Subframe JAGUAR XFR 2010 1.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2797 of 3039

(100-00 General Information, Description and Operation) /

Body Repairs (501-25A Body Repairs - General Information, Description and Operation) /

Corrosion Protection (501-25B Body Repairs - Corrosion Protection, Description and Operation) /

Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

5. Remove the fender apron panel front extension.

For additional information, refer to: Fender Apron Panel Front Extension (501-27 Front End Sheet Metal Repairs, Removal and Installation).

6. Remove the front fender support bracket.

For additional information, refer to: Front Fender Support Bracket (501-27 Front End Sheet Metal Repairs, Removal and Installation).

7. Remove the fender apron panel.

For additional information, refer to: Fender Apron Panel (501-27 Front End Sheet Metal Repairs, Removal and Installation).

8. Remove the engine, transmission / transaxle, front subframe and front

suspension, as an assembly.

For additional information, refer to: Engine (303-01A, Removal) /

Engine (303-01B Engine - V6 3.0L Petrol, Removal) / Engine (303-01D, Removal) /

Engine (303-01E, Removal) /

Transmission - 2.7L Diesel (307-01, Removal) /

Transmission - TDV6 3.0L Diesel (307-01B Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L

Petrol, Removal) /

Transmission (307-01A Automatic Transmission/Transaxle - V6 3.0L Petrol, Removal) /

Transmission - 4.2L (307-01, Removal) /

Transmission - V8 5.0L Petrol/V8 S/C 5.0L Petrol (307-01B Automatic Transmission/Transaxle - TDV6 3.0L Diesel /V8 5.0L Petrol/V8 S/C 5.0L

Petrol, Removal) /

Front Shock Absorber (204-01 Front Suspension, Removal and Installation) /

Front Subframe - 2.7L Diesel (502-00, Removal and Installation) /

Front Subframe - V6 3.0L Petrol (502-00 Uni-Body, Subframe and Mounting System, Removal and Installation) /

Front Subframe - 4.2L, Vehicles Without: Supercharger (502-00, Removal

and Installation) /

Front Subframe - 4.2L, Vehicles With: Supercharger (502-00, Removal

and Installation).

9. Remove the pedestrian protection hood actuator.

For additional information, refer to: Pedestrian Protection Hood Actuator LH (501-20C Pedestrian Protection System, Removal and Installation) / Pedestrian Protection Hood Actuator RH (501-20C Pedestrian Protection System, Removal and Installation).

10. If the drivers side front side member and suspension top mount is to be

repaired, remove the brake master cylinder and reservoir.

For additional information, refer to: Brake Master Cylinder (206-06 Hydraulic Brake Actuation, Removal and Installation) /

Brake Fluid Reservoir (206-06 Hydraulic Brake Actuation, Removal and Installation).

11. If the drivers side front side member and suspension top mount is to be

repaired, remove the brake booster.

Page 2807 of 3039

Published: 11-May-2011

Front End Sheet Metal Repairs - Front Side Member Closing Panel

Removal and Installation

Removal

1. NOTE: The front side member closing panel is

manufactured from High Strength Low Alloy Steel, 350MPa,

(HSLA350).

The front side member closing panel is serviced as a

separate weld-on panel.

2. In this procedure, to ensure the vehicle is correctly aligned, it must be

placed on an approved alignment jig.

3. The front side member closing panel is replaced in conjunction with:

Front bumper cover

Front bumper

Front bumper mounting

Hood

Hood latch panel

Front fender support bracket

Front fender support bracket mounting

Front wheelhouse section

Front side member

Engine, transmission / transaxle, front subframe and front

suspension, as an assembly

4. For additional information relating to this repair procedure please see

the following:

For additional information, refer to: Health and Safety Precautions (100-00 General Information, Description and Operation) /

Body Repairs (501-25A Body Repairs - General Information, Description and Operation) /

Corrosion Protection (501-25B Body Repairs - Corrosion Protection, Description and Operation) /

Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

5. NOTE: This procedure assumes that if the front side member closing

panel is damaged, the front side member will also be damaged.

