hub JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 329 of 3039

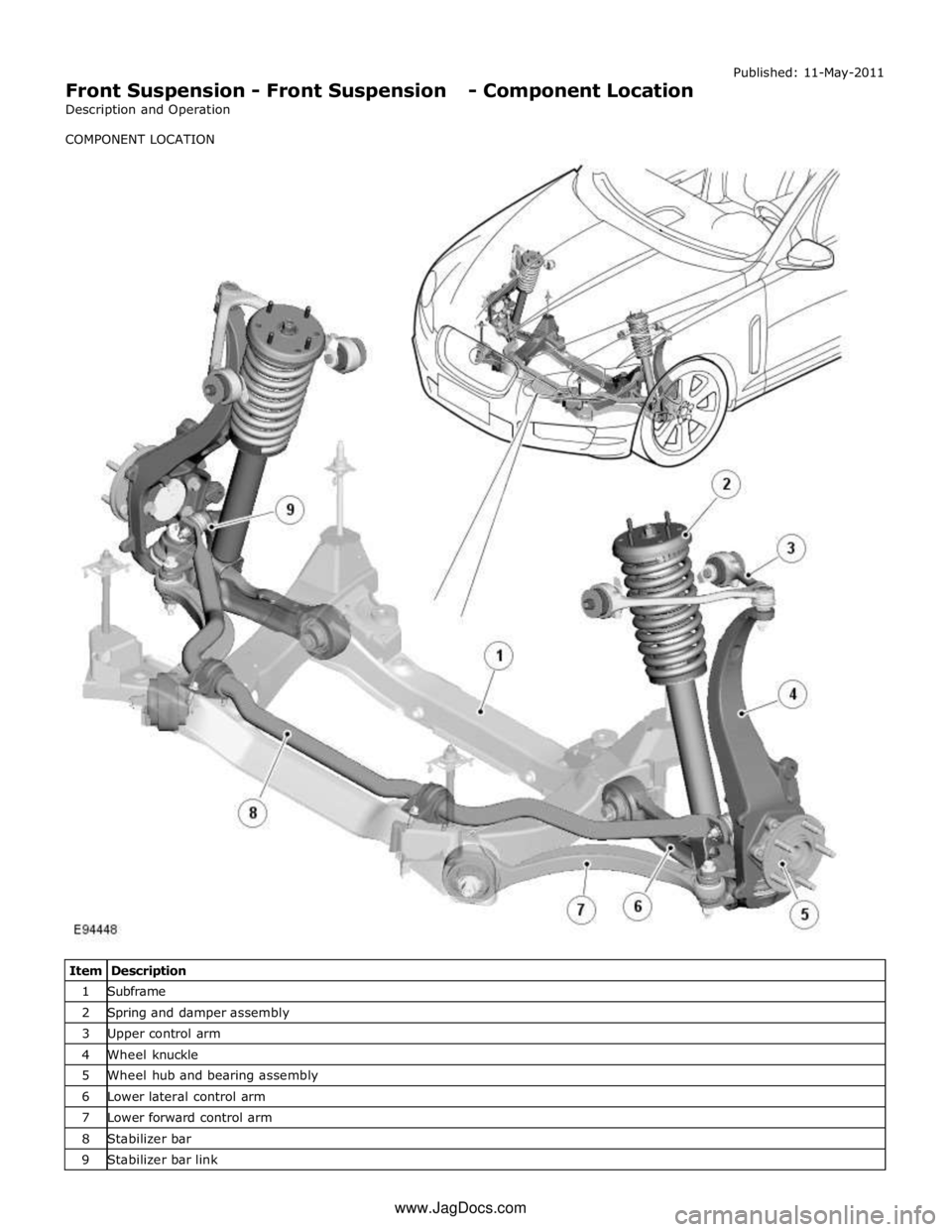

Front Suspension - Front Suspension - Component Location

Description and Operation

COMPONENT LOCATION Published: 11-May-2011

Item Description 1 Subframe 2 Spring and damper assembly 3 Upper control arm 4 Wheel knuckle 5 Wheel hub and bearing assembly 6 Lower lateral control arm 7 Lower forward control arm 8 Stabilizer bar 9 Stabilizer bar link www.JagDocs.com

