fuel injector JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 13 of 2490

Removal and Installation

Fuel Injection Supply Manifo ld LH

(19.60.05)

Fuel Injection Supply Manifold RH (19.60.04)

Fuel Injection Supply Manifold Pipe (19.41.04)

Fuel Injector Vehicles Without: Supercharger (18.10.01)

Fuel Injector Vehicles With: Supercharger (18.10.01)

Fuel Injectors Vehicles With: Supercharger (18.10.02)

Throttle Body (19.70.04)

Throttle Body Gasket (19.70.07)

303‐05: Accessory Drive

Descriptio

n and Operation

Accessory Drive

Removal and Installation

Accessory Drive Belt (12.10.40) ‐ 3.2L NA V8 ‐ AJ26/4.0L NA V8 ‐ AJ27

Accessory Drive Belt (12.10.40) ‐ 4.0L SC V8 ‐ AJ26

Accessory Drive Belt Idler Pulley (12.10.43) ‐ 3.2L NA V8 ‐ AJ26/4.0L NA V8 ‐ AJ27

Accessory Drive Belt Idler Pulle

y (12.10.43) ‐ 4.0L SC V8 ‐ AJ26

Accessory Drive Belt Tensioner (12.10.41) ‐ 3.2L NA V8 ‐ AJ26/4.0L NA V8 ‐ AJ27

Accessory Drive Belt Tensioner (12.10.41) ‐ 4.0L SC V8 ‐ AJ26

Supercharger Belt (18.50.08)

Supercharger Belt Idler Pulley (18.50.09)

Supercharger Belt Tensioner (18.50.24)

303‐06: Starting System

Description and Operati

on

Starting System

Diagnosis and Testing

Starting System

Inspection and Verification

Diagnostic Trouble Code (DTC) Index

Pinpoint Tests

Removal and Installation

Starter Motor (86.60.01)

