battery monitoring module JAGUAR XFR 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 2010, Model line: XFR, Model: JAGUAR XFR 2010 1.GPages: 3039, PDF Size: 58.49 MB

Page 2 of 3039

Table of ContentsContents1: General Information

100: Service Information

100-00: General Information

Description and OperationAbout This Manual

Application and Use of Specifications

Battery and Battery Charging Health and Safety Precautions

Brake System Health and Safety Precautions

Diesel Fuel System Health and Safety Precautions

General Service Information

Health and Safety Precautions

How To Use This Manual

Important Safety Instructions

Petrol and Petrol-Ethanol Fuel Systems Health and Safety Precautions

Solvents, Sealants and Adhesives

Standard Workshop Practices

Symbols Glossary

Supplemental Restraint System (SRS) Health and Safety Precautions

Road/Roller Testing

Window Glass Health and Safety Precautions

Diagnostic Trouble Code (DTC) IndexDTC: Adaptive Damping Module (SUMB)

Diagnostic Trouble Code (DTC) IndexDTC: Anti-Lock Braking System (ABS)

Diagnostic Trouble Code (DTC) IndexDTC: Audio Amplifier Module (AAM)

Diagnostic Trouble Code (DTC) IndexDTC: Blind Spot Monitoring System Module (SODL/SODR)

Diagnostic Trouble Code (DTC) IndexDTC: Central Junction Box (CJB)

Diagnostic Trouble Code (DTC) IndexDTC: Climate Control Module (HVAC)

Diagnostic Trouble Code (DTC) IndexDTC: Digital Audio Broadcast Module (DABM)

Diagnostic Trouble Code (DTC) IndexDTC: Driver Door Module/Passenger Door Module (DDM/PDM)

Diagnostic Trouble Code (DTC) IndexDTC: Driver/Passenger Seat Module (DSM/PSM)

Diagnostic Trouble Code (DTC) IndexDTC: Electric Parking Brake (PBM)

Diagnostic Trouble Code (DTC) Index V8 S/C 5.0L Petrol, DTC: Engine Control Module (ECM)

Diagnostic Trouble Code (DTC) IndexDTC: Front Seat Climate Control Module (DCSM)

Diagnostic Trouble Code (DTC) IndexDTC: Headlamp Control Module (HCM)

Diagnostic Trouble Code (DTC) IndexDTC: Instrument Cluster (IPC)

Diagnostic Trouble Code (DTC) IndexDTC: Integrated Audio Module (IAM)

Diagnostic Trouble Code (DTC) IndexDTC: Integrated Control Panel (FCIMB)

Page 131 of 3039

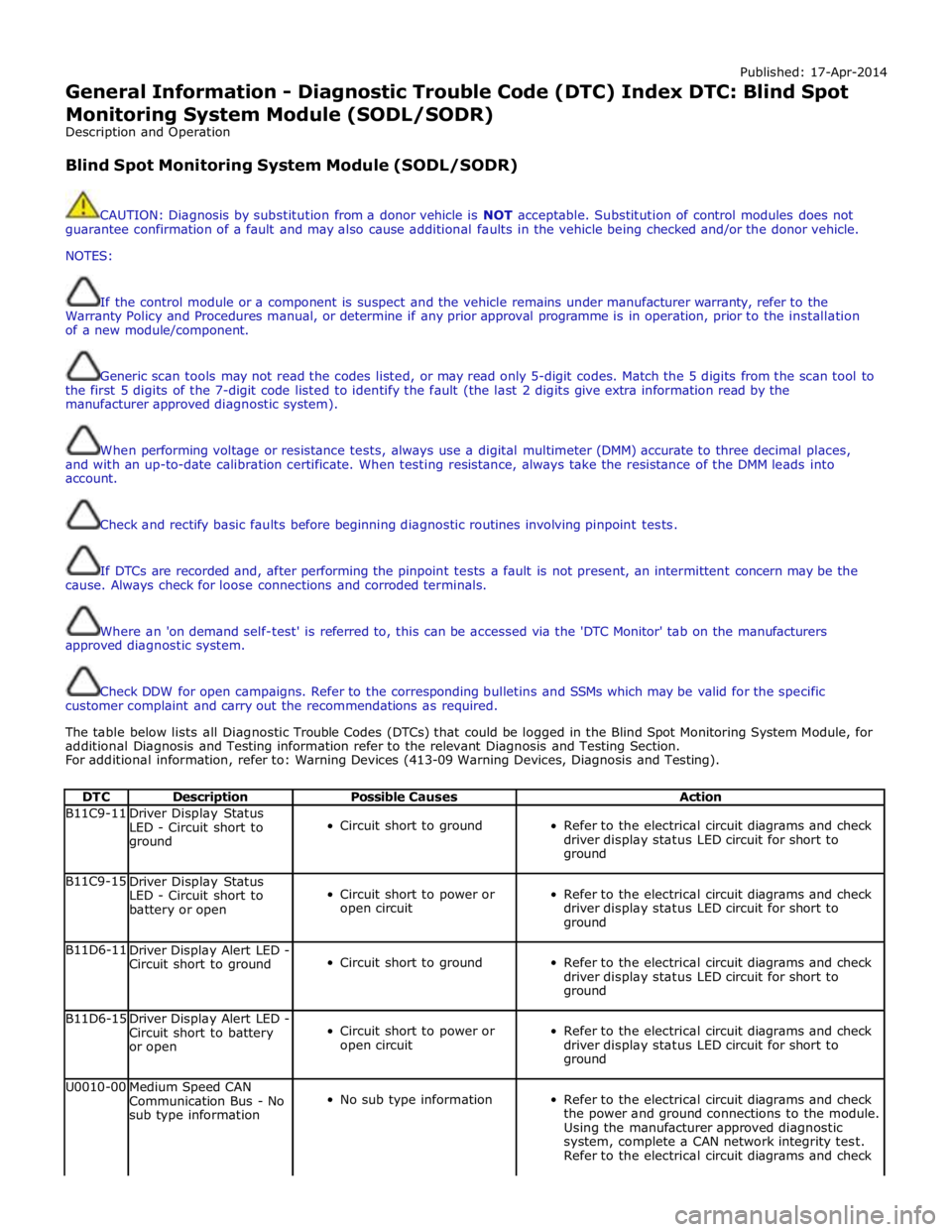

Published: 17-Apr-2014

General Information - Diagnostic Trouble Code (DTC) Index DTC: Blind Spot Monitoring System Module (SODL/SODR)

Description and Operation

Blind Spot Monitoring System Module (SODL/SODR)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle.

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component.

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal places,

and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If DTCs are recorded and, after performing the pinpoint tests a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

Where an 'on demand self-test' is referred to, this can be accessed via the 'DTC Monitor' tab on the manufacturers

approved diagnostic system.

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

The table below lists all Diagnostic Trouble Codes (DTCs) that could be logged in the Blind Spot Monitoring System Module, for

additional Diagnosis and Testing information refer to the relevant Diagnosis and Testing Section.

For additional information, refer to: Warning Devices (413-09 Warning Devices, Diagnosis and Testing).