Page 331 of 3039

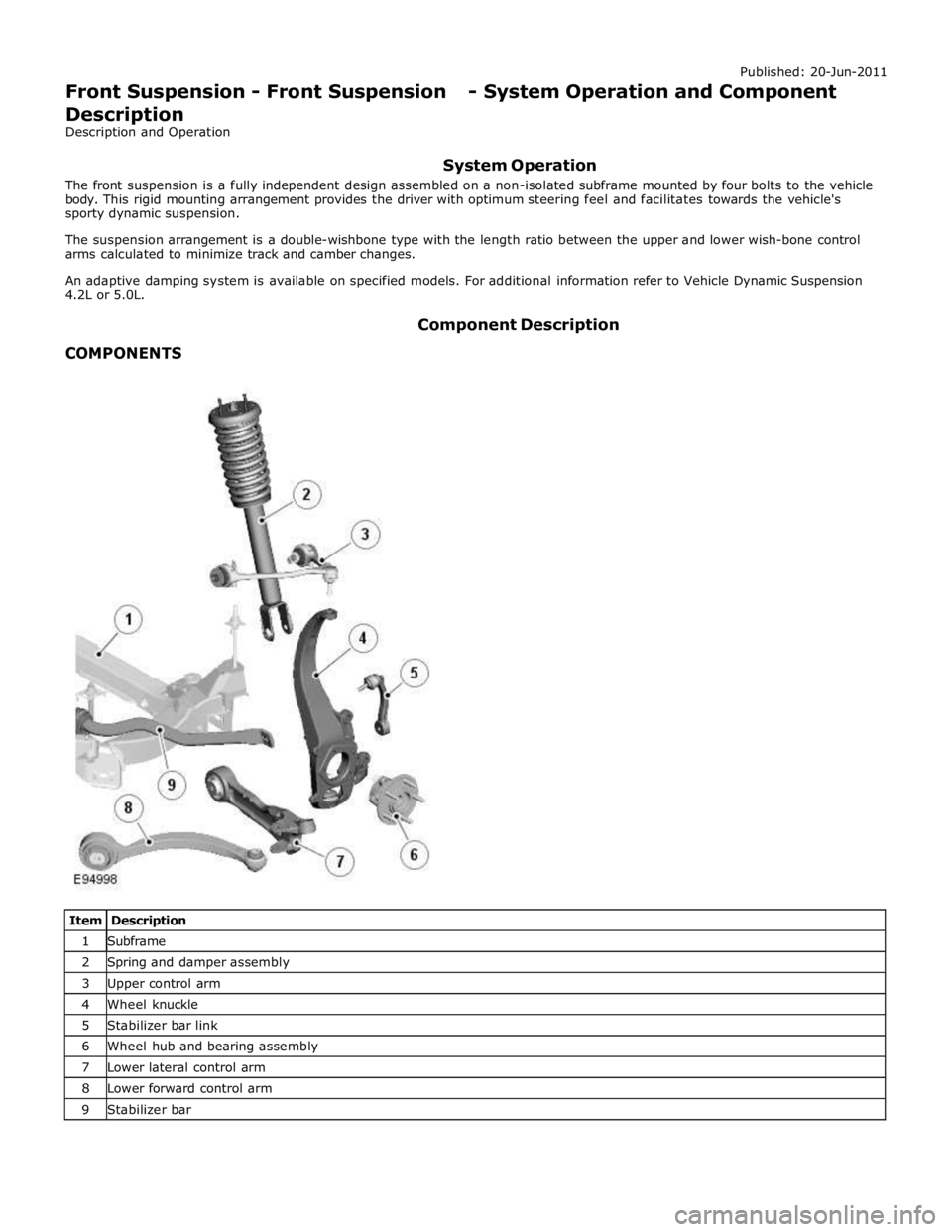

1 Subframe 2 Spring and damper assembly 3 Upper control arm 4 Wheel knuckle 5 Stabilizer bar link 6 Wheel hub and bearing assembly 7 Lower lateral control arm 8 Lower forward control arm 9 Stabilizer bar

Page 332 of 3039

Upper Control Arm

The forged-aluminum upper control arm is a wishbone design and connects to the vehicle body through two plain bushes, and

links to the swan neck wheel knuckle by an integral ball joint. The upper control arm is inclined to provide anti-dive

characteristics under heavy braking, while also controlling geometry for vehicle straight-line stability.

Lower Control Arm

The forged aluminum lower control arms are of the wishbone design; the arms separate to allow for optimum bush tuning:

The rear lateral control arm is fitted with a bush at its inner end which locates between brackets on the subframe. The

arm is secured with an eccentric bolt which provides the adjustment of the suspension camber geometry. The outer end

of the control arm has a tapered hole which locates on a ball joint fitted to the wheel knuckle. An integral clevis bracket

on the forward face of the lateral control arm allows for the attachment of the forward control arm. A bush is fitted

below the clevis bracket to provide for the attachment of the stabilizer bar link. A cross-axis joint is fitted to a

cross-hole in the control arm to provide the location for the clevis attachment of the spring and damper assembly.

