key JAGUAR XFR 2010 1.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 136 of 3039

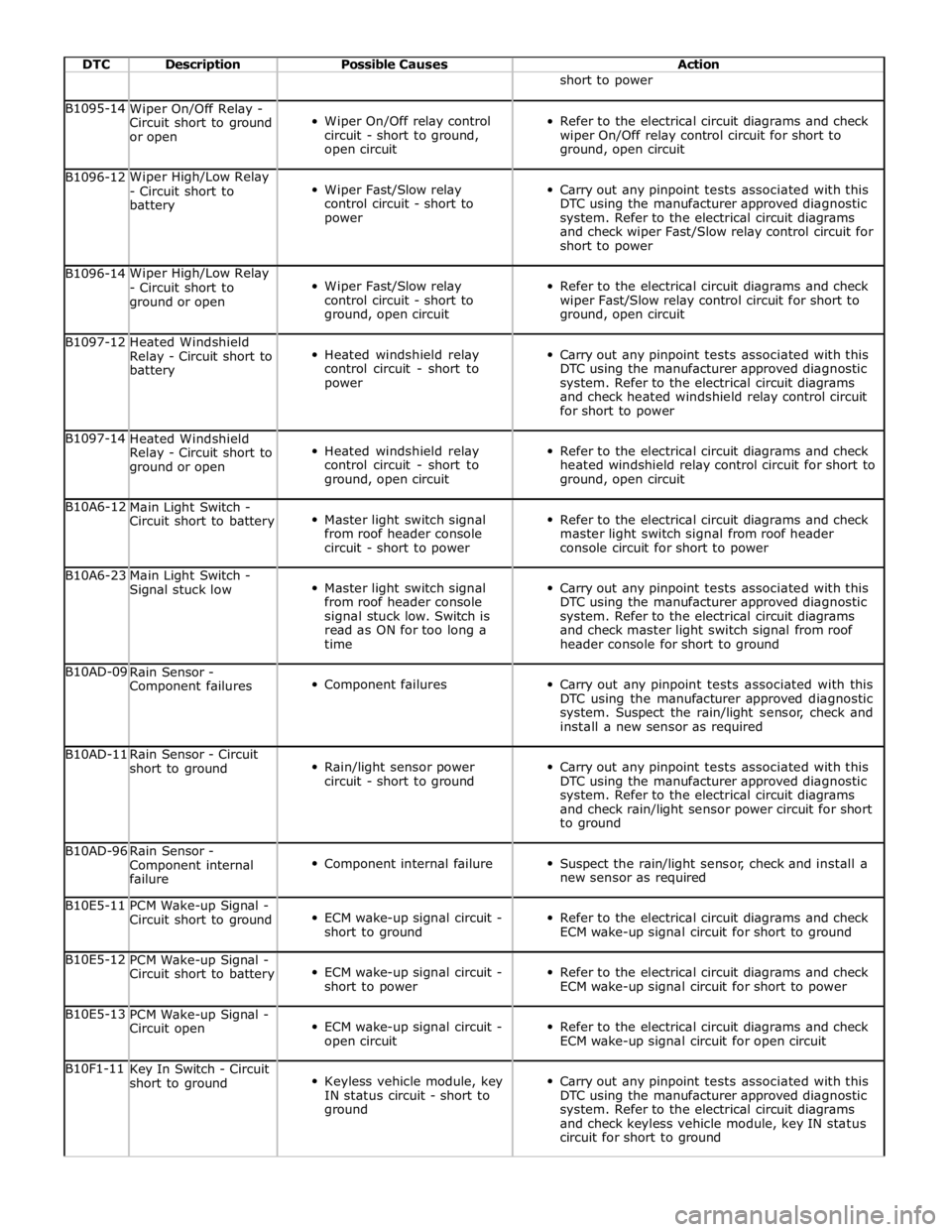

DTC Description Possible Causes Action short to power B1095-14

Wiper On/Off Relay -

Circuit short to ground

or open

Wiper On/Off relay control

circuit - short to ground,

open circuit

Refer to the electrical circuit diagrams and check

wiper On/Off relay control circuit for short to

ground, open circuit B1096-12 Wiper High/Low Relay

- Circuit short to

battery

Wiper Fast/Slow relay

control circuit - short to

power

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check wiper Fast/Slow relay control circuit for

short to power B1096-14 Wiper High/Low Relay

- Circuit short to

ground or open

Wiper Fast/Slow relay

control circuit - short to

ground, open circuit

Refer to the electrical circuit diagrams and check

wiper Fast/Slow relay control circuit for short to

ground, open circuit B1097-12

Heated Windshield

Relay - Circuit short to

battery

Heated windshield relay

control circuit - short to

power

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check heated windshield relay control circuit

for short to power B1097-14

Heated Windshield

Relay - Circuit short to

ground or open

Heated windshield relay

control circuit - short to

ground, open circuit

Refer to the electrical circuit diagrams and check

heated windshield relay control circuit for short to

ground, open circuit B10A6-12

Main Light Switch -

Circuit short to battery

Master light switch signal

from roof header console

circuit - short to power

Refer to the electrical circuit diagrams and check

master light switch signal from roof header

console circuit for short to power B10A6-23

Main Light Switch -

Signal stuck low

Master light switch signal

from roof header console

signal stuck low. Switch is

read as ON for too long a

time

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check master light switch signal from roof

header console for short to ground B10AD-09

Rain Sensor -

Component failures

Component failures

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Suspect the rain/light sensor, check and

install a new sensor as required B10AD-11

Rain Sensor - Circuit

short to ground

Rain/light sensor power

circuit - short to ground

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check rain/light sensor power circuit for short

to ground B10AD-96

Rain Sensor -

Component internal

failure

Component internal failure

Suspect the rain/light sensor, check and install a

new sensor as required B10E5-11

PCM Wake-up Signal -

Circuit short to ground

ECM wake-up signal circuit -

short to ground

Refer to the electrical circuit diagrams and check

ECM wake-up signal circuit for short to ground B10E5-12

PCM Wake-up Signal -

Circuit short to battery

ECM wake-up signal circuit -

short to power

Refer to the electrical circuit diagrams and check

ECM wake-up signal circuit for short to power B10E5-13

PCM Wake-up Signal -

Circuit open

ECM wake-up signal circuit -

open circuit

Refer to the electrical circuit diagrams and check

ECM wake-up signal circuit for open circuit B10F1-11

Key In Switch - Circuit

short to ground

Keyless vehicle module, key

IN status circuit - short to

ground

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check keyless vehicle module, key IN status

