engine JAGUAR X308 1998 2.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 320 of 2490

Brake Sys

tem - General Informatio

n - Brake System BleedingVehicles

With: Standard Brakes

Gen e

ral Procedures

WARNING: WASH HANDS AFTER HANDLING BRAKE FLUID. IF BRAKE FLUID COMES INTO CONTACT WITH THE EYES,

FLUSH EYES WITH COLD RUNNING WATER. IF IRRITATION PERSISTS SEEK MEDICAL ATTENTION. IF BRAKE FLUID IS

TAKEN INTERNALLY, DRINK WATER AND INDUCE VO MITING. GET MEDICAL ATTENTION IMMEDIATELY.

CAUTION: Remove brake fluid spillage imme diately from paint work with clean water.

1. Position vehi cl

e on a four-post lift.

2. Open engine compartment and fit paint work protection covers

to fenders.

3. NO

TE: Make sure the

brake-fluid level does not fall below the

fluid reservoir 'MIN' (minimum) mark when bleeding the brake

system.

Fill fluid reservoir to the 'MAX' (maximum) mark.

4. Prepare l e

ft-hand front, br

ake-caliper for bleeding.

пЃ¬Remove du

st cap.

пЃ¬Connect b

l

eed pipe

and fluid container to bleed nipple.

5. Bleed the brake.

1. Apply pressure to brake pedal

2. Open bleed nipple.

3. Fully depres s brake pedal.

4. Close bleed nipple.

5. Release brake pedal.

6. Wait two seconds to allow system to prime.

7. Repeat procedure until air- free brake fluid is expelled

from the caliper.

6. Tighten bleed nipple, see torque settings below.

Page 322 of 2490

Brake Sys

tem - General Informatio

n - Brake System BleedingVehicles

With: High Performance Brakes

Gen e

ral Procedures

1. WARNINGS:

IF BRAKE FLUID IS TAKEN INTERNALLY, DRINK WATER

AND INDUCE VOMITING. GET MEDICAL ATTENTION

IMMEDIATELY.

WASH HANDS AFTER HANDLING BRAKE FLUID. IF BRAKE

FLUID COMES INTO CONTACT WITH THE EYES, FLUSH EYES

WITH COLD RUNNING WATER. IF IRRITATION PERSISTS SEEK

MEDICAL ATTENTION.

CAUTION: Remove brake flui d spillage immediately from

paint work with clean water.

Position vehicle on a four-post lift.

2. Op

en engine compartment and fit

paint work protection covers

to fenders.

3. NO

TE: Make sure the

brake-fluid level does not fall below the

fluid reservoir 'MIN' (minimum) mark when bleeding the brake

system.

Fill fluid reservoir to the 'MAX' (maximum) mark.

4. Pr

epare the left-hand front,

brake-caliper for bleeding.

пЃ¬Connect b

leed pipes an

d fluid containers to bleed nipples.

5. Bleed the brake.

1. Apply pressure to brake pedal.

2. Open caliper's outer bleed nipple.

3. Fully depres s brake pedal.

Page 343 of 2490

Front Disc Brake - Brake CaliperVehicles

With: Standard Brakes

Re

moval and Installation

Remov

al

W

ARNING: BRAKE DUST, IF INHALED CAN DAMAGE YOUR

HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST INTO THE ATMOSPHERE.

• CAUTIONS:

Replacement of nuts and bolts: Various thread-locking de vices are used on nuts and bolts throughout the vehicle.

These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

Remove brake fluid spilla ge immediately from paint work, with clean water.

A new brake hose must be installe d when replacing a brake caliper.

The brake pad adhesive backing must not be reused, therefore always install new brake pads, irrespective of the

condition of the original pads when replacing a brake caliper. Always replace brake pads as an axle set.

S

pecial Tool(s)

Brake Pedal

Hold Tool

JDS 9013

1. O

pen engine compartment and fit

paint work protection covers

to fenders.

2. Raise vehicle on a four-post lift.

3. Raise front of vehicle and support on stands. Refer to Section

100-02.