Therefore, the replacement procedure for the front side member closing

panel is combined within the front side member procedure.

Remove the front side member.

For additional information, refer to: Front Side Member (501-27 Front End Sheet Metal Repairs, Removal and Installation).

Installation

1. The installation of associated panels and components is the reversal of

removal procedure.

Page 2941 of 3039

NOTE: The illustration may indicate either hand of the service panel, the opposite hand will be similar.

Item Description 1 Luggage compartment lid 2 Rear bumper cover 3 Rear bumper 4 Back panel 5 Rear bumper mounting L/H 6 Rear bumper mounting R/H 7 Quarter panel 8 Quarter panel lower extension 9 Rear wheelhouse outer 10 Spare wheel well 11 Rear floor side extension 12 Rear side member section 13 Rear side member closing panel section Time schedules, rear end

The following information shows the total time taken to replace single panels and complete assemblies. This time includes

removal of Mechanical, Electrical and Trim, (MET), items, plus paint times based on Metallic Clear Over Base Paint, (blends to

adjacent panels are not included)

The times shown were generated by Thatcham, (the Motor Insurance Repair Research Centre), and are to be used as a guide

only.

Single panel times

Panel Description Hours Luggage compartment lid 7.5 Rear bumper cover 6.6 Back panel 9.4 Quarter panel L/H 23.2 Quarter panel R/H 24.2 Headliner remove and install 3.3 Rear window glass remove and install 1.7 Rear subframe and rear suspension remove and install 5.2 Combination panel replacement times

The following panel combination times show the total time to remove/install body panels, MET items and paint times based on

Metallic Clear Over Base Paint process, (blends to adjacent panels are not included).

Combination panel times

Panel Description Hours Luggage compartment lid Rear bumper cover Rear bumper Quarter panel Back panel Headliner remove and install Rear window glass remove and install Total Time L/H 35.2

R/H 35.9 Combination panel times

Panel Description Hours Luggage compartment lid Rear bumper cover Rear bumper Quarter panel L/H and R/H Back panel Headliner remove and install Rear window glass remove and install Total Time 44.7 Combination panel times

Panel Description Hours Luggage compartment lid Rear bumper cover Rear bumper Quarter panel Back panel Rear wheelhouse outer Rear side member section

Page 2942 of 3039

Rear side member closing panel section Spare wheel well Rear floor side extension Rear subframe and rear suspension remove and install Headliner remove and install Rear window glass remove and install Total Time L/H 54.0

R/H 54.5 Combination panel times

Panel Description Hours Luggage compartment lid Rear bumper cover Rear bumper Quarter panel L/H and R/H Back panel Rear wheelhouse outer L/H and R/H Rear side member section L/H and R/H Rear side member closing panel section L/H and R/H Spare wheel well Rear floor side extension L/H and R/H Rear subframe and rear suspension remove and install Headliner remove and install Rear window glass remove and install Total Time 70.5 Combination panel times

Panel Description Hours Luggage compartment lid Rear bumper cover Rear bumper Quarter panel Back panel Rear side member section Rear side member closing panel section Spare wheel well Rear floor side extension Rear subframe and rear suspension remove and install Headliner remove and install Rear window glass remove and install Total Time L/H 50.1

R/H 50.2 Combination panel times

Panel Description Hours Rear bumper cover Rear bumper Back panel Spare wheel well Rear subframe and rear suspension remove and install Total Time 26.8