circuit for short to ground

Page 137 of 3039

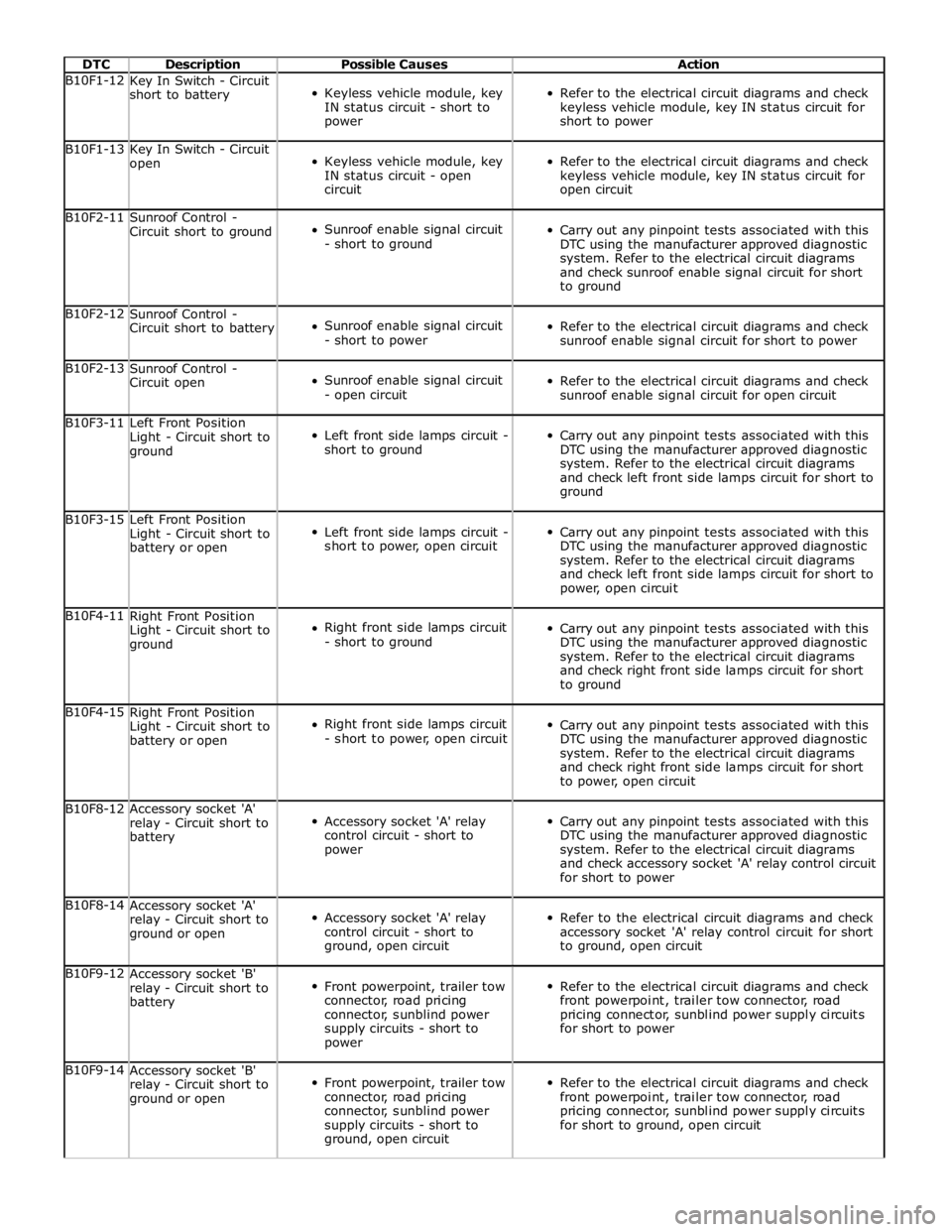

DTC Description Possible Causes Action B10F1-12

Key In Switch - Circuit

short to battery

Keyless vehicle module, key

IN status circuit - short to

power

Refer to the electrical circuit diagrams and check

keyless vehicle module, key IN status circuit for

short to power B10F1-13

Key In Switch - Circuit

open

Keyless vehicle module, key

IN status circuit - open

circuit

Refer to the electrical circuit diagrams and check

keyless vehicle module, key IN status circuit for

open circuit B10F2-11

Sunroof Control -

Circuit short to ground

Sunroof enable signal circuit

- short to ground

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check sunroof enable signal circuit for short

to ground B10F2-12

Sunroof Control -

Circuit short to battery

Sunroof enable signal circuit

- short to power

Refer to the electrical circuit diagrams and check

sunroof enable signal circuit for short to power B10F2-13

Sunroof Control -

Circuit open

Sunroof enable signal circuit

- open circuit

Refer to the electrical circuit diagrams and check

sunroof enable signal circuit for open circuit B10F3-11

Left Front Position

Light - Circuit short to

ground

Left front side lamps circuit -

short to ground

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check left front side lamps circuit for short to

ground B10F3-15

Left Front Position

Light - Circuit short to

battery or open

Left front side lamps circuit -

short to power, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check left front side lamps circuit for short to

power, open circuit B10F4-11

Right Front Position

Light - Circuit short to

ground

Right front side lamps circuit

- short to ground

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check right front side lamps circuit for short

to ground B10F4-15

Right Front Position

Light - Circuit short to

battery or open

Right front side lamps circuit

- short to power, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check right front side lamps circuit for short

to power, open circuit B10F8-12

Accessory socket 'A'

relay - Circuit short to

battery

Accessory socket 'A' relay

control circuit - short to

power

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check accessory socket 'A' relay control circuit

for short to power B10F8-14

Accessory socket 'A'

relay - Circuit short to

ground or open

Accessory socket 'A' relay

control circuit - short to

ground, open circuit

Refer to the electrical circuit diagrams and check

accessory socket 'A' relay control circuit for short

to ground, open circuit B10F9-12

Accessory socket 'B'

relay - Circuit short to

battery

Front powerpoint, trailer tow

connector, road pricing

connector, sunblind power

supply circuits - short to

power

Refer to the electrical circuit diagrams and check

front powerpoint, trailer tow connector, road

pricing connector, sunblind power supply circuits

for short to power B10F9-14

Accessory socket 'B'

relay - Circuit short to

ground or open

Front powerpoint, trailer tow

connector, road pricing

connector, sunblind power

supply circuits - short to

ground, open circuit

Refer to the electrical circuit diagrams and check

front powerpoint, trailer tow connector, road

pricing connector, sunblind power supply circuits

for short to ground, open circuit

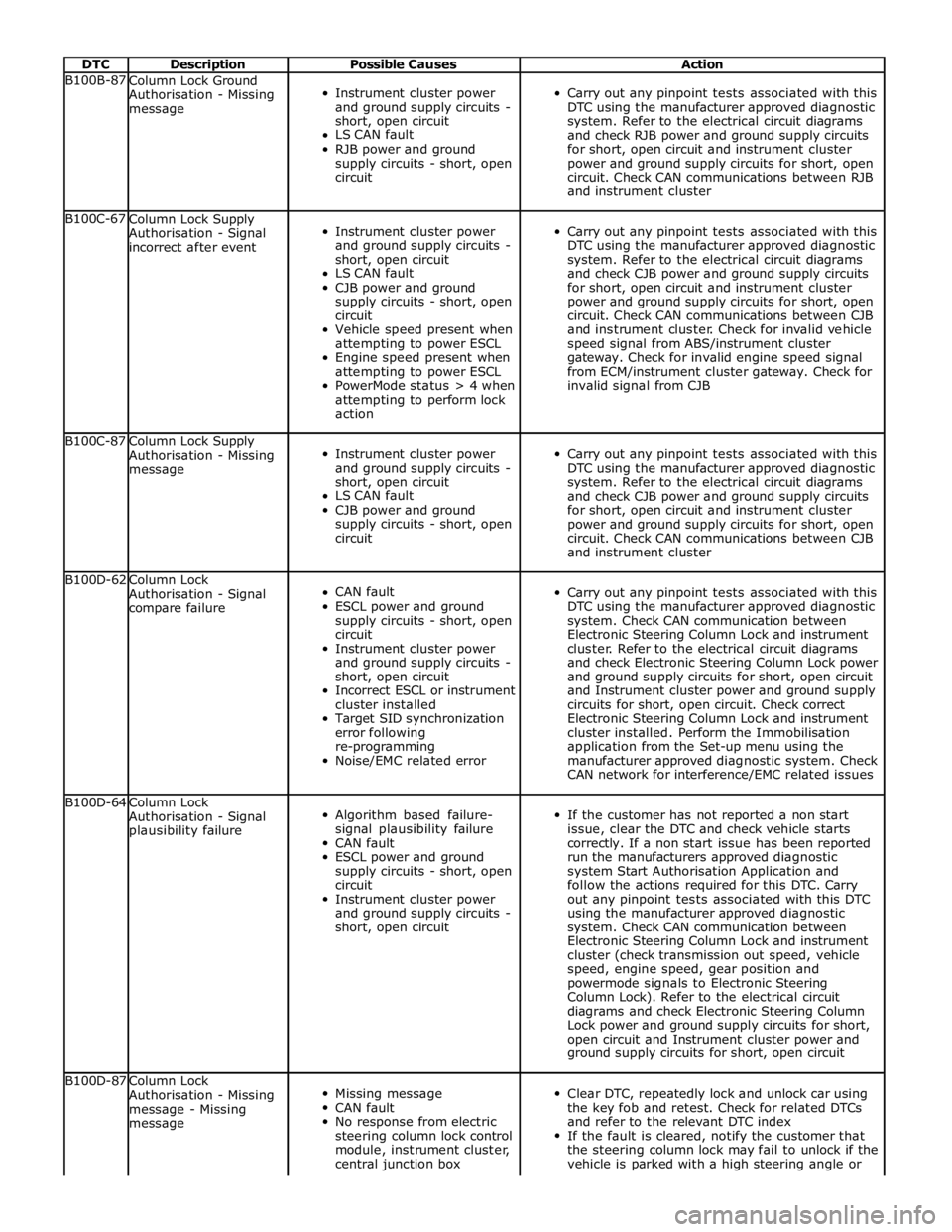

Page 189 of 3039

DTC Description Possible Causes Action B100B-87

Column Lock Ground

Authorisation - Missing

message

Instrument cluster power

and ground supply circuits -

short, open circuit

LS CAN fault

RJB power and ground

supply circuits - short, open

circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check RJB power and ground supply circuits

