height JAGUAR XFR 2010 1.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2332 of 3039

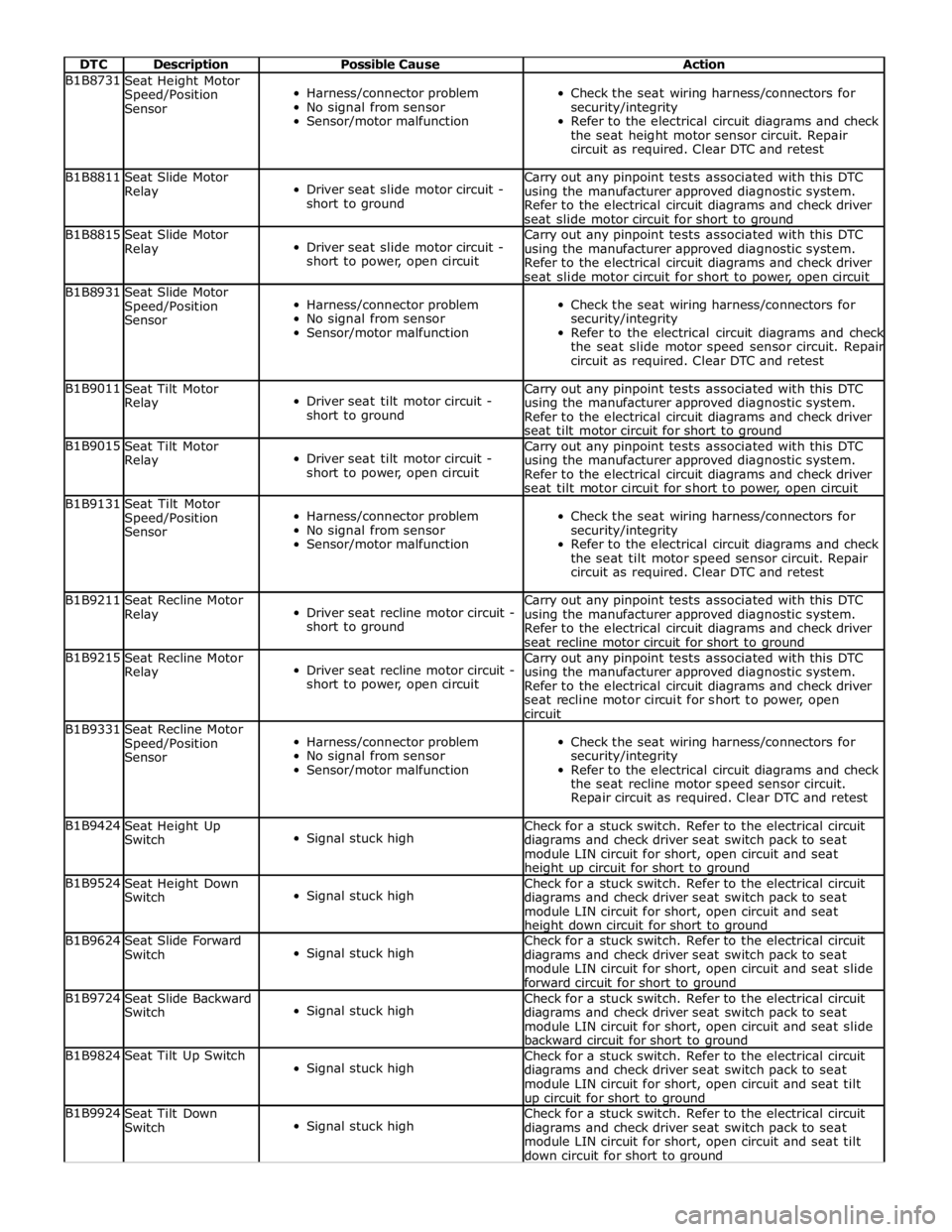

DTC Description Possible Cause Action B1B8731

Seat Height Motor

Speed/Position

Sensor

Harness/connector problem

No signal from sensor

Sensor/motor malfunction

Check the seat wiring harness/connectors for

security/integrity

Refer to the electrical circuit diagrams and check

the seat height motor sensor circuit. Repair

circuit as required. Clear DTC and retest B1B8811

Seat Slide Motor

Relay

Driver seat slide motor circuit -

short to ground Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check driver

seat slide motor circuit for short to ground B1B8815

Seat Slide Motor

Relay

Driver seat slide motor circuit -

short to power, open circuit Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check driver

seat slide motor circuit for short to power, open circuit B1B8931

Seat Slide Motor

Speed/Position

Sensor

Harness/connector problem

No signal from sensor

Sensor/motor malfunction

Check the seat wiring harness/connectors for

security/integrity

Refer to the electrical circuit diagrams and check the seat slide motor speed sensor circuit. Repair circuit as required. Clear DTC and retest B1B9011