The forward control arm is fitted with a fluid-block rubber bush at its inner end which locates between brackets on the

subframe. The arm is secured with an eccentric bolt which provides adjustment of the castor and camber geometry. The

outer end of the control arm is fitted with a cross-axis joint and locates in the integral clevis bracket on the lateral

control arm.

Wheel Knuckle

The cast aluminum wheel knuckle is a swan neck design and attaches to the upper control arm and lower lateral control arm.

The lower lateral control arm locates on a non serviceable ball-joint integral with the wheel knuckle. The lower boss on the

rear of the knuckle provides for the attachment of the steering gear tie-rod ball joint.

The wheel knuckle also provides the mounting locations for the:

wheel hub and bearing assembly

the wheel speed sensor (integral to the wheel hub and bearing assembly)

brake caliper and disc shield.

Stabilizer Bar

The stabilizer bar is attached to the front of the subframe with bushes and mounting brackets. The pressed steel mounting

brackets locate over the bushes and are attached to the cross member with bolts screwed into threaded locations in the

subframe. The stabilizer bar has crimped, 'anti-shuffle' collars pressed in position on the inside edges of the bushes. The

collars prevent sideways movement of the stabilizer bar.

The stabilizer bar is manufactured from 32mm diameter tubular steel on supercharged models and 31mm diameter tubular

steel on diesel and normally aspirated models and has been designed to provide particular characteristics in maintaining roll

rates, specifically in primary ride comfort.

Each end of the stabilizer bar curves rearwards to attach to a ball joint on a stabilizer link. Each stabilizer link is secured to a

bush in the lower lateral arm with a bolt and locknut. The links allow the stabilizer bar to move with the wheel travel providing

maximum effectiveness.

The only difference between the front stabilizer bars, in addition to the diameter, is in the shape to accommodate engine

variant:

a slightly curved bar, between bush centers, for V6 diesel (31 mm dia) and V8 gasoline supercharged (32 mm dia),

a straight bar, between bush centers, for V6 and V8 normally aspirated gasoline engines (31 mm dia).

Spring and Damper Assembly

The spring and damper assemblies are located between the lower lateral arm and the front suspension housing in the inner

wing. Dependant on vehicle model there are three types of coil spring and damper available:

a standard oil passive damper (All models except supercharged),

an adaptive damper, also known as Computer Active Technology Suspension (CATS) on 4.2L supercharged vehicles up to

2010MY, For additional information refer to Vehicle Dynamic Suspension 4.2L.

a continuously variable adaptive damper, also known as Adaptive Dynamics System on 5.0L supercharged vehicles from

2010MY. For additional information refer to Vehicle Dynamic Suspension 5.0L.

The dampers are a monotube design with a spring seat secured by a circlip onto the damper tube. The damper's lower

spherical joint is an integral part of the lateral lower control-arm, and the damper takes the form of a clevis-end, which

straddles the spherical joint.

The damper piston is connected to a damper rod which is sealed at its exit point from the damper body. The threaded outer

end of the damper rod locates through a hole in the top mount. A self locking nut secures the top mount to the damper rod.

The damper rod on the adaptive damper has an electrical connector on the outer end of the damper rod.

Supercharged 4.2L vehicles up to 2010MY: The adaptive damper functions by restricting the flow of hydraulic fluid through

internal galleries in the damper's piston. The adaptive damper has a solenoid operated valve, which when switched allows a

greater flow of hydraulic fluid through the damper's piston. This provides a softer damping characteristic from the damper. The

adaptive damper defaults to a firmer setting when not activated. The solenoid is computer controlled and can switch between

soft and hard damping settings depending on road wheel inputs and vehicle speed.

Supercharged 5.0L vehicles from 2010MY: The variable damper functions by adjustment of a solenoid operated variable orifice,

which opens up an alternative path for oil flow within the damper. When de-energized the bypass is closed and all the oil flows

Page 356 of 3039

Published: 06-Jun-2013

Front Suspension - Front Stabilizer Bar V8 5.0L Petrol/V8 S/C 5.0L Petrol

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

3. Refer to: Air Conditioning (A/C) System Recovery, Evacuation and Charging (412-00 Climate Control System - General Information, General Procedures).

4. Refer to: Radiator Splash Shield (501-02 Front End Body Panels, Removal and Installation).

5. Refer to: Air Deflector (501-02 Front End Body Panels, Removal and Installation).

6. Refer to: Front Wheel Bearing and Wheel Hub - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol (204-01 Front Suspension, Removal and Installation).