Page 2974 of 3039

Rear End Sheet Metal Repairs - Rear Side Member Section

Removal and Installation

Removal Published: 11-May-2011

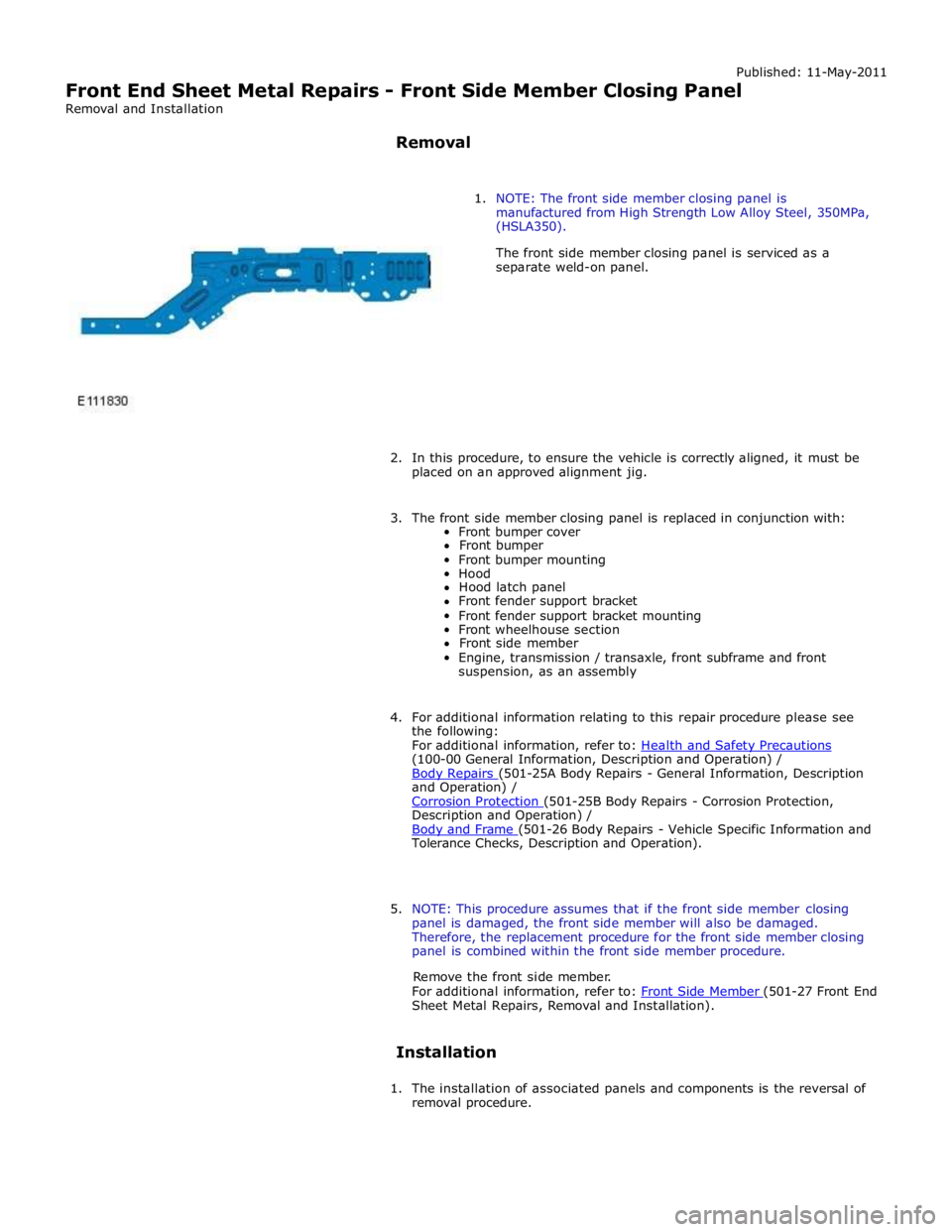

1. NOTE: The rear side member section is manufactured from

High Strength Low Alloy Steel, 350MPa, (HSLA350).

The rear side member section is cut from the rear side

member service panel.

2. This procedure assumes that if the rear side member section is

damaged, the rear side member closing panel section will also be

damaged. Therefore this procedure combines the repair of the rear side

member section and the rear side member closing panel section.

