JAGUAR XJ6 1994 2.G Electrical Diagnostic Manual

Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 327, PDF Size: 13.73 MB

Page 211 of 327

Rear view mirror position adjustments

1. Locate mirror select switch on driver's door switch pack and select driver's side mirror, ie

rotate switch towards the door.

2. Locate rear view mirror joystick switch on driver's door pack.

Operate the switch to give left

/ right and up / down movement. Does the mirror respond

in the correct manner?

3. Yes: Proceed to step 4 or 5.

No:

Japanese market vehicles only

Operate the switch to action 'fold away mode'. Does mirror respond in the correct manner

in each case?

Yes: Proceed to step

5.

No:

All markets

Operate mirror select switch to opposite position and repeat steps

1 to 4 for passenger side

mirror.

With ignition switched to auxiliary, select reverse gear and operate mirror joy

-stick

downwards. Does passenger side mirror dip automatically?

Yes: Proceed to step

7.

No:

Remove key from ignition, close driver's door and allow 30 seconds to elapse. Repeat

steps

1 - 6 and check that adjustment cannot be made.

Test complete; proceed to Memory Position Set.

Abort

test and refer to Diagnostic Sub

-Routines.

4.

Abort test and refer to Diagnostic Sub-Routines.

5.

6.

Abort test and refer to Diagnostic Sub-Routines.

7.

8.

Memory set position - drivefs side

1.

2.

3.

4.

5.

6.

7.

8.

Position the entry / exit switch, located on the LH side of the steering column, to off and

insert the key in the ignition.

Operate switches to position column, mirrors and seats to preferred positions.

Select 'memory' on the driver's door switch pack. Check that switch illuminates.

Depress desired memory button,

1,2 or 3, on door switch pack within 4 seconds of

memory select. Check that a chime sounds to confirm memory storage.

Operate the switches

so that memorized positions are changed. Depress relevant memory

option button,

1,2 or 3 and check that all positional settings are restored as memorized.

Remove key from ignition, close all doors and allow

30 seconds to elapse. Repeat steps 1

to 4 and check that adjustment cannot be made.

Readjust settings so that memorized positions are changed, leave the vehicle and operate

remote memory recall by locking and unlocking using the remote transmitter. Use both

transmitters to check both memory positions. Check all positional settings are restored as

memorized.

Yes: Proceed to step

8.

No:

Test complete. Abort

test and refer to Diagnostic Sub

-Routines.

X300 EDM Issue 1 August 1994 15.4 - 14

Page 212 of 327

Carry out the passenger seat position adjustments procedure below under each of the conditions stated below:

Key in ignition barrel

. Passenger's door open

. Passenger's closed within the last 30 seconds

0 . Auxiliary ON

Passenger seat position adjustments

1.

2.

3.

4.

5.

0

6.

7.

8.

Locate seat switch pack on the side of the seat cushion.

Operate the fore

/ aft movement control switch. Does the seat respond in the correct manner?

Yes: Proceed to step

3.

No:

Operate front and rear, raise / lower movement control switches. Does seat respond in the

correct manner in each case?

Yes: Proceed to step

4.

No:

Operate squab recline / incline movement control switch. Does squab respond in correct

manner?

Yes: Proceed to step

5.

No:

Operate lumbar pump inflate / deflate control switch. Does lumbar pad stiffen and slacken

accordingly?

Yes: Proceed to step

6

No:

Operate headrest raise / lower switch. Does headrest respond in correct manner?

Yes: Proceed to step

7.

No:

Remove key from ignition, close passenger's door and allow 30 seconds to elapse. Repeat

steps

1 - 6 and check that adjustment cannot be made.

Test complete; proceed to Memory Position Set

Abort

test and refer to Diagnostic Sub

-Routines.

Abort test and refer to Diagnostic Sub

-Routines.

Abort test and refer to Diagnostic Sub

-Routines.

Abort test and refer to Diagnostic Sub

-Routines.

