engine JAGUAR X308 1998 2.G Owner's Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 69 of 2490

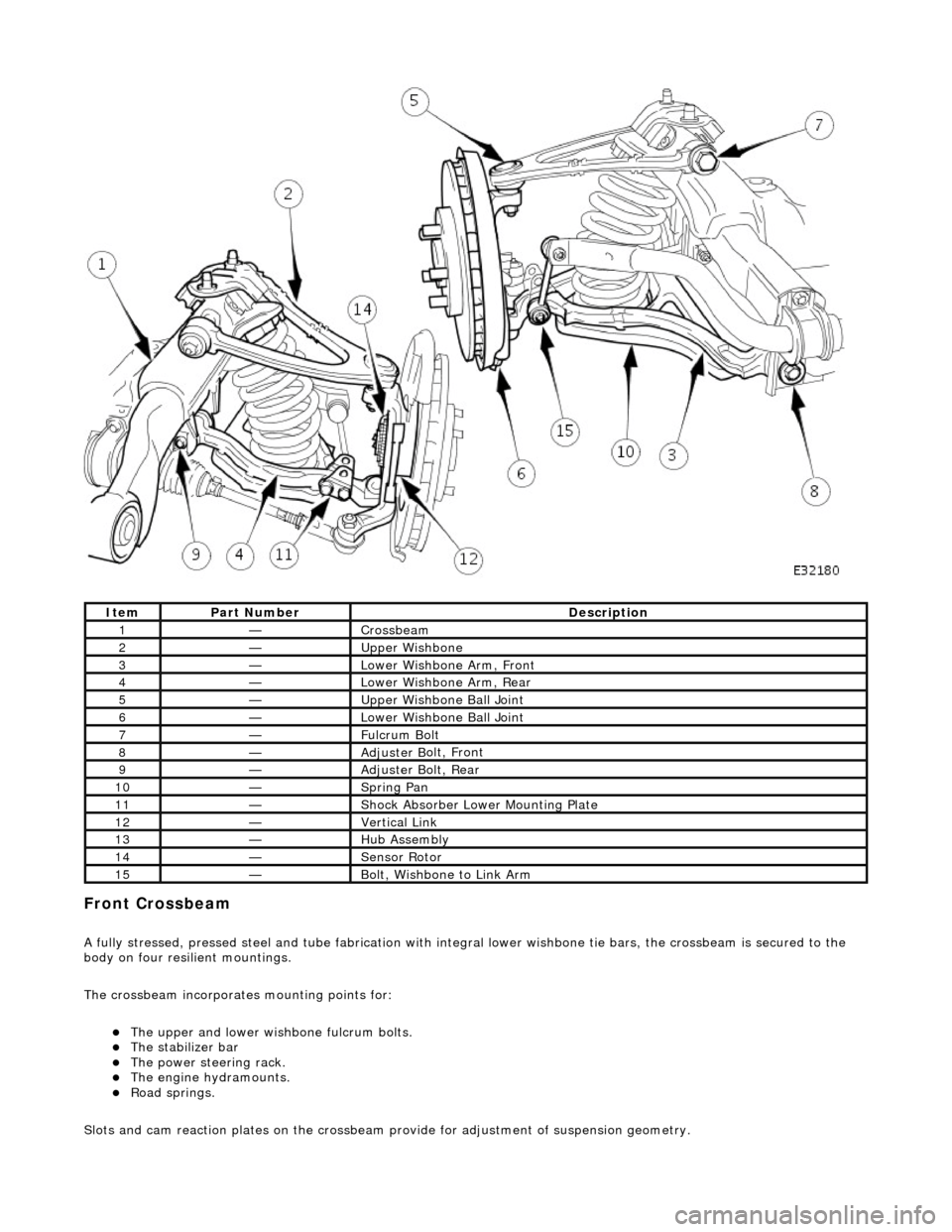

Front C

rossbeam

A

fully stressed, pressed steel and tube fa

brication with integral lower wishbone tie bars, the crossbeam is secured to the

body on four resilient mountings.

The crossbeam incorporates mounting points for:

пЃ¬The u

pper and lower wish

bone fulcrum bolts.

пЃ¬The

stabilizer bar

пЃ¬The power steering rack. пЃ¬The engine h

ydramounts.