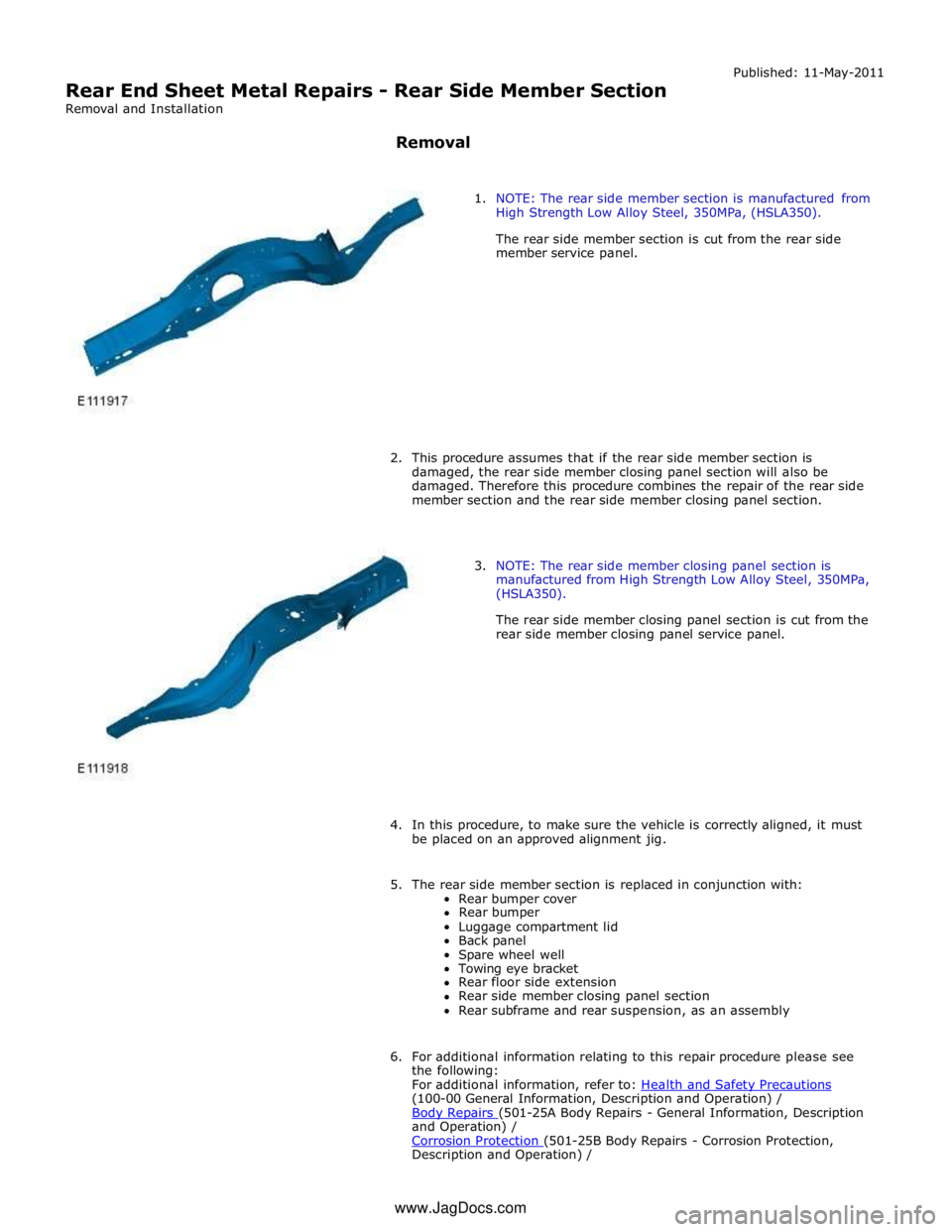

3. NOTE: The rear side member closing panel section is

manufactured from High Strength Low Alloy Steel, 350MPa,

(HSLA350).

The rear side member closing panel section is cut from the

rear side member closing panel service panel.

4. In this procedure, to make sure the vehicle is correctly aligned, it must

be placed on an approved alignment jig.