4. Remove front wheels. See Section 204-04.

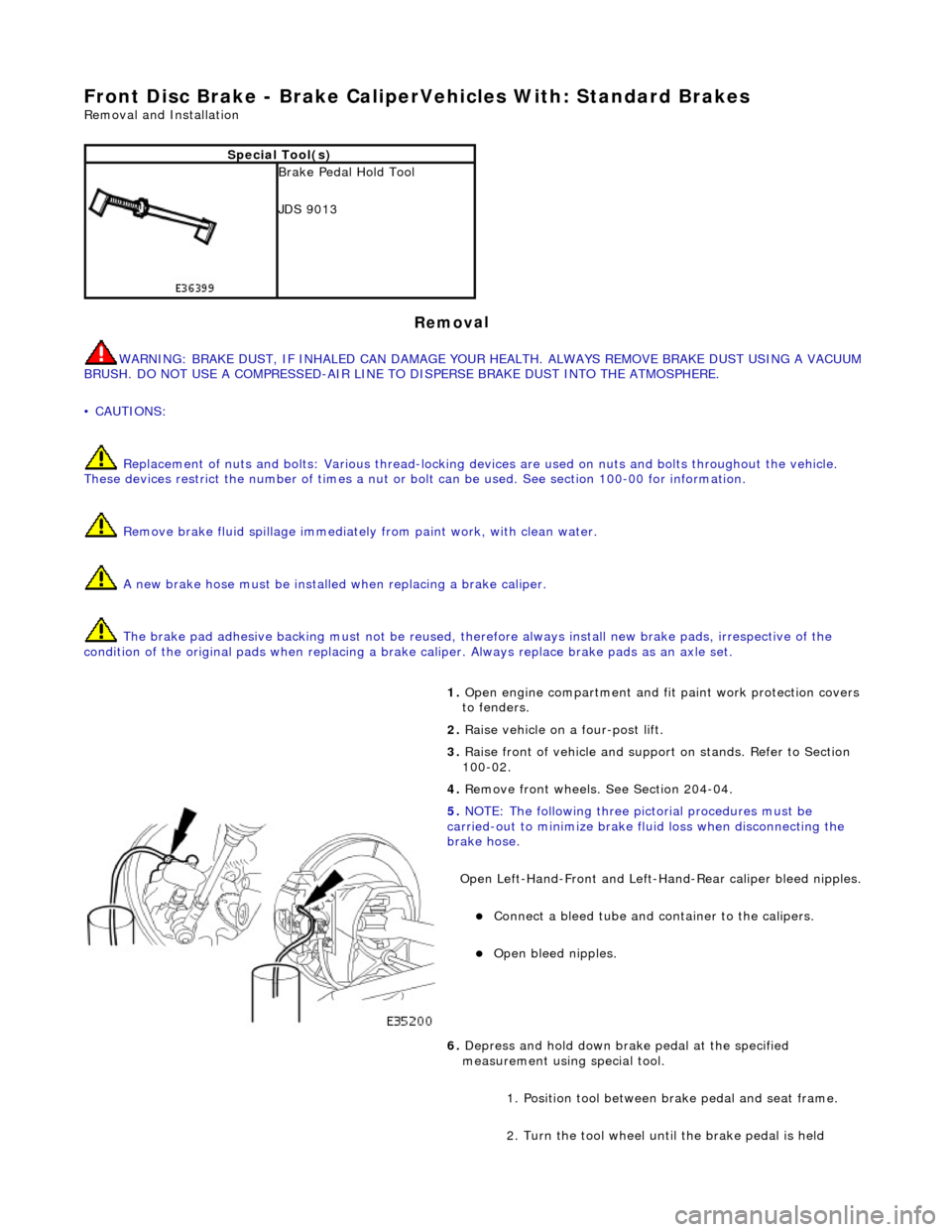

5. NOTE

: The following three pictorial procedures must be

carried-out to minimize brake fl uid loss when disconnecting the

brake hose.

Open Left-Hand-Front and Left-H and-Rear caliper bleed nipples.