DTC Description Possible Causes Action B11C9-11

Driver Display Status

LED - Circuit short to

ground

Circuit short to ground

Refer to the electrical circuit diagrams and check

driver display status LED circuit for short to

ground B11C9-15

Driver Display Status

LED - Circuit short to

battery or open

Circuit short to power or

open circuit

Refer to the electrical circuit diagrams and check

driver display status LED circuit for short to

ground B11D6-11

Driver Display Alert LED -

Circuit short to ground

Circuit short to ground

Refer to the electrical circuit diagrams and check

driver display status LED circuit for short to

ground B11D6-15

Driver Display Alert LED -

Circuit short to battery

or open

Circuit short to power or

open circuit

Refer to the electrical circuit diagrams and check

driver display status LED circuit for short to

ground U0010-00

Medium Speed CAN

Communication Bus - No

sub type information

No sub type information

Refer to the electrical circuit diagrams and check

the power and ground connections to the module.

Using the manufacturer approved diagnostic

system, complete a CAN network integrity test.

Refer to the electrical circuit diagrams and check

Page 133 of 3039

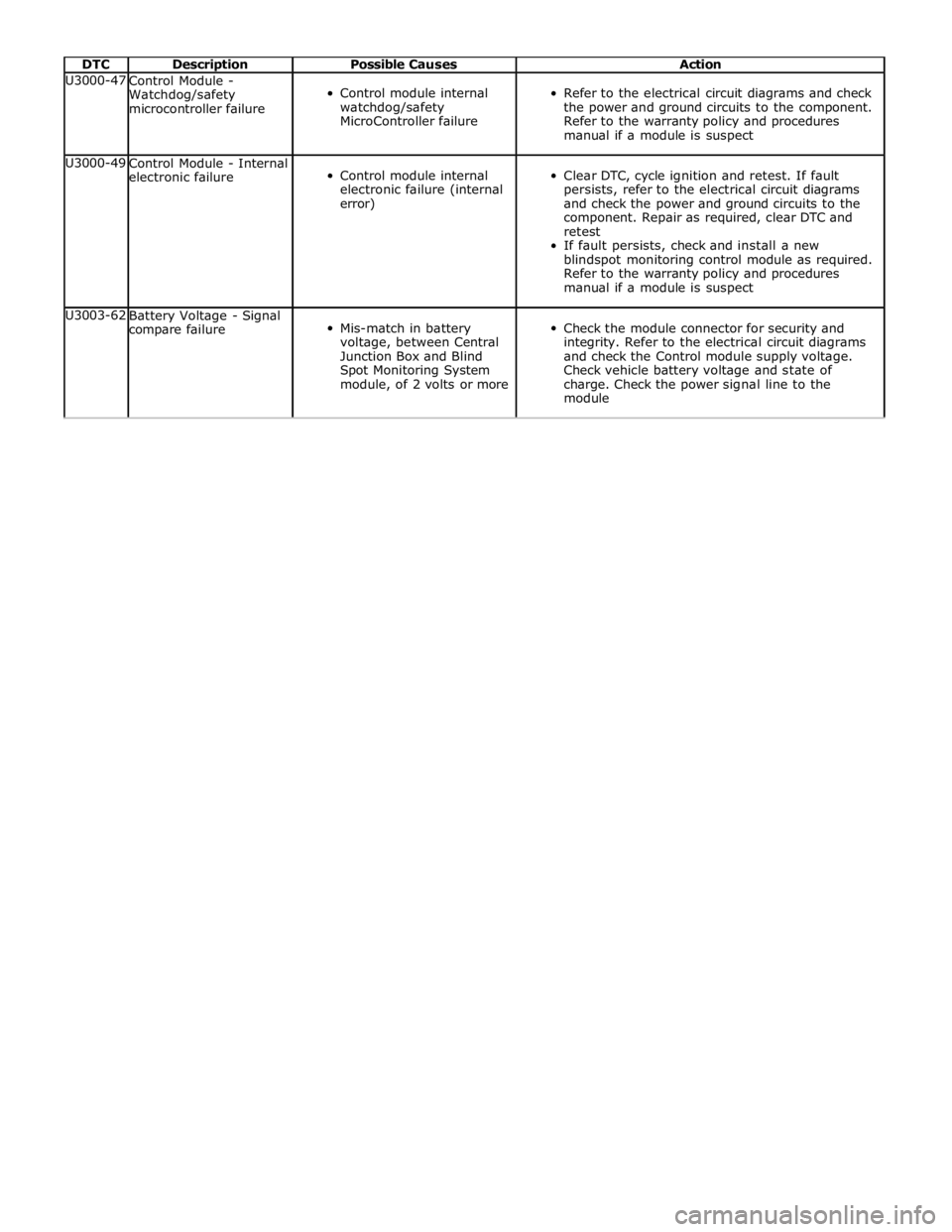

DTC Description Possible Causes Action U3000-47

Control Module -

Watchdog/safety

microcontroller failure

Control module internal

watchdog/safety

MicroController failure

Refer to the electrical circuit diagrams and check

the power and ground circuits to the component.

Refer to the warranty policy and procedures

manual if a module is suspect U3000-49

Control Module - Internal

electronic failure

Control module internal

electronic failure (internal

error)

Clear DTC, cycle ignition and retest. If fault

persists, refer to the electrical circuit diagrams

and check the power and ground circuits to the

component. Repair as required, clear DTC and

retest

If fault persists, check and install a new

blindspot monitoring control module as required.

Refer to the warranty policy and procedures

manual if a module is suspect U3003-62

Battery Voltage - Signal

compare failure

Mis-match in battery

voltage, between Central

Junction Box and Blind

Spot Monitoring System

module, of 2 volts or more

Check the module connector for security and

integrity. Refer to the electrical circuit diagrams

and check the Control module supply voltage.