for short, open circuit and instrument cluster

power and ground supply circuits for short, open

circuit. Check CAN communications between RJB

and instrument cluster B100C-67

Column Lock Supply

Authorisation - Signal

incorrect after event

Instrument cluster power

and ground supply circuits -

short, open circuit

LS CAN fault

CJB power and ground

supply circuits - short, open

circuit

Vehicle speed present when

attempting to power ESCL

Engine speed present when

attempting to power ESCL

PowerMode status > 4 when

attempting to perform lock

action

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check CJB power and ground supply circuits

for short, open circuit and instrument cluster

power and ground supply circuits for short, open

circuit. Check CAN communications between CJB

and instrument cluster. Check for invalid vehicle

speed signal from ABS/instrument cluster

gateway. Check for invalid engine speed signal

from ECM/instrument cluster gateway. Check for

invalid signal from CJB B100C-87

Column Lock Supply

Authorisation - Missing

message

Instrument cluster power

and ground supply circuits -

short, open circuit

LS CAN fault

CJB power and ground

supply circuits - short, open

circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check CJB power and ground supply circuits

for short, open circuit and instrument cluster

power and ground supply circuits for short, open

circuit. Check CAN communications between CJB

and instrument cluster B100D-62

Column Lock

Authorisation - Signal

compare failure

CAN fault

ESCL power and ground

supply circuits - short, open

circuit

Instrument cluster power

and ground supply circuits -

short, open circuit

Incorrect ESCL or instrument

cluster installed

Target SID synchronization

error following

re-programming

Noise/EMC related error

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check CAN communication between

Electronic Steering Column Lock and instrument

cluster. Refer to the electrical circuit diagrams

and check Electronic Steering Column Lock power

and ground supply circuits for short, open circuit

and Instrument cluster power and ground supply

circuits for short, open circuit. Check correct

Electronic Steering Column Lock and instrument

cluster installed. Perform the Immobilisation

application from the Set-up menu using the

manufacturer approved diagnostic system. Check

CAN network for interference/EMC related issues B100D-64

Column Lock

Authorisation - Signal

plausibility failure

Algorithm based failure-

signal plausibility failure

CAN fault

ESCL power and ground

supply circuits - short, open

circuit

Instrument cluster power

and ground supply circuits -

short, open circuit

If the customer has not reported a non start

issue, clear the DTC and check vehicle starts

correctly. If a non start issue has been reported

run the manufacturers approved diagnostic

system Start Authorisation Application and

follow the actions required for this DTC. Carry

out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic

system. Check CAN communication between

Electronic Steering Column Lock and instrument

cluster (check transmission out speed, vehicle

speed, engine speed, gear position and

powermode signals to Electronic Steering

Column Lock). Refer to the electrical circuit

diagrams and check Electronic Steering Column

Lock power and ground supply circuits for short,

open circuit and Instrument cluster power and

ground supply circuits for short, open circuit B100D-87

Column Lock

Authorisation - Missing

message - Missing

message

Missing message

CAN fault

No response from electric

steering column lock control

module, instrument cluster,

central junction box

Clear DTC, repeatedly lock and unlock car using

the key fob and retest. Check for related DTCs

and refer to the relevant DTC index

If the fault is cleared, notify the customer that

the steering column lock may fail to unlock if the

vehicle is parked with a high steering angle or

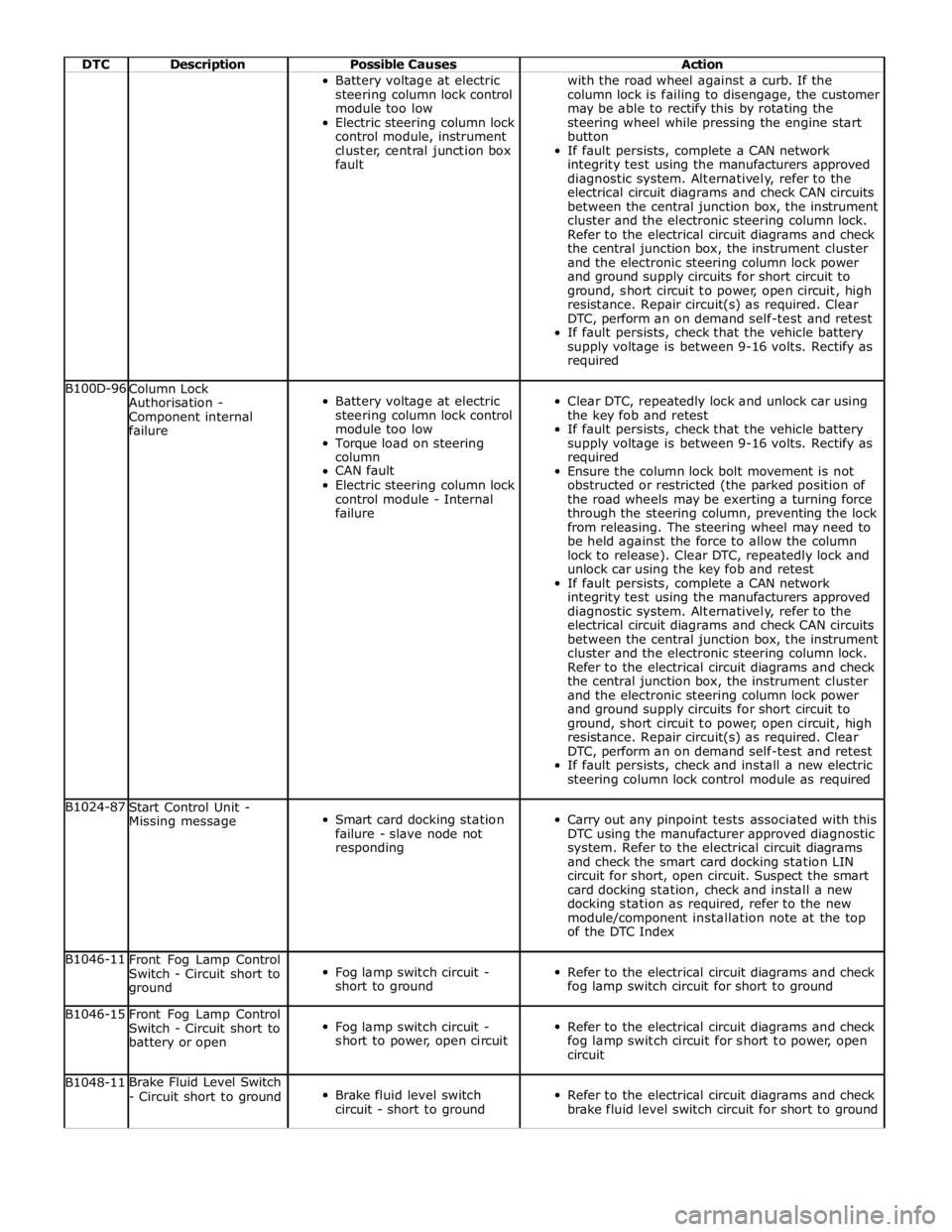

Page 190 of 3039

DTC Description Possible Causes Action Battery voltage at electric

steering column lock control

module too low

Electric steering column lock

control module, instrument

cluster, central junction box

fault with the road wheel against a curb. If the

column lock is failing to disengage, the customer

may be able to rectify this by rotating the

steering wheel while pressing the engine start

button

If fault persists, complete a CAN network

integrity test using the manufacturers approved

diagnostic system. Alternatively, refer to the

electrical circuit diagrams and check CAN circuits

between the central junction box, the instrument

cluster and the electronic steering column lock.