Seat Tilt Motor

Relay

Driver seat tilt motor circuit -

short to ground Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check driver

seat tilt motor circuit for short to ground B1B9015

Seat Tilt Motor

Relay

Driver seat tilt motor circuit -

short to power, open circuit Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check driver

seat tilt motor circuit for short to power, open circuit B1B9131

Seat Tilt Motor

Speed/Position

Sensor

Harness/connector problem

No signal from sensor

Sensor/motor malfunction

Check the seat wiring harness/connectors for

security/integrity

Refer to the electrical circuit diagrams and check

the seat tilt motor speed sensor circuit. Repair

circuit as required. Clear DTC and retest B1B9211

Seat Recline Motor

Relay

Driver seat recline motor circuit -

short to ground Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check driver

seat recline motor circuit for short to ground B1B9215

Seat Recline Motor

Relay

Driver seat recline motor circuit -

short to power, open circuit Carry out any pinpoint tests associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check driver

seat recline motor circuit for short to power, open

circuit B1B9331

Seat Recline Motor

Speed/Position

Sensor

Harness/connector problem

No signal from sensor

Sensor/motor malfunction

Check the seat wiring harness/connectors for

security/integrity

Refer to the electrical circuit diagrams and check

the seat recline motor speed sensor circuit.

Repair circuit as required. Clear DTC and retest B1B9424

Seat Height Up

Switch

Signal stuck high Check for a stuck switch. Refer to the electrical circuit

diagrams and check driver seat switch pack to seat

module LIN circuit for short, open circuit and seat height up circuit for short to ground B1B9524

Seat Height Down

Switch

Signal stuck high Check for a stuck switch. Refer to the electrical circuit

diagrams and check driver seat switch pack to seat

module LIN circuit for short, open circuit and seat height down circuit for short to ground B1B9624

Seat Slide Forward

Switch

Signal stuck high Check for a stuck switch. Refer to the electrical circuit

diagrams and check driver seat switch pack to seat

module LIN circuit for short, open circuit and seat slide

forward circuit for short to ground B1B9724

Seat Slide Backward

Switch

Signal stuck high Check for a stuck switch. Refer to the electrical circuit

diagrams and check driver seat switch pack to seat

module LIN circuit for short, open circuit and seat slide

backward circuit for short to ground B1B9824 Seat Tilt Up Switch

Signal stuck high Check for a stuck switch. Refer to the electrical circuit

diagrams and check driver seat switch pack to seat

module LIN circuit for short, open circuit and seat tilt up circuit for short to ground B1B9924

Seat Tilt Down

Switch

Signal stuck high Check for a stuck switch. Refer to the electrical circuit

diagrams and check driver seat switch pack to seat

module LIN circuit for short, open circuit and seat tilt

down circuit for short to ground

Page 2335 of 3039

B2: COMPARE THE FRONT SEAT FORWARD-REARWARD FREE PLAY AGAINST A SIMILAR SEAT 1 Compare the front seat forward-rearward free play against a similar seat. Is the front seat forward-rearward free play excessive when compared to a similar seat?

Yes

GO to B3. No

The front seat frame is operating correctly. Submit Electronic Product Quality Report (EPQR) with any

further query. B3: CHECK REMAINING FRONT SEAT FRAME FIXINGS 1 Remove front seat and/or any seat covers/trim to allow access to check remaining front seat frame fixings are all installed and to the correct torque. Are all remaining front seat frame fixings installed and to the correct torque?

Yes

Replace front seat frame. Refer to the relevant section of the workshop manual.

No

Install and tighten all remaining front seat frame fixings to correct torque and re-check for excessive

free play.

PINPOINT TEST C : FRONT SEAT FORWARD-REARWARD MOVEMENT NOISY TEST

CONDITIONS DETAILS/RESULTS/ACTIONS C1: COMPARE FRONT SEAT FORWARD-REARWARD MOVEMENT NOISE TO OTHER FRONT SEAT

WARNING: Before work is carried out, make the air bag supplemental restraint system safe. For

additional information, refer to Standard Workshop Practices section of workshop manual. 1 Compare the front seat forward-rearward movement noise to other front seat. Is the front seat forward-rearward movement noise excessive when compared to other front seat?

Yes

GO to C2. No

GO to C3. C2: COMPARE FRONT SEAT FORWARD-REARWARD MOVEMENT NOISE TO FRONT SEAT IN OTHER VEHICLE 1 Compare the front seat forward-rearward movement noise to front seat in other vehicle. Is the front seat forward-rearward movement noise excessive when compared to front seat in other vehicle?

Yes

GO to C3. No

The front seat frame is operating correctly. Submit Electronic Product Quality Report (EPQR) with any

further query. C3: CHECK FOR DEBRIS OBSTRUCTING SEAT MOVEMENT 1 Check for debris obstructing seat movement. Is the front seat forward-rearward movement obstructed by debris?

Yes

Remove obstruction and re-check for noisy forward-rearward seat movement.

No

GO to C4. C4: RE-ALIGN FRONT SEAT FRAME 1 Loosen front seat frame fixings. 2 Set ignition status to 'ON'. 3 Using the front seat switch pack drive the front seat fully forward then fully rearward. 4 Tighten front seat frame fixings to the correct torque. 5 Re-check for noisy seat movement. Is the front seat forward-rearward movement still noisy?

Yes

GO to C5. No

The front seat frame is now operating correctly. C5: CHECK FRONT SEAT FORWARD-REARWARD SEAT MOTOR DRIVE BAR 1 Check front seat drive bar for correct installation and condition. Is the front seat drive bar correctly installed and in a serviceable condition?

Yes

Replace front seat forward-rearward seat motor. Refer to relevant section of workshop manual.

No

Correctly install front seat forward-rearward seat motor drive bar, or replace if required.

PINPOINT TEST D : FRONT SEAT HEIGHT, TILT AND/OR SEAT EXTENSION MOTOR MOVEMENT NOT FUNCTIONING TEST

CONDITIONS DETAILS/RESULTS/ACTIONS D1: CHECK FRONT SEAT HEIGHT, TILT OR EXTENSION MOTOR

Page 2336 of 3039

WARNINGS:

Before work is carried out, make the air bag supplemental restraint system safe. For additional information, refer to

Standard Workshop Practices section of workshop manual.

When carrying out the following steps, stand clear of all moving parts and ensure link harness is routed accordingly. 1 Set ignition status to ' OFF'. 2 Disconnect front seat height, tilt or extension motor connector.

NOTE: It may be that the seat has been driven to the limit of travel along the relevant axis, and when

the link harness is connected, the seat will remain in the same position. If this is the case, a jolt may be felt

from the motor. To confirm the motor operation, swap the link harness to alternate motor pin connections and

the seat should travel in the opposite direction. 3 Using a locally made fused link harness and power supply, connect power and ground to relevant motor. Battery positive terminal Battery negative terminal motor pin 1 motor pin 2 Does the motor operate? Yes

Using manufacturer approved diagnostic system, check for related Diagnostic Trouble Codes (DTCs) and

carry out the repair operations specified. Alternatively, refer to the electrical circuit diagrams and check

relevant motor circuits.

No

Replace the relevant motor. Refer to relevant section of workshop manual.

PINPOINT TEST E : FRONT SEAT HEIGHT, TILT AND/OR EXTENSION MOVEMENT NOISY TEST

CONDITIONS DETAILS/RESULTS/ACTIONS E1: COMPARE THE HEIGHT, TILT OR EXTENSION MOVEMENT NOISE WITH THE OTHER FRONT SEAT

WARNING: Before work is carried out, make the air bag supplemental restraint system safe. For

additional information, refer to Standard Workshop Practices section of workshop manual. 1 Compare the front seat movement noise to other front seat. Is the front seat height, tilt or extension movement noise excessive when compared to other front seat?

Yes

GO to E2. No

GO to E3. E2: COMPARE FRONT SEAT HEIGHT, TILT OR EXTENSION MOVEMENT NOISE TO FRONT SEAT IN OTHER VEHICLE 1 Compare the front seat height, tilt or extension movement noise to front seat in other vehicle. Is the front seat height, tilt or extension movement noise excessive when compared to front seat in other

vehicle?

Yes

GO to E3. No

The front seat frame is operating correctly. Submit Electronic Product Quality Report (EPQR) with any

further query. E3: CHECK FOR DEBRIS OBSTRUCTING SEAT MOVEMENT 1 Check for debris obstructing seat movement. Is the front seat height, tilt or extension movement obstructed by debris?

Yes

Remove obstruction and re-check for noisy height, tilt or extension seat movement.

No

GO to E4. E4: CHECK FOR HEIGHT, TILT OR EXTENSION MOVEMENT MECHANISM LUBRICATION 1 Check and apply manufacturer approved lubrication to seat height, tilt or extension movement mechanism and re-test for noise. Is the front seat height, tilt or extension noise still apparent?

Yes

Replace the relevant motor. Refer to relevant section of workshop manual.

No

The front seat height, tilt or extension motor is operating correctly.

Page 2385 of 3039

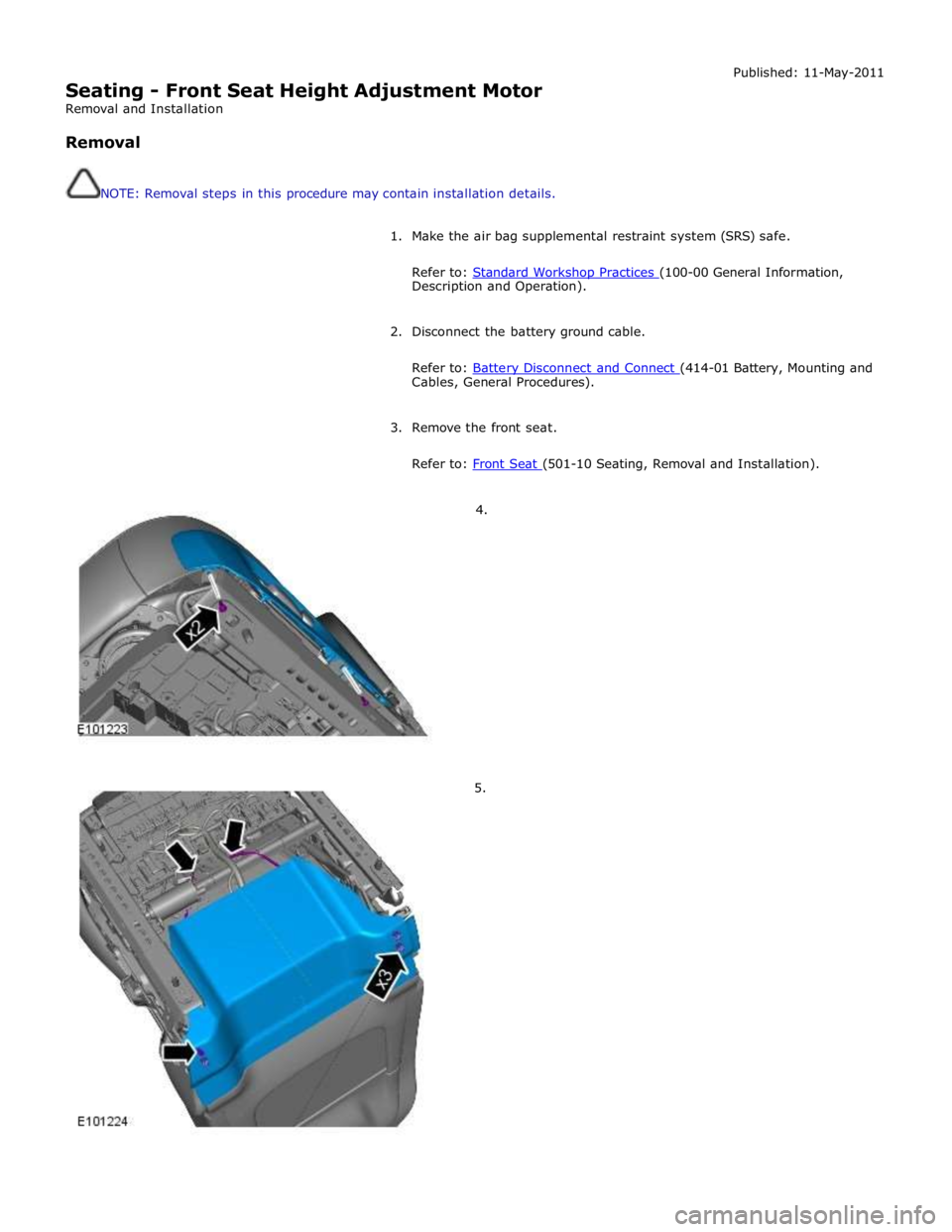

Seating - Front Seat Height Adjustment Motor

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details. Published: 11-May-2011

1. Make the air bag supplemental restraint system (SRS) safe.

Refer to: Standard Workshop Practices (100-00 General Information, Description and Operation).

2. Disconnect the battery ground cable.

Refer to: Battery Disconnect and Connect (414-01 Battery, Mounting and Cables, General Procedures).

3. Remove the front seat.

Refer to: Front Seat (501-10 Seating, Removal and Installation).

4.

5.