Page 44 of 2490

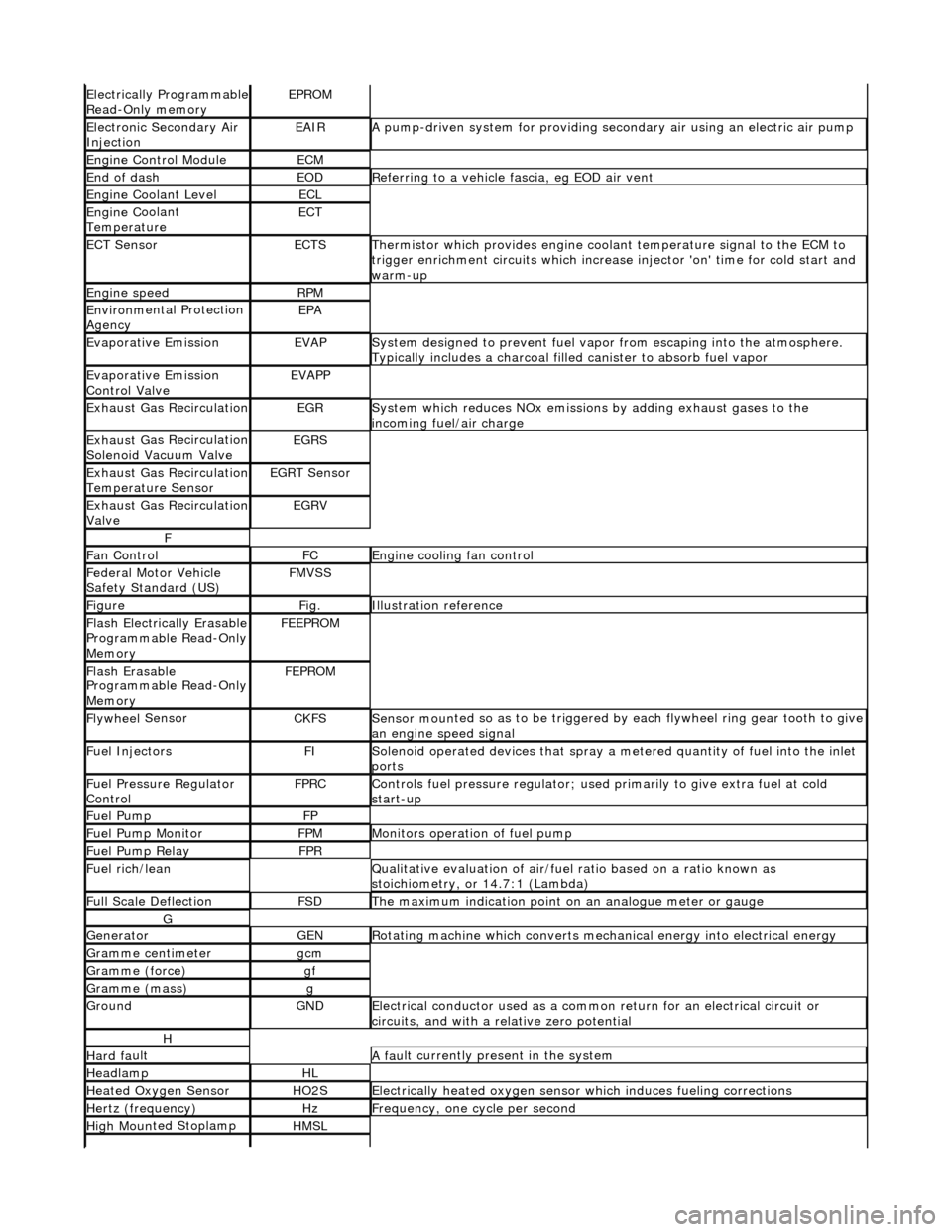

Electrically Programmable

R

ead-Only memory

EPROM

Ele

c

tronic Secondary Air

Injection

EAIRA p

ump-driven system for providing seco

ndary air using an electric air pump

Engine C

ontrol Module

ECM

End of dashEODR

e

ferring to a vehicle fascia, eg EOD air vent

Engine

C

oolant Level

ECL

Engine

C

oolant

Temperature

ECT

ECT Sen s

or

ECTSTherm

i

stor which provides engine coolant temperature signal to the ECM to

trigger enrichment circuits which increase injector 'on' time for cold start and

warm-up

Engine s

peed

RP

M

Environ m

ental Protection

Agency

EPA

Evaporative EmissionEVAPSy stem designed to prevent fu

el vapor from escaping into the atmosphere.

Typically includes a charcoal filled canister to absorb fuel vapor

Evaporative Emission

Control ValveEVAPP

Exhaust G

as Recirculation

EGRSys

t

em which reduces NOx emissions by adding exhaust gases to the

incoming fuel/air charge

Exhaus t G

as Recirculation

Solenoid Vacuum Valve

EGRS

Exhaus t G

as Recirculation

Temperature Sensor

EGRT Sen s

or

Exhaus

t G

as Recirculation

Valve

EGRV

F

F a

n Control

FCEngine

cooling fan control

F

e

deral Motor Vehicle

Safety Standard (US)

FMV S

S

Fi

gur

e

Fi

g.Illustrati

on reference

Flash

E

lectrically Erasable

Programmable Read-Only

Memory

FEE PR

OM

Flash

E

rasable

Programmable Read-Only

Memory

FEP R

OM

Flywhee

l

Sensor

CKFSSens

or moun

ted so as to be

triggered by each flywheel ring gear tooth to give

an engine speed signal

Fue l

Injectors

FISol

e

noid operated devices that spray a metered quantity of fuel into the inlet

ports

F u

el Pressure Regulator

Control

FP RCControls fuel pressure regu l

ator; used primarily to

give extra fuel at cold

start-up

Fue l

Pump

FP

Fue

l

Pump Monitor

FP

MMonitors operation of fuel pump

Fue l

Pump Relay

FP

R

Fu

el rich/lean

Q

u

alitative evaluation

of air/fuel ratio based on a ratio known as

stoichiometry, or 14.7:1 (Lambda)

F u

ll Scale Deflection

FSDTh

e

maximum indication point on

an analogue meter or gauge

G

Gene

rator

GENRot

a

ting machine which converts mechanical energy into electrical energy

G

r

amme centimeter

gcm

Gramm

e

(force)

gf

Gramm

e

(mass)

g

GroundGNDEle

c

trical conductor used

as a common return for an electrical circuit or

circuits, and with a relative zero potential

H

Hard f a

ult

A

fau

lt currently present in the system

HeadlampHL

Heat

ed Oxygen

Sensor

HO2SElectrically

h

eated oxygen sensor which induces fueling corrections

Hertz (frequency)HzFrequ

e

ncy, one cycle per second

High

Moun

ted Stoplamp

HMSL

Page 432 of 2490

It is a reciprocating two

-circuit pu

mp in which one brake circuit is as signed to each pump circuit.

It supplies th

e fluid pressure and vo

lume to supply the brake circuits under ABS and Traction control.

The pump is driven by an electri

c motor, with the pump

housing incorporating two lo w pressure accumulators and

damping chambers for each brake circuit.

The ac cu

mulator stores the pressure and smooths out the output pu

lses from the pump.

ABS Warning Lamp

The sys

tem will be set in a fail-safe mode if a problem is de

tected; a warning lamp on the instrument panel will notify the

driver there is a problem.

Anti-Lock Braking Sy

stem (ABS)

The AB

S components are combined with

an hydraulic booster and a tandem master cylinder to provide a two circuit braking

system. The system comprises, four wheel speed sensor s, a brake control modulator and an ABS warning lamp.

Should a wheel start to lock-up during braking a signal tr ansmitted from the wheel speed sensor to the brake control

modulator will start the hydraulic pump. The brake control modula tor will close the input valve of the line connected to the

locked-wheel to stop any increase in fluid pressure to the br ake caliper. If this fails to prevent the wheel locking, the

pressure in the caliper will be decreased by opening the return valve until th e wheel starts accelerating again. The fluid

pressure from the return va lve is directed into the low pressure accumulator, housed in the pump.

From the low pressure accumulator, fl uid is pumped through the damping cham ber to the brake master cylinder. The

pressure to the brake caliper will then be increased in small steps to maintain maximum adhesion between the tire and road

surface. This is achieved by closing the return valve, and opening the input valve and using the hydraulic pump to increase

the pressure.

Although the system senses all four wheels independently, the rear wheels are regulated as a pair. If a sensor on a rear

wheel detects a wheel decelerating rapidly, then the fluid pressure to both wheels is reduced. The fluid pressure is then

dictated by the wheel having the lowe st adhesion with the road surface.

The ABS system will be set in a fail-safe mode if a problem is detected; a warn ing lamp on the instrument panel will notify

the driver there is a problem. The brake system will still operate conventionally and with the same standard of performance

as a vehicle not equipped with ABS.

Automa tic Stability Control (ASC)

Th

e ASC utilizes the ABS sensing arrangement to provide the maximum traction force to propel the vehicle.

