oil JAGUAR XFR 2010 1.G Service Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 535 of 3039

Thrust race 7 Shim 8 Thrust plate 9 Dished washer 10 Bolt (10 off) 11 Clutch basket 12 Multi-plate clutch and pressure disc 13 Differential case 14 Screw (2 off) 15 Bearing assembly 16 Oil seal 17 Oil slinger inner 18 Oil slinger outer 19 Input flange 20 Pinion nut 21 Collapsible spacer 22 Shim 23 Bearing assembly 24 Pinion shaft 25 Mounting insulator inner (2 off) 26 Mounting insulator rubber (2 off) 27 Mounting insulator outer (2 off) 28 Carrier 29 Oil seal 30 Drain plug 31 Vent 32 Breather cap 33 Shim 34 Bearing assembly 35 Drive gear 36 Shim 37 RH sun gear 38 Circlip 39 Thrust washer (4 off) 40 Planet gear (4 off) 41 Pin (2 off) 42 Shaft 43 LH sun gear 44 Shim 45 Bearing assembly 46 Shim 47 Dowel (2 off) 48 Bolt (4 off) 49 Reduction gear casing 50 Reduction gear 51 Shaft 52 Temperature sensor 53 O-ring seal 54 Motor 55 Screw (4 off) 56 Cover 57 Output actuator locking pin 58 Bolt (9 off)

Page 536 of 3039

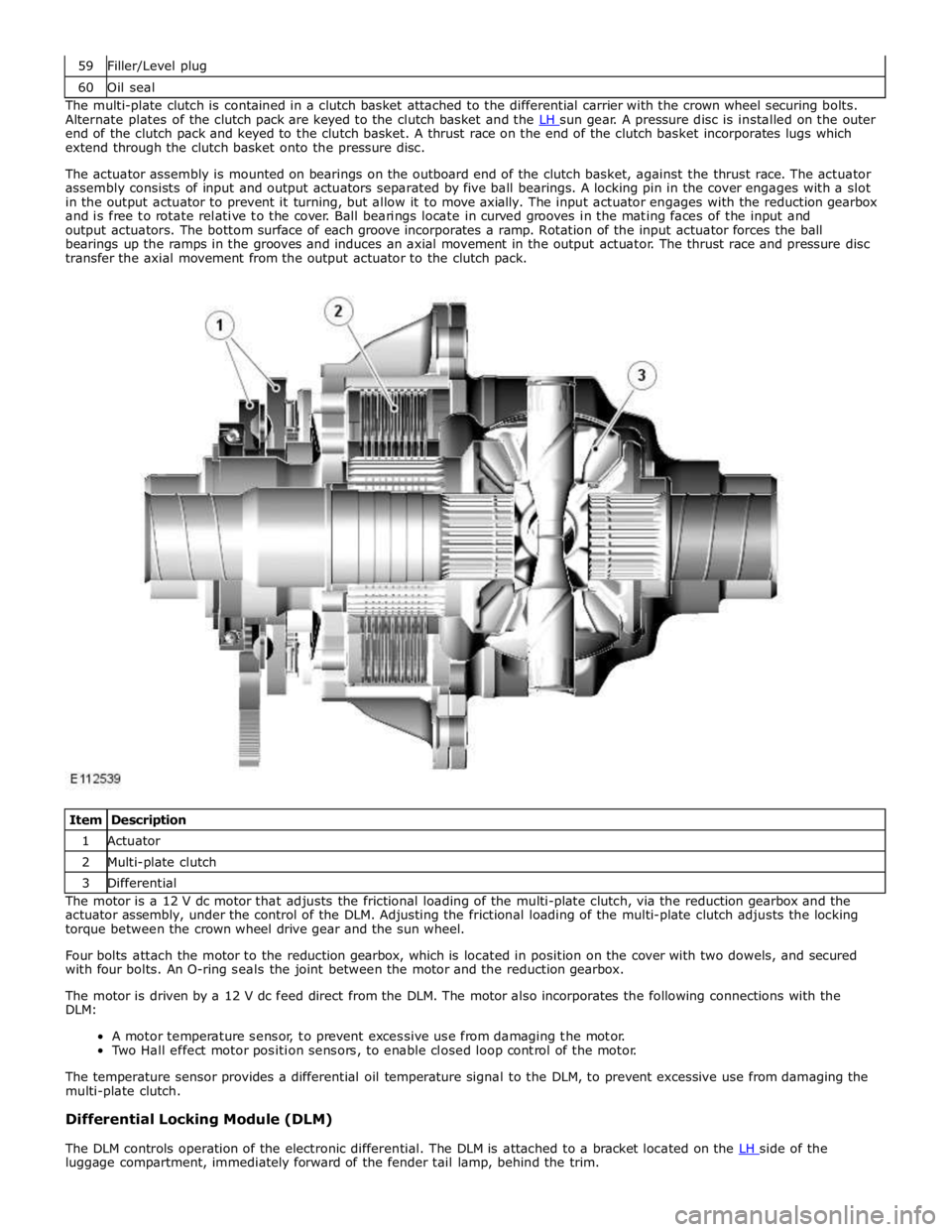

60 Oil seal The multi-plate clutch is contained in a clutch basket attached to the differential carrier with the crown wheel securing bolts.