Refer to the electrical circuit diagrams and check

the central junction box, the instrument cluster

and the electronic steering column lock power

and ground supply circuits for short circuit to

ground, short circuit to power, open circuit, high

resistance. Repair circuit(s) as required. Clear

DTC, perform an on demand self-test and retest

If fault persists, check that the vehicle battery

supply voltage is between 9-16 volts. Rectify as

required B100D-96

Column Lock

Authorisation -

Component internal

failure

Battery voltage at electric

steering column lock control

module too low

Torque load on steering

column

CAN fault

Electric steering column lock

control module - Internal

failure

Clear DTC, repeatedly lock and unlock car using

the key fob and retest

If fault persists, check that the vehicle battery

supply voltage is between 9-16 volts. Rectify as

required

Ensure the column lock bolt movement is not

obstructed or restricted (the parked position of

the road wheels may be exerting a turning force

through the steering column, preventing the lock

from releasing. The steering wheel may need to

be held against the force to allow the column

lock to release). Clear DTC, repeatedly lock and

unlock car using the key fob and retest

If fault persists, complete a CAN network

integrity test using the manufacturers approved

diagnostic system. Alternatively, refer to the

electrical circuit diagrams and check CAN circuits

between the central junction box, the instrument

cluster and the electronic steering column lock.

Refer to the electrical circuit diagrams and check

the central junction box, the instrument cluster

and the electronic steering column lock power

and ground supply circuits for short circuit to

ground, short circuit to power, open circuit, high

resistance. Repair circuit(s) as required. Clear

DTC, perform an on demand self-test and retest

If fault persists, check and install a new electric

steering column lock control module as required B1024-87

Start Control Unit -

Missing message

Smart card docking station

failure - slave node not

responding

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check the smart card docking station LIN

circuit for short, open circuit. Suspect the smart

card docking station, check and install a new

docking station as required, refer to the new

module/component installation note at the top

of the DTC Index B1046-11

Front Fog Lamp Control

Switch - Circuit short to

ground

Fog lamp switch circuit -

short to ground

Refer to the electrical circuit diagrams and check

fog lamp switch circuit for short to ground B1046-15

Front Fog Lamp Control

Switch - Circuit short to

battery or open

Fog lamp switch circuit -

short to power, open circuit

Refer to the electrical circuit diagrams and check

fog lamp switch circuit for short to power, open

circuit B1048-11 Brake Fluid Level Switch

- Circuit short to ground

Brake fluid level switch

circuit - short to ground

Refer to the electrical circuit diagrams and check

brake fluid level switch circuit for short to ground

Page 191 of 3039

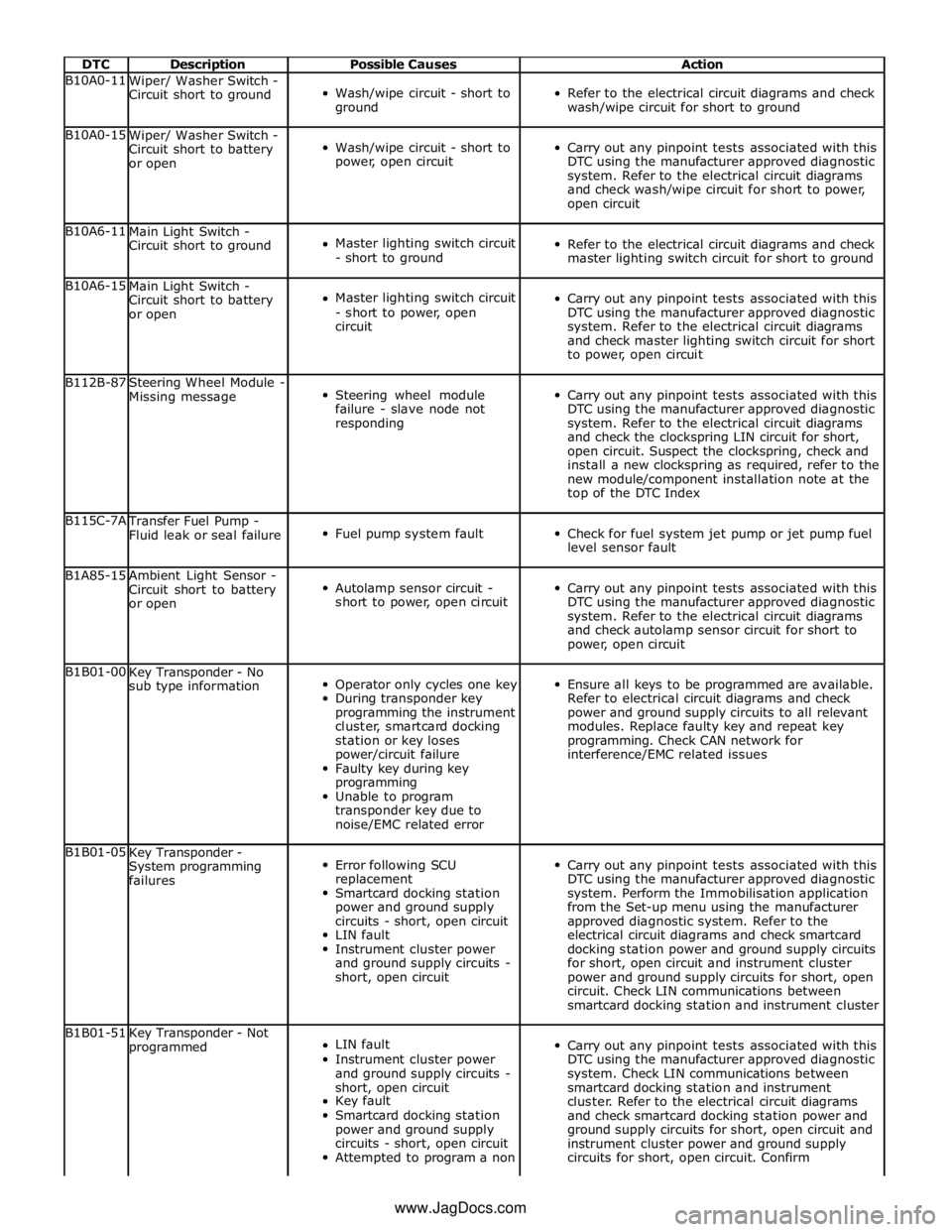

DTC Description Possible Causes Action B10A0-11

Wiper/ Washer Switch -

Circuit short to ground

Wash/wipe circuit - short to

ground

Refer to the electrical circuit diagrams and check

wash/wipe circuit for short to ground B10A0-15

Wiper/ Washer Switch -

Circuit short to battery

or open

Wash/wipe circuit - short to

power, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check wash/wipe circuit for short to power,

open circuit B10A6-11

Main Light Switch -

Circuit short to ground

Master lighting switch circuit

- short to ground

Refer to the electrical circuit diagrams and check

master lighting switch circuit for short to ground B10A6-15

Main Light Switch -

Circuit short to battery

or open

Master lighting switch circuit

- short to power, open

circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check master lighting switch circuit for short

to power, open circuit B112B-87

Steering Wheel Module -

Missing message

Steering wheel module

failure - slave node not

responding

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check the clockspring LIN circuit for short,

open circuit. Suspect the clockspring, check and

install a new clockspring as required, refer to the

new module/component installation note at the

top of the DTC Index B115C-7A Transfer Fuel Pump -

Fluid leak or seal failure

Fuel pump system fault

Check for fuel system jet pump or jet pump fuel

level sensor fault B1A85-15

Ambient Light Sensor -

Circuit short to battery

or open

Autolamp sensor circuit -

short to power, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check autolamp sensor circuit for short to

power, open circuit B1B01-00

Key Transponder - No

sub type information

Operator only cycles one key

During transponder key

programming the instrument

cluster, smartcard docking

station or key loses

power/circuit failure

Faulty key during key

programming

Unable to program

transponder key due to

noise/EMC related error

Ensure all keys to be programmed are available.