The ASC is switched on when the engine is started. The system can be switched off by pressing the 'ASC OFF' (the switched

is marked 'TRAC OFF' on vehicles fitted with traction control). The switch, which is situated in the center console switchpack,

lights up to warn that the system is sw itched off. An 'ASC' amber warning light flashes on the instrument panel when the

system detects a spinning wheel.

The ASC system uses engine intervention to reduce the torque delivered to the drive wheels to prevent them spinning.

Engine torque is re duced in three ways:

The

throttle is moved towards the closed position.

The ignition is retarded. F

u

el is cut-off at the cylinder injectors.

Wheel spin is detected by the wheel sp eed sensors and communicated to the AB S/TCCM. The ABS/TCCM uses information

from the controller area network (CAN) to calculate the torque that the engine should produce to stop the wheel spinning.

Torque reductions are then requested from the engine control module (ECM ) through the CAN. The throttle is then

positioned to provide the target torque, which has been calculated to prevent wheel spin. During the transient phase of

torque reduction the fuel is cut-off and th e ignition retarded Both the fuel cut-off an d ignition retard will be restored to

normal when the throttle is set to its new position.

The ASC uses a brake control modulator with six solenoid va lves: three normally open inlet valves and three normally

Page 527 of 2490

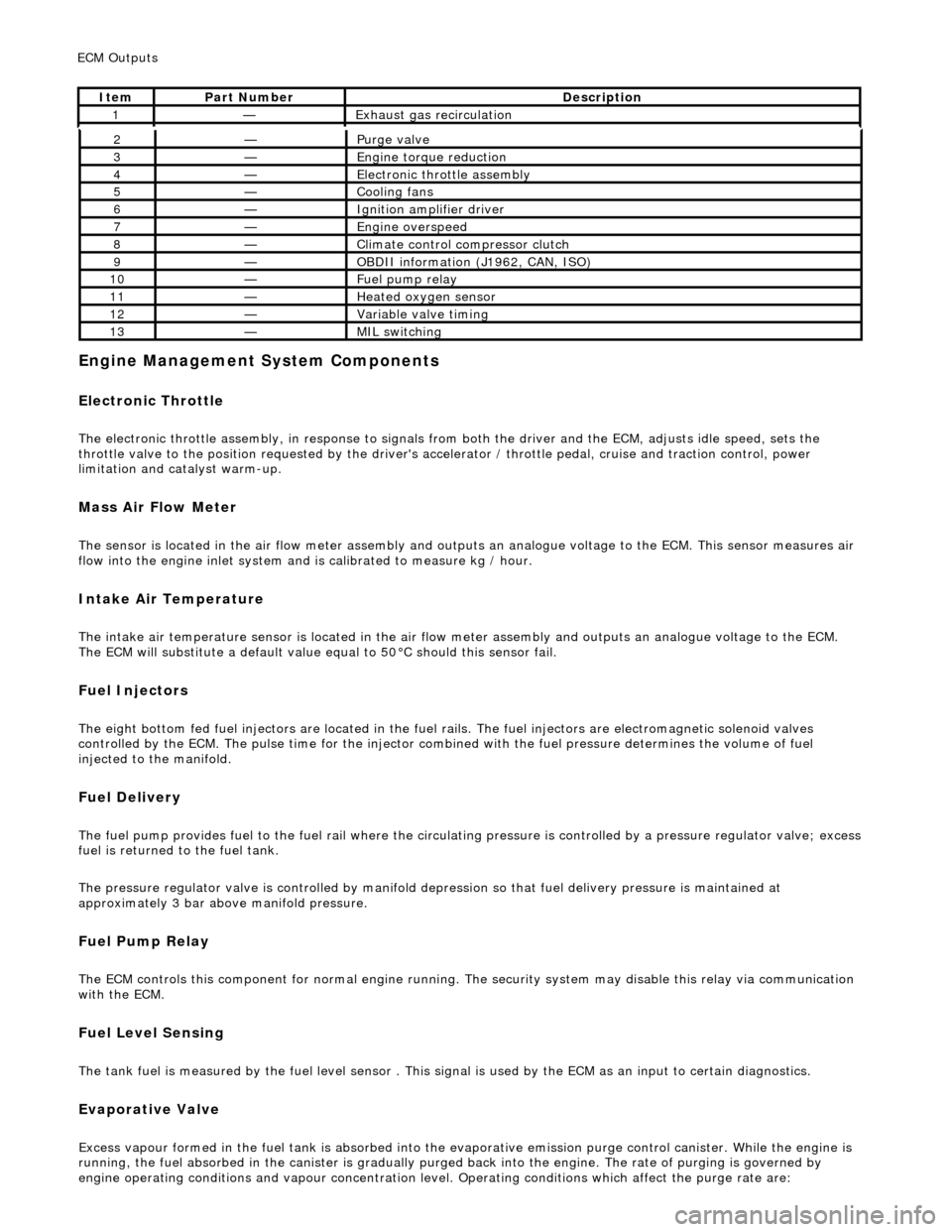

E

ngine Management System Components

Electronic Throt

tle

The

electronic throttle assembly, in resp

onse to signals from both the driver and the ECM, adjusts idle speed, sets the

throttle valve to the position requested by the driver's accelerator / throttle pedal, cruise and traction control, power

limitation and catalyst warm-up.

Mass

Air Flow Meter

The sensor i

s located in the air flow mete

r assembly and outputs an analogue voltag e to the ECM. This sensor measures air

flow into the engine inlet system and is calibrated to measure kg / hour.

In

take Air Temperature

Th

e intake air temperature sensor is loca

ted in the air flow meter assembly and outputs an analogue voltage to the ECM.

The ECM will substitute a default value eq ual to 50°C should this sensor fail.

Fuel Injectors

The eigh

t bottom fed fuel injectors are located in the fuel rails. Th

e fuel injectors are electromagnetic solenoid valves

controlled by the ECM. The pulse time for the injector combined with the fuel pr essure determines the volume of fuel

injected to the manifold.

Fue

l Delivery

The fu

el pump provides fuel to the fuel rail where the circulat

ing pressure is controlled by a pressure regulator valve; excess

fuel is returned to the fuel tank.

The pressure regulator valve is controlled by manifold depression so that fuel delivery pressure is maintained at

approximately 3 bar above manifold pressure.

Fuel Pump

Relay

The ECM controls thi

s component for normal

engine running. The security system may disable this relay via communication

with the ECM.

Fuel Lev

el Sensing

The tank fuel

is measured by the fuel le

vel sensor . This signal is used by the ECM as an in put to certain diagnostics.

Eva

porative Valve

Excess vapour

formed in the fuel tank is

absorbed into the evaporative emission pu rge control canister. While the engine is

running, the fuel absorbed in the canister is gradually purged back into the engine. The rate of purging is governed by

engine operating conditions and vapour concentration level. Operating conditions which affect the purge rate are:

2—Purge

valve

3—Engine

torque reduction

4—E

lectronic throttle assembly

5—Coo

ling fans

6—Ignition amplifier driver

7—Engine overspeed

8—Cli

mate control compressor clutch

9—O

BDII information (J1962, CAN, ISO)

10—F

uel pump relay

11—Heat

ed oxygen sensor

12—Vari

able valve timing

13—MIL sw

itching

ECM Out

puts

It

em

Par

t Number

De

scription

1—Exhaus

t gas recirculation

Page 530 of 2490

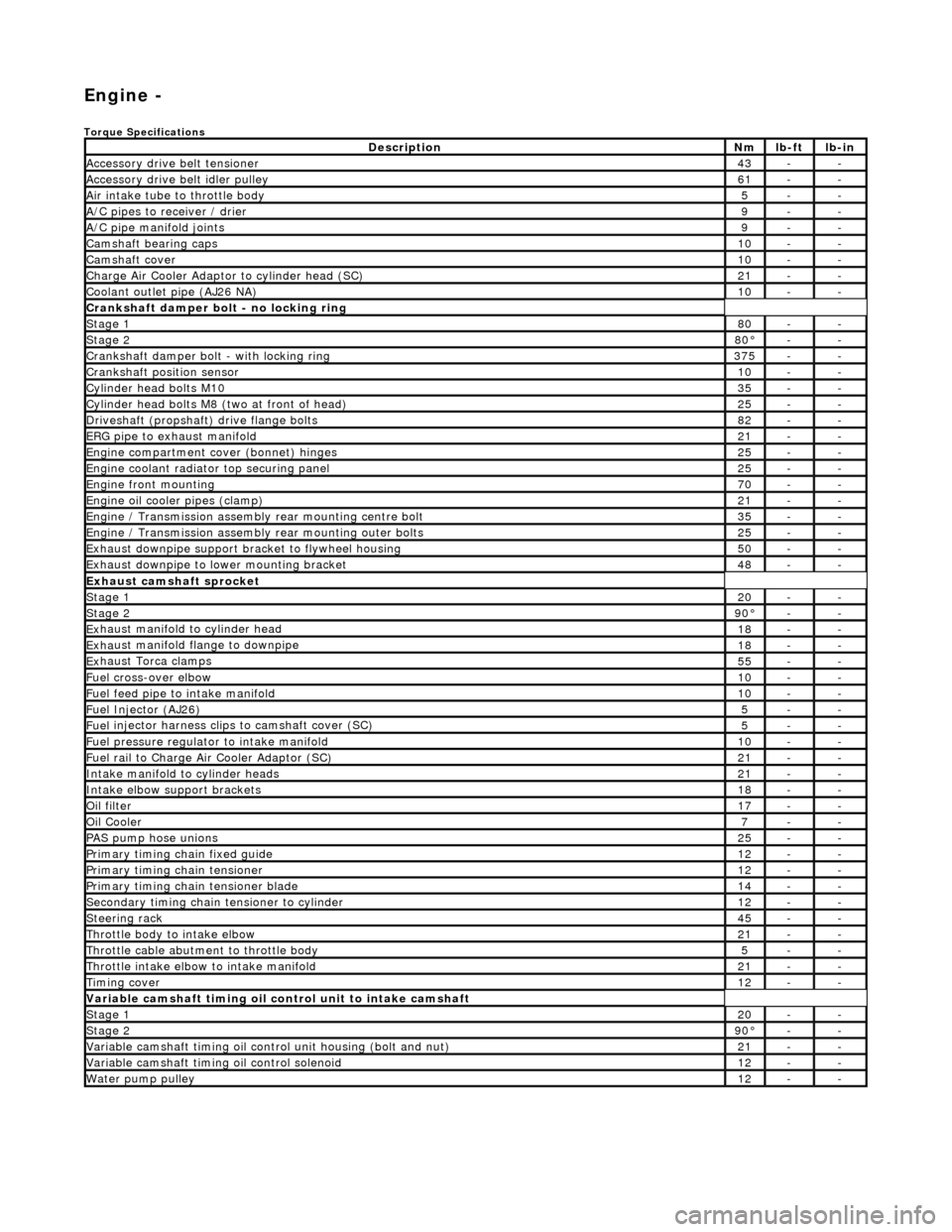

Engi

ne -

Torqu

e Specifications

De

s

cription

Nmlb

-

ft

lb

-

in

A

ccessory

drive belt tensioner

43--

A

ccessory

drive belt idler pulley

61--

Air in

ta

ke tube to throttle body

5--

A/C

pipes t

o receiver / drier

9--

A/C pipe m

anifold joints

9--

Camsh

aft bearin

g caps10--

Ca

msh

aft cove

r10--

Ch

arge Air Co

oler Adaptor to cylinder head (SC)

21--

Co

olan

t outlet pipe (AJ26 NA)

10--

Cran

kshaft damper bolt - no lockin

g ring

St

ag

e 1

80--

Stag

e 2

80°--

C

r

ankshaft damper bolt - with locking ring

37

5--

Cra

nkshaft position sensor

10--

Cy

li

nder head bolts M10

35--

Cy

lin

der head bolts M8 (two at front of head)

25--

Driv

es

haft (propshaft) drive flan

ge bo

l

ts

82--

ERG p

i

pe to exhaust manifold

21--

Engi

ne compartment cover (bonnet) hinges

25--

En

gine

coolant radiator top securing panel

25--

E

ng

ine front mounting

70--

En

gine

oil cooler pipes (clamp)

21--

En

gi

ne / Transmission assembly rear mounting centre bolt

35--

En

gi

ne / Transmission assembly rear mounting outer bolts

25--

Ex

ha

ust downpipe support bracket to flywheel housing

50--

Ex

ha

ust downpipe to lower mounting bracket

48--

E

x

haust camshaft sprocket

St

age 120--

Stage 290 °--

Ex

haust manifold to cylinder head

18--

Ex

ha

ust manifold flange to downpipe

18--

E

x

haust Torca clamps

55--

Fuel cross-over elbo

w

10--

Fu

el f

eed pipe to intake manifold

10--

Fuel

Injector (AJ

26)

5--

Fuel

injector ha

rness clips to camshaft cover (SC)

5--

Fu

el p

ressure re

gu

l

ator to intake manifold

10--

F

u

el rail to Char

ge

A

ir Cooler Adaptor (SC)

21--

In

ta

ke manifold to cylinder heads

21--

Inta

ke elbow support brackets

18--

Oil f

i

lter

17--

Oil C

o

oler

7--

P

AS pu

mp hose unions

25--

P

r

imary timing chain fixed guide

12--

P

r

imary timing chain tensioner

12--

Pr

imary timing chain tensioner blade

14--

S

e

condary timing chain tensioner to cylinder

12--

S

t

eerin

g ra

ck45--

Thro

ttle body to intake elbow

21--

Th

ro

ttle cable abutment to throttle body

5--

Th

ro

ttle intake elbow to intake manifold

21--

Ti

mi

ng cover

12--

Variable camshaft t

i

ming oil control unit to intake camshaft

St

ag

e 1

20--

St

ag

e 2

90

°--

Var

iable camshaft timing oil control unit housing (bolt and nut)