Alternate plates of the clutch pack are keyed to the clutch basket and the LH sun gear. A pressure disc is installed on the outer end of the clutch pack and keyed to the clutch basket. A thrust race on the end of the clutch basket incorporates lugs which

extend through the clutch basket onto the pressure disc.

The actuator assembly is mounted on bearings on the outboard end of the clutch basket, against the thrust race. The actuator

assembly consists of input and output actuators separated by five ball bearings. A locking pin in the cover engages with a slot

in the output actuator to prevent it turning, but allow it to move axially. The input actuator engages with the reduction gearbox

and is free to rotate relative to the cover. Ball bearings locate in curved grooves in the mating faces of the input and

output actuators. The bottom surface of each groove incorporates a ramp. Rotation of the input actuator forces the ball

bearings up the ramps in the grooves and induces an axial movement in the output actuator. The thrust race and pressure disc

transfer the axial movement from the output actuator to the clutch pack.

Item Description 1 Actuator 2 Multi-plate clutch 3 Differential The motor is a 12 V dc motor that adjusts the frictional loading of the multi-plate clutch, via the reduction gearbox and the

actuator assembly, under the control of the DLM. Adjusting the frictional loading of the multi-plate clutch adjusts the locking

torque between the crown wheel drive gear and the sun wheel.

Four bolts attach the motor to the reduction gearbox, which is located in position on the cover with two dowels, and secured

with four bolts. An O-ring seals the joint between the motor and the reduction gearbox.

The motor is driven by a 12 V dc feed direct from the DLM. The motor also incorporates the following connections with the

DLM:

A motor temperature sensor, to prevent excessive use from damaging the motor.

Two Hall effect motor position sensors, to enable closed loop control of the motor.

The temperature sensor provides a differential oil temperature signal to the DLM, to prevent excessive use from damaging the

multi-plate clutch.

Differential Locking Module (DLM)

The DLM controls operation of the electronic differential. The DLM is attached to a bracket located on the LH side of the luggage compartment, immediately forward of the fender tail lamp, behind the trim.