Refer to electrical circuit diagrams and check

power and ground supply circuits to all relevant

modules. Replace faulty key and repeat key

programming. Check CAN network for

interference/EMC related issues B1B01-05

Key Transponder -

System programming

failures

Error following SCU

replacement

Smartcard docking station

power and ground supply

circuits - short, open circuit

LIN fault

Instrument cluster power

and ground supply circuits -

short, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Perform the Immobilisation application

from the Set-up menu using the manufacturer

approved diagnostic system. Refer to the

electrical circuit diagrams and check smartcard

docking station power and ground supply circuits

for short, open circuit and instrument cluster

power and ground supply circuits for short, open

circuit. Check LIN communications between

smartcard docking station and instrument cluster B1B01-51

Key Transponder - Not

programmed

LIN fault

Instrument cluster power

and ground supply circuits -

short, open circuit

Key fault

Smartcard docking station

power and ground supply

circuits - short, open circuit

Attempted to program a non

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check LIN communications between

smartcard docking station and instrument

cluster. Refer to the electrical circuit diagrams

and check smartcard docking station power and

ground supply circuits for short, open circuit and

instrument cluster power and ground supply

circuits for short, open circuit. Confirm www.JagDocs.com

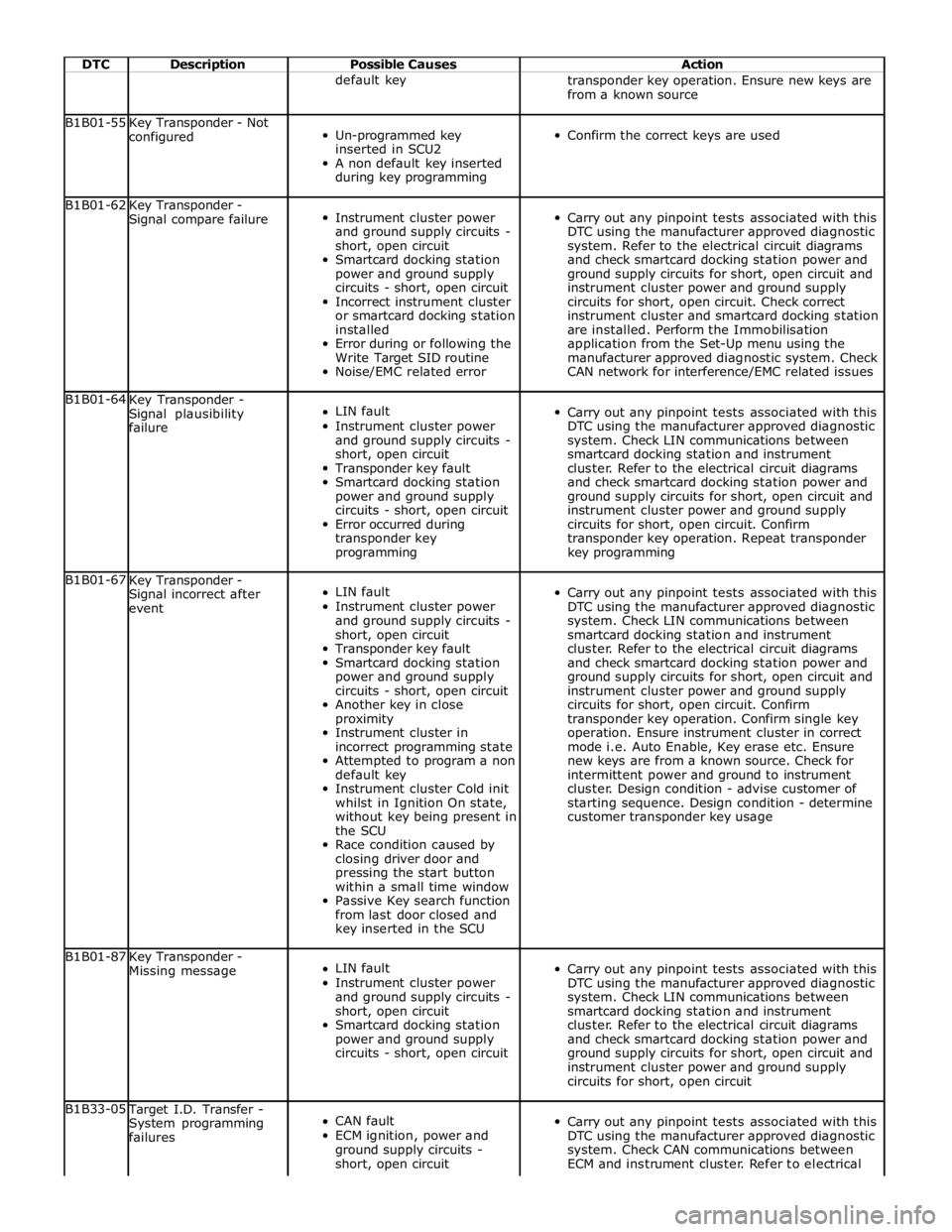

Page 192 of 3039

DTC Description Possible Causes Action default key

transponder key operation. Ensure new keys are

from a known source B1B01-55

Key Transponder - Not

configured

Un-programmed key

inserted in SCU2

A non default key inserted

during key programming

Confirm the correct keys are used B1B01-62

Key Transponder -

Signal compare failure

Instrument cluster power

and ground supply circuits -

short, open circuit

Smartcard docking station

power and ground supply

circuits - short, open circuit

Incorrect instrument cluster

or smartcard docking station

installed

Error during or following the

Write Target SID routine

Noise/EMC related error

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams

and check smartcard docking station power and

ground supply circuits for short, open circuit and

instrument cluster power and ground supply

circuits for short, open circuit. Check correct

instrument cluster and smartcard docking station

are installed. Perform the Immobilisation

application from the Set-Up menu using the

manufacturer approved diagnostic system. Check

CAN network for interference/EMC related issues B1B01-64

Key Transponder -

Signal plausibility

failure

LIN fault

Instrument cluster power

and ground supply circuits -

short, open circuit

Transponder key fault

Smartcard docking station

power and ground supply

circuits - short, open circuit

Error occurred during

transponder key

programming

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check LIN communications between

smartcard docking station and instrument

cluster. Refer to the electrical circuit diagrams

and check smartcard docking station power and

ground supply circuits for short, open circuit and

instrument cluster power and ground supply

circuits for short, open circuit. Confirm

transponder key operation. Repeat transponder

key programming B1B01-67

Key Transponder -

Signal incorrect after

event

LIN fault

Instrument cluster power

and ground supply circuits -

short, open circuit

Transponder key fault

Smartcard docking station

power and ground supply

circuits - short, open circuit

Another key in close

proximity

Instrument cluster in

incorrect programming state

Attempted to program a non

default key

Instrument cluster Cold init

whilst in Ignition On state,

without key being present in

the SCU

Race condition caused by

closing driver door and

pressing the start button

within a small time window

Passive Key search function

from last door closed and

key inserted in the SCU

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check LIN communications between

smartcard docking station and instrument

cluster. Refer to the electrical circuit diagrams

and check smartcard docking station power and

ground supply circuits for short, open circuit and

instrument cluster power and ground supply

circuits for short, open circuit. Confirm

transponder key operation. Confirm single key

operation. Ensure instrument cluster in correct

mode i.e. Auto Enable, Key erase etc. Ensure

new keys are from a known source. Check for

intermittent power and ground to instrument

cluster. Design condition - advise customer of

starting sequence. Design condition - determine

customer transponder key usage B1B01-87

Key Transponder -

Missing message

LIN fault

Instrument cluster power

and ground supply circuits -

short, open circuit

Smartcard docking station

power and ground supply

circuits - short, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check LIN communications between

smartcard docking station and instrument

cluster. Refer to the electrical circuit diagrams

and check smartcard docking station power and

ground supply circuits for short, open circuit and

instrument cluster power and ground supply

circuits for short, open circuit B1B33-05 Target I.D. Transfer -

System programming

failures

CAN fault

ECM ignition, power and

ground supply circuits -

short, open circuit

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check CAN communications between