пЃ¬R

oad springs.

Slots and cam reaction pl ates on the crossbeam provide for ad justment of suspension geometry.

It

em

Par

t Number

De

scription

1—Cro

ssbeam

2—Upper

Wishbone

3—Lower Wi

shbone Arm, Front

4—Lower Wi

shbone Arm, Rear

5—Upper

Wishbone Ball Joint

6—Lower Wi

shbone Ball Joint

7—Ful

crum Bolt

8—Adjuster B

olt, Front

9—Adjuster B

olt, Rear

10—S

pring Pan

11—Shock Absorber Lower M

ounting Plate

12—Vertical Link

13—Hub Assembly

14—Sensor R

otor

15—B

olt, Wishbone to Link Arm

Page 118 of 2490

6. Re

lease stabilizer bar from link arms.

пЃ¬R

e

move stabilizer bar to link arm ball joint securing nut.

пЃ¬Repeat operation

at opp

osite

end of stabilizer bar.

7. Slacken stabil

izer bar securing bolts.

8. NO

TE: On vehicles fitted with an engine oil cooler, it may be

necessary to release the stabilizer bar from each ball joint in turn

to achieve the required cl earance from cooler pipes.

Remove stabilizer bar from crossbeam.

пЃ¬R e

move stabilizer bar securing bolts.

пЃ¬R

e

move stabilizer bar and mounting brackets from

crossbeam.

9. Remove mounting brackets and rubbers from stabilizer bar.

Page 123 of 2490

I

nstallation

6.

R

elease stabilizer bar from link arms.

пЃ¬R

emove nut securing stabilizer bar to link.

пЃ¬R

elease link arm from stabilizer bar.

пЃ¬Repeat operation

at opposite

end of stabilizer bar.

7. N

OTE: On vehicles fitted with an engine oil cooler, it may be

necessary to release the stabilizer bar from each ball joint in turn

to achieve the required cl earance from cooler pipes.

Remove stabilizer bar from crossbeam.

пЃ¬R

emove stabilizer bar securing bolts.

пЃ¬R

emove stabilizer bar mountin

g brackets and remove bar

from crossbeam.

8. Re

move mounting brackets and

rubbers from stabilizer bar.

1. CAUTION: Make sure the Ca strol NTR grease is only

applied to the inner surface of the mounting bushes. Failure to

follow this instruction may affect the retention of the bushes in

the retaining brackets.

Page 266 of 2490

WHE

N CHANGING A WHEEL, ENSURE THAT THE VEHICLE CANNOT MOVE. ALWAYS APPLY THE PARK BRAKE AND

SELECT TRANSMISSION 'P' POSITION.

NEVER RUN THE ENGINE WITH ONE WHEEL OFF THE GROUND, FOR EXAMPLE, WHEN CHANGING THE WHEEL. THE

VEHICLE COULD MOVE.

TIGHTEN THE WHEEL NUTS TO SPECIFICATION. WHEELS MAY COME LOOSE IF OVER OR UNDER TIGHTENED.

USE WHEELS AND WHEEL NUTS DESI GNED FOR XJ SERIES VEHICLES ONLY. AFTERMARKET WHEELS OR WHEEL

NUTS MAY NOT FIT OR FUNCTION PROPERLY AND COULD CAUSE INJURY OR DAMAGE.

In

spection and Verification

To maximize ti

re performance, inspec

t the tires frequently for signs of:

пЃ¬Unev

en wear.

пЃ¬Incorrect

ti

re pressure.

пЃ¬Wh

ee

l imbalance.

пЃ¬Cuts. пЃ¬Abrasi

ons.

пЃ¬B

u

lges (blister).

пЃ¬Ply s

e

paration.

пЃ¬Embedded objects. пЃ¬Impact damage.

Inspe c

tion should be

more frequent when:

пЃ¬Continuo

us high speed op

eration is required.

пЃ¬Ra

pid or extreme temperatures changes occur.

пЃ¬R

o

ad surfaces are rough.

пЃ¬Roads ar

e littered

with debris.

Tread W

e

ar Indicator

•

NO

TE: Tire condition must comply with prevailing local legislation.

New tires must be installed if the wear in dicators are exposed or if there is severe shoulder wear. Shoulder wear is usually

caused by either excessive camber or toe on tires.

T i

re Vibration Diagnosis

A

tir

e vibration diagnostic procedure always

begins with a road test. The road test and the custom er interview (if available)

will provide much of the information need ed to find the source of vibration.

During the road test, drive the vehicle on a road that is smooth and free of undulations. If vibration is apparent, note and

record the following:

пЃ¬The s p

eed at which the vibration occurs.

пЃ¬W

h

at type of vibration occurs in each

speed range - mechanical or audible.

пЃ¬How the vibrati

on is affected

by changes in the following:

- -engine torque

- -vehicle speed

- -engine speed.

пЃ¬Type of v i

bration - sensitivity:

- - torque sensitive,

- - vehicle speed sensitive,

- - or engine speed sensitive.

Page 267 of 2490

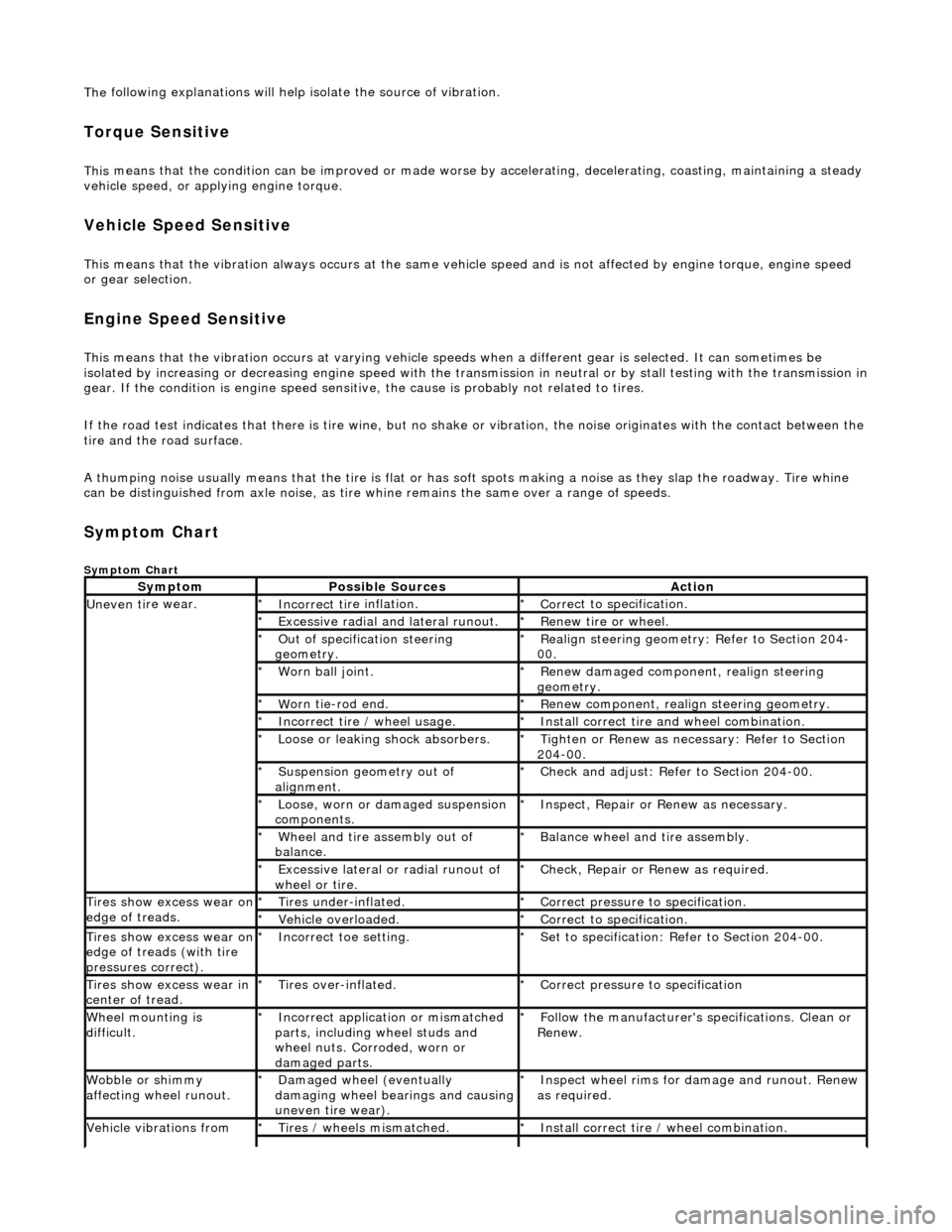

The

following explanations will help isolate the source of vibration.

Torque Sensitive

This

means that the condition can be impr

oved or made worse by accelerating, dece lerating, coasting, maintaining a steady

vehicle speed, or applying engine torque.

Ve

hicle Speed Sensitive

This means th

at the vibration al

ways occurs at the same vehicle speed and is not affected by engine torque, engine speed

or gear selection.

Engine Speed Sensit

ive

This means th

at the vibration

occurs at varying vehicle spee ds when a different gear is selected. It can sometimes be

isolated by increasing or decreasing engine speed with the tran smission in neutral or by stall testing with the transmission in

gear. If the condition is engine speed sensitive, the cause is probably not related to tires.

If the road test indicates that there is tire wine, but no shake or vibration, the noise originates with the contact between th e

tire and the road surface.

A thumping noise usually means that the tire is flat or has soft spots making a noise as they slap the roadway. Tire whine

can be distinguished from axle no ise, as tire whine remains the same over a range of speeds.

Sym

ptom Chart

Sy

mptom Chart

Sy

mptom

Possib

le Sources

Acti

on

Uneven ti

re wear.

Incorrect ti

re inflation.

*

Cor

rect to specification.

*

Exce

ssive radial an

d lateral runout.

*

Renew tire

or wheel.

*

O

ut of specification steering

geometry.

*

R

ealign steering geometry: Refer to Section 204-

00.

*

W

orn ball joint.

*

Renew

damaged component, realign steering

geometry.

*

W

orn tie-rod end.

*

R

enew component, realign steering geometry.

*

Incorrect

tire / wheel usage.

*

Inst

all correct tire and wheel combination.

*

Loose or leaki

ng shock absorbers.

*

Tigh

ten or Renew as nece

ssary: Refer to Section

204-00.

*

Suspensi

on geometry out of

alignment.

*

Che

ck and adjust: Refer to Section 204-00.

*

Loose, worn or da mage

d suspension

components.

*

In

spect, Repair or Renew as necessary.

*

Wh

eel and tire assembly out of

balance.

*

Balance wheel an

d tire assembly.

*

Excessive later

al or radial runout of

wheel or tire.

*

Check, Repair o

r

Renew as required.

*

Tire

s show excess wear on

edge of treads.

Ti

res under-inflated.

*

Cor

rect pressure to specification.

*

Vehi

cle overloaded.

*

Cor

rect to specification.

*

Tire

s show excess wear on

edge of treads (with tire

pressures correct).

Incorre

ct toe setting.

*

Se

t to specification: Refer to Section 204-00.

*

Tire

s show excess wear in

center of tread.

Tire

s over-inflated.

*

Cor

rect pressure to specification

*

W

heel mounting is

difficult.

Incorrect app

lication or mismatched

parts, including wheel studs and

wheel nuts. Corroded, worn or

damaged parts.

*

Fol

low the manufacturer's specifications. Clean or

Renew.

*

Wobble or sh

immy

affecting wheel runout.

Damaged wh

eel (eventually

damaging wheel bearings and causing

uneven tire wear).

*

Inspect wheel rims for

damage and runout. Renew

as required.

*

Vehicle vibrations from

Tire

s / wheels mismatched.

*

Inst

all correct tire / wheel combination.

*

Page 278 of 2490

Vehicle Dynamic Suspension - Vehicle Dynamic Suspension

Diagn

osis and Testing

Refer to the PDU User Guide for details of diagnosing and testing the Adaptive Damping System. The PDU interrogates the

ADCM directly via the K and L lines to the J1962 diagnostic socket.

The PDU will give an indication of the integrity of each electron ic and electrical component. It will indicate, for example, that

the accelerometers are not broken, but not that they functionin g correctly when the vehicle is in motion. However, it is

exceptional for an accelero meter to function incorrectly in its dynamic mode if it is proved to be functioning when static.

Basic Checks

The accele

rometers have the following ch

aracteristics. At 0g (no movement of the body) each vertical accelerometer

outputs approximately 2.5V steady voltage; the lateral acce lerometer outputs approximately 1.5V. The voltage output due

to body movement is proportional to acceleration in the acceleration axis, up to approximately 4.5V and down to

approximately 0.5V.

Before changing any component, refer to the circuit diagrams and check the cont inuity of relevant harness circuits; in some

instances, the PDU will not different iate between a faulty component an d a damaged connection or wiring.

Check the following fuses:

пЃ¬En

gine compartment fuse

box, fuse F5 (10A).

пЃ¬Engine m

anagement fuse

box, fuse F1 (20A).

Check the following ADCM input/output lines:

пЃ¬Sy stem erro

r output from the ADCM

to the instrument cluster.

пЃ¬Vehicl

e speed output from the inst

rument cluster to the ADCM.

пЃ¬Foo

tbrake signal to the ADCM.

Check any relevant connections to confirm that the connection is electrically sound and that a terminal pin has not been

pushed back into the connector shell, ie. not ma king a connection to its mating pin or socket.

Page 313 of 2490

Do t

he disc brake caliper pistons

and pins bind, leak or stick?

Yes INSTALL new calipers as necessary. TE ST the system for normal operation.

No GO to C4

.

C4: INSPECT BR

AKE DISCS

Check the brake discs fo

r excess

ive damage, thickness variatio n or runout. For additional

information, refer to General Procedures in this section.

1

D

oes excessive damage or runout exist?

Yes INSTALL new brake discs and brak e pads as necessary. TEST the system for normal operation.

No GO to C5

.

C5: INSPECT THE FRONT HU

B AND WHEEL BEARING ASSEMBLY

Check the fr

ont hub and wheel bearing assembly.

For additional information, refer toSection 204

-00

Su

spension System

- General

Information

. 1

Are th

e wheel bearings OK?

Yes GO to C6

.

No

INSTALL new wheel bearings. For additional inform ation, refer toSection 204

-01

Front Suspension

.

TEST the system

for normal operation.

C

6: CHECK SUSPENSION BUSHES AND BALL JOINTS.

Chec

k all suspension bu

shes and ball joints.

1

Are th

e suspension bushes and ball joints OK?

Yes Vehicle is OK.

No INSTALL new front suspension bushes and ball joints as required. For additional information, refer

toSection 204

-01

Front Suspension

. INSTALL n

ew rear suspension bush

es and ball joints as required.

For additional informat ion, refer toSection 204

-0

2 Rear Suspension

.

P

INPOINT TEST D : THE PEDAL FEELS SPONGY

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

D

1: CHECK FOR SPONGY PEDAL (ENGINE OFF)

Check f

or a firm brake pedal.

1

Is th

e brake pedal effort an

d brake pedal travel normal?

Yes Vehicle is OK.

No GO to D2

.

D2:

CHECK BRAKE PEDAL RESERVE (ENGINE OFF)

Pump th

e brake pedal 10 times and

hold on the final application.

1

Does th

e brake pedal feel fi

rm on final application?

Yes GO to D3

.

No

BLEED the brake system. For additional information, re fer to General Procedures in this section. TEST

the system for normal operation.

D3:

CHECK BRAKE PEDAL RESERVE (ENGINE ON)

Engine is

idle.

1

Apply the brake pedal ligh

tl

y three or four times.

2

W

ait 15 seconds for the vacuum to recover.

3

Push down on

the brake pedal until it stops moving

downward or an increased resistance to the brake

pedal travel occurs.

4

Hol

d the brake pedal in the applied position while increasing the engine speed to 2000 revs/min.

5

Re

lease the accelerator pedal.

6

Does th

e brake pedal move downward as

the engine speed returns to idle?

Yes GO to D4

.

No

CHECK the vacuum to brake booster. For additional information, refer toSection 206

-0

7 Power Brake

Actuation.

Page 315 of 2490

Are th

ere any external brake system leaks?

Yes REPAIR as necessary. ADD fluid and BLEED the brak e system. For additional information, refer to

General Procedures in this section. TEST the system for normal operation.

No GO to F3

.

F

3: CARRY OUT A BRAKE MASTER CYLINDER BYPASS TEST

Te

st for brake master cylinder bypass condition. Re

fer to Brake Master Cylinder Component Test in

this section.

1

A

re any concerns found?

Yes INSTALL a new brake master cylinder, ADD flui d and BLEED the brake system. For additional

information, refer to General Proc edures in this section. TEST the system for normal operation.

No System is OK.

PINPO

INT TEST G : EXCESSIVE BRAKE PEDAL EFFORT

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

G1

: CHECK BRAKE PADS

Check the brake pads for wear, contamin

atio

n, correct installation, damage and type.

1

A

re any concerns found?

Yes INSTALL the front brake pads correctly or INSTALL ne w front brake pads if necessary. For additional

information, refer toSection 206

-03

Front Disc Brake

. INSTALL the

rear brake pads correctly or

INSTALL new rear brake pads if necessary. For additional information, refer toSection 206

-04

Rear

Di

sc Brake

. REPEAT road test.

No

GO to G2

.

G2:

CHECK VACUUM

Di

sconnect the vacuum booster hose from the booster.

1

Conne

ct a vacuum/pressure tester to the vacuum hose.

2

Ru

n the engine at normal operating temperature.

3

Re

cord the vacuum reading.

4

Is

the reading 40.5kPa (1

2 in-Hg) or greater?

Yes GO to G3

.

No

LOCATE and REPAIR the source of low vacuum . TEST the system for normal operation.

G3

: INSPECT SYSTEM

Swi

tch the engine off.

1

Re

connect the vacuum hose.

2

Inspect th

e brake booster, rubber grommet, and al

l vacuum plumbing for cracks, holes, damaged

connections, or missing clamps.

3

Pump th

e brake pedal several time

s to exhaust the vacuum. Push down on the brake pedal and hold.

4

Does th

e brake pedal move down

when the engine is started?

Yes Vacuum system is OK.

No GO to G4

.

G4

: CHECK POWER BRAKE BOOSTER VALVE

Check the brake booster valve. For

add

itional information, refer to

Brake Booster in this section.

1

Is th

e power brake booster valve OK?

Yes CHECK the brake booster. Fo r additional information, refer to Brak e Booster in this section. INSTALL a

new brake booster if necessary. TEST the system for normal operation.

No INSTALL a new brake booster valve. TEST the system for normal operation.

P

INPOINT TEST H : BRAKE LOCKUP

DURING LIGHT BRAKE PEDAL FORCE

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

H1

: TEST BRAKE LOCKUP

Page 317 of 2490

Yes

Vehicle is OK.

No GO to J2

.

J

2: CHECK BRAKE FLUID LEVEL

Check the brake master cyli

nder reservoir fluid level.

1

Is the fl

uid level OK?

Yes GO to J3

.

No

CHECK brake master cylinder reservoir sealing points. For additional information, refer to Brake

Master Cylinder in this section. ADD brake fl uid and BLEED the brake system. For additional

information, refer to General Proc edures in this section. TEST the system for normal operation.

REPEAT road test if necessary.

J

3: CHECK BRAKE PEDAL RESERVE

Engine is

idle.

1

Apply the brake pedal ligh

tl

y three or four times.

2

W

ait 15 seconds for the vacuum to replenish.

3

Push down on

the brake pedal until it stops moving

downward or an increased resistance to the brake

pedal travel occurs.

4

Hol

d the brake pedal in the applied position while increasing the engine speed to 2000 revs/min.

5

Re

lease the accelerator pedal.

6

Does th

e brake pedal move downward as

the engine speed returns to idle?

Yes GO to J4

.

No

CHECK the vacuum to the brake booster. Fo r additional information, refer toSection 206

-0

7 Power

Brake Ac

tuation

.

J

4: CHECK THE FRONT HUB AND BEARING ASSEMBLY

Check the fr

ont hub and bearing assembly. Fo

r additional information, refer toSection 204

-01

Front

Suspe

nsion

. 1

Are th

e front wheel bearings loose?

Yes INSTALL a new front wheel bearin g if damaged. For additional information, refer toSection 204

-01

F

ront Suspension

. TEST

the system for normal operation.

No CHECK the front brake discs for thickness variances. For additional information, refer to General

Procedures in this section.

PINPO

INT TEST K : SLOW OR INCOMPLETE BRAKE PEDAL RETURN

TE

ST

CONDITIONS

D

ETAILS/RESULTS/ACTIONS

K1: C

HECK FOR BRAKE PEDAL RETURN

Ru

n the engine at fast idle while

making several brake applications.

1

Pull the

brake pedal rearward with approximately 44.5 N (10lb) force.

2

Relea

se the brake pedal and measure

the distance to the toe board.

3

Make a hard brake

application.

4

Relea

se the brake pedal and measure the brake

pedal to toe board distance. The brake pedal

should return to its original position.

5

Does th

e brake pedal return

to its original position?

Yes Vehicle is OK.

No GO to K2

.

K

2: CHECK FOR BRAKE PEDAL BINDING

Check the brake pedal to make

s

ure it is operating freely.

1

Is th

e brake pedal operating freely?

Yes INSTALL a new brake booster. For addi tional information, refer toSection 206

-0

7 Power Brake

Actuation. TEST

the system for normal operation.

No REPAIR or INSTALL new brake pedal. TE ST the system for normal operation.

Page 318 of 2490

Comp

onent Tests

Bra

k

e Booster

1.

1. Chec k all

hoses and connections. All unused vacuum connectors should be capped. Hoses and their connections

should be correctly secured and in good condition with no holes and no collapsed areas. Inspect the valve on the

brake booster for damage.

2. 2. Check the hydraulic brake system for leaks or low fluid.

3. 3. With the transmission in PARK, stop the engine and apply the parking brake. Pump the brake pedal several times

to exhaust all vacuum in the system.

4. 4. With the engine switched off and all vacuum in the system exhausted, appl y the brake pedal and hold it down.

Start the engine. If the vacuum system is operating, the brake pedal will tend to move downward under constant

foot pressure. If no motion is felt, the vacuum booster system is not functioning.

5. 5. Remove the vacuum hose from the brake booster. Manifold vacuum should be available at the brake booster end

of the hose with the engine at idle speed and the transm ission in PARK or NEUTRAL. Make sure that all unused

vacuum outlets are correctly capped, hose connectors are correctly secured and vacuum hoses are in good

condition. When it is established that manifold vacuum is available to the brake booster, connect the vacuum hose

to the brake booster and repeat Step 3. If no downward movement of the brake pedal is felt, install a new brake

booster.

6. 6. Operate the engine for a minimum of 10 seconds at a fast idle. Stop the engine and allow the vehicle to stand for

10 minutes. Then, apply th e brake pedal with approximately 89 N ( 20lb) of force. The pedal feel (brake

application) should be the same as that noted with the engine running. If the brake pedal feels hard (no power

assist), install a new valve and then re peat the test. If the brake pedal still feels hard, in stall a new brake booster.

If the brake pedal movement feels spongy, bleed the brak e system. For additional information, refer to General

Procedures in this section.

Bra k

e Master Cylinder

Usual

l

y, the first and strongest

indicator of anything wrong in the brake syst em is a feeling through the brake pedal. In

diagnosing the condition of the brake master cylinder, check pedal feel as evidence of a brake concern. Check for brake

warning lamp illumination and the brake fluid le vel in the brake master cylinder reservoir.

Normal Conditio

ns

The fo

llowing conditions are considered norm

al and are not indications that the brake master cylinder is in need of repair.

пЃ¬New bra

ke systems are designed to produc

e a pedal effort that is not as hard as in the past. Complaints of light

pedal efforts should be compared to the pedal effort s of another vehicle of the same model and year.

пЃ¬The fl

uid level will fall with brake pad wear.

Abnormal Conditions

•

NOTE: Prior to carrying out any diag

nosis, make sure the brake system warning indicator is functional.

Changes in the brake pedal feel or brake pedal travel are in dicators that something could be wrong in the brake system. The

diagnostic procedure and techniques use brake pedal feel, warning indicator illu mination and low brake fluid level as

indicators to diagnosing brake system co ncerns. The following conditions are cons idered abnormal and indicate that the

brake master cylinder is in need of repair:

пЃ¬Brake ped a

l goes down fast. Th

is could be caused by an ex ternal or internal leak.

пЃ¬Brake pedal goes down slowly

. This could be

caused by an internal or external leak.

пЃ¬Brak

e pedal is low or feels spongy. This condition may be ca

used by no fluid in the brake master cylinder, reservoir