Page 540 of 3039

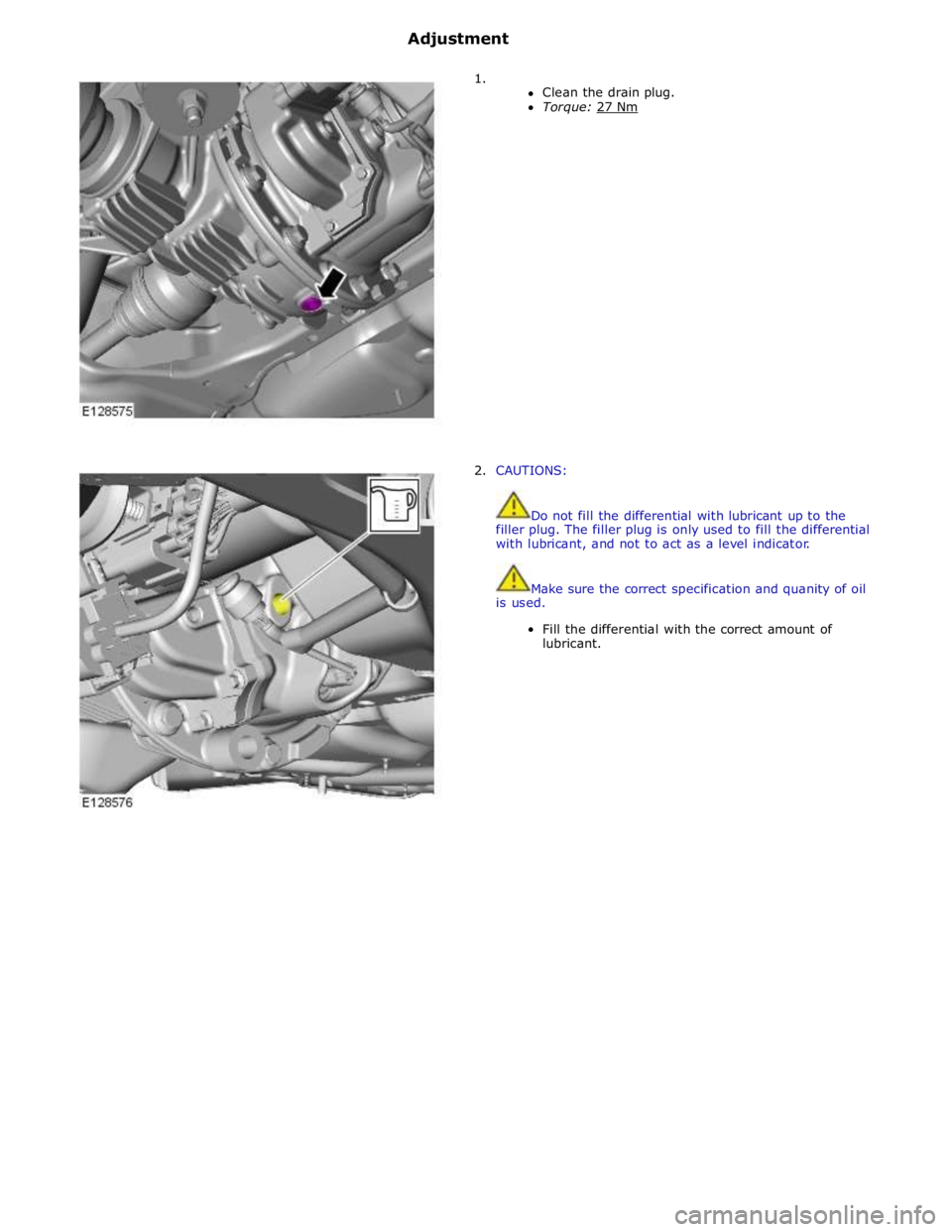

Adjustment

1.

Clean the drain plug.

Torque: 27 Nm

2. CAUTIONS:

Do not fill the differential with lubricant up to the

filler plug. The filler plug is only used to fill the differential

with lubricant, and not to act as a level indicator.

Make sure the correct specification and quanity of oil

is used.

Fill the differential with the correct amount of

lubricant.