7. Refer to: Engine Cover - V8 5.0L Petrol/V8 S/C 5.0L Petrol (501-05 Interior Trim and Ornamentation, Removal and Installation).

8.

Secure the radiator assembly. 303-021

Engine support bracket Special Tool(s) www.JagDocs.com

Page 373 of 3039

Published: 11-May-2011

Front Suspension - Front Wheel Bearing and Wheel Hub TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L Petrol

Removal and Installation

Removal

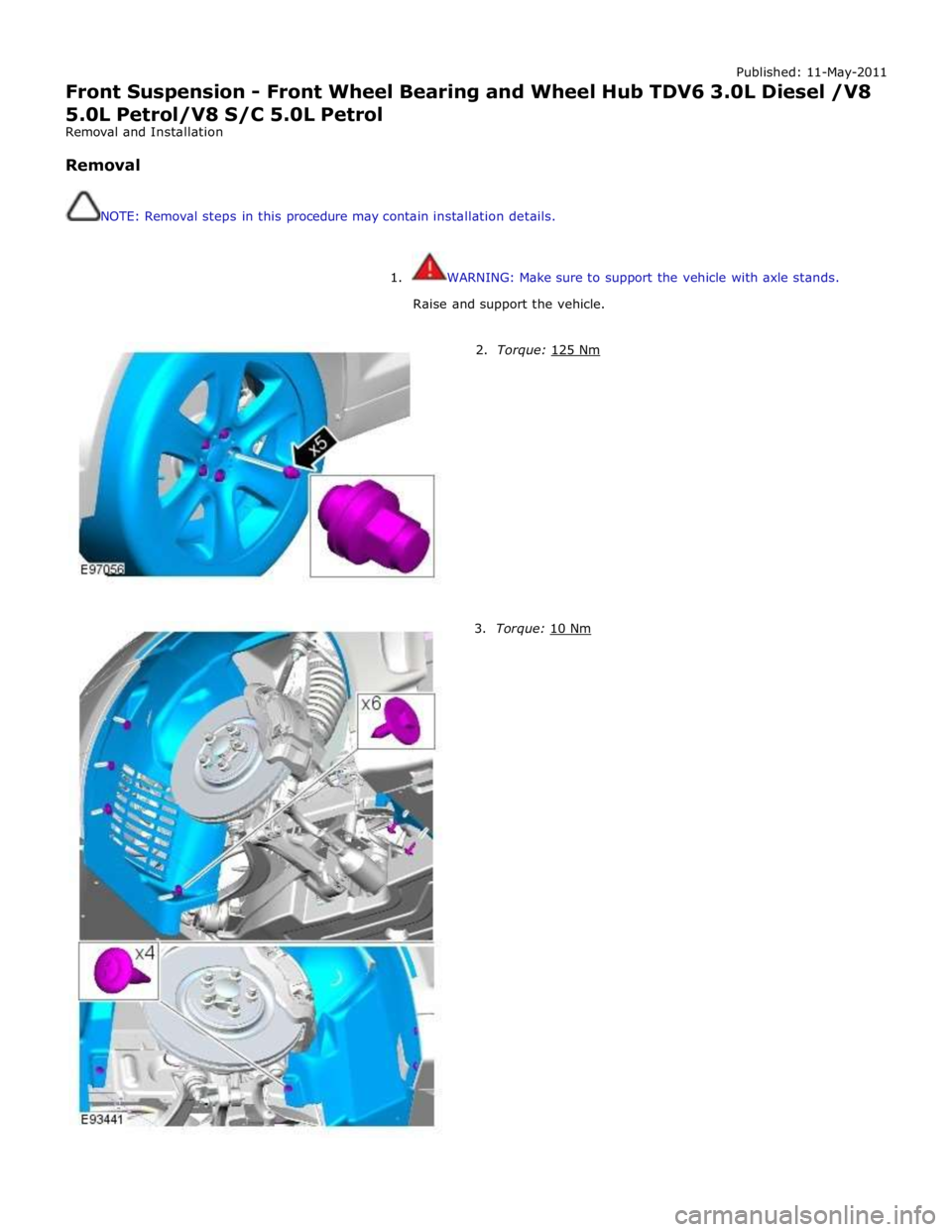

NOTE: Removal steps in this procedure may contain installation details.

1. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

2. Torque: 125 Nm 3. Torque: 10 Nm

Page 375 of 3039

7. CAUTIONS:

Discard the bolts.

Make sure that the area around the component is

clean and free of foreign material.

Do not attempt to release the wheel hub by hitting it

with a hammer directly, loosen the wheel hub retaining

bolts partially before applying an even amount of force to

the head of each bolts to release the wheel hub from the

wheel knuckle. Failure to follow this instruction may cause

damage to the component.