Check vehicle battery voltage and state of

charge. Check the power signal line to the

module

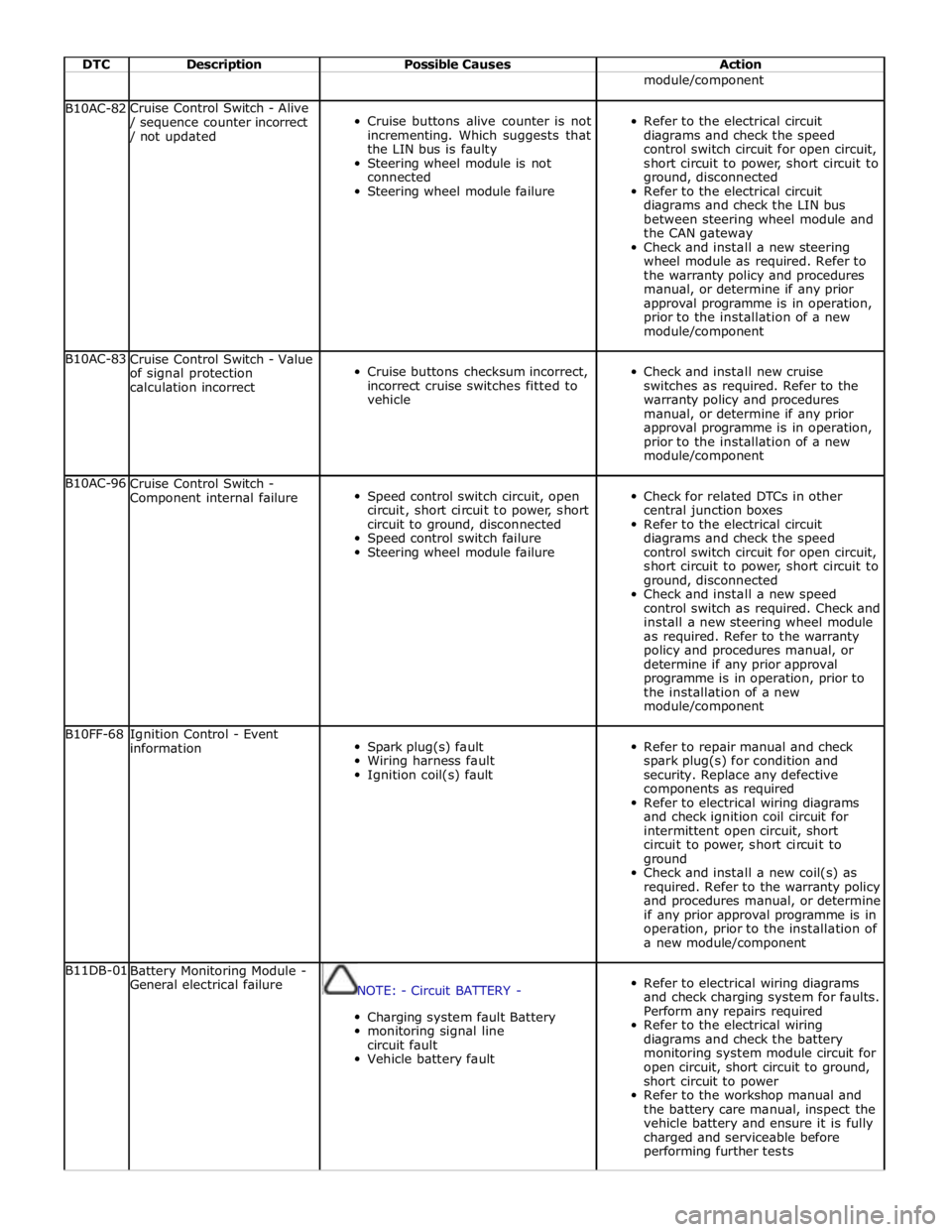

Page 165 of 3039

DTC Description Possible Causes Action module/component B10AC-82 Cruise Control Switch - Alive / sequence counter incorrect / not updated

Cruise buttons alive counter is not

incrementing. Which suggests that

the LIN bus is faulty

Steering wheel module is not

connected

Steering wheel module failure

Refer to the electrical circuit

diagrams and check the speed

control switch circuit for open circuit,

short circuit to power, short circuit to

ground, disconnected

Refer to the electrical circuit

diagrams and check the LIN bus

between steering wheel module and

the CAN gateway

Check and install a new steering

wheel module as required. Refer to

the warranty policy and procedures

manual, or determine if any prior

approval programme is in operation,

prior to the installation of a new

module/component B10AC-83

Cruise Control Switch - Value

of signal protection

calculation incorrect

Cruise buttons checksum incorrect,

incorrect cruise switches fitted to

vehicle

Check and install new cruise

switches as required. Refer to the

warranty policy and procedures

manual, or determine if any prior

approval programme is in operation,

prior to the installation of a new

module/component B10AC-96

Cruise Control Switch -

Component internal failure

Speed control switch circuit, open

circuit, short circuit to power, short

circuit to ground, disconnected

Speed control switch failure

Steering wheel module failure

Check for related DTCs in other

central junction boxes

Refer to the electrical circuit

diagrams and check the speed

control switch circuit for open circuit,

short circuit to power, short circuit to

ground, disconnected

Check and install a new speed

control switch as required. Check and

install a new steering wheel module

as required. Refer to the warranty

policy and procedures manual, or

determine if any prior approval

programme is in operation, prior to

the installation of a new

module/component B10FF-68

Ignition Control - Event

information

Spark plug(s) fault

Wiring harness fault

Ignition coil(s) fault

Refer to repair manual and check

spark plug(s) for condition and

security. Replace any defective

components as required

Refer to electrical wiring diagrams

and check ignition coil circuit for

intermittent open circuit, short

circuit to power, short circuit to

ground

Check and install a new coil(s) as

required. Refer to the warranty policy

and procedures manual, or determine

if any prior approval programme is in

operation, prior to the installation of

a new module/component B11DB-01

Battery Monitoring Module -

General electrical failure

NOTE: - Circuit BATTERY -

Charging system fault Battery

monitoring signal line

circuit fault

Vehicle battery fault

Refer to electrical wiring diagrams

and check charging system for faults.

Perform any repairs required

Refer to the electrical wiring

diagrams and check the battery

monitoring system module circuit for

open circuit, short circuit to ground,

short circuit to power

Refer to the workshop manual and

the battery care manual, inspect the

vehicle battery and ensure it is fully

charged and serviceable before

performing further tests

Page 166 of 3039

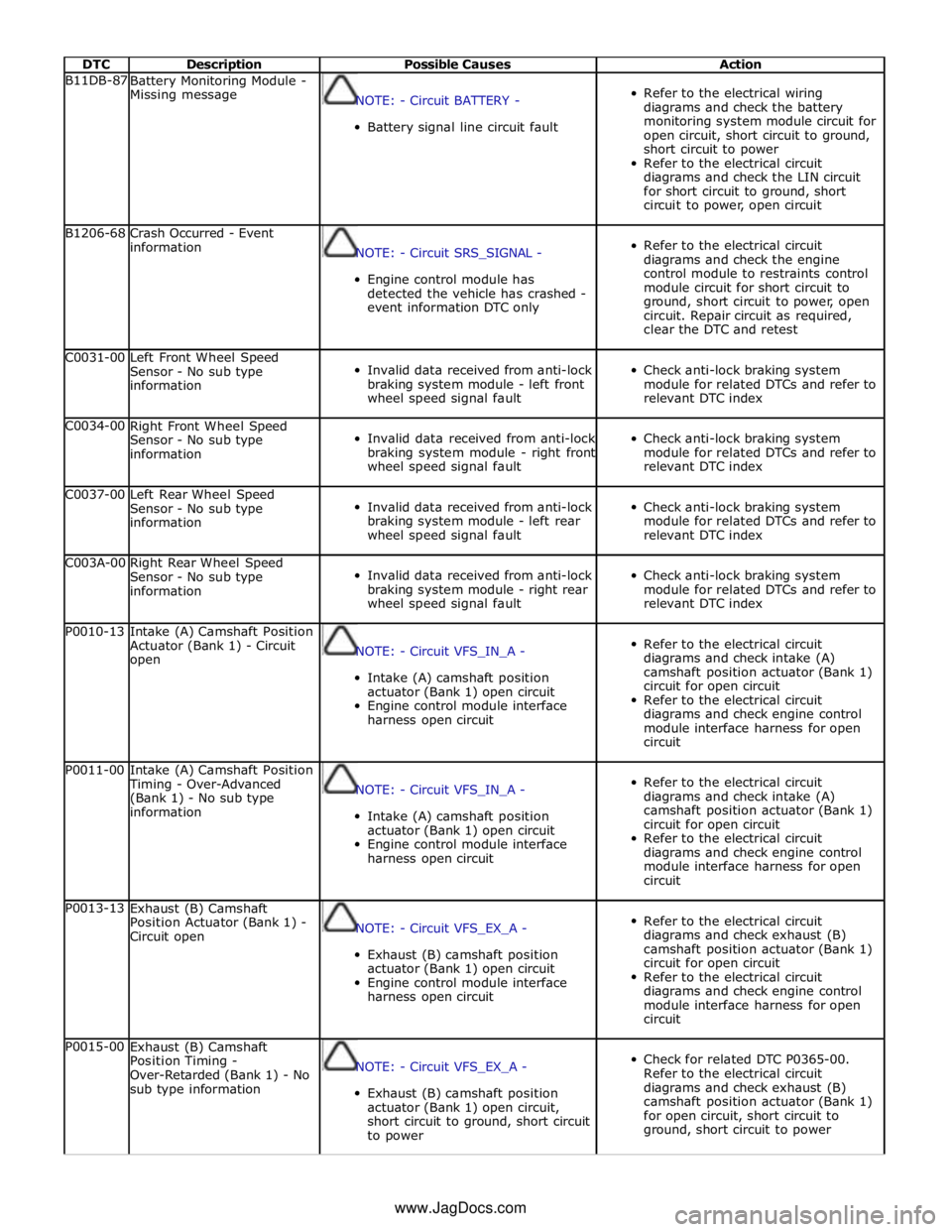

DTC Description Possible Causes Action B11DB-87

Battery Monitoring Module -

Missing message

NOTE: - Circuit BATTERY -

Battery signal line circuit fault

Refer to the electrical wiring

diagrams and check the battery

monitoring system module circuit for

open circuit, short circuit to ground,

short circuit to power

Refer to the electrical circuit

diagrams and check the LIN circuit

for short circuit to ground, short

circuit to power, open circuit B1206-68

Crash Occurred - Event

information

NOTE: - Circuit SRS_SIGNAL -

Engine control module has

detected the vehicle has crashed -

event information DTC only

Refer to the electrical circuit

diagrams and check the engine

control module to restraints control

module circuit for short circuit to

ground, short circuit to power, open

circuit. Repair circuit as required,

clear the DTC and retest C0031-00

Left Front Wheel Speed

Sensor - No sub type

information

Invalid data received from anti-lock

braking system module - left front

wheel speed signal fault

Check anti-lock braking system

module for related DTCs and refer to

relevant DTC index C0034-00

Right Front Wheel Speed

Sensor - No sub type

information

Invalid data received from anti-lock

braking system module - right front

wheel speed signal fault

Check anti-lock braking system

module for related DTCs and refer to

relevant DTC index C0037-00

Left Rear Wheel Speed

Sensor - No sub type

information

Invalid data received from anti-lock

braking system module - left rear

wheel speed signal fault

Check anti-lock braking system

module for related DTCs and refer to

relevant DTC index C003A-00

Right Rear Wheel Speed

Sensor - No sub type

information

Invalid data received from anti-lock

braking system module - right rear

wheel speed signal fault

Check anti-lock braking system

module for related DTCs and refer to

relevant DTC index P0010-13

Intake (A) Camshaft Position

Actuator (Bank 1) - Circuit

open

NOTE: - Circuit VFS_IN_A -

Intake (A) camshaft position

actuator (Bank 1) open circuit

Engine control module interface

harness open circuit

Refer to the electrical circuit

diagrams and check intake (A)

camshaft position actuator (Bank 1)

circuit for open circuit

Refer to the electrical circuit

diagrams and check engine control

module interface harness for open

circuit P0011-00

Intake (A) Camshaft Position

Timing - Over-Advanced

(Bank 1) - No sub type

information

NOTE: - Circuit VFS_IN_A -

Intake (A) camshaft position

actuator (Bank 1) open circuit

Engine control module interface

harness open circuit

Refer to the electrical circuit

diagrams and check intake (A)

camshaft position actuator (Bank 1)

circuit for open circuit

Refer to the electrical circuit

diagrams and check engine control

module interface harness for open

circuit P0013-13

Exhaust (B) Camshaft

Position Actuator (Bank 1) -

Circuit open

NOTE: - Circuit VFS_EX_A -

Exhaust (B) camshaft position

actuator (Bank 1) open circuit

Engine control module interface

harness open circuit

Refer to the electrical circuit

diagrams and check exhaust (B)

camshaft position actuator (Bank 1)

circuit for open circuit

Refer to the electrical circuit

diagrams and check engine control

module interface harness for open

circuit P0015-00

Exhaust (B) Camshaft

Position Timing -

Over-Retarded (Bank 1) - No

sub type information

NOTE: - Circuit VFS_EX_A -

Exhaust (B) camshaft position

actuator (Bank 1) open circuit,

short circuit to ground, short circuit

to power

Check for related DTC P0365-00.

Refer to the electrical circuit

diagrams and check exhaust (B)

camshaft position actuator (Bank 1)

for open circuit, short circuit to

ground, short circuit to power www.JagDocs.com

Page 220 of 3039

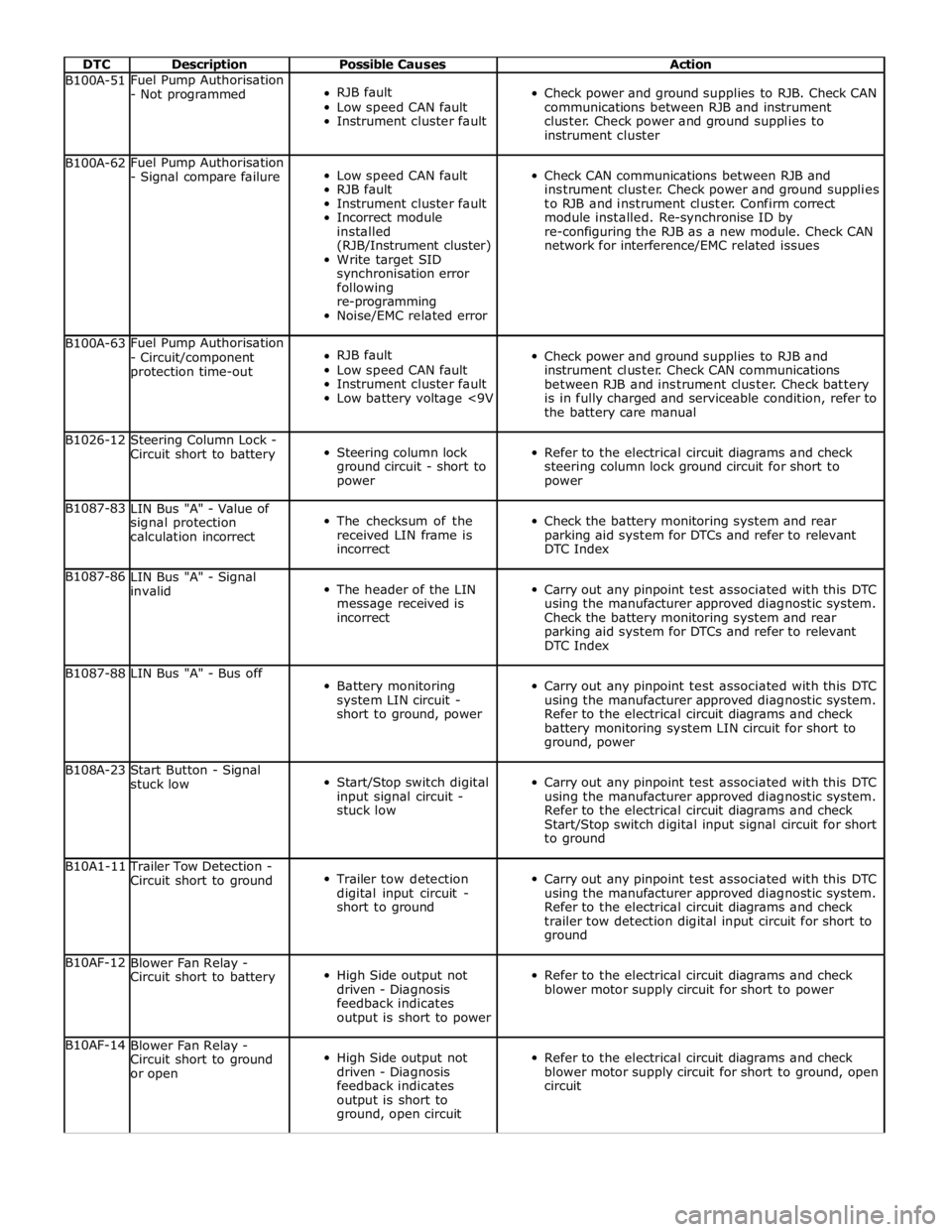

DTC Description Possible Causes Action B100A-51 Fuel Pump Authorisation

- Not programmed

RJB fault

Low speed CAN fault

Instrument cluster fault

Check power and ground supplies to RJB. Check CAN

communications between RJB and instrument

cluster. Check power and ground supplies to

instrument cluster B100A-62 Fuel Pump Authorisation

- Signal compare failure

Low speed CAN fault

RJB fault

Instrument cluster fault

Incorrect module

installed

(RJB/Instrument cluster)

Write target SID

synchronisation error

following

re-programming

Noise/EMC related error

Check CAN communications between RJB and

instrument cluster. Check power and ground supplies

to RJB and instrument cluster. Confirm correct

module installed. Re-synchronise ID by

re-configuring the RJB as a new module. Check CAN

network for interference/EMC related issues B100A-63 Fuel Pump Authorisation

- Circuit/component

protection time-out

RJB fault

Low speed CAN fault

Instrument cluster fault

Low battery voltage <9V

Check power and ground supplies to RJB and

instrument cluster. Check CAN communications

between RJB and instrument cluster. Check battery

is in fully charged and serviceable condition, refer to

the battery care manual B1026-12

Steering Column Lock -

Circuit short to battery

Steering column lock

ground circuit - short to

power

Refer to the electrical circuit diagrams and check

steering column lock ground circuit for short to

power B1087-83

LIN Bus "A" - Value of

signal protection

calculation incorrect

The checksum of the

received LIN frame is

incorrect

Check the battery monitoring system and rear

parking aid system for DTCs and refer to relevant

DTC Index B1087-86

LIN Bus "A" - Signal

invalid

The header of the LIN

message received is

incorrect

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Check the battery monitoring system and rear

parking aid system for DTCs and refer to relevant

DTC Index B1087-88 LIN Bus "A" - Bus off

Battery monitoring

system LIN circuit -

short to ground, power

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

battery monitoring system LIN circuit for short to

ground, power B108A-23

Start Button - Signal

stuck low

Start/Stop switch digital

input signal circuit -

stuck low

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

Start/Stop switch digital input signal circuit for short

to ground B10A1-11 Trailer Tow Detection -

Circuit short to ground

Trailer tow detection

digital input circuit -

short to ground

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

trailer tow detection digital input circuit for short to

ground B10AF-12

Blower Fan Relay -

Circuit short to battery

High Side output not

driven - Diagnosis

feedback indicates

output is short to power

Refer to the electrical circuit diagrams and check

blower motor supply circuit for short to power B10AF-14

Blower Fan Relay -

Circuit short to ground

or open

High Side output not

driven - Diagnosis

feedback indicates

output is short to

ground, open circuit

Refer to the electrical circuit diagrams and check

blower motor supply circuit for short to ground, open

circuit

Page 223 of 3039

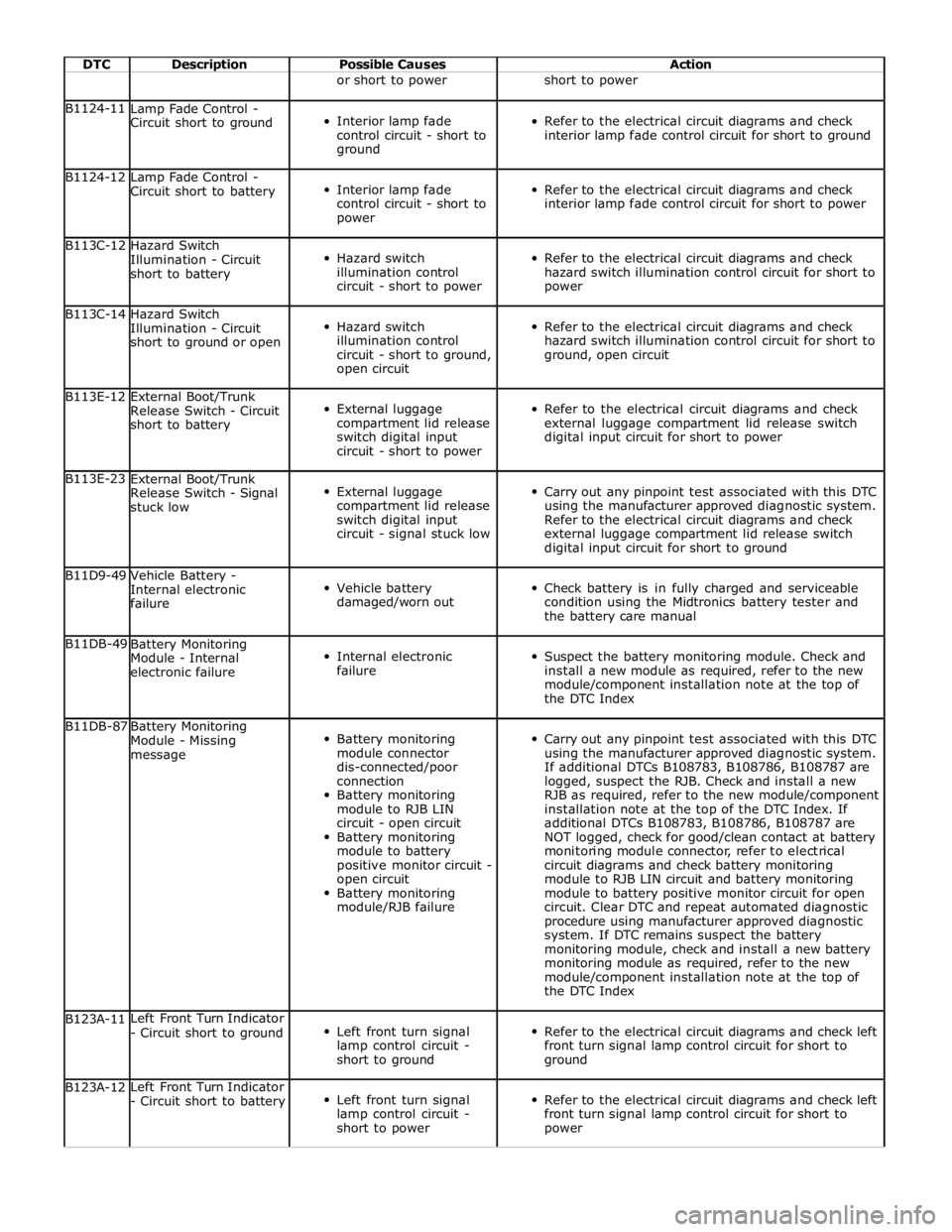

DTC Description Possible Causes Action or short to power short to power B1124-11

Lamp Fade Control -

Circuit short to ground

Interior lamp fade

control circuit - short to

ground

Refer to the electrical circuit diagrams and check

interior lamp fade control circuit for short to ground B1124-12

Lamp Fade Control -

Circuit short to battery

Interior lamp fade

control circuit - short to

power

Refer to the electrical circuit diagrams and check

interior lamp fade control circuit for short to power B113C-12

Hazard Switch

Illumination - Circuit

short to battery

Hazard switch

illumination control

circuit - short to power

Refer to the electrical circuit diagrams and check

hazard switch illumination control circuit for short to

power B113C-14

Hazard Switch

Illumination - Circuit

short to ground or open

Hazard switch

illumination control

circuit - short to ground,

open circuit

Refer to the electrical circuit diagrams and check

hazard switch illumination control circuit for short to

ground, open circuit B113E-12

External Boot/Trunk

Release Switch - Circuit

short to battery

External luggage

compartment lid release

switch digital input

circuit - short to power

Refer to the electrical circuit diagrams and check

external luggage compartment lid release switch

digital input circuit for short to power B113E-23

External Boot/Trunk

Release Switch - Signal

stuck low

External luggage

compartment lid release

switch digital input

circuit - signal stuck low

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

Refer to the electrical circuit diagrams and check

external luggage compartment lid release switch

digital input circuit for short to ground B11D9-49

Vehicle Battery -

Internal electronic

failure

Vehicle battery

damaged/worn out

Check battery is in fully charged and serviceable

condition using the Midtronics battery tester and

the battery care manual B11DB-49

Battery Monitoring

Module - Internal

electronic failure

Internal electronic

failure

Suspect the battery monitoring module. Check and

install a new module as required, refer to the new

module/component installation note at the top of

the DTC Index B11DB-87

Battery Monitoring

Module - Missing

message

Battery monitoring

module connector

dis-connected/poor

connection

Battery monitoring

module to RJB LIN

circuit - open circuit

Battery monitoring

module to battery

positive monitor circuit -

open circuit

Battery monitoring

module/RJB failure

Carry out any pinpoint test associated with this DTC

using the manufacturer approved diagnostic system.