Page 565 of 3039

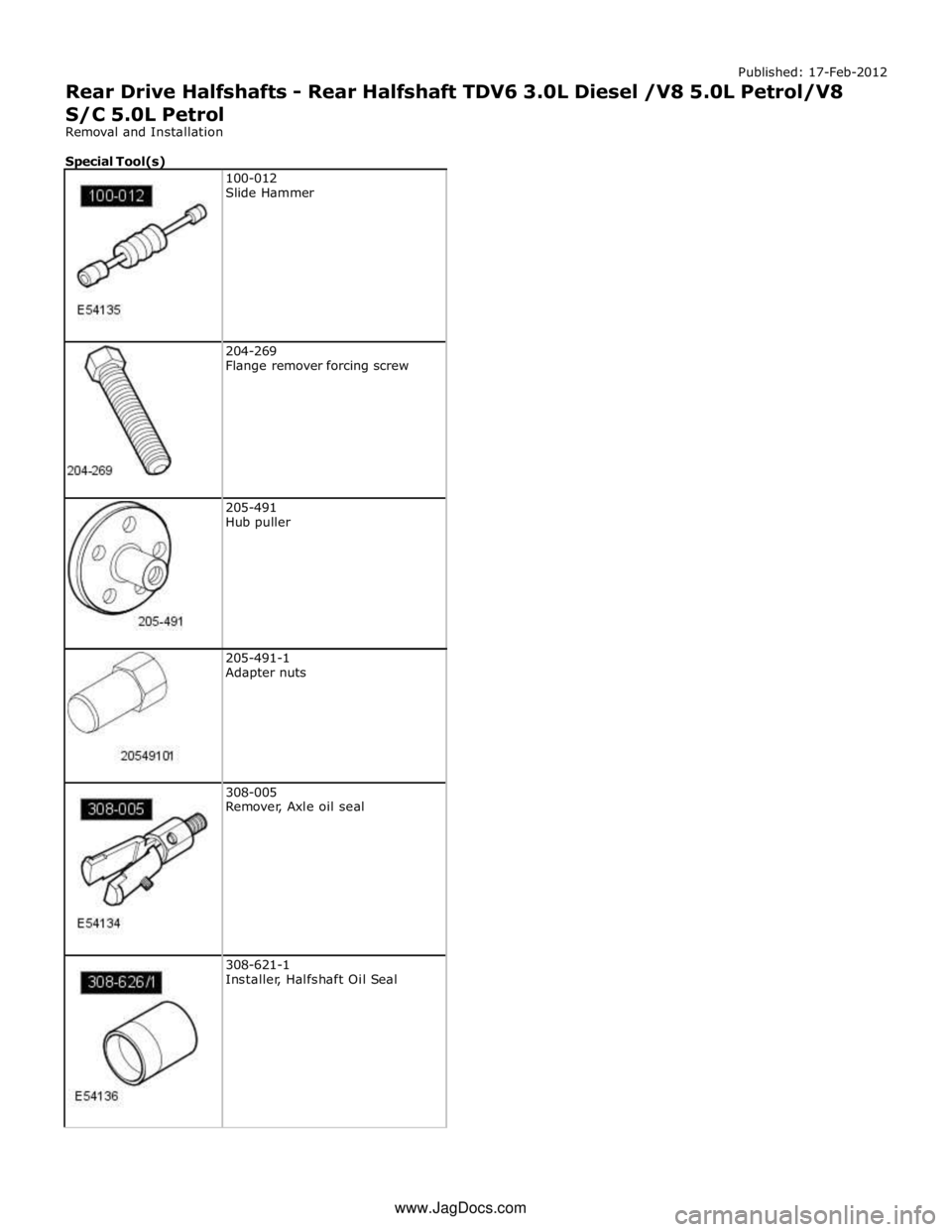

204-269

Flange remover forcing screw

205-491

Hub puller

205-491-1

Adapter nuts

308-005

Remover, Axle oil seal

308-621-1

Installer, Halfshaft Oil Seal www.JagDocs.com

Page 566 of 3039

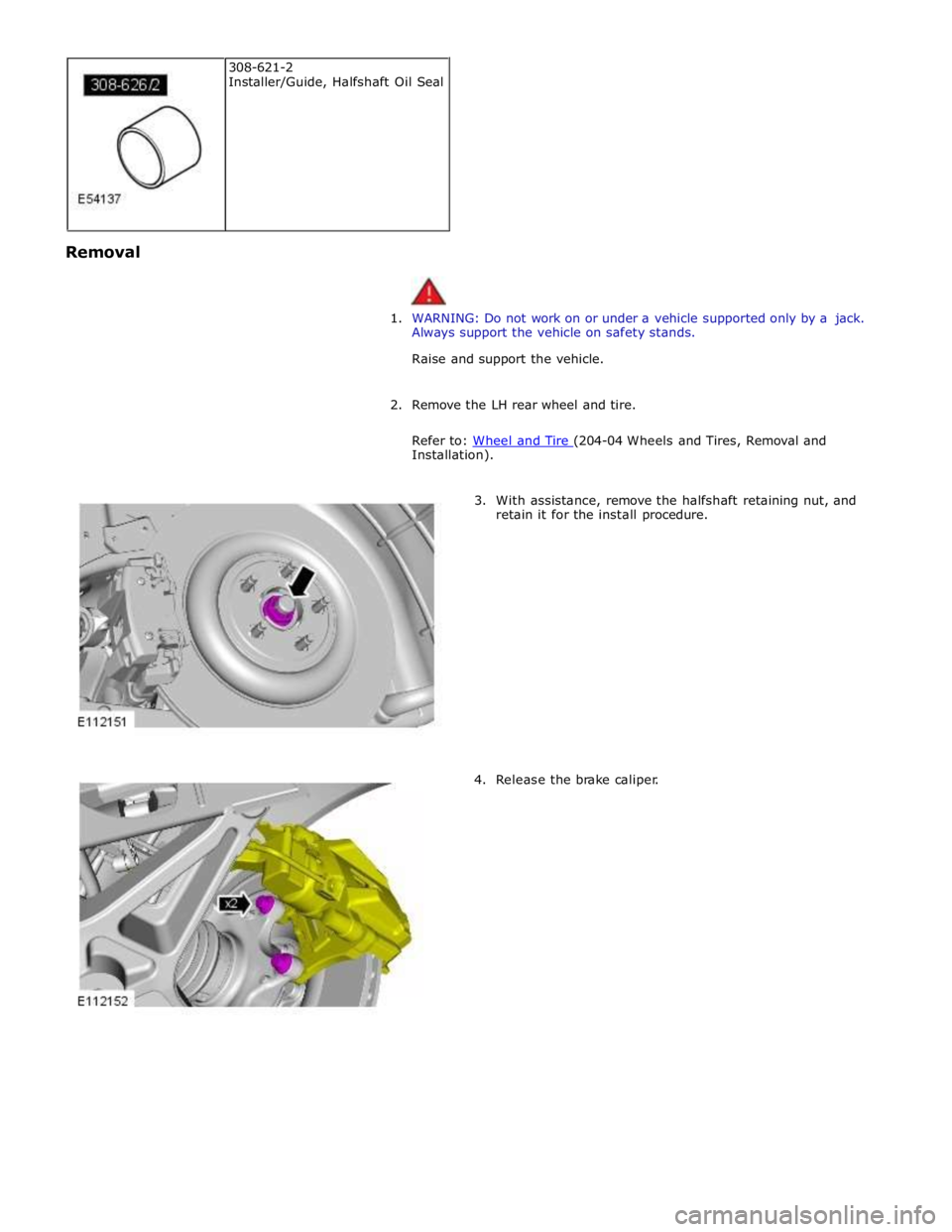

Removal

1. WARNING: Do not work on or under a vehicle supported only by a jack.

Always support the vehicle on safety stands.

Raise and support the vehicle.

2. Remove the LH rear wheel and tire.

Refer to: Wheel and Tire (204-04 Wheels and Tires, Removal and Installation).

3. With assistance, remove the halfshaft retaining nut, and

retain it for the install procedure.