ECM and instrument cluster. Refer to electrical

Page 227 of 3039

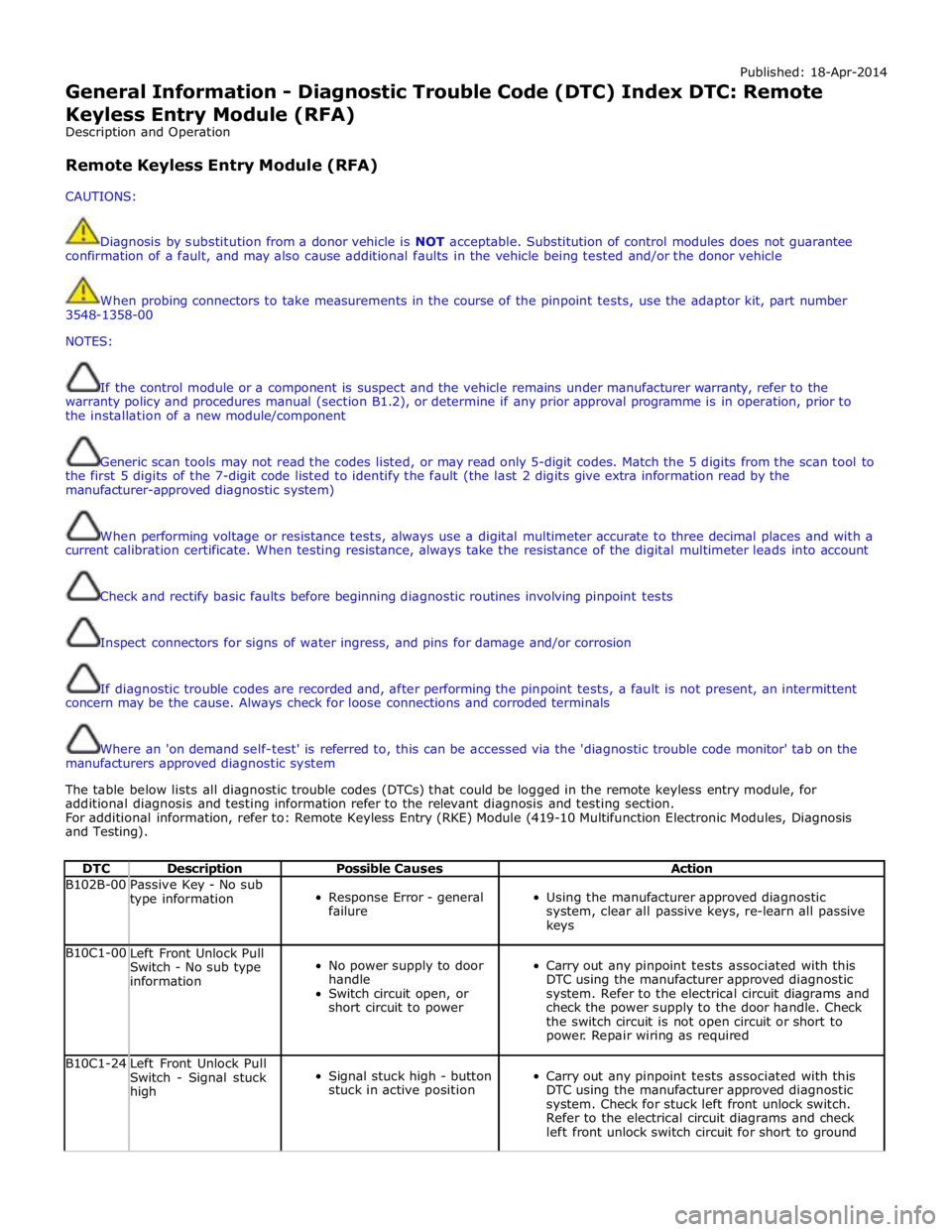

Published: 18-Apr-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Remote

Keyless Entry Module (RFA)

Description and Operation

Remote Keyless Entry Module (RFA)

CAUTIONS:

Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not guarantee

confirmation of a fault, and may also cause additional faults in the vehicle being tested and/or the donor vehicle

When probing connectors to take measurements in the course of the pinpoint tests, use the adaptor kit, part number

3548-1358-00

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

warranty policy and procedures manual (section B1.2), or determine if any prior approval programme is in operation, prior to

the installation of a new module/component

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer-approved diagnostic system)

When performing voltage or resistance tests, always use a digital multimeter accurate to three decimal places and with a

current calibration certificate. When testing resistance, always take the resistance of the digital multimeter leads into account

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests

Inspect connectors for signs of water ingress, and pins for damage and/or corrosion

If diagnostic trouble codes are recorded and, after performing the pinpoint tests, a fault is not present, an intermittent

concern may be the cause. Always check for loose connections and corroded terminals

Where an 'on demand self-test' is referred to, this can be accessed via the 'diagnostic trouble code monitor' tab on the

manufacturers approved diagnostic system

The table below lists all diagnostic trouble codes (DTCs) that could be logged in the remote keyless entry module, for

additional diagnosis and testing information refer to the relevant diagnosis and testing section.

For additional information, refer to: Remote Keyless Entry (RKE) Module (419-10 Multifunction Electronic Modules, Diagnosis

and Testing).

DTC Description Possible Causes Action B102B-00

Passive Key - No sub

type information

Response Error - general

failure

Using the manufacturer approved diagnostic

system, clear all passive keys, re-learn all passive

keys B10C1-00

Left Front Unlock Pull

Switch - No sub type

information

No power supply to door

handle

Switch circuit open, or

short circuit to power

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Refer to the electrical circuit diagrams and

check the power supply to the door handle. Check

the switch circuit is not open circuit or short to

power. Repair wiring as required B10C1-24

Left Front Unlock Pull

Switch - Signal stuck

high

Signal stuck high - button

stuck in active position

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Check for stuck left front unlock switch.

