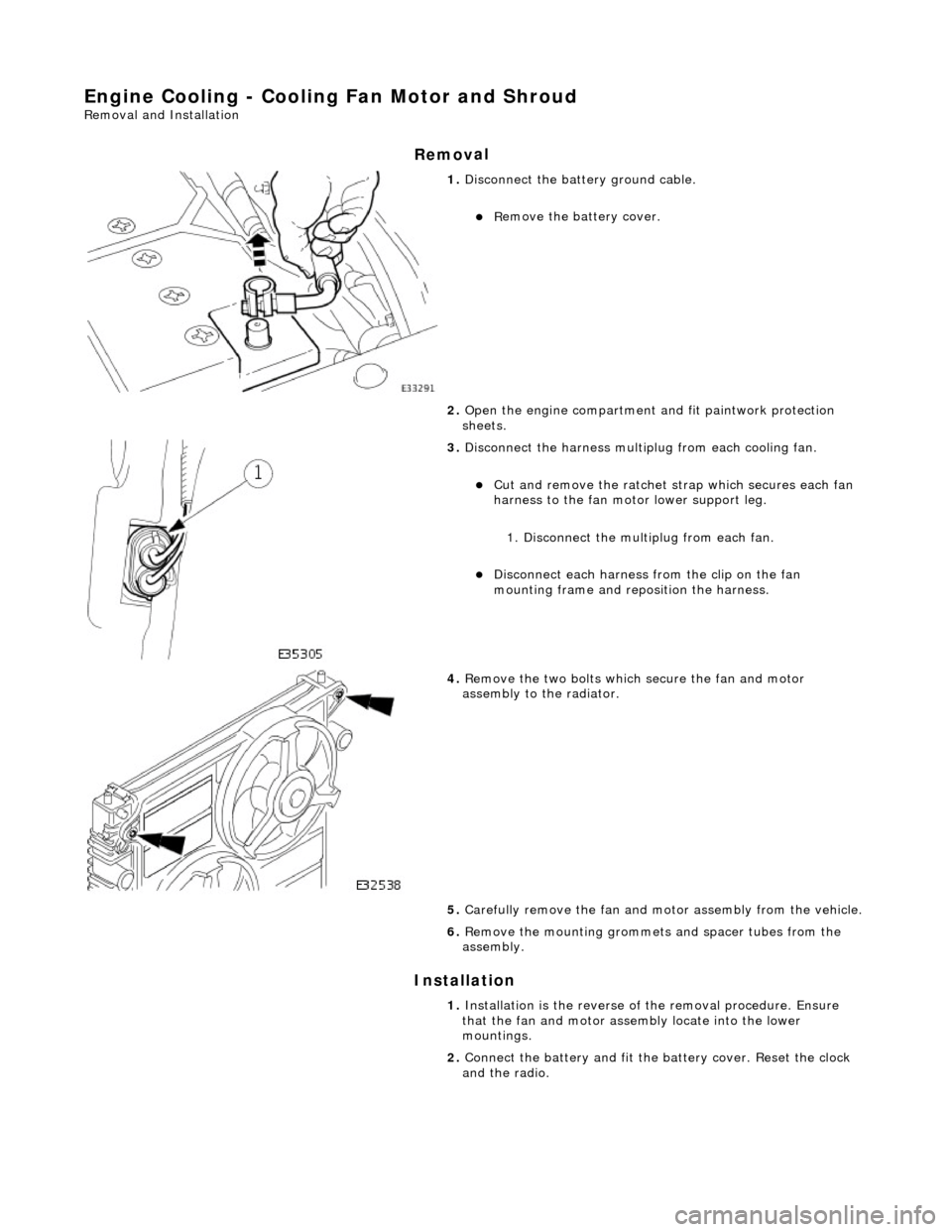

Engine Cooling - Cooling Fan Motor and Shroud

Re

moval and Installation

Remov

al

Installation

1.

Di

sconnect the batt

ery ground cable.

R

emove the battery cover.

2. Open the engine compartment and fit paintwork protection

sheets.

3. Disc

onnect the harness multip

lug from each cooling fan.

Cut an

d remove the ratchet st

rap which secures each fan

harness to the fan moto r lower support leg.

1. Disconnect the mult iplug from each fan.

Di

sconnect each harness

from the clip on the fan

mounting frame and repo sition the harness.