4. Release the brake caliper. 308-621-2

Installer/Guide, Halfshaft Oil Seal

Page 570 of 3039

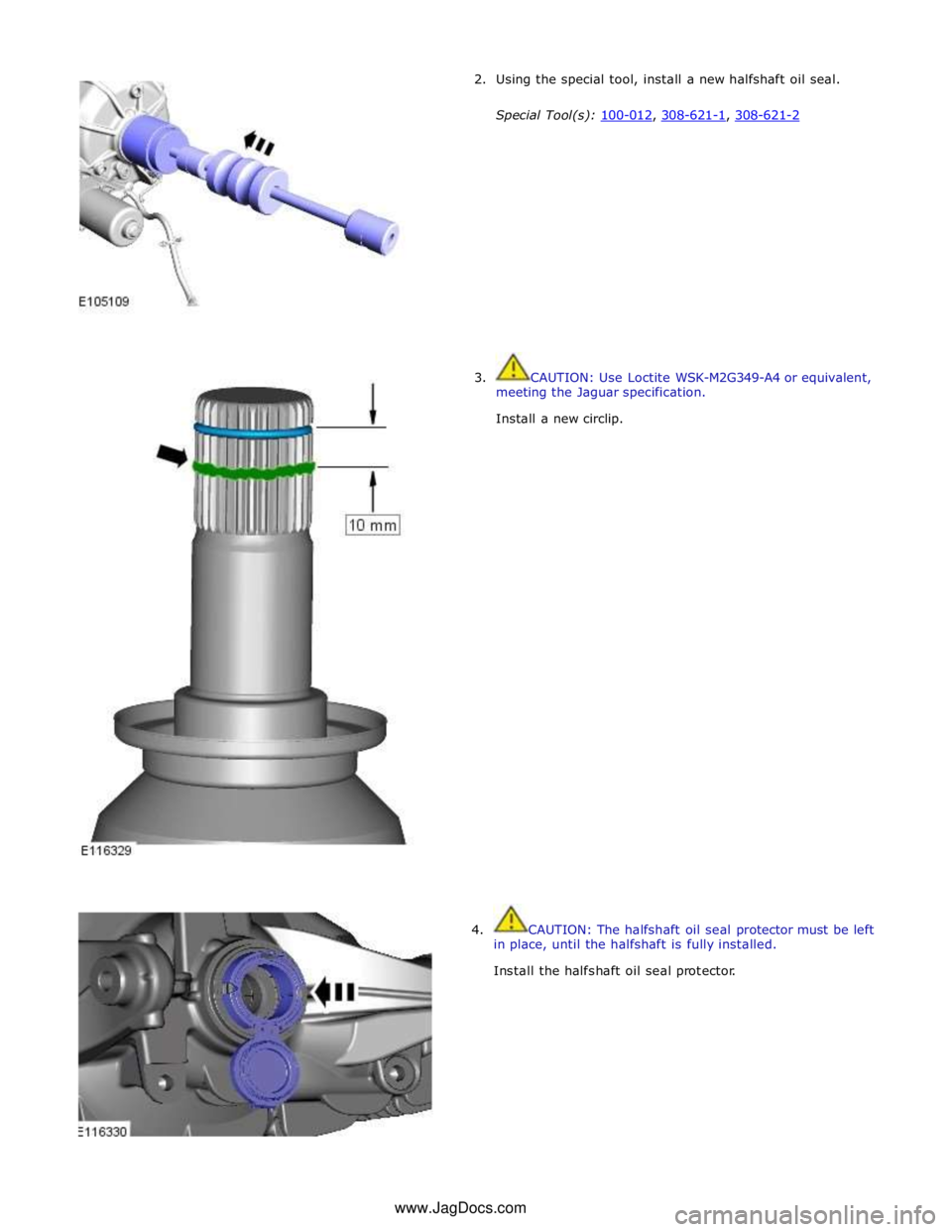

3. CAUTION: Use Loctite WSK-M2G349-A4 or equivalent,

meeting the Jaguar specification.

Install a new circlip.

4. CAUTION: The halfshaft oil seal protector must be left

in place, until the halfshaft is fully installed.