If additional DTCs B108783, B108786, B108787 are

logged, suspect the RJB. Check and install a new

RJB as required, refer to the new module/component

installation note at the top of the DTC Index. If

additional DTCs B108783, B108786, B108787 are

NOT logged, check for good/clean contact at battery

monitoring module connector, refer to electrical

circuit diagrams and check battery monitoring

module to RJB LIN circuit and battery monitoring

module to battery positive monitor circuit for open

circuit. Clear DTC and repeat automated diagnostic

procedure using manufacturer approved diagnostic

system. If DTC remains suspect the battery

monitoring module, check and install a new battery

monitoring module as required, refer to the new

module/component installation note at the top of

the DTC Index B123A-11 Left Front Turn Indicator

- Circuit short to ground

Left front turn signal

lamp control circuit -

short to ground

Refer to the electrical circuit diagrams and check left

front turn signal lamp control circuit for short to

ground B123A-12 Left Front Turn Indicator

- Circuit short to battery

Left front turn signal

lamp control circuit -

short to power

Refer to the electrical circuit diagrams and check left

front turn signal lamp control circuit for short to

power

Page 246 of 3039

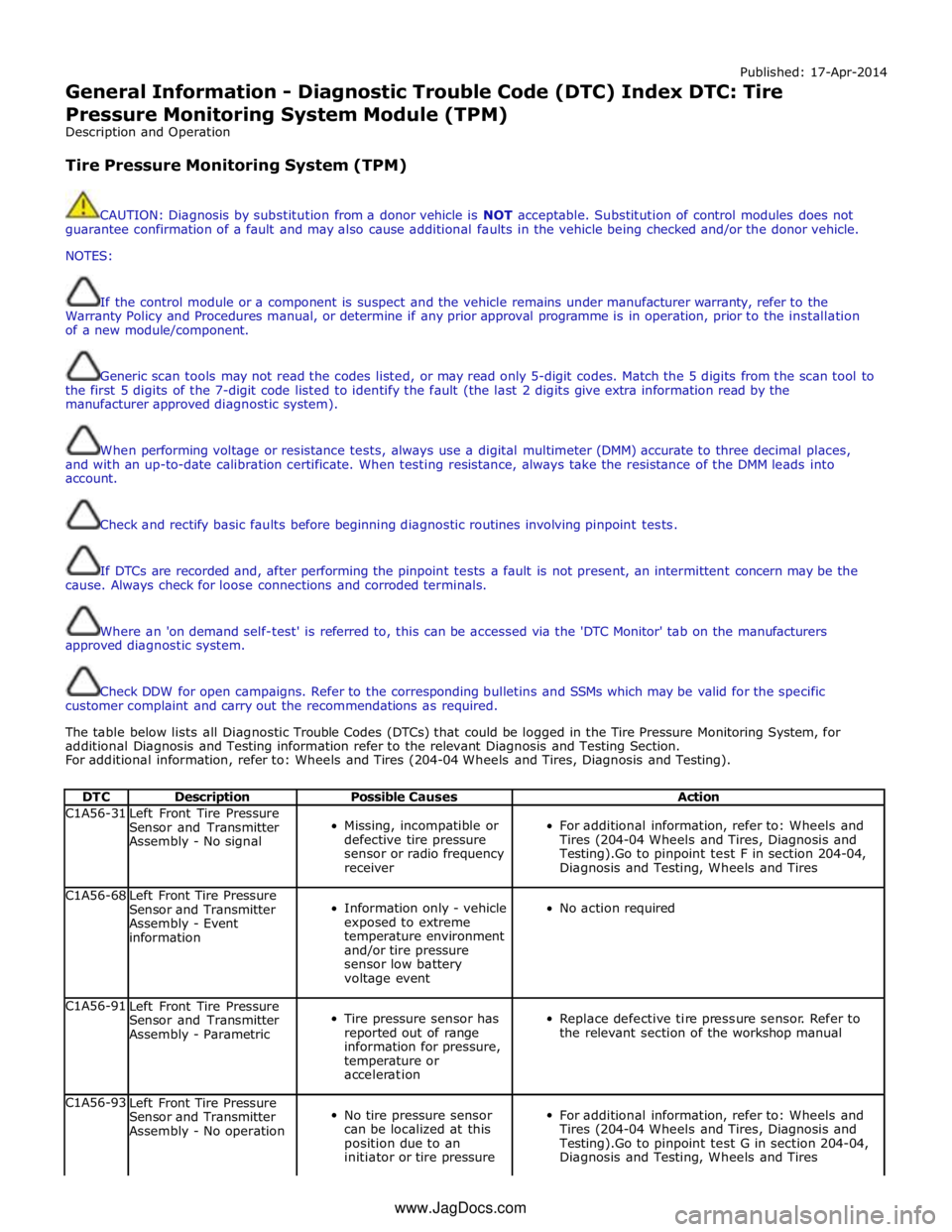

Published: 17-Apr-2014

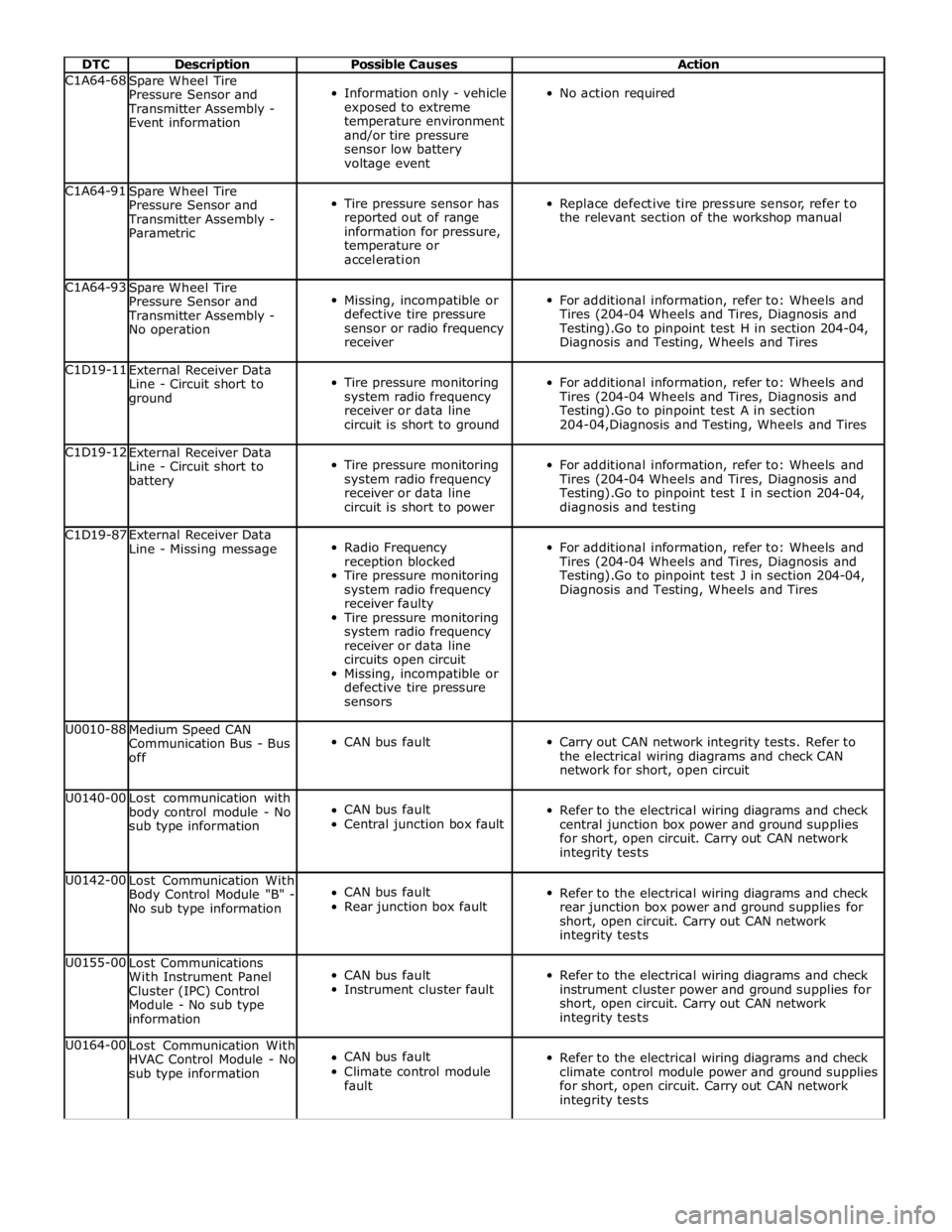

General Information - Diagnostic Trouble Code (DTC) Index DTC: Tire

Pressure Monitoring System Module (TPM)

Description and Operation

Tire Pressure Monitoring System (TPM)

CAUTION: Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not

guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle.

NOTES:

If the control module or a component is suspect and the vehicle remains under manufacturer warranty, refer to the

Warranty Policy and Procedures manual, or determine if any prior approval programme is in operation, prior to the installation

of a new module/component.

Generic scan tools may not read the codes listed, or may read only 5-digit codes. Match the 5 digits from the scan tool to

the first 5 digits of the 7-digit code listed to identify the fault (the last 2 digits give extra information read by the

manufacturer approved diagnostic system).

When performing voltage or resistance tests, always use a digital multimeter (DMM) accurate to three decimal places,

and with an up-to-date calibration certificate. When testing resistance, always take the resistance of the DMM leads into

account.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

If DTCs are recorded and, after performing the pinpoint tests a fault is not present, an intermittent concern may be the

cause. Always check for loose connections and corroded terminals.

Where an 'on demand self-test' is referred to, this can be accessed via the 'DTC Monitor' tab on the manufacturers

approved diagnostic system.

Check DDW for open campaigns. Refer to the corresponding bulletins and SSMs which may be valid for the specific

customer complaint and carry out the recommendations as required.

The table below lists all Diagnostic Trouble Codes (DTCs) that could be logged in the Tire Pressure Monitoring System, for

additional Diagnosis and Testing information refer to the relevant Diagnosis and Testing Section.

For additional information, refer to: Wheels and Tires (204-04 Wheels and Tires, Diagnosis and Testing).