пЃ¬Connect

a bleed tube and co

ntainer to the calipers.

пЃ¬O

pen bleed nipples.

6. Depress and hold down brak e pedal at the specified

measurement using special tool.

1. Position tool between brake pedal and seat frame.

2. Turn the tool wheel unti l the brake pedal is held

Page 347 of 2490

Front Disc Brake - Brake CaliperVehicles With: High Performance Brakes

Re

moval and Installation

Remov

al

S

pecial Tool(s)

Brake Pedal

Hold Tool

JDS 9013

1. WARNING: BRAKE DUST, IF INHALED CAN DAMAGE

YOUR HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRE SSED-AIR LINE TO DISPERSE

BRAKE DUST INTO THE ATMOSPHERE.

• CAUTIONS:

Replacement of nuts and bolts: Various thread-locking

devices are used on nuts and bolts throughout the vehicle. These

devices restrict the number of ti mes a nut or bolt can be used.

See section 100-00 for information.

Remove brake fluid spillage immediately from paint work,

with clean water.

The Brembo caliper is aligned to the brake disc when it is

first installed to the vehicle, therefore, care must be taken not to

disturb this alignment. When removing the caliper; remove the

bolts that secure the anchor bracket to the vertical link only. DO

NOT loosen any other caliper bolts.

Open engine compartment and fit paint work protection covers

to fenders.

2. R

aise vehicle on a four-post lift.

3. Raise front of vehicle and support on stands. Refer to Section

100-02.

4. Remove front wheels. Refe r to operation 74.20.05.

5. NOTE

: The following three pictorial procedures must be

carried-out to minimize brake fl uid loss when disconnecting the

brake hose.

Open Left-Hand-Front and Left-H and-Rear caliper bleed nipples.

пЃ¬Connect

a bleed tube and co

ntainer to the calipers.

пЃ¬O

pen bleed nipples.

6. Depress and hold down brak e pedal at the specified

measurement using the special tool.

Page 351 of 2490

Front Dis

c Brake - Brake DiscVe

hicles With: Standard Brakes

Re

moval and Installation

Remov

al

• WAR

NINGS:

BRAKE DISCS MUST ALWAYS BE REPLACED IN PAIRS.

BRAKE DUST, IF INHALED CAN DAMAGE YOUR HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM BRUSH.

DO NOT USE A COMPRESSED-AIR LINE TO DI SPERSE BRAKE DUST INTO THE ATMOSPHERE.

CAUTION: Replacement of nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

1. O

pen engine compartment and in

stall paint work protection

covers to fenders.

2. Raise front of vehicle and suppo rt on stands. See Section 100-

02.