Install the halfshaft oil seal protector. www.JagDocs.com

Page 571 of 3039

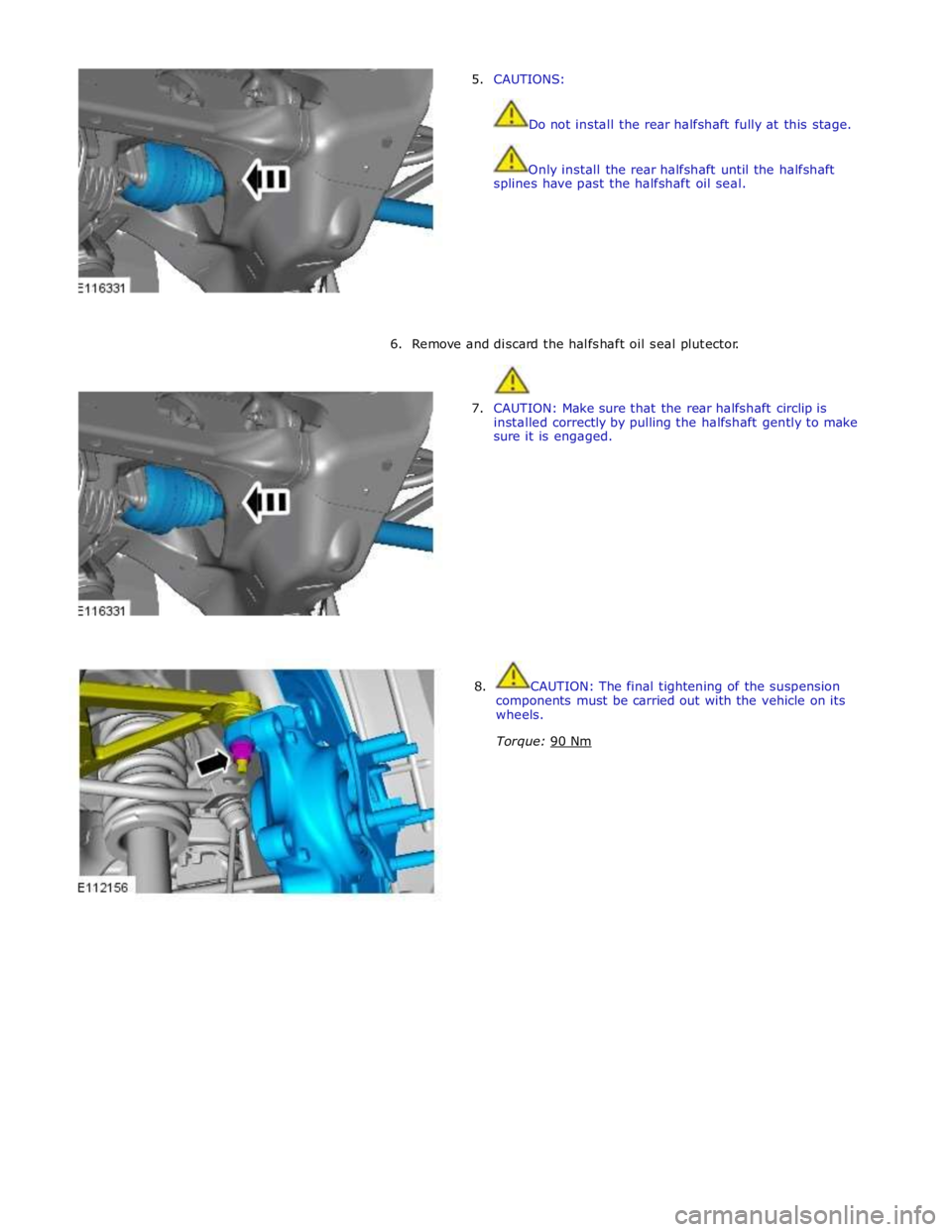

5. CAUTIONS:

Do not install the rear halfshaft fully at this stage.

Only install the rear halfshaft until the halfshaft

splines have past the halfshaft oil seal.

6. Remove and discard the halfshaft oil seal plutector.

7. CAUTION: Make sure that the rear halfshaft circlip is

installed correctly by pulling the halfshaft gently to make

sure it is engaged.

8. CAUTION: The final tightening of the suspension

components must be carried out with the vehicle on its

wheels.

Torque: 90 Nm

Page 688 of 3039

Published: 08-Oct-2012

Power Brake Actuation - Brake Vacuum Pump V8 5.0L Petrol/V8 S/C 5.0L

Petrol

Removal and Installation

Removal

CAUTION: Make sure that all openings are sealed. Use new blanking caps.

NOTE: Removal steps in this procedure may contain installation details.

1. WARNING: Make sure to support the vehicle with axle stands.

Raise and support the vehicle.

2. Refer to: Engine Oil Draining and Filling (303-01, General Procedures).

3.