21--

Va

ria

ble camshaft timi

ng oil control solenoid

12--

Wa

ter pump pulley

12--

Page 708 of 2490

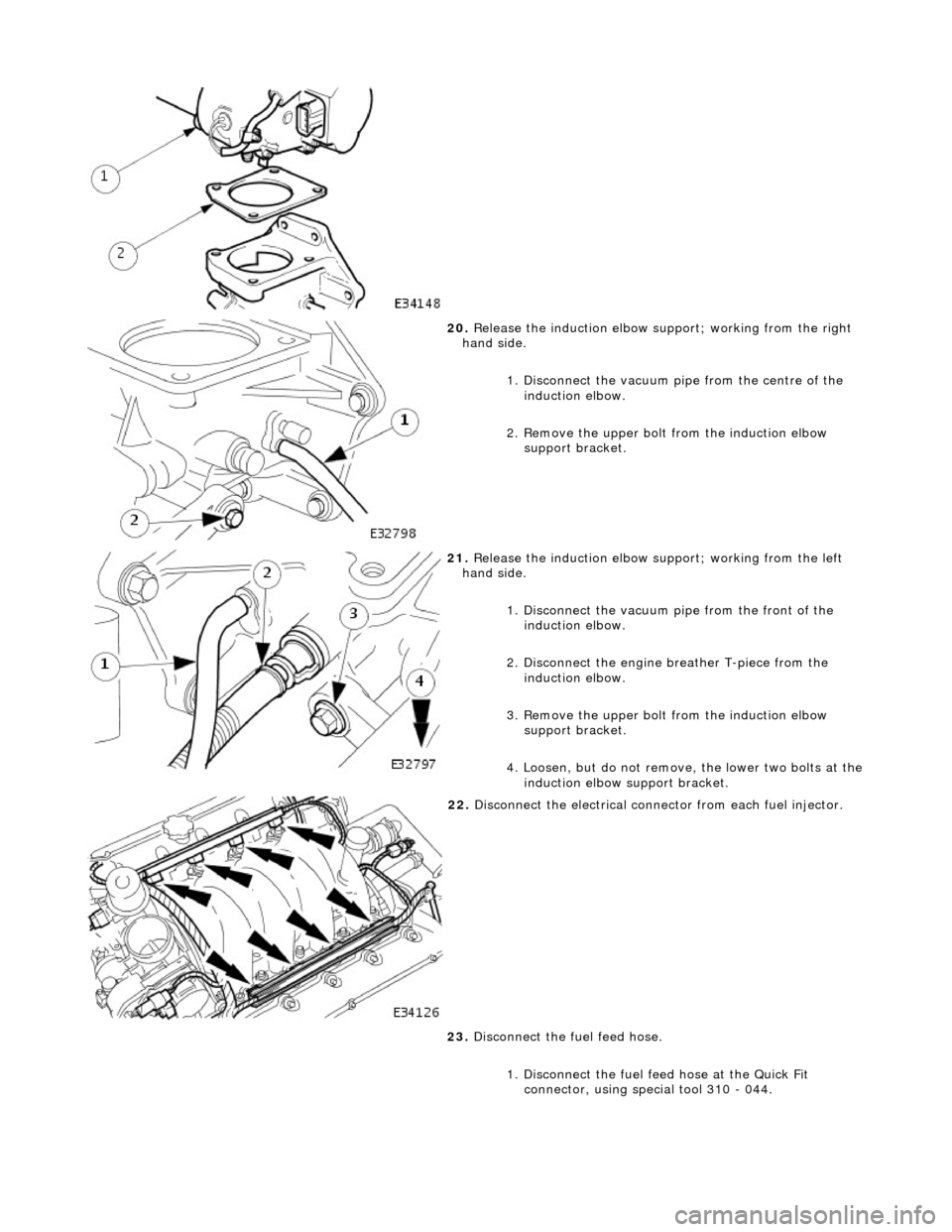

20. Release the induction elbow su pport; working from the right

hand side.

1. Disconnect the vacuum pi pe from the centre of the

induction elbow.

2. Remove the upper bolt from the induction elbow support bracket.

21. Release the induction elbow su pport; working from the left

hand side.

1. Disconnect the vacuum pipe from the front of the

induction elbow.

2. Disconnect the engine breather T-piece from the induction elbow.

3. Remove the upper bolt from the induction elbow support bracket.

4. Loosen, but do not remove , the lower two bolts at the

induction elbow support bracket.

22. Disconnect the electrical conne ctor from each fuel injector.

23. Disconnect the fuel feed hose.

1. Disconnect the fuel f eed hose at the Quick Fit

connector, using special tool 310 - 044.

Page 710 of 2490

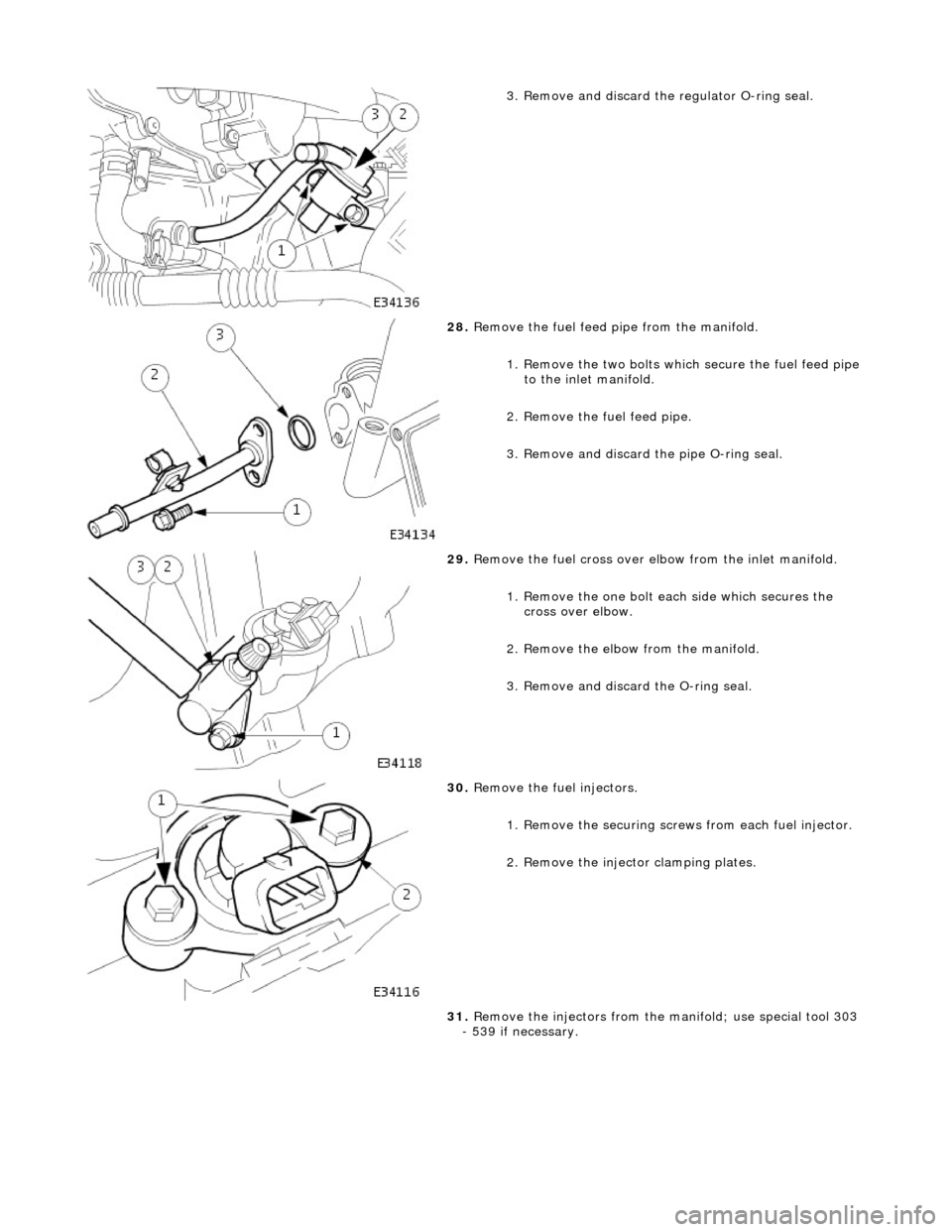

3. Remove and discard the regulator O-ring seal.

28. Remove the fuel feed pipe from the manifold.

1. Remove the two bolts which secure the fuel feed pipe

to the inlet manifold.