Abort test and refer to Diagnostic Sub

-Routines.

Memory

set position - passenger's side

1.

2.

0 3.

4.

5.

6.

7.

0

Insert the key in the ignition.

Operate switches to adjust seat to preferred positions.

Select 'memory' on the passenger's door switch pack. Check that switch surround

i I I um i nates.

Depress desired memory button,

1,2 or 3, on door switch pack within 4 seconds of

memory select. Check that

a chime sounds to confirm memory storage.

Operate the switches

so that memorized positions are changed. Depress relevant memory

option button,

1, 2 or 3 and check that all positional settings are restored as memorized.

Yes: Proceed to step

6.

No:

Remove key from ignition, close door and allow 30 seconds to elapse. Repeat steps 1 - 4

and check that adjustment cannot be made.

Test complete. Abort

test and refer to Diagnostic Sub

-Routines.

X300 EDM 15.4 - 15 Issue 1 August 1994

Page 213 of 327

Electrical rl

Carry out the exit 1 entry mode procedure below under the conditions stated below:

. Key in ignition barrel

. Driver's door closed

. Auxiliary ON

. Park brake ON

. Gear selector in Park.

Exit 1 Entry Mode

1.

2.

3.

From the driver's seat, position the memory mode switch, located on the LH side of the

steering column, to auto.

Operate the seat, column and mirror switches to preferred driving position.

Note:

Remove key from ignition. Check that seat moves backwards and column tilts upwards

and away, creating maximum space for exit.

Yes: Proceed to step

4.

No:

Seat must be a minimum of 50mm from rear end stop.

Abort test and refer to Diagnostic Sub

-Routines.

4.

5.

3.

Refit key in ignition, open driver's door. Check that seat moves backwards and column tilts

upwards and away, creating maximum space for exit.

Yes: Proceed to step

5.

No:

Leave key in ignition and exit the vehicle, closing driver's door. Ensure that column and

seat return to driving position. Re-enter vehicle and ensure that column and seat move to

entry position. Close door and check that seat

/ column return to previously selected

driving positions.

Yes: Test complete.

No: Refer to Diagnostic Sub-Routines.

Abort

test and refer to Diagnostic Sub

-Routines.

Seat heaters (driver and passenger)

1.

2.

Turn ignition ON and locate heater select switch on the center console.

Operate the switch to initiate seat heating. Does the switch surround illuminate?

Yes: Proceed to step

3.

No:

Allow sufficient time for heater to take effect. Does seat heat level increase in all

designated areas?

Abort

test and refer to Diagnostic Sub

-Routines.

4.

5.

Yes: Proceed to step 4.

No:

Allow time span to exceed 12 minutes. Does switch surround light extinguish and heating

cease?

Yes: Proceed to step

5.

No:

Re-select heating, allow cycle to commence then operate switch again. Does switch

surround light extinguish and heating cease?

Yes: Test complete

No: Refer to Diagnostic Sub-Routines.

Abort

test and refer to Diagnostic Sub

-Routines.

Abort test and refer to Diagnostic Sub

-Routines.

Page 214 of 327

Electrical rl

15.4.8 DlAG NOSTIC SUB-ROU T1 NES

0

The following information details possible fault conditions, causes and remedies. Detail test procedures for compo-

nents are covered in 'PIN-POINT TESTS' (Sub-Section 15.4.9).

Fault:

Possible causes:

Remedy:

Fault: Possible causes:

Remedy:

0

Fault:

Possible causes:

Remedy:

Fault:

Possible causes:

Remedy: Driver's

seat adjustment inoperative

1.

2.

3. Mechanical mechanism fault.

1.

2.

3.

No power supply to SCM.

Wiring harness or connectors faulty.

Check fuses

in 'A' post base fuse boxes.

Check harness and connectors between

SCM -fuse box,

SCM

-switch pack and SCM - motors.

Identify and repair mechanical faults.

Seat positional adjustment restricted

1.

2. Motor faulty.

3. