engine JAGUAR X308 1998 2.G Service Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 361 of 2490

Front Dis

c Brake - Brake PadsVehicl

es With: High Performance Brakes

Re

moval and Installation

Remov

al

1.

W

ARNING: BRAKE DUST, IF INHALED CAN DAMAGE

YOUR HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRE SSED-AIR LINE TO DISPERSE

BRAKE DUST INTO THE ATMOSPHERE. Failure to follow this

instruction may result in personal injury.

• CAUTIONS:

Brake pads must always be replaced in axle sets.

Replacement of nuts and bolts: Various thread-locking

devices are used on nuts and bolts throughout the vehicle. These

devices restrict the number of ti mes a nut or bolt can be used.

For additional information, refer to: General Service Information

(10

0-00 General Information,

Description and Operation).

The High Performance brake ca liper is aligned to the brake

disc when it is first installed to the vehicle, therefore, care must

be taken not to disturb this alignment. When removing the

caliper; remove the bolts that se cure the anchor bracket to the

vertical link only. DO NOT loosen any other caliper bolts.

Open engine compartment and fit paint work protection covers

to fenders.

2. R

aise front of vehicle an

d support on stands.

For additional information, refer to: Using the Workshop Jack

(10

0-02 Jacking and Lifting, General Procedures).

3. Remove front wheels. Refer to operation.

For additional information, refer to: Wheel and Tire

(20

4-04

Wheels and Tires, Remo val and Installation).

4. CAUTI

ON: Remove brake flui

d spillage immediately from

paint work, with clean water.

Loosen brake fluid reservoir-cap.

пЃ¬Position a cloth around the

reservoir to collect any fluid

spillage.

5. Remove brake

pads from caliper.

1. Remove 'R' clips.

2. Withdraw pins from caliper.

3. Remove anti-rattle spring.

4. Discard brake pads.

Page 363 of 2490

Install brake pads

i

nto caliper.

пЃ¬Slo

wly retract caliper pi

stons into caliper.

1. Install pads.

2. Position anti-rattle spring.

3. Install pins.

4. Install 'R' clips.

4. Repeat above procedure to install opposite side brake pads.

5. Fit wheels.

For additional information, refer to: Wheel and Tire

(20

4-04

Wheels and Tires, Remo val and Installation).

6. Remove stands and lower vehicle.

For additional information, refer to: Using the Workshop Jack

(10

0-02 Jacking and Lifting, General Procedures).

7. CAUTI

ON: Remove brake flui

d spillage immediately from

paint work, with clean water.

Check brake fluid level.

пЃ¬Check brak

e fluid level is

at the maximum mark.

пЃ¬Re

move cloth.

пЃ¬Fi

t cap.

8.

R

emove paint work protection

covers, and close engine

compartment.

9. Start the engine and repeatedly press the brake pedal until

brake pressure is evident.

Page 372 of 2490

Rear Disc Brake - Brake CaliperVehicles With: High Performance Brakes

Remo

val and Installation

Remov

a

l

S

p

ecial Tool(s)

Brake Pedal

H

old Tool

JDS 9013

1. WARNING: BRAKE DUST, IF INHALED CAN DAMAGE

YOUR HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRE SSED-AIR LINE TO DISPERSE

BRAKE DUST INTO THE ATMOSPHERE.

• CAUTIONS:

Replacement of nuts and bolts: Various thread-locking

devices are used on nuts and bolts throughout the vehicle. These

devices restrict the number of ti mes a nut or bolt can be used.

See section 100-00 for information.

Remove brake fluid spillage immediately from paint work,

with clean water.

The Brembo caliper is aligned to the brake disc when it is

first installed to the vehicle, therefore, care must be taken not to

disturb this alignment. When removing the caliper; remove the

bolts that secure the anchor brac ket to the hub carrier only. DO

NOT loosen any other caliper bolts.

Open engine compartment and fit paint work protection covers

to fenders.

2. Raise

vehicle on a four-post lift.

3. Raise front of vehicle and support on stands. Refer to Section

100-02.

4. Remove front wheels. Refe r to operation 74.20.05.

5. NOTE : Th

e following three pictorial procedures must be

carried-out to minimize brake fl uid loss when disconnecting the

brake hose.

Open Left-Hand-Front and Left-H and-Rear caliper bleed nipples.

пЃ¬Connect a

bleed tube and co

ntainer to the calipers.

пЃ¬Op

en bleed nipples.

6. Depress and hold down brak e pedal at the specified

measurement using the special tool.

Page 376 of 2490

Rear Disc

Brake - Brake DiscVe

hicles With: Standard Brakes

Remo

val and Installation

Remov

a

l

• WAR

N

INGS:

BRAKE DISCS MUST ALWAYS BE REPLACED IN PAIRS.

BRAKE DUST, IF INHALED CAN DAMAGE YOUR HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM BRUSH.

DO NOT USE A COMPRESSED-AIR LINE TO DI SPERSE BRAKE DUST INTO THE ATMOSPHERE.

CAUTION: Replacement of nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

1. Op

en engine compartment and fit

paint work protection covers

to fenders.

2. Raise rear of vehicle and support on stands. Refer to section

100-02.

3. Remove rear wheels. Refer to section 204-04.

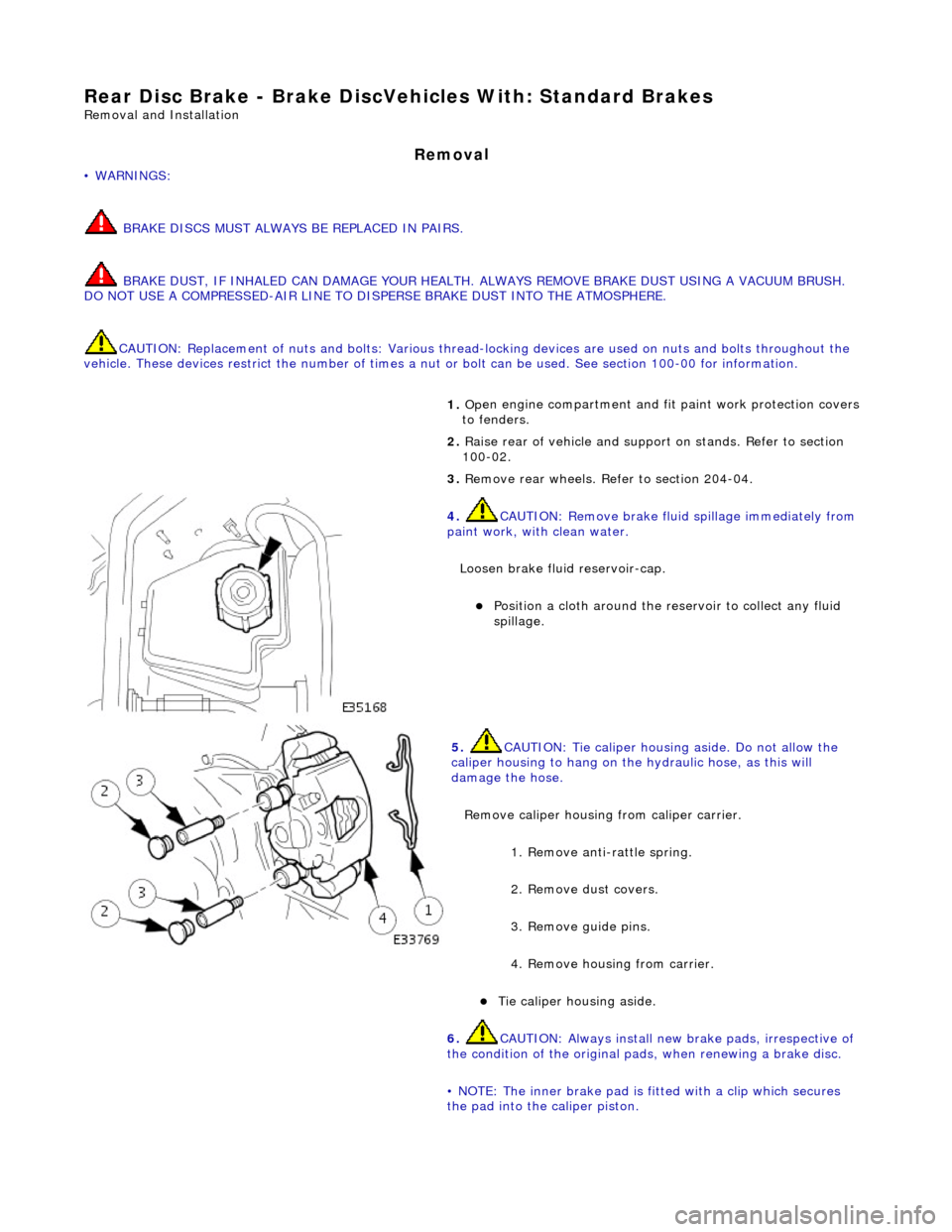

4. CAUTIO

N: Remove brake flui

d spillage immediately from

paint work, with clean water.

Loosen brake fluid reservoir-cap.

пЃ¬Position a cloth around the reser

voir to collect any fluid

spillage.

5. CAUT

ION: Tie caliper housing aside. Do not allow the

caliper housing to hang on the hydraulic hose, as this will

damage the hose.

Remove caliper housing from caliper carrier.

1. Remove anti-rattle spring.

2. Remove dust covers.

3. Remove guide pins.

4. Remove housing from carrier.

пЃ¬Tie

caliper housing aside.

6.

CAUTIO

N: Always install new brake pads, irrespective of

the condition of the original pads, when renewing a brake disc.

• NOTE: The inner brake pad is fitted with a clip which secures

the pad into the caliper piston.

Page 379 of 2490

6. CAUTI

ON: Always install new brake pads, irrespective of

the condition of the original pads, when renewing a brake disc.

• NOTE: Clean caliper piston to pad mating surface.

Install brake pads to caliper housing.

пЃ¬Remove paper backing from pads to reveal

adhesive shim.

Install brake pads, in sert clip located on back of inner pad

into caliper piston.

7. Inst

all caliper housing to caliper carrier.

1. Align housing to carrier.

2. Install and tighten gu ide pins to 25-30 Nm.

3. Install dust covers.

4. Install anti-rattle spring.

8. Repeat above procedure to inst all opposite side brake disc.

9. Fit wheels. Refer to section 204-04.

10. Remove stands and lower vehicl e. Refer to section 100-02.

11

.

CAUTION: Remove brake fl uid spillage immediately

from paint work, wi th clean water.

Check brake fluid level.

пЃ¬Check brak

e fluid level is

at the maximum mark.

пЃ¬Re

move cloth.

пЃ¬Fi

t cap.

12

.

Remove paint work protection covers, and close engine

compartment.

13. Start the engine and repeatedly press the brake pedal until

brake pressure is evident.

Page 380 of 2490

Rear Disc

Brake - Brake DiscVehicl

es With: High Performance Brakes

Remo

val and Installation

Remov

a

l

1.

WAR N

INGS:

BRAKE DISCS MUST ALWAYS BE REPLACED IN PAIRS.

BRAKE DUST, IF INHALED CAN DAMAGE YOUR HEALTH.

ALWAYS REMOVE BRAKE DUST USING A VACUUM BRUSH. DO

NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST

INTO THE ATMOSPHERE.

• CAUTIONS:

Replacement of nuts and bolts: Various thread-locking

devices are used on nuts and bolts throughout the vehicle. These

devices restrict the number of ti mes a nut or bolt can be used.

See section 100-00 for information.

The Brembo caliper is aligned to the brake disc when it is

first installed to the vehicle, therefore, care must be taken not to

disturb this alignment. When removing the caliper; remove the

bolts that secure the anchor brac ket to the hub carrier only. DO

NOT loosen any other caliper bolts.

Open engine compartment and fit paint work protection covers

to fenders.

2. Ra

ise rear of vehicle and support

on stands. Refer to section

100-02.

3. Remove rear wheels. Refer to section 204-04.

4. CAUTIO

N: Remove brake flui

d spillage immediately from

paint work, with clean water.

Loosen brake fluid reservoir-cap.

пЃ¬Position a cloth around the reser

voir to collect any fluid

spillage.

5. CAUTIO

N: Always install new brake pads, irrespective of

the condition of the original pads, when renewing brake discs.

Remove brake pads from caliper. 1. Withdraw pins from caliper.

2. Remove anti-rattle spring.

3. Discard brake pads.

Page 383 of 2490

Note the condition of pins

and replace if necessary.

Install brake pads. Refer to 70 .40.09 for anti-squeal grease

application.

пЃ¬Sl

owly retract caliper pistons.

1. Install pads.

2. Position anti-rattle spring.

3. Install pins - make sure pin collets are fully engaged

into caliper.

6. Repeat

above procedure to inst

all opposite side brake disc.

7. Fit wheels. Refer to section 204-04.

8. Remove stands and lower vehicl e. Refer to section 100-02.

9. CAUTI

ON: Remove brake flui

d spillage immediately from

paint work, with clean water.

Check brake fluid level.

пЃ¬Check brak

e fluid level is

at the maximum mark.

пЃ¬Re

move cloth.

пЃ¬Fi

t cap.

10

.

Remove paint work protection covers, and close engine

compartment.

11. Start the engine and repeatedly press the brake pedal until

brake pressure is evident.

Page 384 of 2490

Rear Di

sc Brake - Brake PadsVe

hicles With: Standard Brakes

Remo

val and Installation

Remov

a

l

W

A

RNING: BRAKE DUST, IF INHALED CAN DAMAGE YOUR

HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST INTO THE ATMOSPHERE.

CAUTION: Replacement of nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

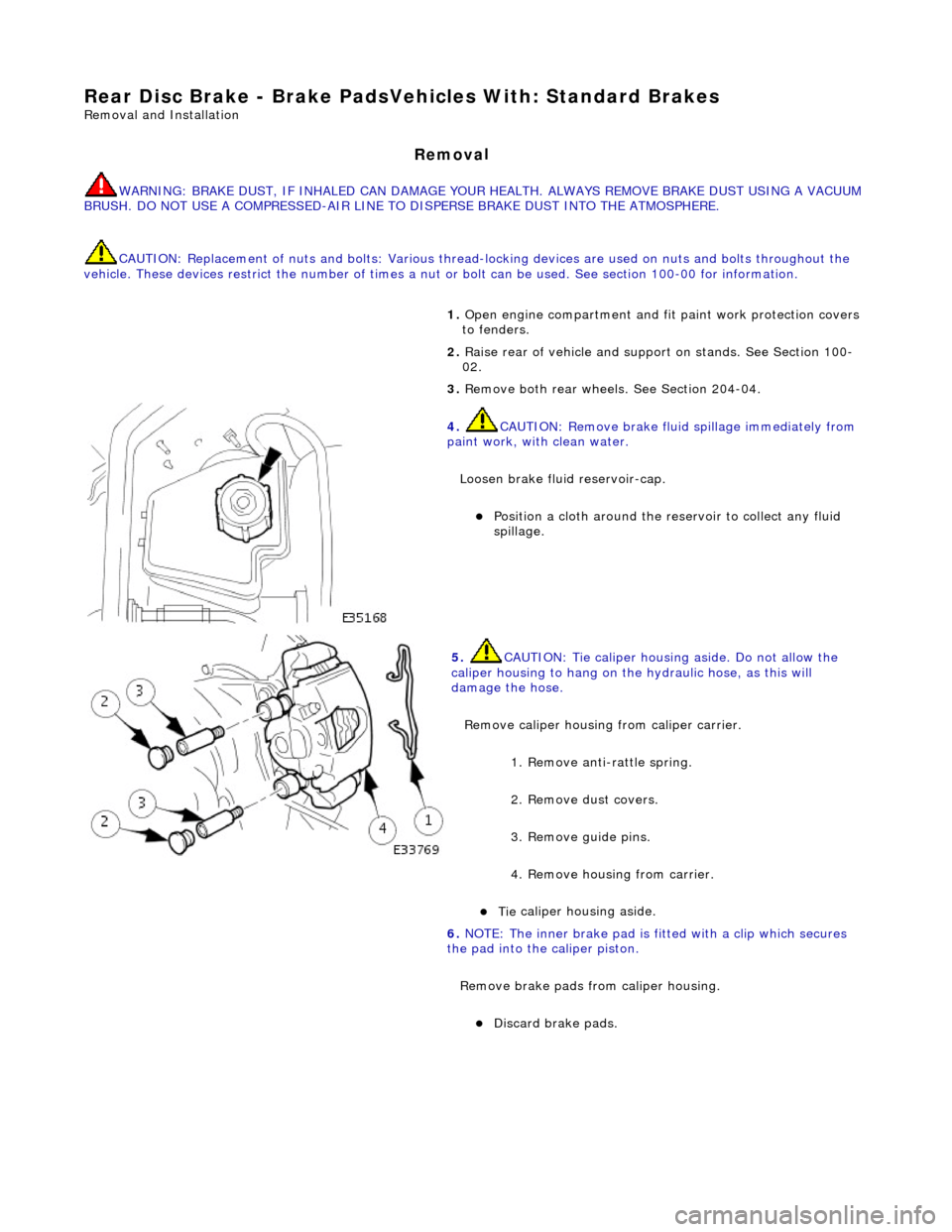

1. Op

en engine compartment and fit

paint work protection covers

to fenders.

2. Raise rear of vehicl e and support on stan ds. See Section 100-

02.

3. Remove both rear wheels. See Section 204-04.

4. CAUTIO

N: Remove brake flui

d spillage immediately from

paint work, with clean water.

Loosen brake fluid reservoir-cap.

пЃ¬Position a cloth around the reser

voir to collect any fluid

spillage.

5. CAUT

ION: Tie caliper housing aside. Do not allow the

caliper housing to hang on the hydraulic hose, as this will

damage the hose.

Remove caliper housing from caliper carrier.

1. Remove anti-rattle spring.

2. Remove dust covers.

3. Remove guide pins.

4. Remove housing from carrier.

пЃ¬Tie

caliper housing aside.

6.

NO TE

: The inner brake pad is fitt

ed with a clip which secures

the pad into the caliper piston.

Remove brake pads from caliper housing.

пЃ¬Discard b

rake pads.

Page 386 of 2490

6.

Remove stan ds and lower veh

icl

e. Refer to Section 100-02.

7. CAUTI

O

N: Remove brake flui

d spillage immediately from

paint work, with clean water.

Check brake fluid level.

пЃ¬Check brak e flu

id level is

at the maximum mark.

пЃ¬Remo

ve cloth.

пЃ¬Fi

t ca

p.

8.

Re

move paint work protection

covers, and close engine

compartment.

9. Start the engine and repeatedly press the brake pedal until

brake pressure is evident.

Page 387 of 2490

Rear Dis

c Brake - Brake PadsVehicl

es With: High Performance Brakes

Re

moval and Installation

Remov

al

1.

W

ARNING: BRAKE DUST, IF INHALED CAN DAMAGE

YOUR HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRE SSED-AIR LINE TO DISPERSE

BRAKE DUST INTO THE ATMOSPHERE. Failure to follow this

instruction may result in personal injury.

• CAUTIONS:

Brake pads must always be replaced in axle sets.

Replacement of nuts and bolts: Various thread-locking

devices are used on nuts and bolts throughout the vehicle. These

devices restrict the number of ti mes a nut or bolt can be used.

For additional information, refer to: General Service Information

(10

0-00 General Information,

Description and Operation).

The High performance brake caliper is aligned to the brake

disc when it is first installed to the vehicle, therefore, care must

be taken not to disturb this alignment. When removing the

caliper; remove the bolts that se cure the anchor bracket to the

vertical link only. DO NOT loosen any other caliper bolts.

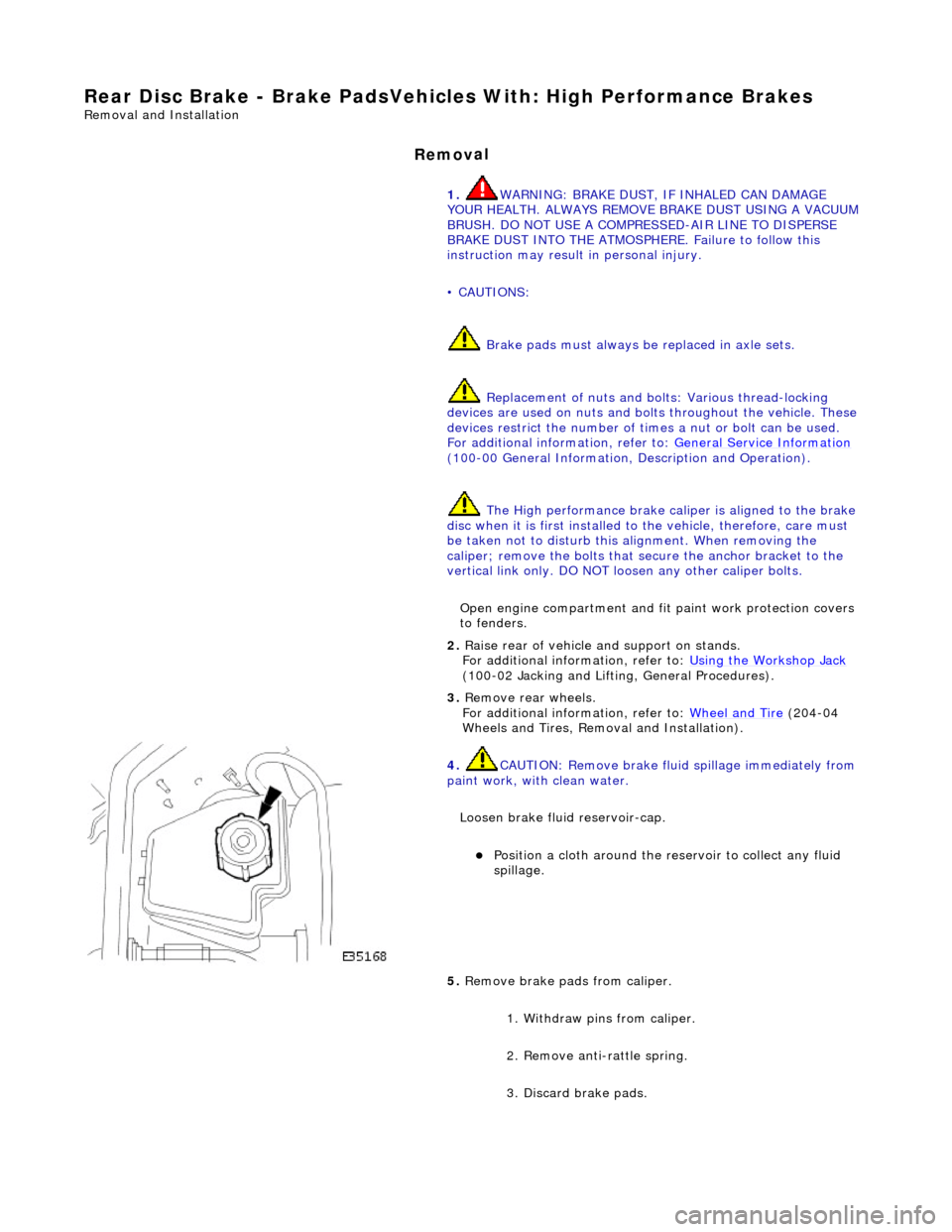

Open engine compartment and fit paint work protection covers

to fenders.

2. R

aise rear of vehicle an

d support on stands.

For additional information, refer to: Using the Workshop Jack

(10

0-02 Jacking and Lifting, General Procedures).

3. Remove rear wheels.

For additional information, refer to: Wheel and Tire

(20

4-04

Wheels and Tires, Remo val and Installation).

4. CAUTI

ON: Remove brake flui

d spillage immediately from

paint work, with clean water.

Loosen brake fluid reservoir-cap.

пЃ¬Position a cloth around the

reservoir to collect any fluid

spillage.

5. Remove brake

pads from caliper.

1. Withdraw pins from caliper.

2. Remove anti-rattle spring.

3. Discard brake pads.