NOTES:

Some variation in the illustrations may occur, but the

essential information is always correct.

LH illustration shown, RH is similar.

Install the components to their original fitted

positions.

Torque: 90 Nm

Installation

1. To install, reverse the removal procedure. www.JagDocs.com

Page 376 of 3039

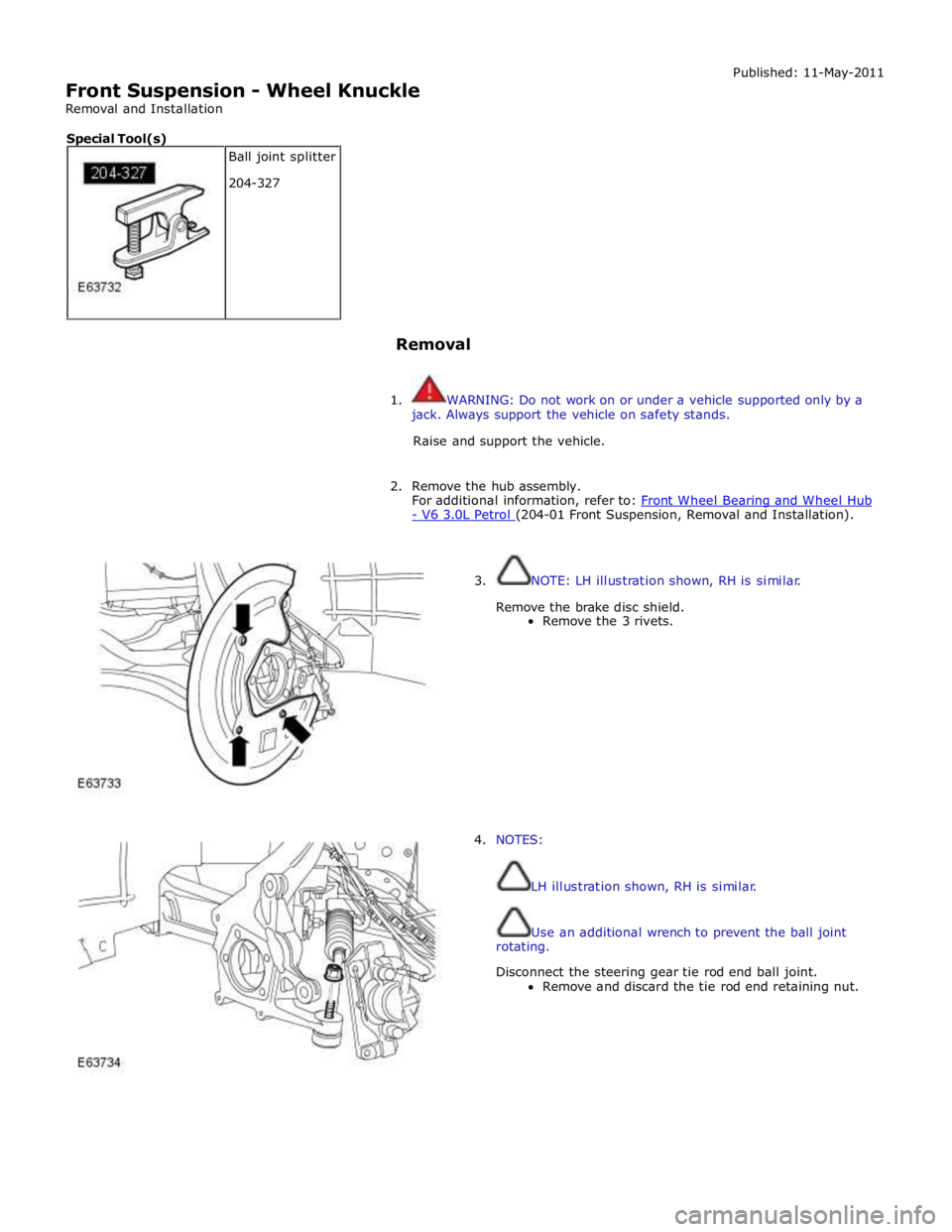

Front Suspension - Wheel Knuckle

Removal and Installation Published: 11-May-2011

Removal

1. WARNING: Do not work on or under a vehicle supported only by a

jack. Always support the vehicle on safety stands.

Raise and support the vehicle.

2. Remove the hub assembly.

For additional information, refer to: Front Wheel Bearing and Wheel Hub - V6 3.0L Petrol (204-01 Front Suspension, Removal and Installation).