DTC Description Possible Causes Action C1A56-31

Left Front Tire Pressure

Sensor and Transmitter

Assembly - No signal

Missing, incompatible or

defective tire pressure

sensor or radio frequency

receiver

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test F in section 204-04,

Diagnosis and Testing, Wheels and Tires C1A56-68

Left Front Tire Pressure

Sensor and Transmitter

Assembly - Event

information

Information only - vehicle

exposed to extreme

temperature environment

and/or tire pressure

sensor low battery

voltage event

No action required C1A56-91

Left Front Tire Pressure

Sensor and Transmitter

Assembly - Parametric

Tire pressure sensor has

reported out of range

information for pressure,

temperature or

acceleration

Replace defective tire pressure sensor. Refer to

the relevant section of the workshop manual C1A56-93

Left Front Tire Pressure

Sensor and Transmitter

Assembly - No operation

No tire pressure sensor

can be localized at this

position due to an

initiator or tire pressure

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test G in section 204-04,

Diagnosis and Testing, Wheels and Tires www.JagDocs.com

Page 249 of 3039

DTC Description Possible Causes Action C1A64-68

Spare Wheel Tire

Pressure Sensor and Transmitter Assembly -

Event information

Information only - vehicle

exposed to extreme

temperature environment

and/or tire pressure

sensor low battery

voltage event

No action required C1A64-91

Spare Wheel Tire

Pressure Sensor and Transmitter Assembly -

Parametric

Tire pressure sensor has

reported out of range

information for pressure,

temperature or

acceleration

Replace defective tire pressure sensor, refer to

the relevant section of the workshop manual C1A64-93

Spare Wheel Tire

Pressure Sensor and Transmitter Assembly -

No operation

Missing, incompatible or

defective tire pressure

sensor or radio frequency

receiver

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test H in section 204-04,

Diagnosis and Testing, Wheels and Tires C1D19-11

External Receiver Data

Line - Circuit short to

ground

Tire pressure monitoring

system radio frequency

receiver or data line

circuit is short to ground

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test A in section

204-04,Diagnosis and Testing, Wheels and Tires C1D19-12

External Receiver Data

Line - Circuit short to

battery

Tire pressure monitoring

system radio frequency

receiver or data line

circuit is short to power

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test I in section 204-04,

diagnosis and testing C1D19-87

External Receiver Data

Line - Missing message

Radio Frequency

reception blocked

Tire pressure monitoring

system radio frequency

receiver faulty

Tire pressure monitoring

system radio frequency

receiver or data line

circuits open circuit

Missing, incompatible or

defective tire pressure

sensors

For additional information, refer to: Wheels and

Tires (204-04 Wheels and Tires, Diagnosis and

Testing).Go to pinpoint test J in section 204-04,

Diagnosis and Testing, Wheels and Tires U0010-88

Medium Speed CAN

Communication Bus - Bus

off

CAN bus fault

Carry out CAN network integrity tests. Refer to

the electrical wiring diagrams and check CAN

network for short, open circuit U0140-00

Lost communication with

body control module - No

sub type information

CAN bus fault

Central junction box fault

Refer to the electrical wiring diagrams and check

central junction box power and ground supplies

for short, open circuit. Carry out CAN network

integrity tests U0142-00

Lost Communication With

Body Control Module "B" -

No sub type information

CAN bus fault

Rear junction box fault

Refer to the electrical wiring diagrams and check

rear junction box power and ground supplies for

short, open circuit. Carry out CAN network

integrity tests U0155-00

Lost Communications

With Instrument Panel

Cluster (IPC) Control

Module - No sub type

information

CAN bus fault

Instrument cluster fault

Refer to the electrical wiring diagrams and check

instrument cluster power and ground supplies for

short, open circuit. Carry out CAN network

integrity tests U0164-00

Lost Communication With

HVAC Control Module - No

sub type information

CAN bus fault

Climate control module

fault

Refer to the electrical wiring diagrams and check

climate control module power and ground supplies

for short, open circuit. Carry out CAN network

integrity tests

Page 256 of 3039

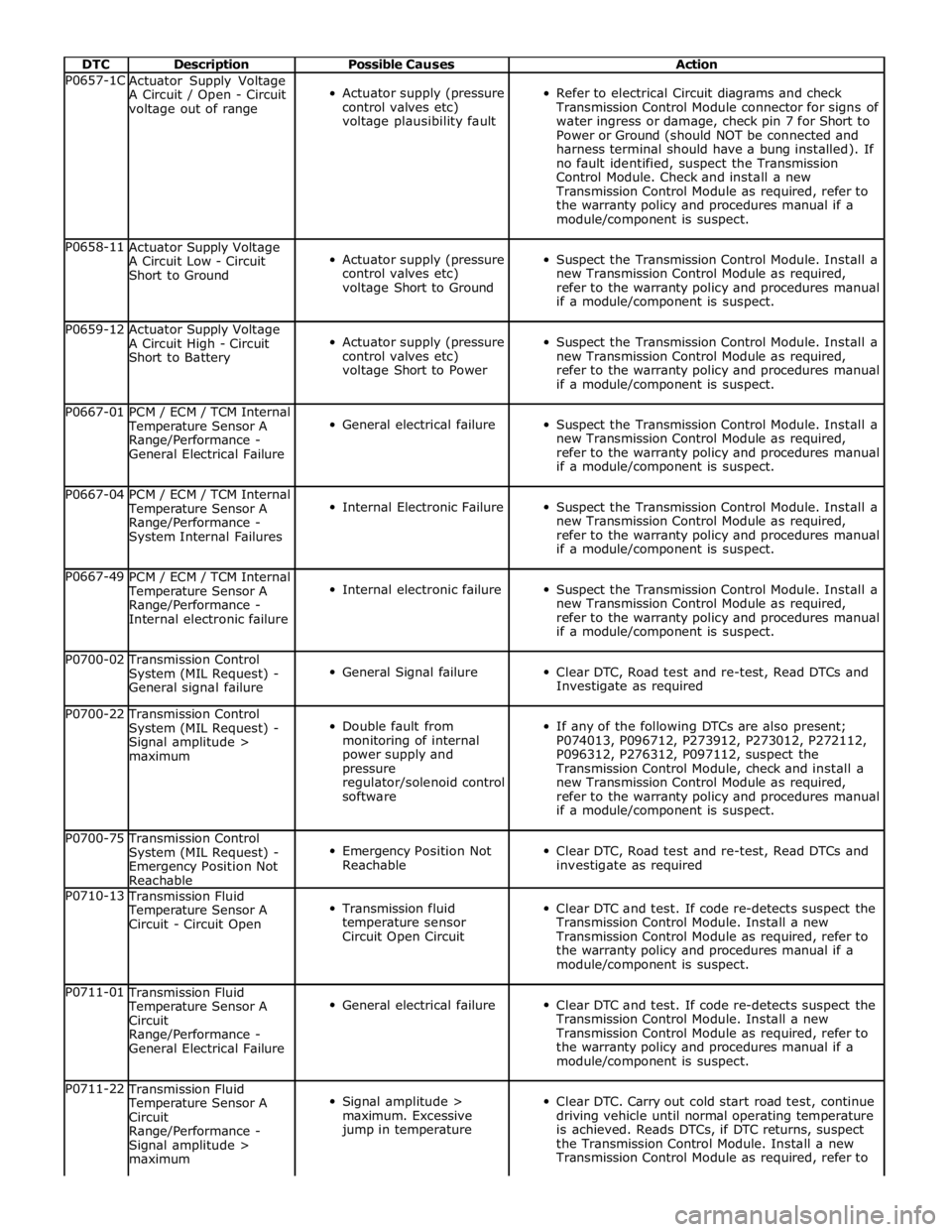

DTC Description Possible Causes Action P0657-1C

Actuator Supply Voltage

A Circuit / Open - Circuit

voltage out of range

Actuator supply (pressure

control valves etc)

voltage plausibility fault

Refer to electrical Circuit diagrams and check

Transmission Control Module connector for signs of

water ingress or damage, check pin 7 for Short to

Power or Ground (should NOT be connected and

harness terminal should have a bung installed). If

no fault identified, suspect the Transmission

Control Module. Check and install a new

Transmission Control Module as required, refer to

the warranty policy and procedures manual if a

module/component is suspect. P0658-11

Actuator Supply Voltage

A Circuit Low - Circuit

Short to Ground

Actuator supply (pressure

control valves etc)

voltage Short to Ground

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0659-12

Actuator Supply Voltage

A Circuit High - Circuit

Short to Battery

Actuator supply (pressure

control valves etc)

voltage Short to Power

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0667-01

PCM / ECM / TCM Internal Temperature Sensor A

Range/Performance -

General Electrical Failure

General electrical failure

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0667-04

PCM / ECM / TCM Internal Temperature Sensor A

Range/Performance -

System Internal Failures

Internal Electronic Failure

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0667-49

PCM / ECM / TCM Internal Temperature Sensor A

Range/Performance -

Internal electronic failure

Internal electronic failure

Suspect the Transmission Control Module. Install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0700-02 Transmission Control

System (MIL Request) -

General signal failure

General Signal failure

Clear DTC, Road test and re-test, Read DTCs and

Investigate as required P0700-22 Transmission Control

System (MIL Request) -

Signal amplitude >

maximum

Double fault from

monitoring of internal

power supply and

pressure

regulator/solenoid control

software

If any of the following DTCs are also present;

P074013, P096712, P273912, P273012, P272112,

P096312, P276312, P097112, suspect the

Transmission Control Module, check and install a

new Transmission Control Module as required,

refer to the warranty policy and procedures manual

if a module/component is suspect. P0700-75 Transmission Control

System (MIL Request) -

Emergency Position Not

Reachable

Emergency Position Not

Reachable

Clear DTC, Road test and re-test, Read DTCs and

investigate as required P0710-13 Transmission Fluid Temperature Sensor A

Circuit - Circuit Open

Transmission fluid

temperature sensor

Circuit Open Circuit

Clear DTC and test. If code re-detects suspect the

Transmission Control Module. Install a new

Transmission Control Module as required, refer to

the warranty policy and procedures manual if a

module/component is suspect. P0711-01 Transmission Fluid Temperature Sensor A

Circuit

Range/Performance -

General Electrical Failure

General electrical failure

Clear DTC and test. If code re-detects suspect the

Transmission Control Module. Install a new

Transmission Control Module as required, refer to

the warranty policy and procedures manual if a

module/component is suspect. P0711-22 Transmission Fluid Temperature Sensor A

Circuit

Range/Performance -

Signal amplitude >

maximum

Signal amplitude >

maximum. Excessive

jump in temperature

Clear DTC. Carry out cold start road test, continue

driving vehicle until normal operating temperature

is achieved. Reads DTCs, if DTC returns, suspect

the Transmission Control Module. Install a new

Transmission Control Module as required, refer to