2. Remove the fuel feed pipe.

3. Remove and discard the pipe O-ring seal.

29. Remove the fuel cross over elbow from the inlet manifold.

1. Remove the one bolt each side which secures the cross over elbow.

2. Remove the elbow from the manifold.

3. Remove and discard the O-ring seal.

30. Remove the fuel injectors.

1. Remove the securing scre ws from each fuel injector.

2. Remove the inject or clamping plates.

31. Remove the injectors from the ma nifold; use special tool 303

- 539 if necessary.

Page 711 of 2490

Installation

32. Remove and discard the sixt een sealing rings from the

injectors.

33. Remove the throttle induction elbow from the inlet manifold.

1. Remove the seven bolts which secure the throttle induction elbow.

2. Remove the elbow.

3. Remove the induction elbow seal from the manifold.

1. Clean all parts and relevant mating faces.

2. Fit the fuel pressure regulator to the manifold.

1. Lubricate and fit a new O-ri ng seal to the regulator.

2. Fit the pressure regulator to the manifold.

3. Fit the two bolts which secu re the pressure regulator.

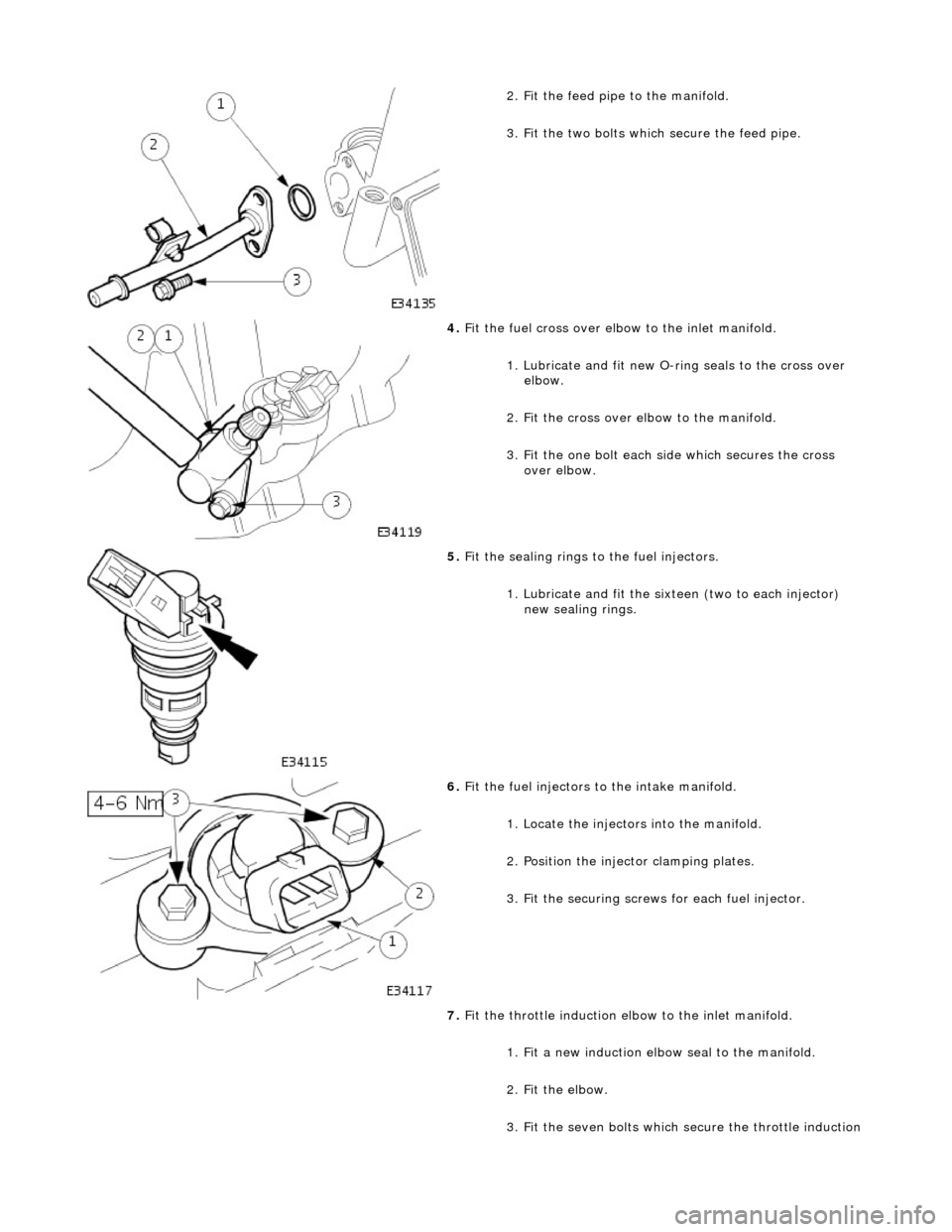

3. Fit the fuel feed pipe to the manifold.

1. Lubricate and fit a new O-ri ng seal to the feed pipe.

Page 712 of 2490

2. Fit the feed pipe to the manifold.

3. Fit the two bolts which secure the feed pipe.

4. Fit the fuel cross over elbow to the inlet manifold.

1. Lubricate and fit new O-ri ng seals to the cross over

elbow.