3. NOTE: LH illustration shown, RH is similar.

Remove the brake disc shield.

Remove the 3 rivets.

4. NOTES:

LH illustration shown, RH is similar.

Use an additional wrench to prevent the ball joint

rotating.

Disconnect the steering gear tie rod end ball joint.

Remove and discard the tie rod end retaining nut. Ball joint splitter

204-327 Special Tool(s)

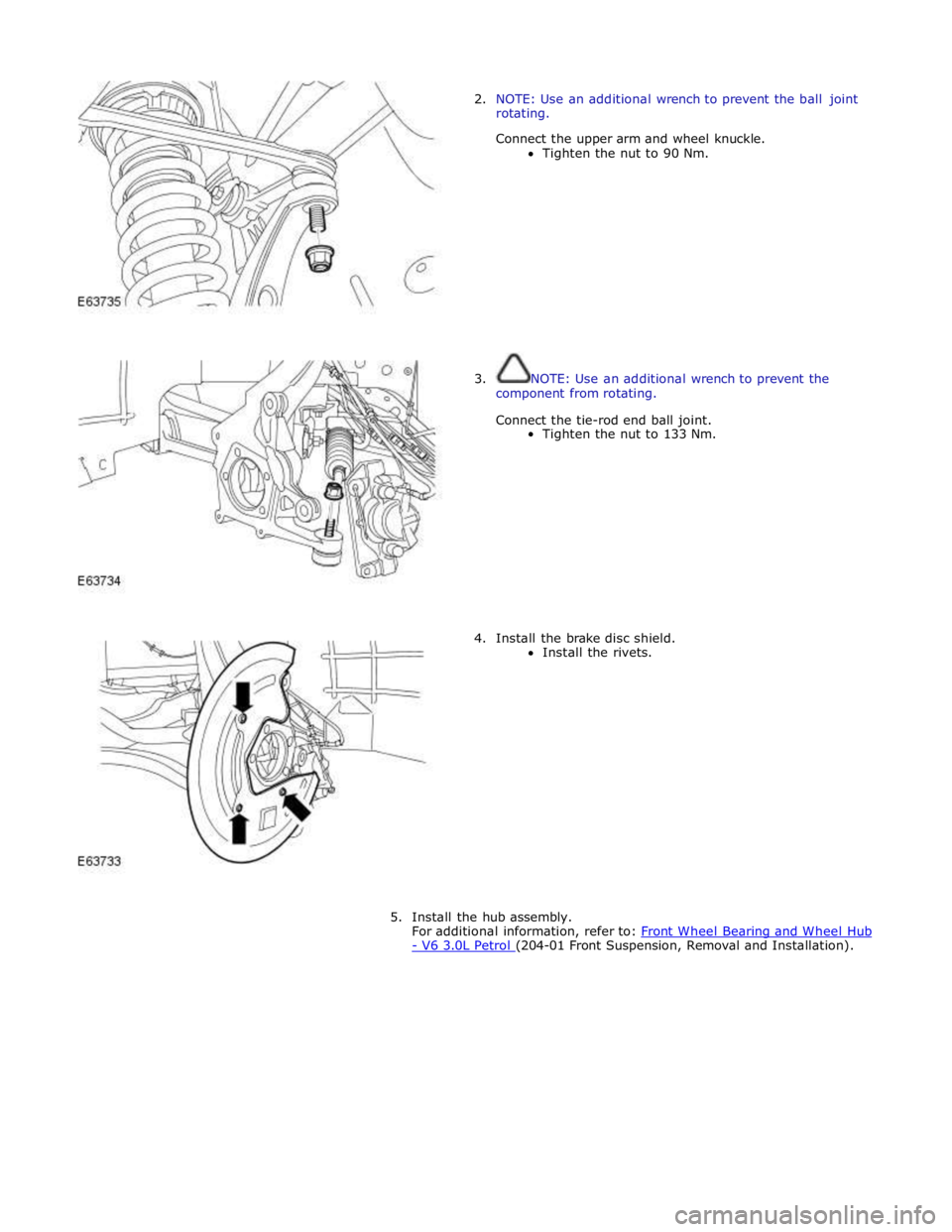

Page 378 of 3039

2. NOTE: Use an additional wrench to prevent the ball joint

rotating.

Connect the upper arm and wheel knuckle.

Tighten the nut to 90 Nm.

3. NOTE: Use an additional wrench to prevent the

component from rotating.

Connect the tie-rod end ball joint.

Tighten the nut to 133 Nm.

4. Install the brake disc shield.

Install the rivets.