4. R

emove the two bolts which

secure the fan and motor

assembly to the radiator.

5. Carefully remove the fan and mo tor assembly from the vehicle.

6. Re

move the mounting grommets

and spacer tubes from the

assembly.

1. Installation is the reverse of the remova l procedure. Ensure

that the fan and motor assembly locate into the lower

mountings.

2. Connect the battery and fit the battery cover. Reset the clock

and the radio.

Page 979 of 2490

16

.

Refill the cooling system. Refer to the Refill procedure in

General Procedures.

17. Repressurise the climate cont rol system. Refer to Section

412-03 Observe all safety warnin gs and precautions stated in

that section.

18. Close the engine compartment cover.

19. Connect the battery and fit the battery cover. Reset the clock

and the radio.

Page 986 of 2490

16

. Re

fill the cooling system. Refer to the Refill procedure in

General Procedures.

17. Repressurise the climate cont rol system. Refer to Section

412-03 Observe all safety warnin gs and precautions stated in

that section.

18. Close the engine compartment cover.

19. Connect the battery and fit the battery cover. Reset the clock

and the radio.

Page 1001 of 2490

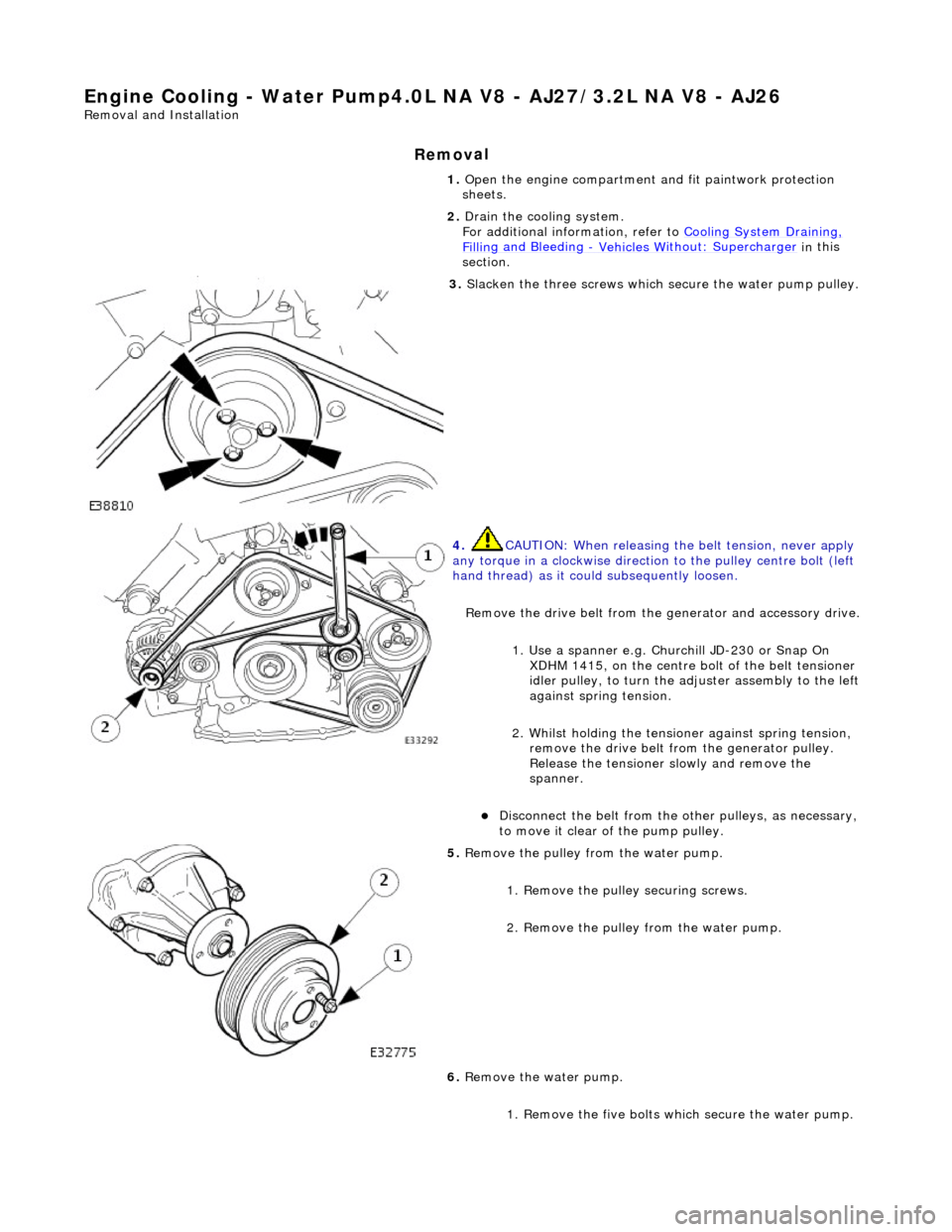

Engine Cooling - Water Pump4.0L NA V8 - AJ27/ 3.2L NA V8 - AJ26

Re

moval and Installation

Remov

al

1.

O

pen the engine compartment and fit paintwork protection

sheets.

2. Drain the cooling system.

For additional information, refer to Cooling System Draining,

Fillin

g and Bleeding

- Vehicles W

ithout: Supercharger

in

this

section.

3. Sl

acken the three screws which

secure the water pump pulley.

4. CAUTI

ON: When releasing the

belt tension, never apply

any torque in a clockwise direction to the pulley ce ntre bolt (left

hand thread) as it could subsequently loosen.

Remove the drive belt from the generator and accessory drive.

1. Use a spanner e.g. Churchill JD-230 or Snap On XDHM 1415, on the centre bo lt of the belt tensioner

idler pulley, to turn the adju ster assembly to the left

against spring tension.

2. Whilst holding the tensioner against spring tension, remove the drive belt from the generator pulley.

Release the tensioner sl owly and remove the

spanner.

D

isconnect the belt from the ot

her pulleys, as necessary,

to move it clear of the pump pulley.

5. Re

move the pulley from the water pump.

1. Remove the pulley securing screws.

2. Remove the pulley from the water pump.

6. Remove the water pump.