4. CAUTION: Be prepared to collect escaping oil.

Torque: 12 Nm

Page 811 of 3039

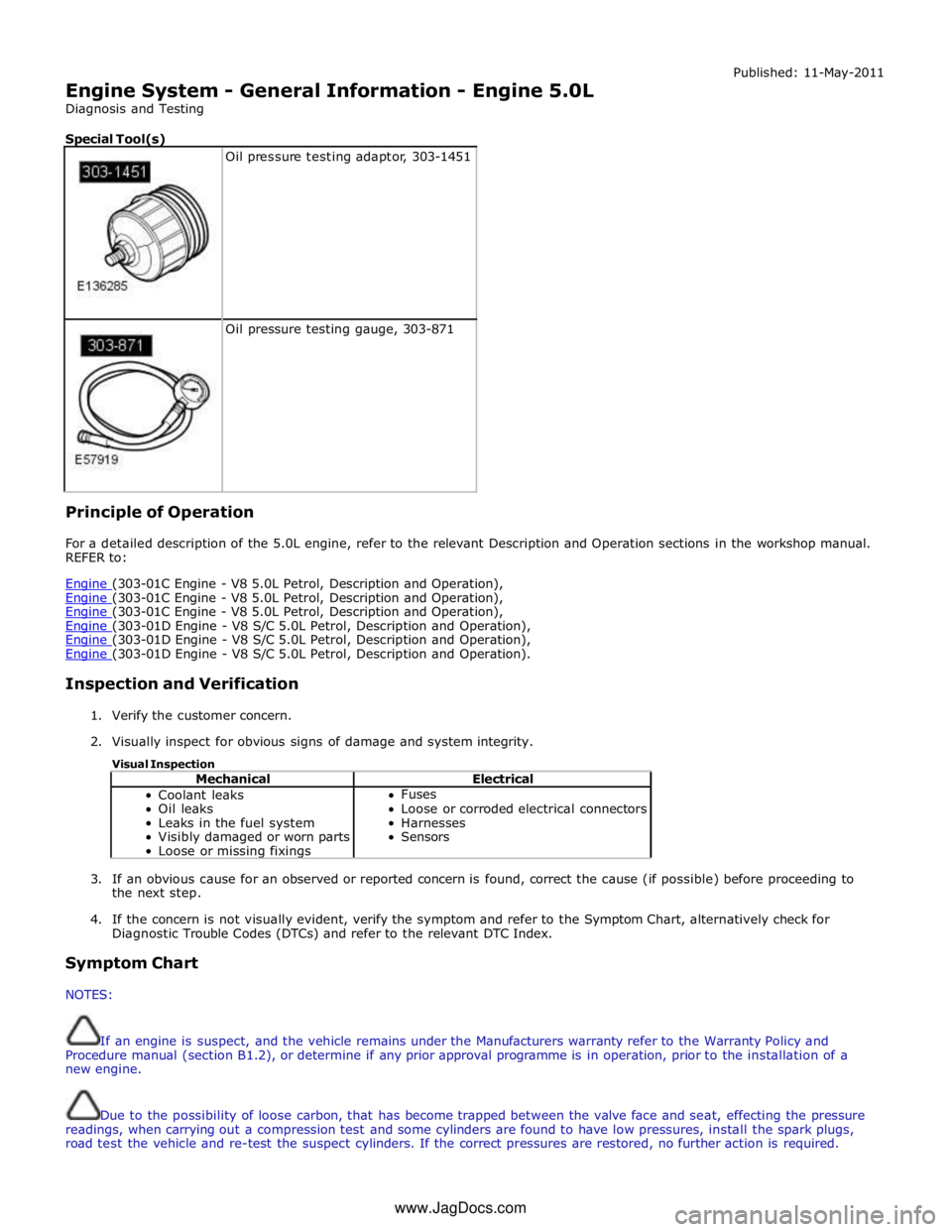

Engine System - General Information - Engine 5.0L

Diagnosis and Testing

Special Tool(s)

Oil pressure testing adaptor, 303-1451

Oil pressure testing gauge, 303-871 Principle of Operation Published: 11-May-2011

For a detailed description of the 5.0L engine, refer to the relevant Description and Operation sections in the workshop manual.

REFER to:

Engine (303-01C Engine - V8 5.0L Petrol, Description and Operation), Engine (303-01C Engine - V8 5.0L Petrol, Description and Operation), Engine (303-01C Engine - V8 5.0L Petrol, Description and Operation), Engine (303-01D Engine - V8 S/C 5.0L Petrol, Description and Operation), Engine (303-01D Engine - V8 S/C 5.0L Petrol, Description and Operation), Engine (303-01D Engine - V8 S/C 5.0L Petrol, Description and Operation).

Inspection and Verification

1. Verify the customer concern.

2. Visually inspect for obvious signs of damage and system integrity.

Visual Inspection

Mechanical Electrical Coolant leaks

Oil leaks

Leaks in the fuel system

Visibly damaged or worn parts

Loose or missing fixings Fuses

Loose or corroded electrical connectors

Harnesses

Sensors

3. If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to

the next step.

4. If the concern is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for

Diagnostic Trouble Codes (DTCs) and refer to the relevant DTC Index.