3. Remove front wheels. Re fer to Section 204-04.

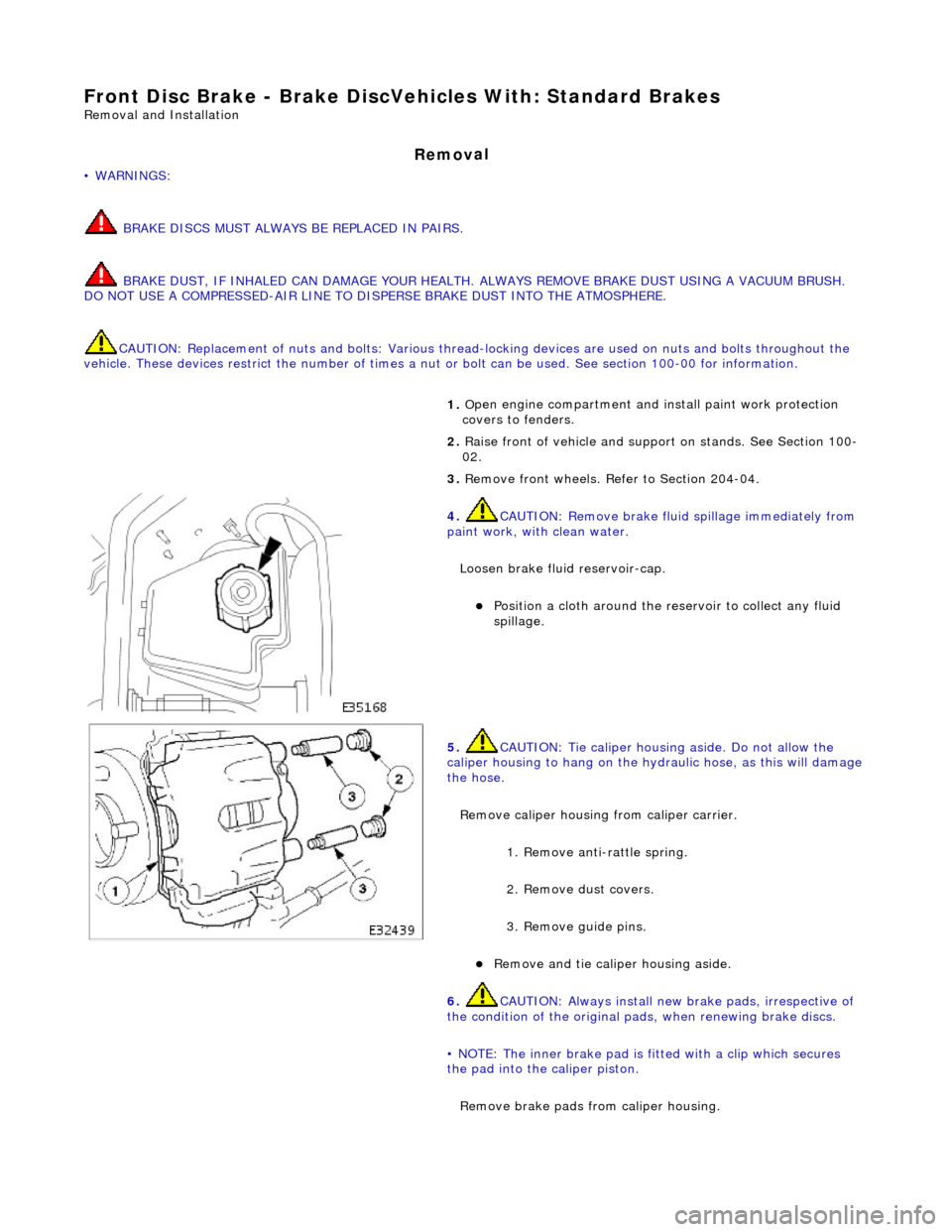

4. CAUTI

ON: Remove brake flui

d spillage immediately from

paint work, with clean water.

Loosen brake fluid reservoir-cap.

пЃ¬Position a cloth around the

reservoir to collect any fluid

spillage.

5. CAU

TION: Tie caliper housing aside. Do not allow the

caliper housing to hang on the hydraulic hose, as this will damage

the hose.

Remove caliper housing from caliper carrier.

1. Remove anti-rattle spring.

2. Remove dust covers.

3. Remove guide pins.

пЃ¬Re

move and tie caliper housing aside.

6.

CAUTI

ON: Always install new brake pads, irrespective of

the condition of the original pads, when renewing brake discs.

• NOTE: The inner brake pad is fitted with a clip which secures

the pad into the caliper piston.

Remove brake pads from caliper housing.

Page 354 of 2490

пЃ¬Remo

ve cloth.

пЃ¬Fit ca

p.

10. Remove paint work protection covers, and close engine

compartment.

11. Start the engine and repeatedly press the brake pedal until

brake pressure is evident.

Page 355 of 2490

Front Dis

c Brake - Brake DiscVehicles With: High Performance Brakes

Re

moval and Installation

Remov

al

1.

WAR

NINGS:

BRAKE DISCS MUST ALWAYS BE REPLACED IN PAIRS.

BRAKE DUST, IF INHALED CAN DAMAGE YOUR HEALTH.

ALWAYS REMOVE BRAKE DUST USING A VACUUM BRUSH. DO

NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST

INTO THE ATMOSPHERE.

