front brake pad JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 609 of 3039

Published: 11-May-2011

Front Disc Brake - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol - Front Disc Brake - System Operation and Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired

Item Description 1 Battery 2 Megafuse (250 A) 3 Front brake pad wear sensor 4 Rear brake pad wear sensor 5 Instrument cluster 6 CJB (central junction box) 7 Power distribution box

Page 610 of 3039

BRAKE CALIPERS System Operation

When hydraulic pressure is supplied to the caliper, the pistons extend to force the inner pad against the brake disc. The caliper

reacts and slides along two guide pins to bring the outer pad into contact with the brake disc.

BRAKE PAD WEAR SENSORS

When a brake pad incorporating a brake pad wear sensor is approximately 75% worn, the sensor wire within the pad material

is worn through and the brake pad wear sensor goes open circuit. When the instrument cluster detects the open circuit, it

illuminates the amber LED (light emitting diode) in the brake warning indicator, displays an appropriate warning in the

message center and sounds a warning chime.

Refer to: Instrument Cluster (413-01 Instrument Cluster, Description and Operation).

NOTE: A new pad wear sensor lead must be fitted whenever the brake pads are changed, irrespective of the brake pad

warning sensor being triggered.

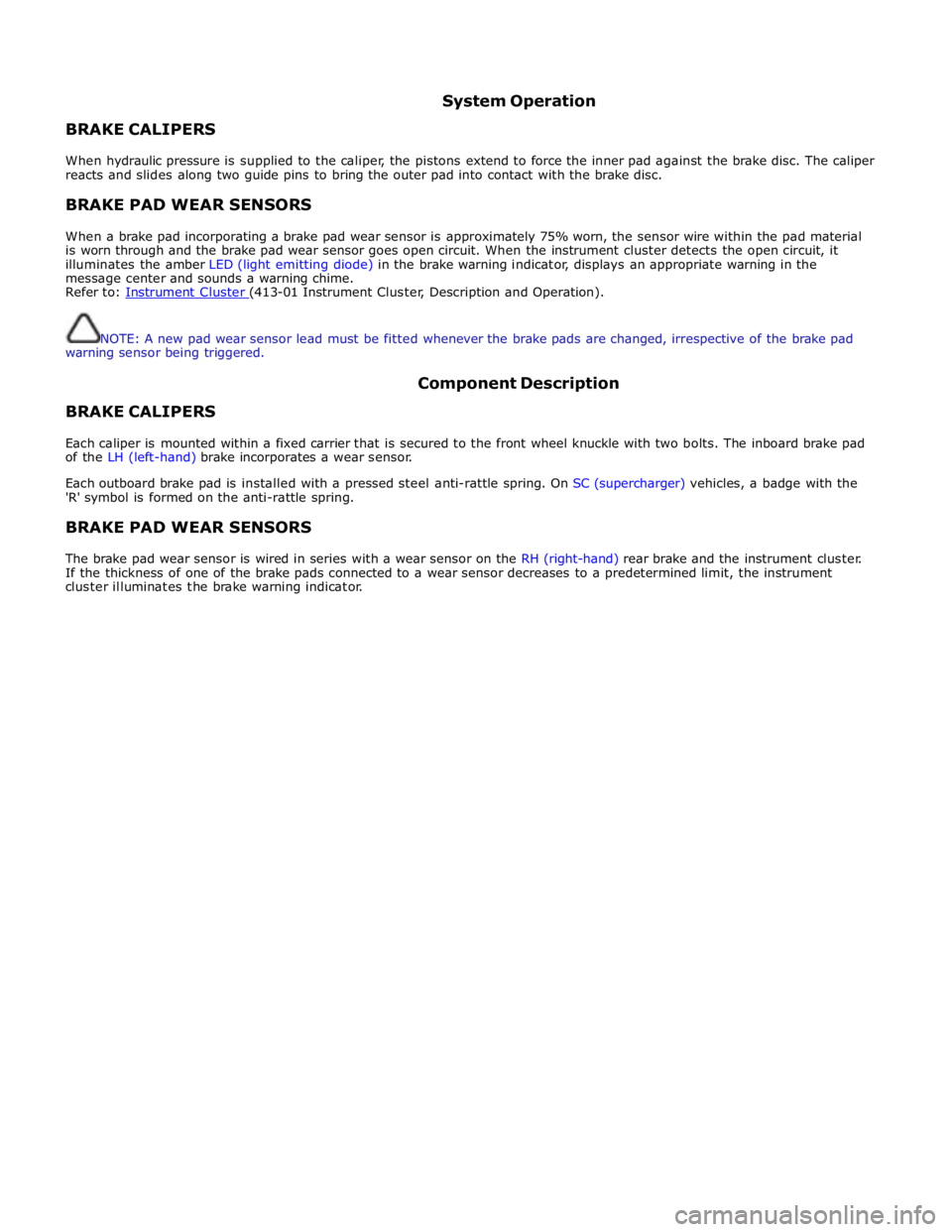

BRAKE CALIPERS Component Description

Each caliper is mounted within a fixed carrier that is secured to the front wheel knuckle with two bolts. The inboard brake pad

of the LH (left-hand) brake incorporates a wear sensor.

Each outboard brake pad is installed with a pressed steel anti-rattle spring. On SC (supercharger) vehicles, a badge with the

'R' symbol is formed on the anti-rattle spring.

BRAKE PAD WEAR SENSORS

The brake pad wear sensor is wired in series with a wear sensor on the RH (right-hand) rear brake and the instrument cluster.

If the thickness of one of the brake pads connected to a wear sensor decreases to a predetermined limit, the instrument

cluster illuminates the brake warning indicator.

Page 618 of 3039

Published: 11-May-2011

Front Disc Brake - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol - Brake Disc Vehicles With: High Performance Brakes

Removal and Installation

Removal

CAUTION: Brake discs must be renewed in pairs.

NOTE: Removal steps in this procedure may contain installation details.

1. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

2. Refer to: Brake Pads - Vehicles With: High Performance Brakes (206-03B Front Disc Brake - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol,

Removal and Installation).

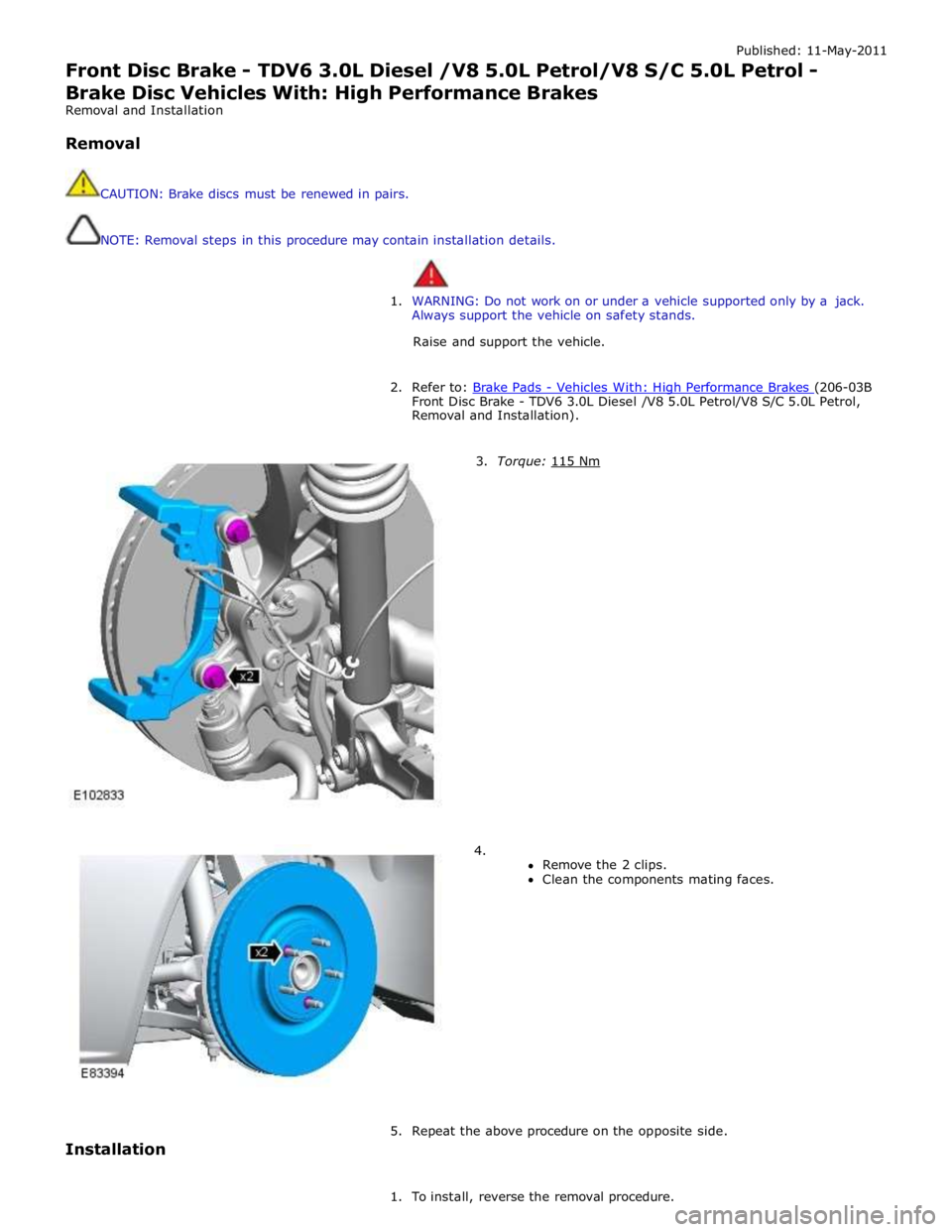

3. Torque: 115 Nm 4.

Remove the 2 clips.

Clean the components mating faces.

Installation 5. Repeat the above procedure on the opposite side.

1. To install, reverse the removal procedure.

Page 619 of 3039

Published: 11-May-2011

Front Disc Brake - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol - Brake Pads Vehicles With: High Performance Brakes

Removal and Installation

Removal

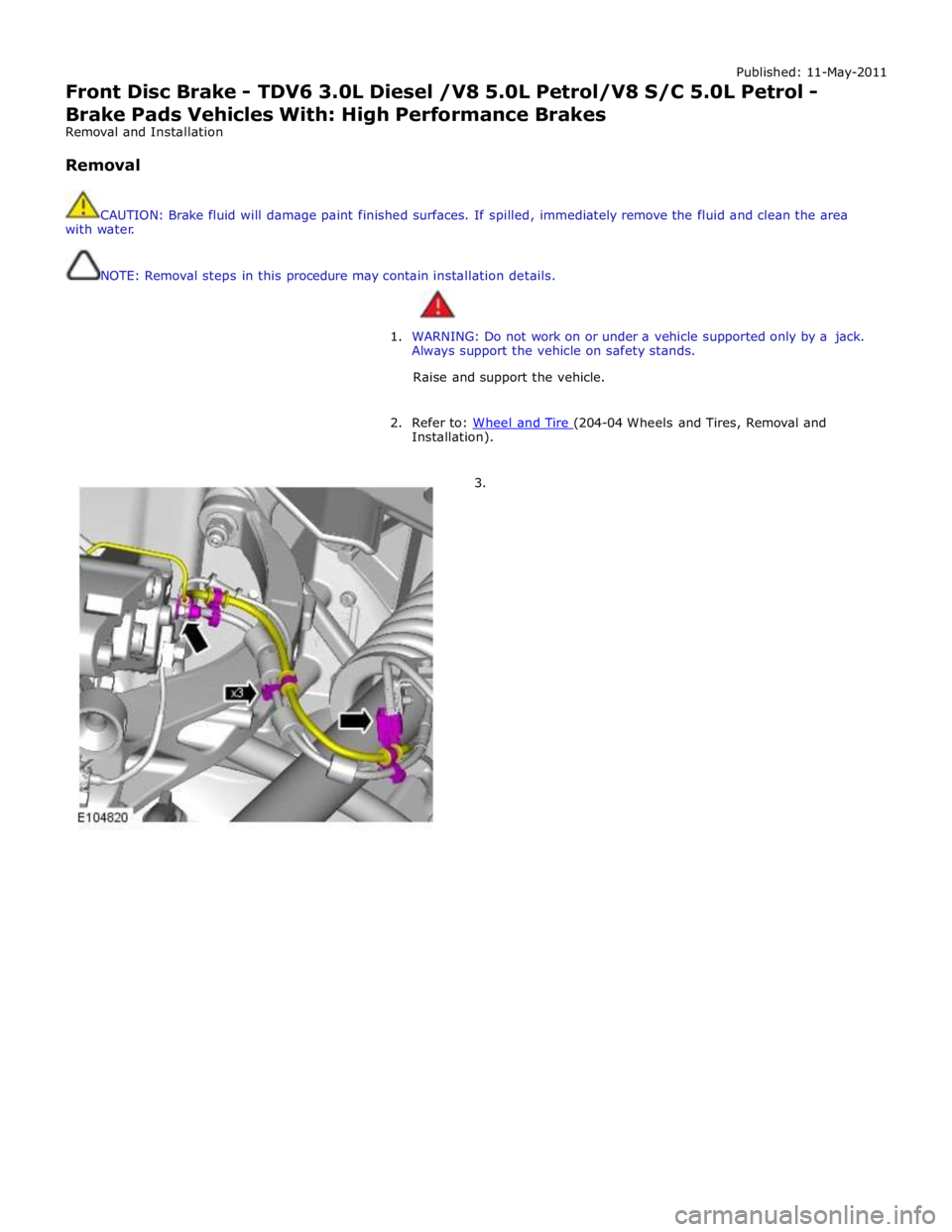

CAUTION: Brake fluid will damage paint finished surfaces. If spilled, immediately remove the fluid and clean the area

with water.

NOTE: Removal steps in this procedure may contain installation details.

1. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

2. Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

3.

Page 631 of 3039

Published: 11-May-2011

Rear Disc Brake - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol - Rear

Disc Brake - System Operation and Component Description

Description and Operation

Control Diagram

NOTE: A = Hardwired

Item Description 1 Battery 2 Megafuse (250 A) 3 Front brake pad wear sensor 4 Rear brake pad wear sensor 5 Instrument cluster 6 CJB (central junction box) 7Powerdistributionbox

Page 632 of 3039

BRAKE CALIPERS System Operation

When hydraulic pressure is supplied to the caliper, the pistons extend to force the inner pad against the brake disc. The caliper

reacts and slides along two guide pins to bring the outer pad into contact with the brake disc.

BRAKE PAD WEAR SENSORS

When a brake pad incorporating a brake pad wear sensor is approximately 75% worn, the sensor wire within the pad material

is worn through and the brake pad wear sensor goes open circuit. When the instrument cluster detects the open circuit, it

illuminates the amber LED (light emitting diode) in the brake warning indicator, displays an appropriate warning in the

message center and sounds a warning chime.

Refer to: Instrument Cluster (413-01 Instrument Cluster, Description and Operation).

NOTE: A new pad wear sensor lead must be fitted whenever the brake pads are changed, irrespective of the brake pad

warning sensor being triggered.

BRAKE CALIPERS Component Description

Each caliper is mounted within a fixed carrier that is secured to the rear wheel knuckle with two bolts. Each outboard brake pad

is installed with a wire anti-rattle spring.

The brake calipers on SC (supercharger) vehicles are painted and also include a logo badge, secured with two screws, which

must be removed in order to change the brake pads.

The inboard brake pad of the RH (right-hand) brake incorporates a wear sensor.

BRAKE PAD WEAR SENSORS

The brake pad wear sensor is wired in series with a wear sensor on the LH (left-hand) front brake and the instrument cluster. If

the thickness of one of the brake pads connected to a wear sensor decreases to a predetermined limit, the instrument cluster

illuminates the brake warning indicator.

Page 720 of 3039

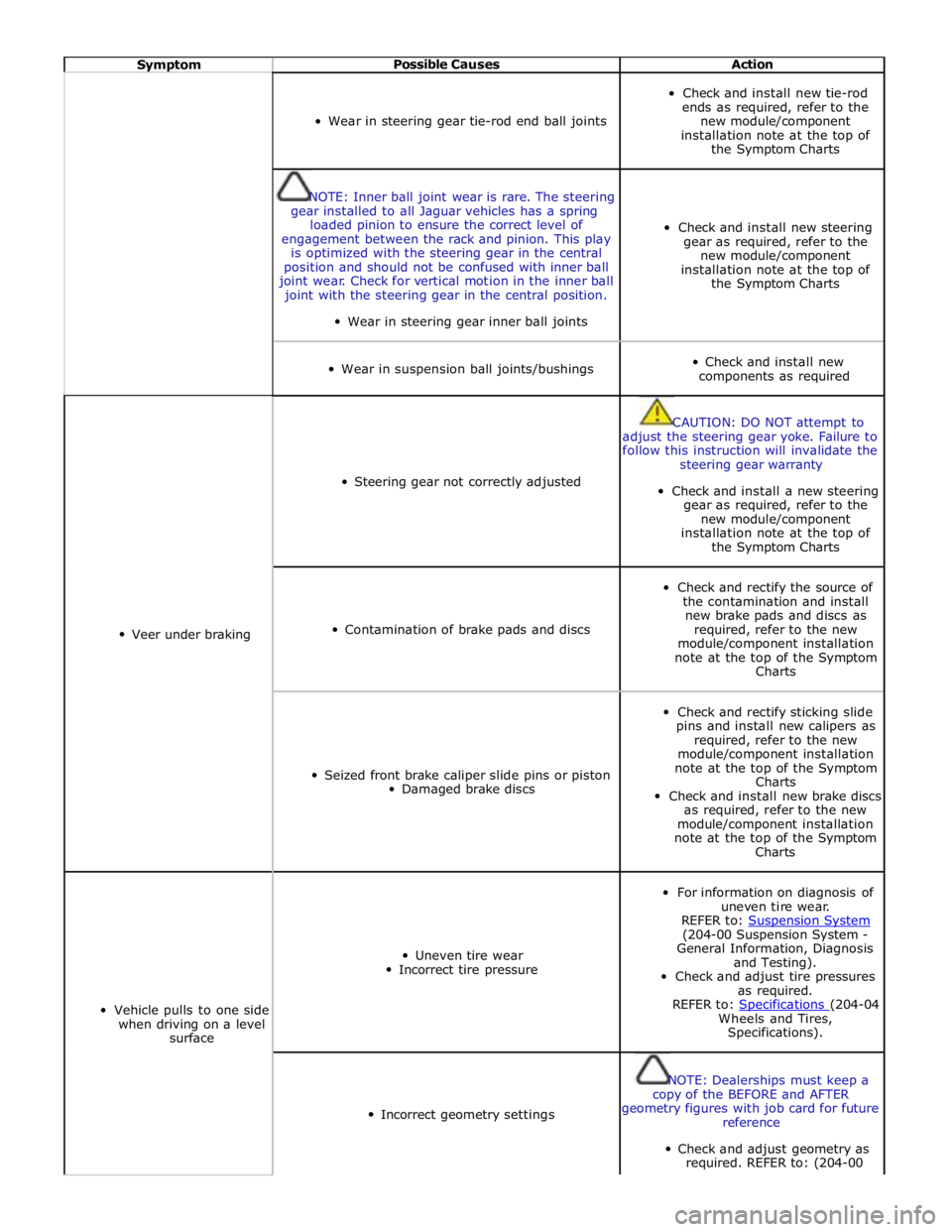

Symptom Possible Causes Action

Wear in steering gear tie-rod end ball joints

Check and install new tie-rod

ends as required, refer to the

new module/component

installation note at the top of

the Symptom Charts

NOTE: Inner ball joint wear is rare. The steering

gear installed to all Jaguar vehicles has a spring

loaded pinion to ensure the correct level of

engagement between the rack and pinion. This play

is optimized with the steering gear in the central

position and should not be confused with inner ball

joint wear. Check for vertical motion in the inner ball

joint with the steering gear in the central position.

Wear in steering gear inner ball joints

Check and install new steering

gear as required, refer to the

new module/component

installation note at the top of

the Symptom Charts

Wear in suspension ball joints/bushings

Check and install new

components as required

Veer under braking

Steering gear not correctly adjusted

CAUTION: DO NOT attempt to

adjust the steering gear yoke. Failure to

follow this instruction will invalidate the

steering gear warranty

Check and install a new steering

gear as required, refer to the

new module/component

installation note at the top of

the Symptom Charts

Contamination of brake pads and discs

Check and rectify the source of

the contamination and install

new brake pads and discs as

required, refer to the new

module/component installation

note at the top of the Symptom

Charts

Seized front brake caliper slide pins or piston

Damaged brake discs

Check and rectify sticking slide

pins and install new calipers as

required, refer to the new

module/component installation

note at the top of the Symptom

Charts

Check and install new brake discs

as required, refer to the new

module/component installation

note at the top of the Symptom

Charts

Vehicle pulls to one side

when driving on a level

surface

Uneven tire wear

Incorrect tire pressure

For information on diagnosis of

uneven tire wear.

REFER to: Suspension System (204-00 Suspension System -

General Information, Diagnosis

and Testing).

Check and adjust tire pressures

as required.

REFER to: Specifications (204-04 Wheels and Tires,

Specifications).

Incorrect geometry settings

NOTE: Dealerships must keep a

copy of the BEFORE and AFTER

geometry figures with job card for future

reference

Check and adjust geometry as

required. REFER to: (204-00

Page 1295 of 3039

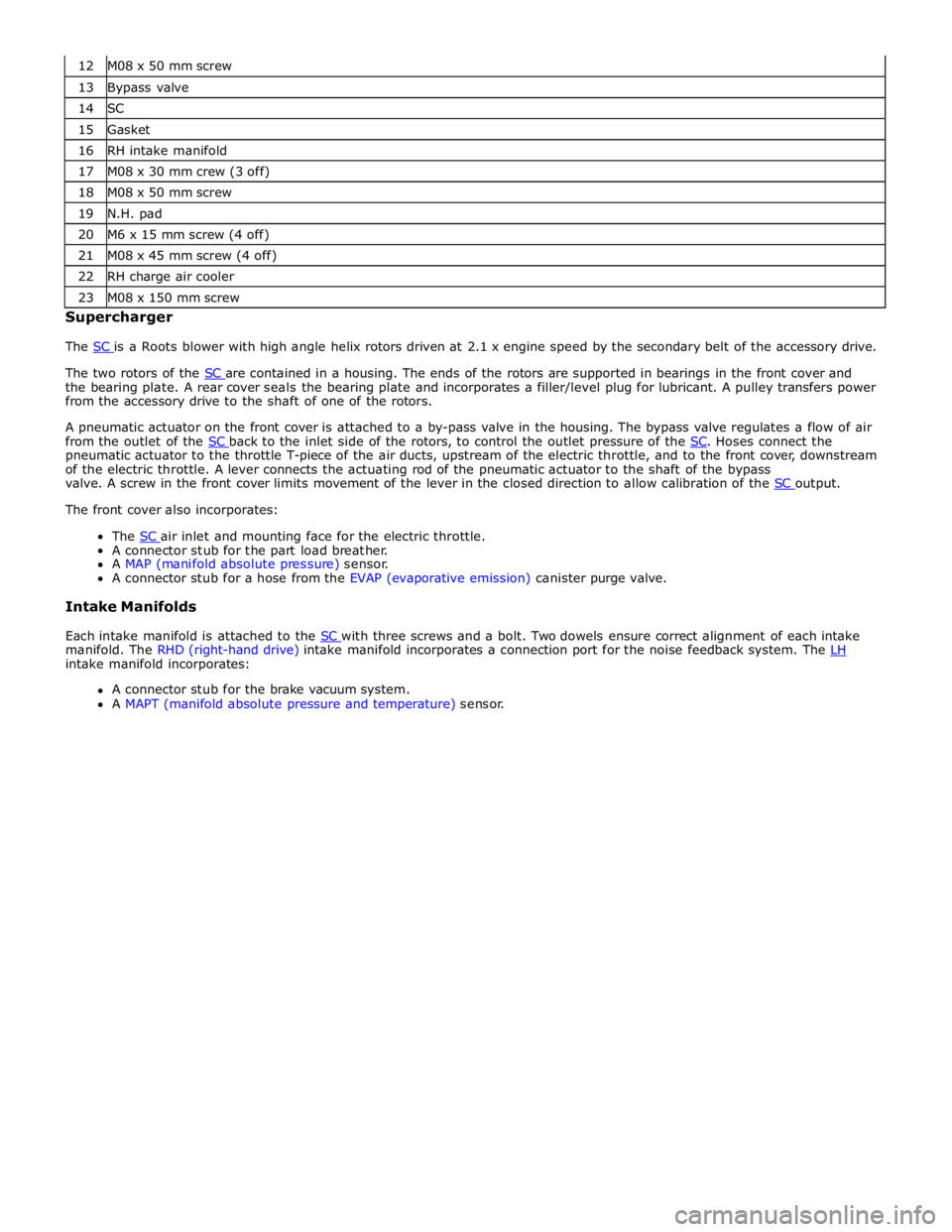

13 Bypass valve 14 SC 15 Gasket 16 RH intake manifold 17 M08 x 30 mm crew (3 off) 18 M08 x 50 mm screw 19 N.H. pad 20 M6 x 15 mm screw (4 off) 21 M08 x 45 mm screw (4 off) 22 RH charge air cooler 23 M08 x 150 mm screw Supercharger

The SC is a Roots blower with high angle helix rotors driven at 2.1 x engine speed by the secondary belt of the accessory drive.

The two rotors of the SC are contained in a housing. The ends of the rotors are supported in bearings in the front cover and the bearing plate. A rear cover seals the bearing plate and incorporates a filler/level plug for lubricant. A pulley transfers power

from the accessory drive to the shaft of one of the rotors.

A pneumatic actuator on the front cover is attached to a by-pass valve in the housing. The bypass valve regulates a flow of air

from the outlet of the SC back to the inlet side of the rotors, to control the outlet pressure of the SC. Hoses connect the pneumatic actuator to the throttle T-piece of the air ducts, upstream of the electric throttle, and to the front cover, downstream

of the electric throttle. A lever connects the actuating rod of the pneumatic actuator to the shaft of the bypass

valve. A screw in the front cover limits movement of the lever in the closed direction to allow calibration of the SC output. The front cover also incorporates:

The SC air inlet and mounting face for the electric throttle. A connector stub for the part load breather.

A MAP (manifold absolute pressure) sensor.

A connector stub for a hose from the EVAP (evaporative emission) canister purge valve.

Intake Manifolds

Each intake manifold is attached to the SC with three screws and a bolt. Two dowels ensure correct alignment of each intake manifold. The RHD (right-hand drive) intake manifold incorporates a connection port for the noise feedback system. The LH intake manifold incorporates:

A connector stub for the brake vacuum system.

A MAPT (manifold absolute pressure and temperature) sensor.