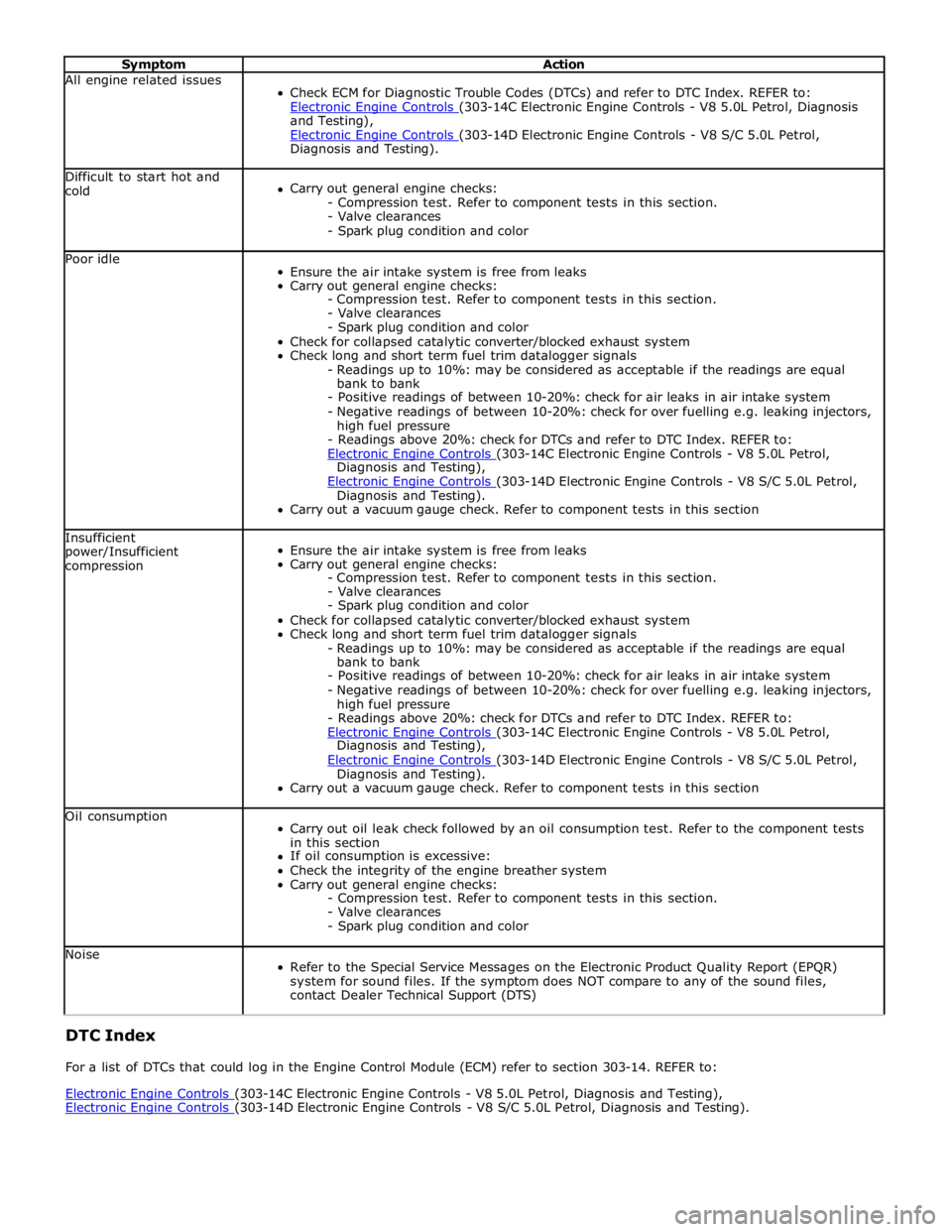

Symptom Chart

NOTES:

If an engine is suspect, and the vehicle remains under the Manufacturers warranty refer to the Warranty Policy and

Procedure manual (section B1.2), or determine if any prior approval programme is in operation, prior to the installation of a

new engine.

Due to the possibility of loose carbon, that has become trapped between the valve face and seat, effecting the pressure

readings, when carrying out a compression test and some cylinders are found to have low pressures, install the spark plugs,

road test the vehicle and re-test the suspect cylinders. If the correct pressures are restored, no further action is required. www.JagDocs.com

Page 812 of 3039

Symptom Action All engine related issues

Check ECM for Diagnostic Trouble Codes (DTCs) and refer to DTC Index. REFER to:

Electronic Engine Controls (303-14C Electronic Engine Controls - V8 5.0L Petrol, Diagnosis and Testing),

Electronic Engine Controls (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol, Diagnosis and Testing). Difficult to start hot and

cold

Carry out general engine checks:

- Compression test. Refer to component tests in this section.

- Valve clearances

- Spark plug condition and color Poor idle

Ensure the air intake system is free from leaks

Carry out general engine checks:

- Compression test. Refer to component tests in this section.

- Valve clearances

- Spark plug condition and color

Check for collapsed catalytic converter/blocked exhaust system

Check long and short term fuel trim datalogger signals

- Readings up to 10%: may be considered as acceptable if the readings are equal

bank to bank

- Positive readings of between 10-20%: check for air leaks in air intake system

- Negative readings of between 10-20%: check for over fuelling e.g. leaking injectors,

high fuel pressure

- Readings above 20%: check for DTCs and refer to DTC Index. REFER to:

Electronic Engine Controls (303-14C Electronic Engine Controls - V8 5.0L Petrol, Diagnosis and Testing),

Electronic Engine Controls (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol, Diagnosis and Testing).

Carry out a vacuum gauge check. Refer to component tests in this section Insufficient

power/Insufficient

compression

Ensure the air intake system is free from leaks

Carry out general engine checks:

- Compression test. Refer to component tests in this section.

- Valve clearances

- Spark plug condition and color

Check for collapsed catalytic converter/blocked exhaust system

Check long and short term fuel trim datalogger signals

- Readings up to 10%: may be considered as acceptable if the readings are equal

bank to bank

- Positive readings of between 10-20%: check for air leaks in air intake system

- Negative readings of between 10-20%: check for over fuelling e.g. leaking injectors,

high fuel pressure

- Readings above 20%: check for DTCs and refer to DTC Index. REFER to:

Electronic Engine Controls (303-14C Electronic Engine Controls - V8 5.0L Petrol, Diagnosis and Testing),

Electronic Engine Controls (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol, Diagnosis and Testing).

Carry out a vacuum gauge check. Refer to component tests in this section Oil consumption

Carry out oil leak check followed by an oil consumption test. Refer to the component tests

in this section

If oil consumption is excessive:

Check the integrity of the engine breather system

Carry out general engine checks:

- Compression test. Refer to component tests in this section.

- Valve clearances

- Spark plug condition and color Noise

Refer to the Special Service Messages on the Electronic Product Quality Report (EPQR)

system for sound files. If the symptom does NOT compare to any of the sound files,

contact Dealer Technical Support (DTS) DTC Index

For a list of DTCs that could log in the Engine Control Module (ECM) refer to section 303-14. REFER to:

Electronic Engine Controls (303-14C Electronic Engine Controls - V8 5.0L Petrol, Diagnosis and Testing), Electronic Engine Controls (303-14D Electronic Engine Controls - V8 S/C 5.0L Petrol, Diagnosis and Testing).