• CAUTIONS:

Replacement of nuts and bolts: Various thread-locking

devices are used on nuts and bolts throughout the vehicle. These

devices restrict the number of ti mes a nut or bolt can be used.

See section 100-00 for information.

The Brembo caliper is aligned to the brake disc when it is

first installed to the vehicle, therefore, care must be taken not to

disturb this alignment. When removing the caliper; remove the

bolts that secure the anchor bracket to the vertical link only. DO

NOT loosen any other caliper bolts.

The front brake discs are dire ctional and must be installed

to the correct side of the vehi cle. Refer to Description and

Operation, section 206-03 for further information.

Do not loosen bolts securing brake disc to disc mounting.

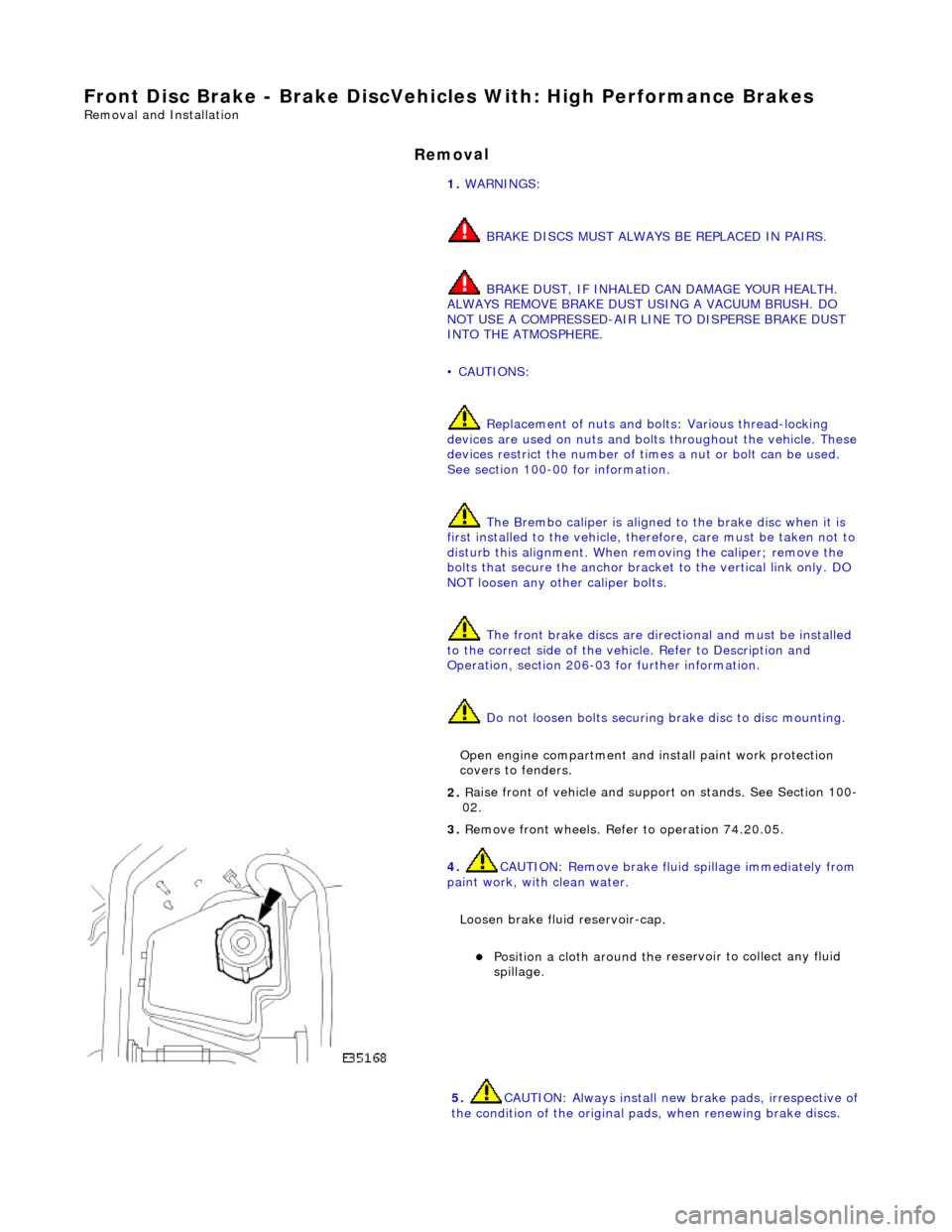

Open engine compartment and in stall paint work protection

covers to fenders.