5. Install the hub assembly.

For additional information, refer to: Front Wheel Bearing and Wheel Hub - V6 3.0L Petrol (204-01 Front Suspension, Removal and Installation).

Page 390 of 3039

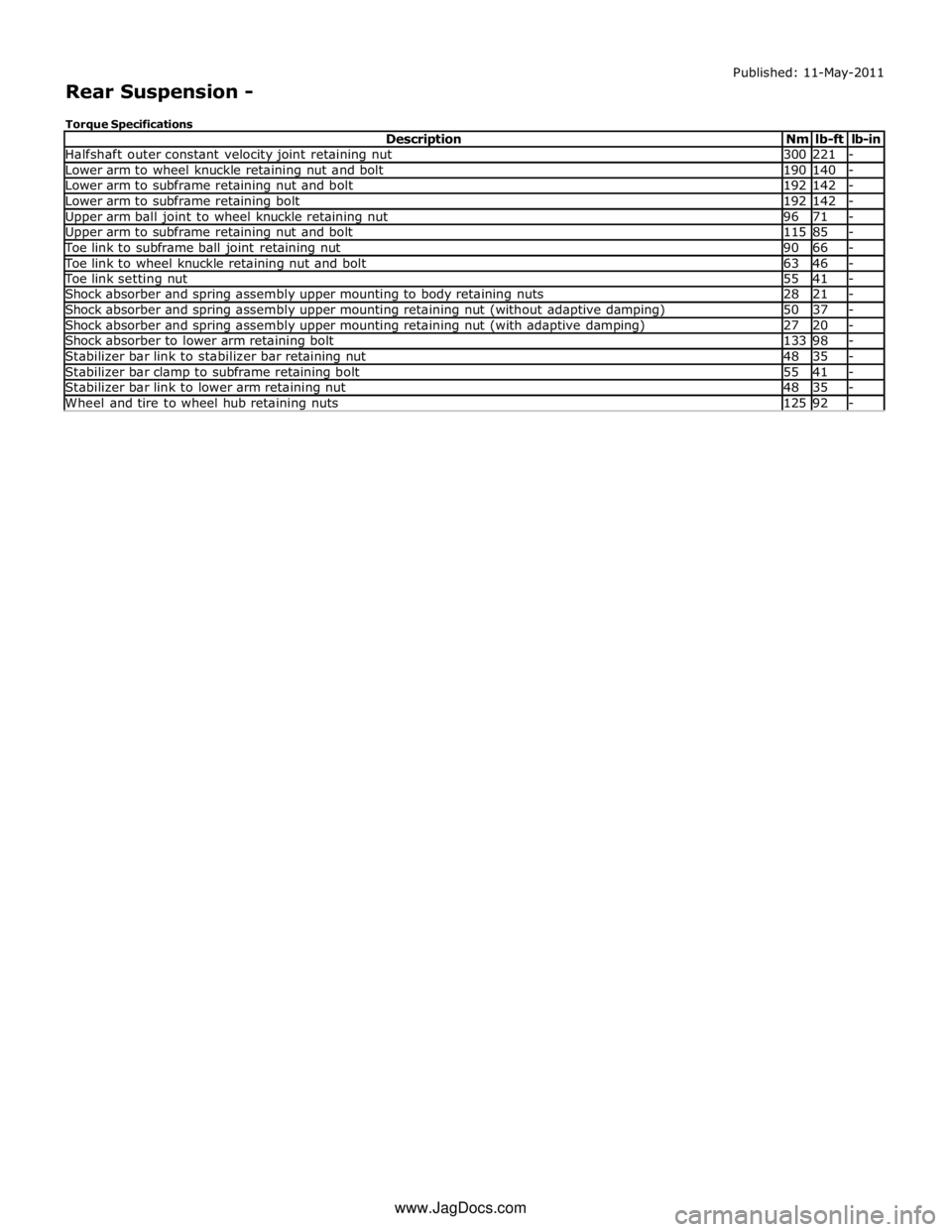

Halfshaft outer constant velocity joint retaining nut 300 221 - Lower arm to wheel knuckle retaining nut and bolt 190 140 - Lower arm to subframe retaining nut and bolt 192 142 - Lower arm to subframe retaining bolt 192 142 - Upper arm ball joint to wheel knuckle retaining nut 96 71 - Upper arm to subframe retaining nut and bolt 115 85 - Toe link to subframe ball joint retaining nut 90 66 - Toe link to wheel knuckle retaining nut and bolt 63 46 - Toe link setting nut 55 41 - Shock absorber and spring assembly upper mounting to body retaining nuts 28 21 - Shock absorber and spring assembly upper mounting retaining nut (without adaptive damping) 50 37 - Shock absorber and spring assembly upper mounting retaining nut (with adaptive damping) 27 20 - Shock absorber to lower arm retaining bolt 133 98 - Stabilizer bar link to stabilizer bar retaining nut 48 35 - Stabilizer bar clamp to subframe retaining bolt 55 41 - Stabilizer bar link to lower arm retaining nut 48 35 - Wheel and tire to wheel hub retaining nuts 125 92 - www.JagDocs.com