5. The rear side member section is replaced in conjunction with:

Rear bumper cover

Rear bumper

Luggage compartment lid

Back panel

Spare wheel well

Towing eye bracket

Rear floor side extension

Rear side member closing panel section

Rear subframe and rear suspension, as an assembly

6. For additional information relating to this repair procedure please see

the following:

For additional information, refer to: Health and Safety Precautions (100-00 General Information, Description and Operation) /

Body Repairs (501-25A Body Repairs - General Information, Description and Operation) /

Corrosion Protection (501-25B Body Repairs - Corrosion Protection, Description and Operation) / www.JagDocs.com

Page 2992 of 3039

Rear End Sheet Metal Repairs - Spare Wheel Well

Removal and Installation

Removal Published: 11-May-2011

1. NOTE: The spare wheel well is manufactured from mild steel.

The spare wheel well is serviced as a separate weld-on panel, it is not

serviced with the towing eye bracket, the spare wheel retaining bracket,

or its weld studs.

2. The spare wheel well is replaced in conjunction with:

Rear bumper cover

Rear bumper Back

panel

Towing eye bracket

Rear subframe and rear suspension, as an assembly

3. For additional information relating to this repair procedure please see

the following:

For additional information, refer to: Health and Safety Precautions (100-00 General Information, Description and Operation) /

Body Repairs (501-25A Body Repairs - General Information, Description and Operation) /

Corrosion Protection (501-25B Body Repairs - Corrosion Protection, Description and Operation) /

Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

4. Remove the back panel.

For additional information, refer to: Back Panel (501-30 Rear End Sheet Metal Repairs, Removal and Installation).

Page 2993 of 3039

5. Disconnect the generator electrical connectors.

6. Disconnect the battery positive cable and position it to one side.

7. Remove the rear subframe and rear suspension, as an assembly.

For additional information, refer to: Rear Subframe - V6 3.0L Petrol (502-00 Uni-Body, Subframe and Mounting System, Removal and

Installation).

8. Remove the fuel tank filler pipe.

For additional information, refer to: Fuel Tank Filler Pipe (310-01B,

Removal and Installation).

9. Release the left-hand and right-hand luggage floor wiring harnesses and

position them to one side.

10. Make sure that the rear seats are covered to prevent any damage during

this repair procedure.

11. NOTE: If undamaged, the left-hand and right-hand rear bumper

retaining brackets should be reinstalled.

Remove the left-hand and right-hand rear bumper retaining brackets.

Page 3013 of 3039

Front lower arm to front subframe retaining nut and bolt 175 129 - Rear lower arm to front subframe retaining nut and bolt 175 129 - Engine mount lower retaining nut 63 46 - Steering gear retaining bolts 100 74 - Front Shock absorber and spring assembly retaining bolt 175 129 - Front subframe to body front retaining bolt Stage 1 100 73 - Stage 2 270° 270° - Front subframe to body rear retaining bolt Stage 1 80 59 - Stage 2 240° 240° - Front Stabilizer bar link retaining nuts 43 31 - Front Stabilizer bar link retaining bolts 55 41 - Rear Shock absorber and spring assembly retaining bolt 133 98 - Rear subframe reinforcement plate retaining bolts 47 35 - Rear subframe to body retaining bolts Stage 1 80 59 - Stage 2 240° 240° -