2. R

aise front of vehicle and suppo

rt on stands. See Section 100-

02.

3. Remove front wheels. Refe r to operation 74.20.05.

4. CAUTI

ON: Remove brake flui

d spillage immediately from

paint work, with clean water.

Loosen brake fluid reservoir-cap.

пЃ¬Position a cloth around the

reservoir to collect any fluid

spillage.

5. CAUTI

ON: Always install new brake pads, irrespective of

the condition of the original pads, when renewing brake discs.

Page 358 of 2490

9.

CAUTIO

N: Remove brake flui

d spillage immediately from

paint work, with clean water.

Check brake fluid level.

пЃ¬Check brak e flu

id level is

at the maximum mark.

пЃ¬Remo

ve cloth.

пЃ¬Fi

t ca

p.

10.

R

emove paint work protection

covers, and close engine

compartment.

11. Start the engine and repeatedly press the brake pedal until

brake pressure is evident.

Page 359 of 2490

Front Dis

c Brake - Brake PadsVe

hicles With: Standard Brakes

Re

moval and Installation

Remov

al

W

ARNING: BRAKE DUST, IF INHALED CAN DAMAGE YOUR

HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST INTO THE ATMOSPHERE.

CAUTION: Replacement of nuts and bolts: Various thread-locking devices are used on nuts and bolts throughout the

vehicle. These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

1. O

pen engine compartment and fit

paint work protection covers

to fenders.

2. Raise front of vehicle and suppo rt on stands. See Section 100-

02.