Refer to the electrical circuit diagrams and check

left front unlock switch circuit for short to ground

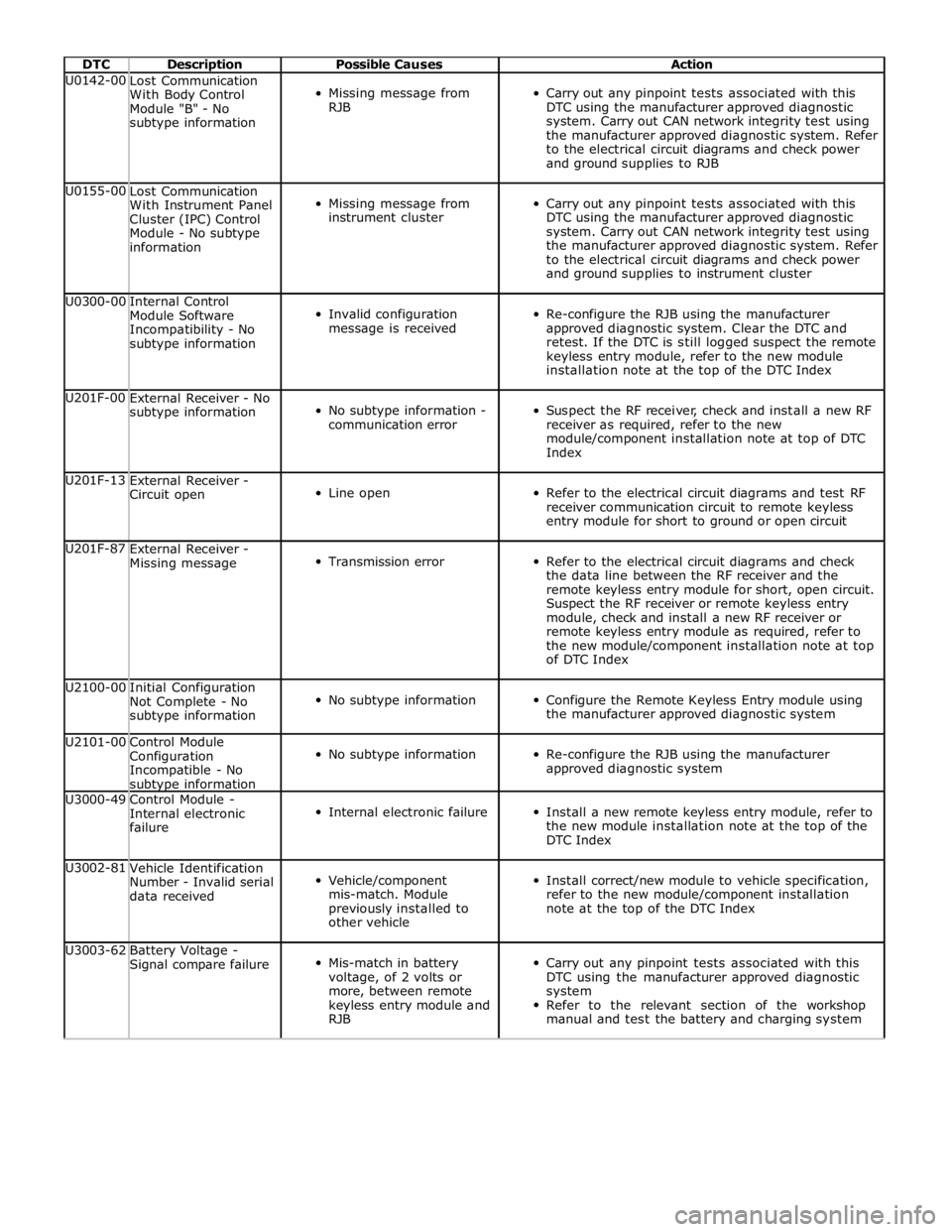

Page 230 of 3039

DTC Description Possible Causes Action U0142-00

Lost Communication

With Body Control

Module "B" - No

subtype information

Missing message from

RJB

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Carry out CAN network integrity test using

the manufacturer approved diagnostic system. Refer

to the electrical circuit diagrams and check power

and ground supplies to RJB U0155-00

Lost Communication

With Instrument Panel

Cluster (IPC) Control

Module - No subtype

information

Missing message from

instrument cluster

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system. Carry out CAN network integrity test using

the manufacturer approved diagnostic system. Refer

to the electrical circuit diagrams and check power

and ground supplies to instrument cluster U0300-00

Internal Control

Module Software

Incompatibility - No

subtype information

Invalid configuration

message is received

Re-configure the RJB using the manufacturer

approved diagnostic system. Clear the DTC and

retest. If the DTC is still logged suspect the remote

keyless entry module, refer to the new module

installation note at the top of the DTC Index U201F-00

External Receiver - No

subtype information

No subtype information -

communication error

Suspect the RF receiver, check and install a new RF

receiver as required, refer to the new

module/component installation note at top of DTC

Index U201F-13

External Receiver -

Circuit open

Line open

Refer to the electrical circuit diagrams and test RF

receiver communication circuit to remote keyless

entry module for short to ground or open circuit U201F-87

External Receiver -

Missing message

Transmission error

Refer to the electrical circuit diagrams and check

the data line between the RF receiver and the

remote keyless entry module for short, open circuit.

Suspect the RF receiver or remote keyless entry

module, check and install a new RF receiver or

remote keyless entry module as required, refer to

the new module/component installation note at top

of DTC Index U2100-00

Initial Configuration

Not Complete - No

subtype information

No subtype information

Configure the Remote Keyless Entry module using

the manufacturer approved diagnostic system U2101-00

Control Module

Configuration

Incompatible - No subtype information

No subtype information

Re-configure the RJB using the manufacturer

approved diagnostic system U3000-49

Control Module -

Internal electronic

failure

Internal electronic failure

Install a new remote keyless entry module, refer to

the new module installation note at the top of the

DTC Index U3002-81

Vehicle Identification

Number - Invalid serial

data received

Vehicle/component

mis-match. Module

previously installed to

other vehicle

Install correct/new module to vehicle specification,

refer to the new module/component installation

note at the top of the DTC Index U3003-62

Battery Voltage -

Signal compare failure

Mis-match in battery

voltage, of 2 volts or

more, between remote

keyless entry module and

RJB

Carry out any pinpoint tests associated with this

DTC using the manufacturer approved diagnostic

system

Refer to the relevant section of the workshop

manual and test the battery and charging system

Page 243 of 3039

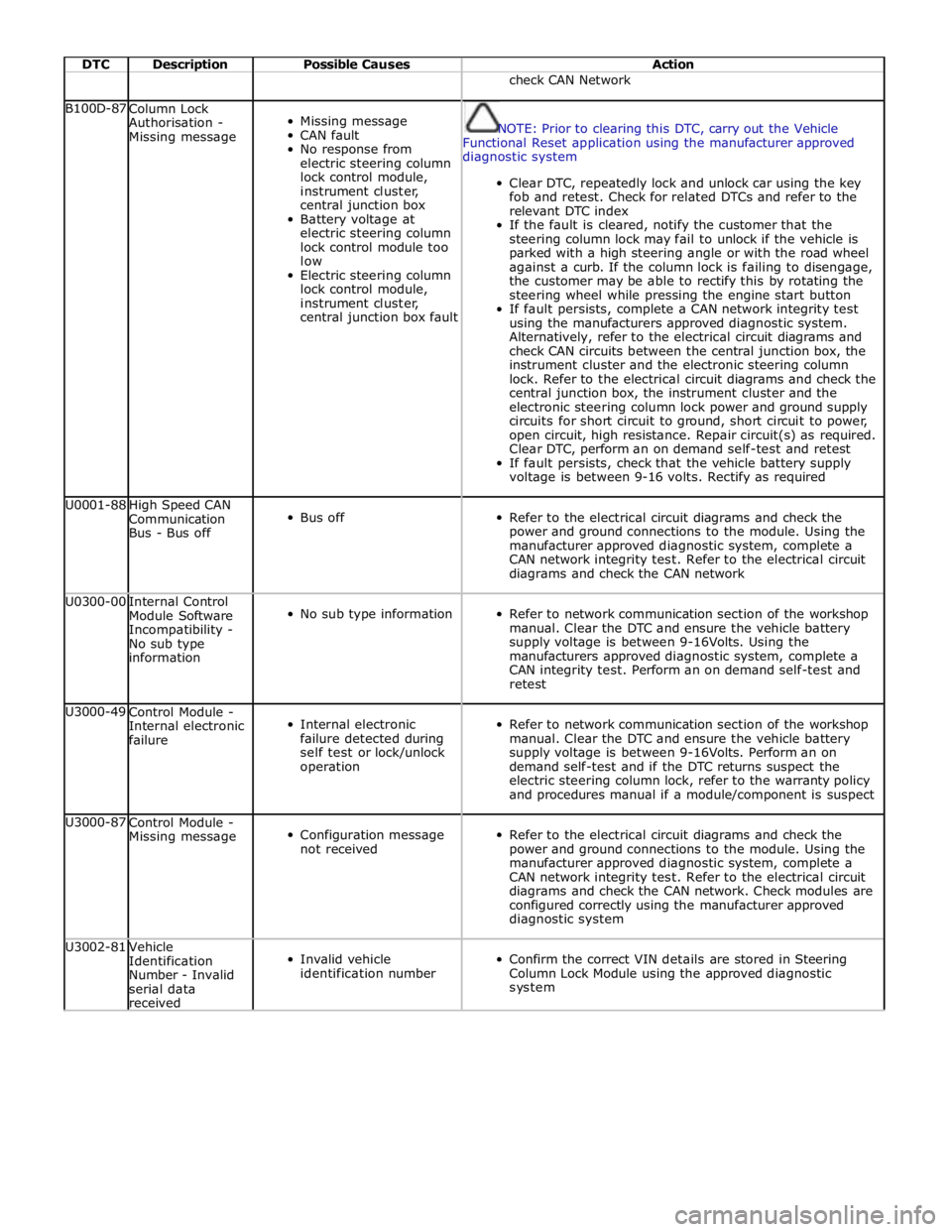

DTC Description Possible Causes Action check CAN Network B100D-87

Column Lock

Authorisation -

Missing message

Missing message

CAN fault

No response from

electric steering column

lock control module,

instrument cluster,

central junction box

Battery voltage at

electric steering column

lock control module too

low

Electric steering column

lock control module,

instrument cluster,

central junction box fault

NOTE: Prior to clearing this DTC, carry out the Vehicle

Functional Reset application using the manufacturer approved

diagnostic system

Clear DTC, repeatedly lock and unlock car using the key

fob and retest. Check for related DTCs and refer to the

relevant DTC index

If the fault is cleared, notify the customer that the

steering column lock may fail to unlock if the vehicle is

parked with a high steering angle or with the road wheel

against a curb. If the column lock is failing to disengage,

the customer may be able to rectify this by rotating the

steering wheel while pressing the engine start button

If fault persists, complete a CAN network integrity test

using the manufacturers approved diagnostic system.