Page 3014 of 3039

Published: 31-Jul-2013

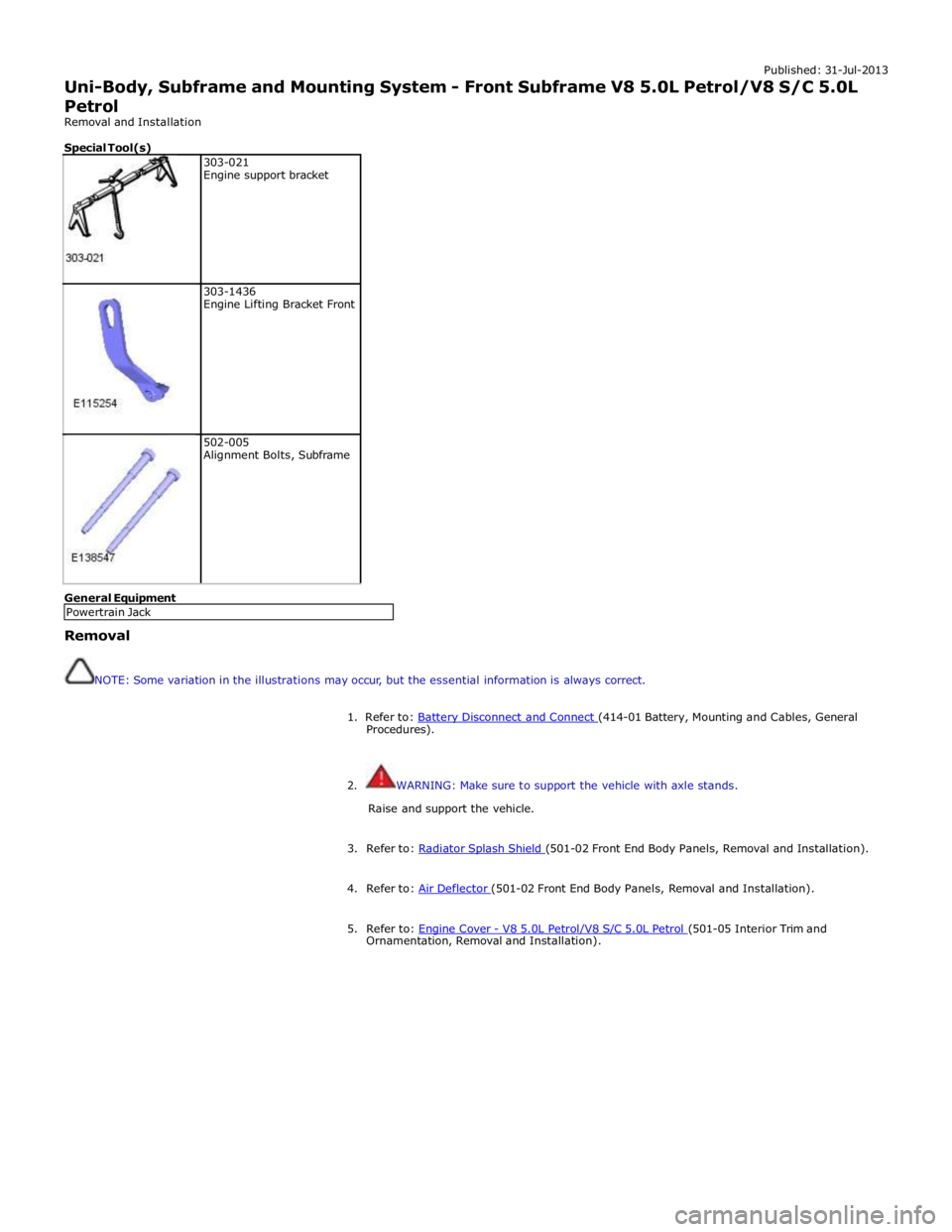

Uni-Body, Subframe and Mounting System - Front Subframe V8 5.0L Petrol/V8 S/C 5.0L Petrol

Removal and Installation

Special Tool(s)

303-021

Engine support bracket

303-1436

Engine Lifting Bracket Front

502-005

Alignment Bolts, Subframe General Equipment

Removal

NOTE: Some variation in the illustrations may occur, but the essential information is always correct.

1. Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

2. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

3. Refer to: Radiator Splash Shield (501-02 Front End Body Panels, Removal and Installation). 4. Refer to: Air Deflector (501-02 Front End Body Panels, Removal and Installation). 5. Refer to: Engine Cover - V8 5.0L Petrol/V8 S/C 5.0L Petrol (501-05 Interior Trim and Ornamentation, Removal and Installation). Powertrain Jack

Page 3023 of 3039

5.

6. Install the special tool to the front subframe.

Special Tool(s): 502-005