3. Remove front wheels. See Section 204-04.

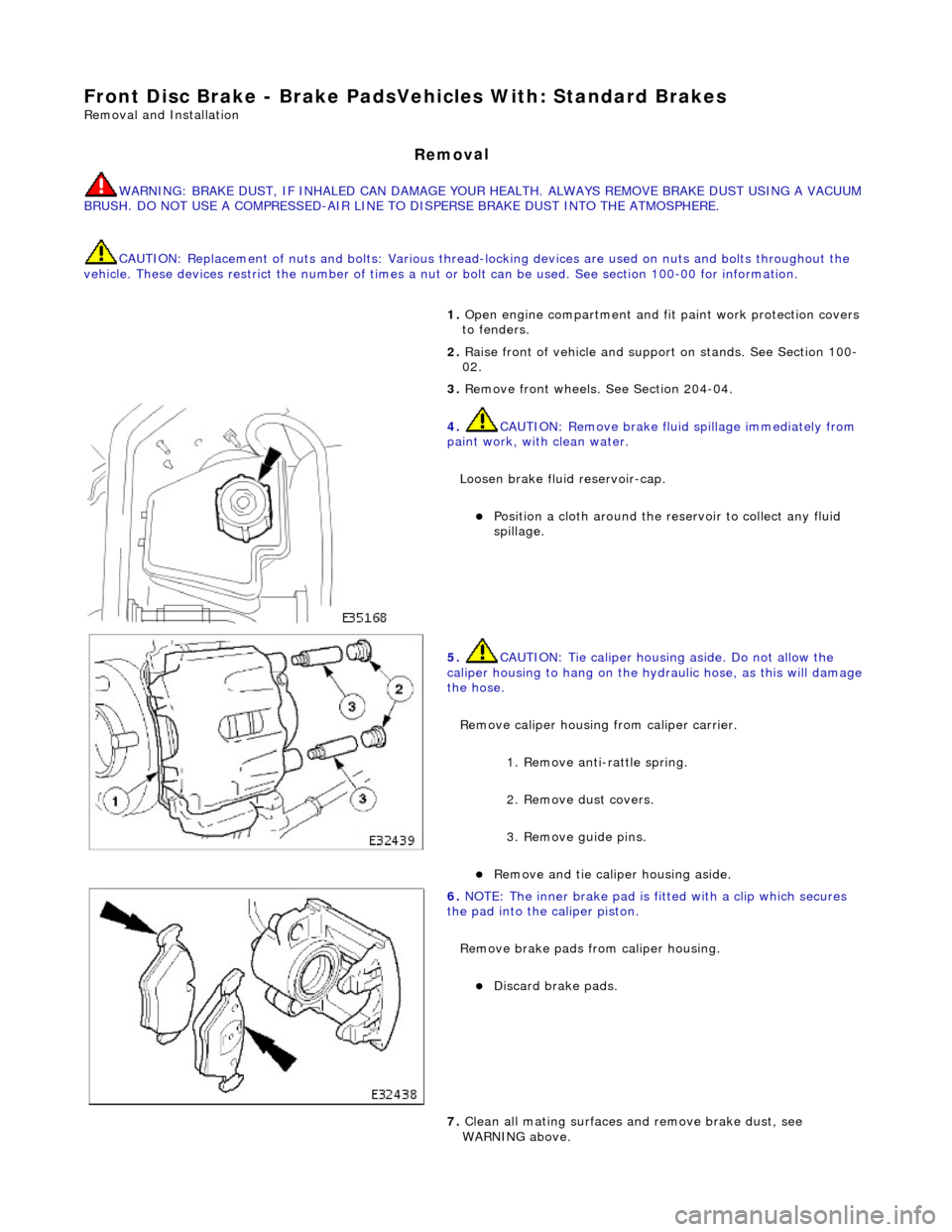

4. CAUTI

ON: Remove brake flui

d spillage immediately from

paint work, with clean water.

Loosen brake fluid reservoir-cap.

пЃ¬Position a cloth around the

reservoir to collect any fluid

spillage.

5. CAU

TION: Tie caliper housing aside. Do not allow the

caliper housing to hang on the hydraulic hose, as this will damage

the hose.

Remove caliper housing from caliper carrier.

1. Remove anti-rattle spring.

2. Remove dust covers.

3. Remove guide pins.

пЃ¬Re

move and tie caliper housing aside.

6.

NO

TE: The inner brake pad is fitt

ed with a clip which secures

the pad into the caliper piston.

Remove brake pads from caliper housing.

пЃ¬Discard

brake pads.

7. Clean all mating surfaces and remove brake dust, see

WARNING above.

Page 360 of 2490

In

stallation

8.

Repeat ab

ove procedure to remo

ve opposite side brake pads.

1. CAUTIO

N: Retracting the caliper piston may cause the

fluid reservoir to over-flow. Remove brake fluid spillage

immediately from paint work, with clean water.

• NOTE: Clean caliper piston to pad mating surface.

Install brake pads in to caliper housing.

1. Slowly retract piston into caliper housing.

2. Remove paper backing from pads to reveal adhesive shim. Install brake pads, insert clip located on back of

inner pad into caliper piston.

2. Instal

l caliper housing to caliper carrier.

пЃ¬Align hou

s

ing to carrier.

1. Install and tighten guide pins to 25-30 Nm.

2. Install dust covers.

3. Install anti-rattle spring.

3. Repeat above procedure to install opposite side brake pads.

4. Fit wheels. Refer to section 204-04.

5. Remove stands and lower vehicl e. Refer to section 100-02.

6. CAUTIO

N: Remove brake flui

d spillage immediately from

paint work, with clean water.

Check brake fluid level.

пЃ¬Check brak e flu

id level is

at the maximum mark.

пЃ¬Remo

ve cloth.

пЃ¬Fi

t ca

p.

7.

Re

move paint work protection

covers, and close engine

compartment.

8. Start the engine and repeatedly press the brake pedal until

brake pressure is evident.