Page 2590 of 3039

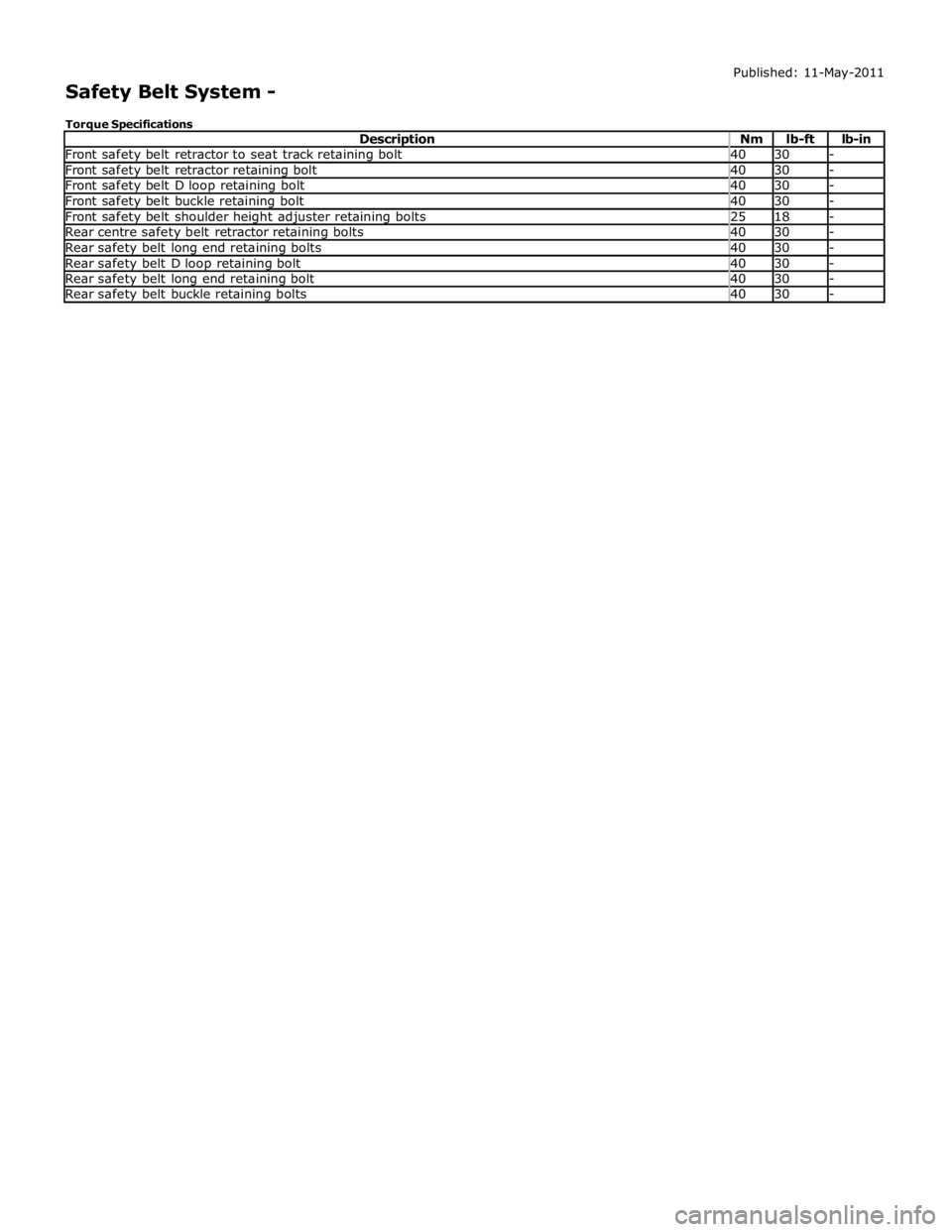

Front safety belt retractor to seat track retaining bolt 40 30 - Front safety belt retractor retaining bolt 40 30 - Front safety belt D loop retaining bolt 40 30 - Front safety belt buckle retaining bolt 40 30 - Front safety belt shoulder height adjuster retaining bolts 25 18 - Rear centre safety belt retractor retaining bolts 40 30 - Rear safety belt long end retaining bolts 40 30 - Rear safety belt D loop retaining bolt 40 30 - Rear safety belt long end retaining bolt 40 30 - Rear safety belt buckle retaining bolts 40 30 -

Page 2599 of 3039

PINPOINT TEST G : D-LOOP NOT ROTATING CORRECTLY TEST

CONDITIONS DETAILS/RESULTS/ACTIONS G1: D-LOOP NOT ROTATING CORRECTLY 1 Refer to the 501-20 removal and installation section of the workshop manual, remove any trim panels required to expose the D loop (anchor point) and the seatbelt retractor 2 Ensure there are no obstructions and the webbing does not catch or rub, the D loop (anchor point) rotates correctly and if installed the confirm the height adjuster operates correctly 3 Check for correct operation twice Does the webbing move freely then retract correctly? Yes

Refer to the 501-20 removal and installation section of the workshop manual, reinstall any trim panels,

ensure there are no obstructions and the webbing does not catch or rub. No further action required

No

Replace as required. Refer to the warranty policy and procedures manual, or determine if any prior approval programme is in operation, prior to the installation of a new module/component

PINPOINT TEST H : SEATBELT BUCKLE – NOT LATCHING/JAMMED TEST

CONDITIONS DETAILS/RESULTS/ACTIONS H1: SEATBELT BUCKLE – NOT LATCHING/JAMMED

CAUTION: Do not insert any objects or tools into the buckle head 1 Visually inspect the buckle head for evidence of damage. If damaged replace as required 2 Depress the buckle release (red button) and (Using a torch) carry out visual inspection for any evidence of debris/material or foreign objects in the buckle head 3 If required remove the pretensioner from the vehicle. Remove the seat. Remove the pretensioner from the seat frame 4 Do not insert any objects or tools buckle head With the buckle removed invert and attempt to shake out any debris 5 Attempt to latch the tongue in the buckle Does the seat belt buckle operate correctly Yes

Reinstall any components, no further action required

No

Replace the pretensioner, REFER to:

Diagnostic Trouble Code (DTC) Index - DTC: Restraints Control Module (RCM) (100-00 General

Information, Description and Operation),

Rear Safety Belt Buckle (501-20A Safety Belt System, Removal and Installation). www.JagDocs.com

Page 2607 of 3039

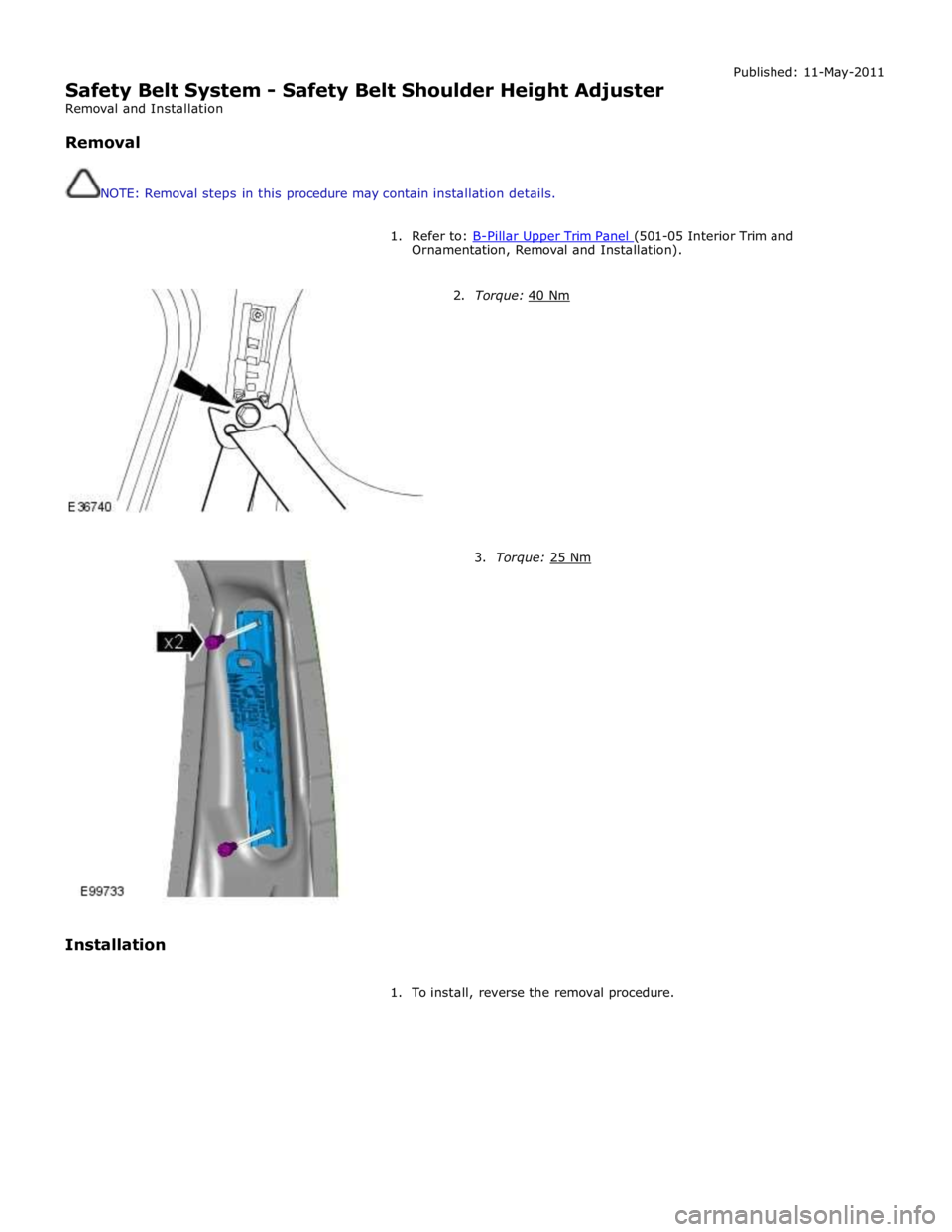

Safety Belt System - Safety Belt Shoulder Height Adjuster

Removal and Installation

Removal

NOTE: Removal steps in this procedure may contain installation details. Published: 11-May-2011

1. Refer to: B-Pillar Upper Trim Panel (501-05 Interior Trim and Ornamentation, Removal and Installation).

2. Torque: 40 Nm

Installation

3. Torque: 25 Nm

1. To install, reverse the removal procedure.

Page 2708 of 3039

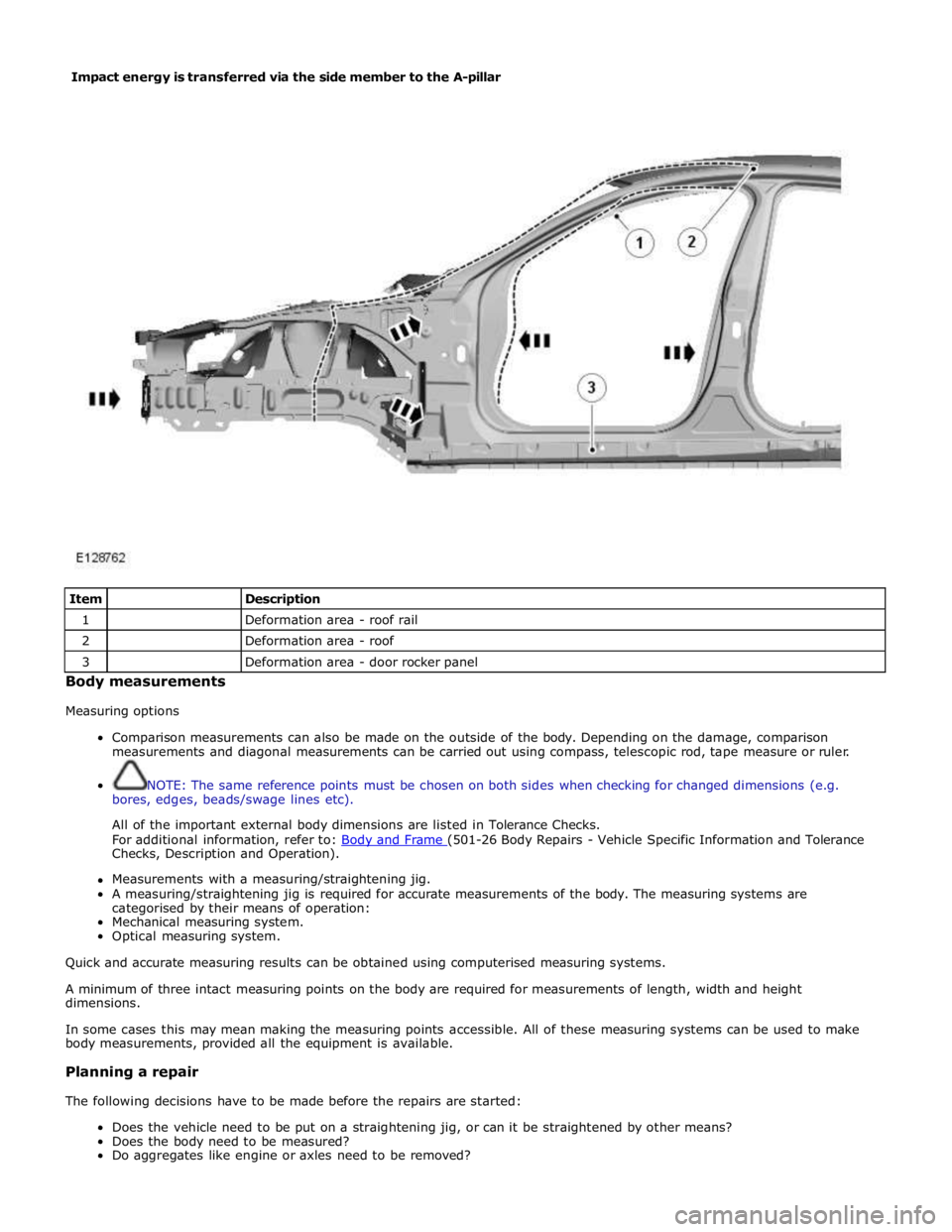

Item

Description 1

Deformation area - roof rail 2

Deformation area - roof 3

Deformation area - door rocker panel Body measurements

Measuring options

Comparison measurements can also be made on the outside of the body. Depending on the damage, comparison

measurements and diagonal measurements can be carried out using compass, telescopic rod, tape measure or ruler.

NOTE: The same reference points must be chosen on both sides when checking for changed dimensions (e.g.

bores, edges, beads/swage lines etc).

All of the important external body dimensions are listed in Tolerance Checks.

For additional information, refer to: Body and Frame (501-26 Body Repairs - Vehicle Specific Information and Tolerance Checks, Description and Operation).

Measurements with a measuring/straightening jig.

A measuring/straightening jig is required for accurate measurements of the body. The measuring systems are

categorised by their means of operation:

Mechanical measuring system.

Optical measuring system.

Quick and accurate measuring results can be obtained using computerised measuring systems.

A minimum of three intact measuring points on the body are required for measurements of length, width and height

dimensions.

In some cases this may mean making the measuring points accessible. All of these measuring systems can be used to make

body measurements, provided all the equipment is available.

Planning a repair

The following decisions have to be made before the repairs are started:

Does the vehicle need to be put on a straightening jig, or can it be straightened by other means?

Does the body need to be measured?

Do aggregates like engine or axles need to be removed? Impact energy is transferred via the side member to the A-pillar

Page 2716 of 3039

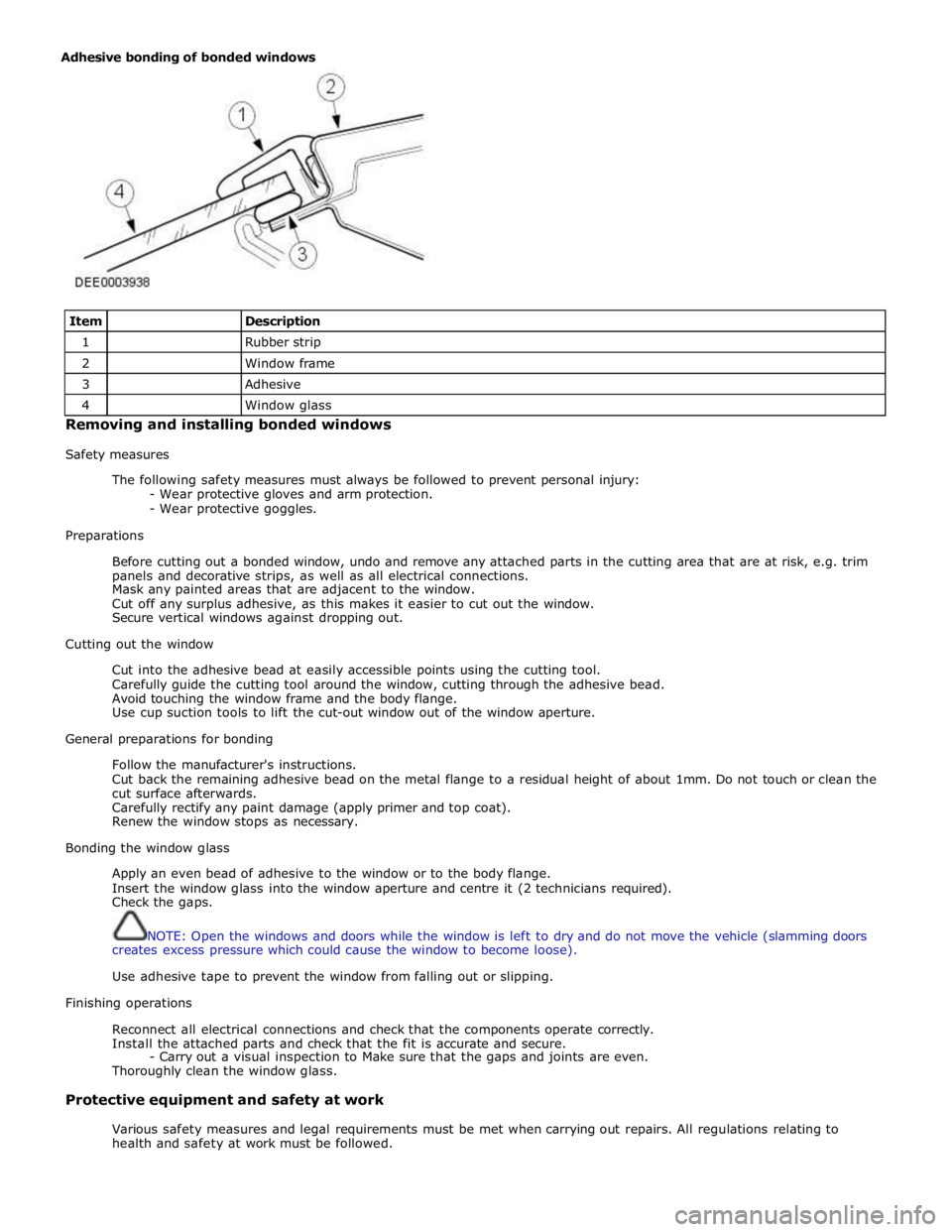

Item

Description 1

Rubber strip 2

Window frame 3

Adhesive 4

Window glass Removing and installing bonded windows

Safety measures

The following safety measures must always be followed to prevent personal injury:

- Wear protective gloves and arm protection.

- Wear protective goggles.

Preparations

Before cutting out a bonded window, undo and remove any attached parts in the cutting area that are at risk, e.g. trim

panels and decorative strips, as well as all electrical connections.

Mask any painted areas that are adjacent to the window.

Cut off any surplus adhesive, as this makes it easier to cut out the window.

Secure vertical windows against dropping out.

Cutting out the window

Cut into the adhesive bead at easily accessible points using the cutting tool.

Carefully guide the cutting tool around the window, cutting through the adhesive bead.

Avoid touching the window frame and the body flange.

Use cup suction tools to lift the cut-out window out of the window aperture.

General preparations for bonding

Follow the manufacturer's instructions.

Cut back the remaining adhesive bead on the metal flange to a residual height of about 1mm. Do not touch or clean the

cut surface afterwards.

Carefully rectify any paint damage (apply primer and top coat).

Renew the window stops as necessary.

Bonding the window glass

Apply an even bead of adhesive to the window or to the body flange.

Insert the window glass into the window aperture and centre it (2 technicians required).

Check the gaps.

NOTE: Open the windows and doors while the window is left to dry and do not move the vehicle (slamming doors

creates excess pressure which could cause the window to become loose).

Use adhesive tape to prevent the window from falling out or slipping.

Finishing operations

Reconnect all electrical connections and check that the components operate correctly.

Install the attached parts and check that the fit is accurate and secure.

- Carry out a visual inspection to Make sure that the gaps and joints are even.

Thoroughly clean the window glass.

Protective equipment and safety at work

Various safety measures and legal requirements must be met when carrying out repairs. All regulations relating to

health and safety at work must be followed. Adhesive bonding of bonded windows