Alternatively, refer to the electrical circuit diagrams and

check CAN circuits between the central junction box, the

instrument cluster and the electronic steering column

lock. Refer to the electrical circuit diagrams and check the

central junction box, the instrument cluster and the

electronic steering column lock power and ground supply

circuits for short circuit to ground, short circuit to power,

open circuit, high resistance. Repair circuit(s) as required.

Clear DTC, perform an on demand self-test and retest

If fault persists, check that the vehicle battery supply

voltage is between 9-16 volts. Rectify as required U0001-88

High Speed CAN

Communication

Bus - Bus off

Bus off

Refer to the electrical circuit diagrams and check the

power and ground connections to the module. Using the

manufacturer approved diagnostic system, complete a

CAN network integrity test. Refer to the electrical circuit

diagrams and check the CAN network U0300-00

Internal Control

Module Software

Incompatibility -

No sub type

information

No sub type information

Refer to network communication section of the workshop

manual. Clear the DTC and ensure the vehicle battery

supply voltage is between 9-16Volts. Using the

manufacturers approved diagnostic system, complete a

CAN integrity test. Perform an on demand self-test and

retest U3000-49

Control Module -

Internal electronic

failure

Internal electronic

failure detected during

self test or lock/unlock

operation

Refer to network communication section of the workshop

manual. Clear the DTC and ensure the vehicle battery

supply voltage is between 9-16Volts. Perform an on

demand self-test and if the DTC returns suspect the

electric steering column lock, refer to the warranty policy

and procedures manual if a module/component is suspect U3000-87

Control Module -

Missing message

Configuration message

not received

Refer to the electrical circuit diagrams and check the

power and ground connections to the module. Using the

manufacturer approved diagnostic system, complete a

CAN network integrity test. Refer to the electrical circuit

diagrams and check the CAN network. Check modules are

configured correctly using the manufacturer approved

diagnostic system U3002-81

Vehicle

Identification

Number - Invalid

serial data

received

Invalid vehicle

identification number

Confirm the correct VIN details are stored in Steering

Column Lock Module using the approved diagnostic

system

Page 284 of 3039

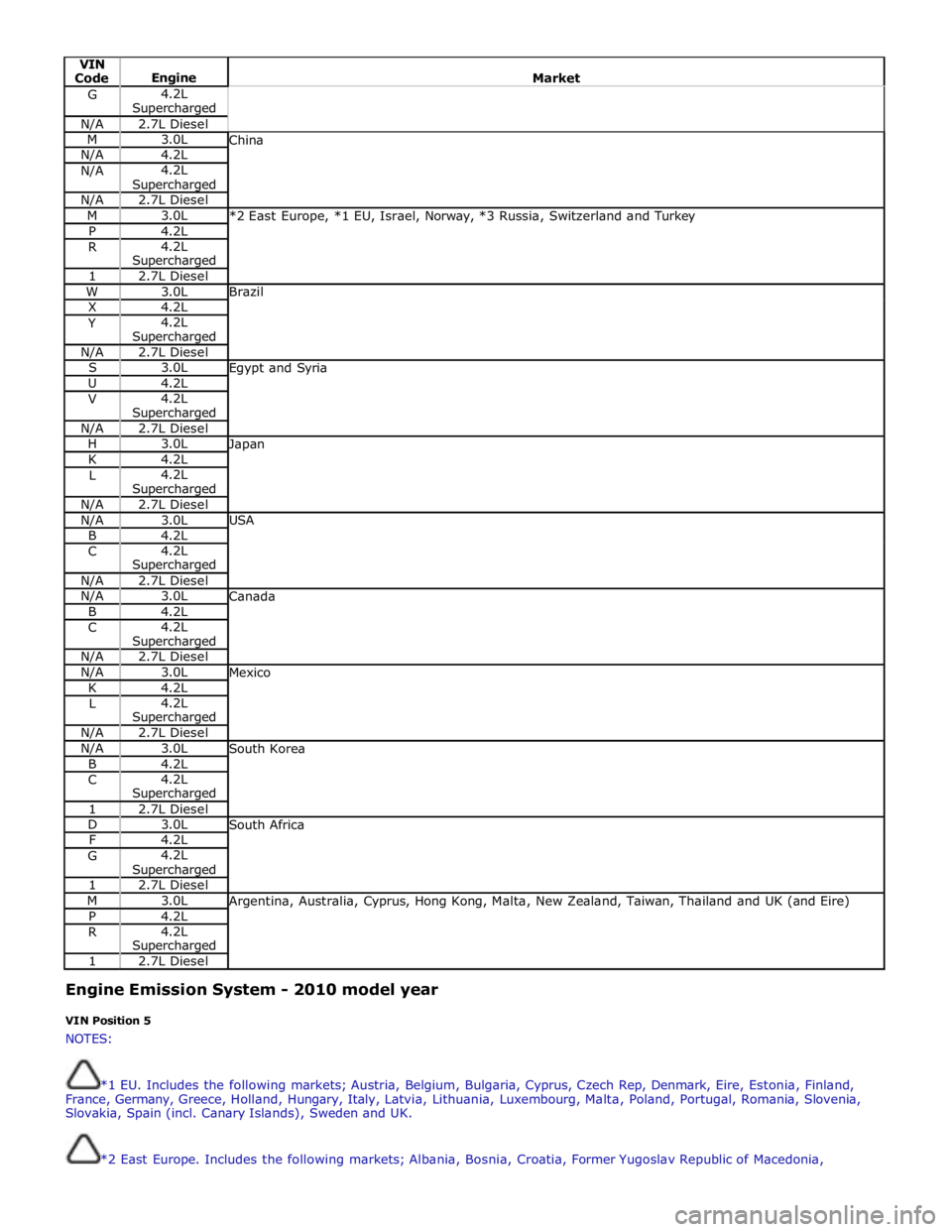

VIN

Code

Engine

Market G 4.2L

Supercharged N/A 2.7L Diesel M 3.0L

China N/A 4.2L N/A 4.2L

Supercharged N/A 2.7L Diesel M 3.0L

*2 East Europe, *1 EU, Israel, Norway, *3 Russia, Switzerland and Turkey P 4.2L R 4.2L

Supercharged 1 2.7L Diesel W 3.0L

Brazil X 4.2L Y 4.2L

Supercharged N/A 2.7L Diesel S 3.0L

Egypt and Syria U 4.2L V 4.2L

Supercharged N/A 2.7L Diesel H 3.0L

Japan K 4.2L L 4.2L

Supercharged N/A 2.7L Diesel N/A 3.0L

USA B 4.2L C 4.2L

Supercharged N/A 2.7L Diesel N/A 3.0L

Canada B 4.2L C 4.2L

Supercharged N/A 2.7L Diesel N/A 3.0L

Mexico K 4.2L L 4.2L

Supercharged N/A 2.7L Diesel N/A 3.0L

South Korea B 4.2L C 4.2L

Supercharged 1 2.7L Diesel D 3.0L

South Africa F 4.2L G 4.2L

Supercharged 1 2.7L Diesel M 3.0L

Argentina, Australia, Cyprus, Hong Kong, Malta, New Zealand, Taiwan, Thailand and UK (and Eire) P 4.2L R 4.2L

Supercharged 1 2.7L Diesel Engine Emission System - 2010 model year

VIN Position 5

NOTES:

*1 EU. Includes the following markets; Austria, Belgium, Bulgaria, Cyprus, Czech Rep, Denmark, Eire, Estonia, Finland,

France, Germany, Greece, Holland, Hungary, Italy, Latvia, Lithuania, Luxembourg, Malta, Poland, Portugal, Romania, Slovenia,

Slovakia, Spain (incl. Canary Islands), Sweden and UK.

*2 East Europe. Includes the following markets; Albania, Bosnia, Croatia, Former Yugoslav Republic of Macedonia,