Page 391 of 3039

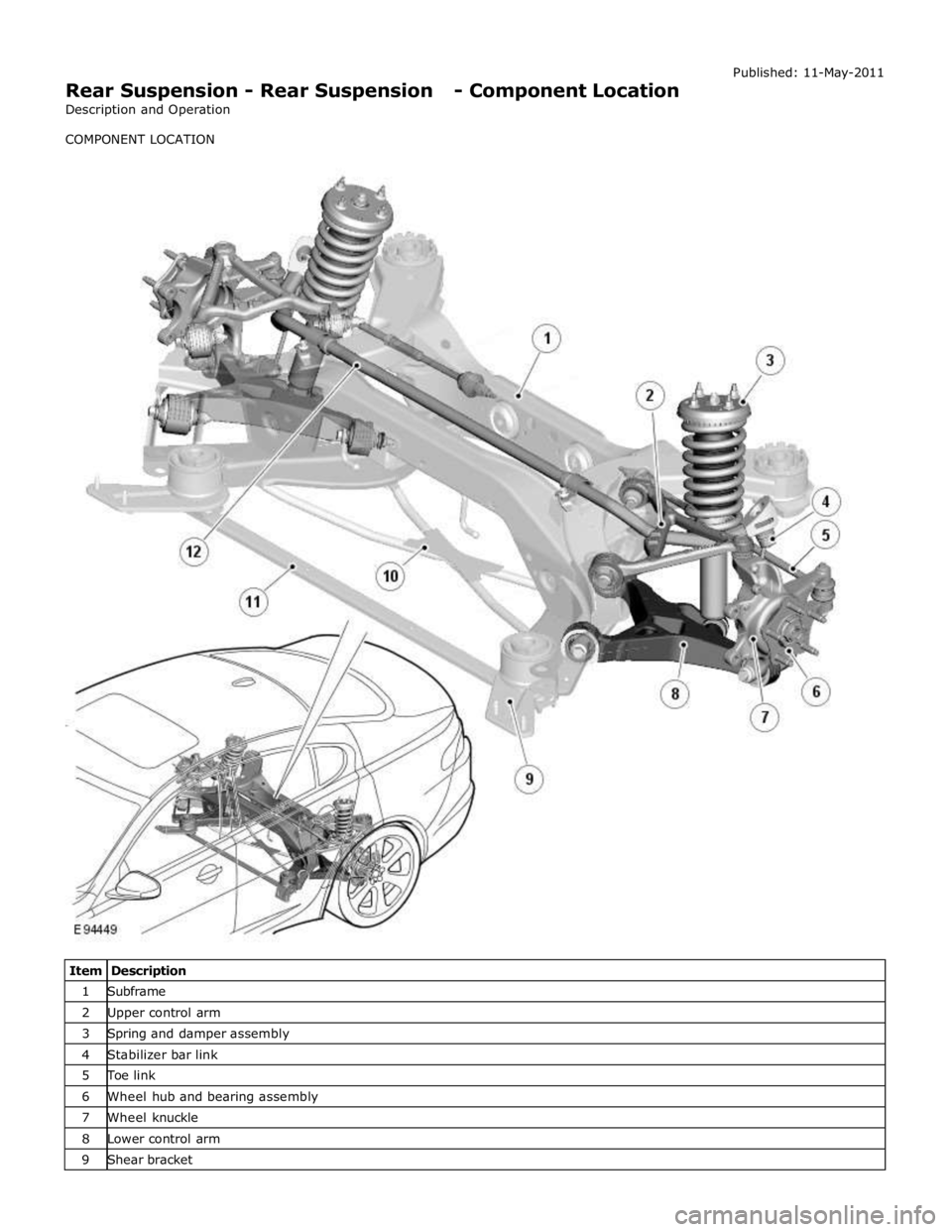

Rear Suspension - Rear Suspension - Component Location

Description and Operation

COMPONENT LOCATION Published: 11-May-2011

Item Description 1 Subframe 2 Upper control arm 3 Spring and damper assembly 4 Stabilizer bar link 5 Toe link 6 Wheel hub and bearing assembly 7 Wheel knuckle 8 Lower control arm 9 Shear bracket