1. Remove the five bolts wh ich secure the water pump.

Page 1004 of 2490

Engine Cooling - Water Pump4.0L SC V8 - AJ26

Remo

val and Installation

Remov

a

l

1.

Op

en the engine compartment and fit paintwork protection

sheets.

2. Drain the cooling system.

For additional information, refer to Cooling System Draining,

Filling and Bleedin

g

- Vehicles With

: Supercharger in this

section.

3. Remove the supercharger driv e belt. Refer to Operation

18.50.08.

4. Slacken the three screws whi

ch

secure the water pump pulley.

5. CAUTIO

N: When releasing the

belt tension, never apply

any torque in a clockwise direction to the pulley ce ntre bolt (left

hand thread) as it could subsequently loosen.

Remove the drive belt from the generator and accessory drive.

1. Use a spanner e.g. Churchill JD-230 or Snap On XDHM 1415, on the centre bo lt of the belt tensioner

idler pulley, to turn the adju ster assembly to the left

against spring tension.

2. Whilst holding the tensioner against spring tension, remove the drive belt from the generator pulley.

Release the tensioner sl owly and remove the

spanner.

Di

sconnect the belt from the ot

her pulleys, as necessary,

to move it clear of the pump pulley.

6. Remove t

he pulley from the water pump.

1. Remove the pulley securing screws.

2. Remove the pulley from the water pump.

7. Remove the water pump.

Page 1007 of 2490

W

ater Pump Pulley Vehicles Without: Supercharger

26.50.05

Removal

1. Open the engine compartment and fit paintwork protection sheets.

2

. Slacken the three screws which secure the water pump pulley.

3

.

C

AUTION:

When releasing the belt tension, never apply any torque in a clockwise direction to the pulley

centre bolt (left hand thread) as it could subsequently loosen.

Remove the drive belt from the generator and accessory drive. 1. Use a spanner e.g. Churchill JD-230 or Snap On XDHM 1415, on the centre bolt of the belt tensioner idler pulley, to turn the adjuster assembly to the left against spring tension.

Page 1009 of 2490

W

ater Pump Pulley Vehicles With: Supercharger

26.50.05

Removal

1. Open the engine compartment and fit paintwork protection sheets.

2. Remove the supercharger drive belt. Refer to Operation <<18.50.08>>.

3

. Slacken the three screws which secure the water pump pulley.

4

.

C

AUTION:

When releasing the belt tension, never apply any torque in a clockwise direction to the pulley

centre bolt (left hand thread) as it could subsequently loosen.