2. Fit the cross over elbow to the manifold.

3. Fit the one bolt each side which secures the cross over elbow.

5. Fit the sealing rings to the fuel injectors.

1. Lubricate and fit the sixteen (two to each injector) new sealing rings.

6. Fit the fuel injectors to the intake manifold.

1. Locate the injectors into the manifold.

2. Position the injector clamping plates.

3. Fit the securing screws for each fuel injector.

7. Fit the throttle induction elbow to the inlet manifold.

1. Fit a new induction elbow seal to the manifold.

2. Fit the elbow.

3. Fit the seven bolts which secure the throttle induction

Page 714 of 2490

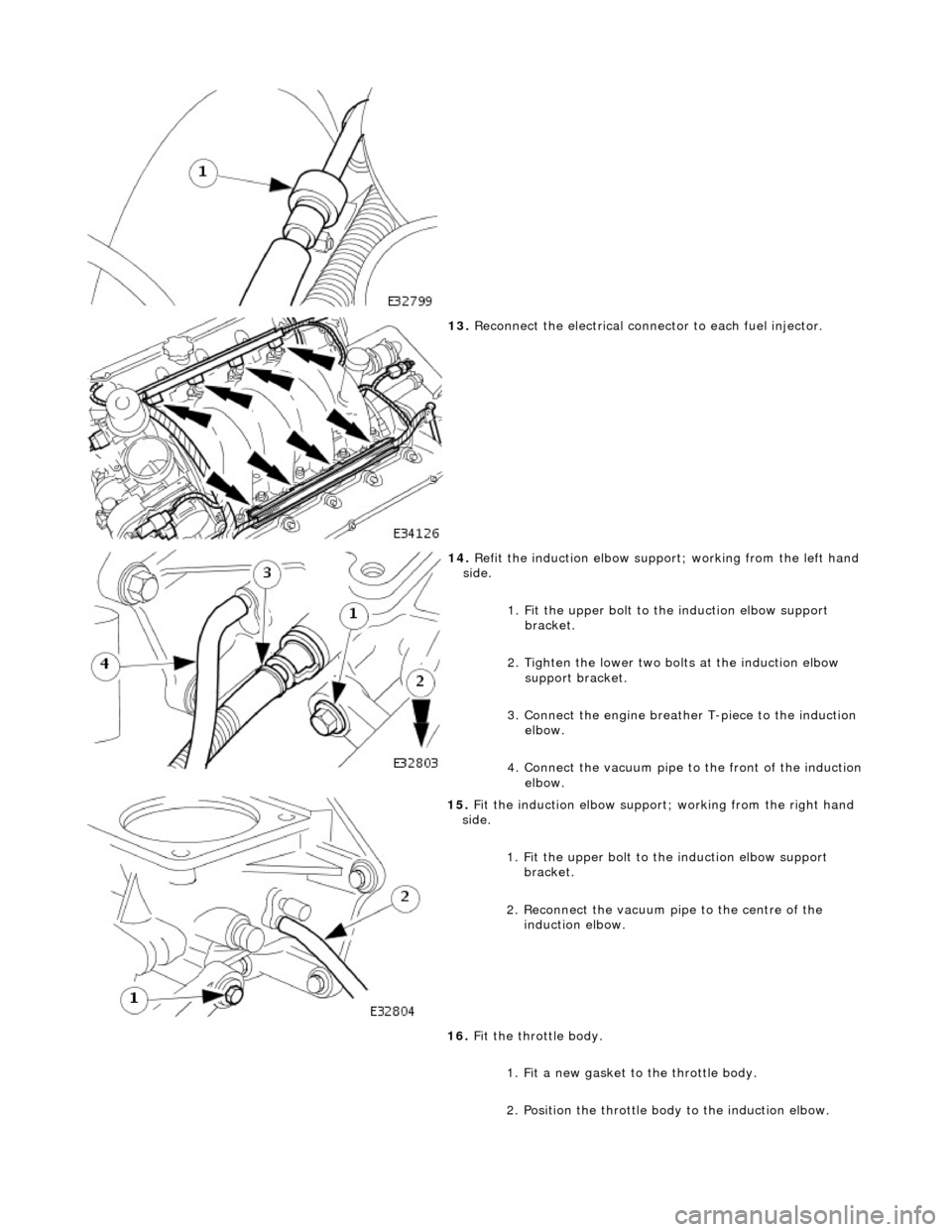

13. Reconnect the electrical connector to each fuel injector.

14. Refit the induction elbow support ; working from the left hand

side.

1. Fit the upper bolt to the induction elbow support

bracket.

2. Tighten the lower two bolts at the induction elbow support bracket.

3. Connect the engine breather T-piece to the induction elbow.

4. Connect the vacuum pipe to the front of the induction

elbow.

15. Fit the induction elbow support; working from the right hand

side.

1. Fit the upper bolt to the induction elbow support

bracket.

2. Reconnect the vacuum pi pe to the centre of the

induction elbow.

16. Fit the throttle body.

1. Fit a new gasket to the throttle body.

2. Position the throttle body to the induction elbow.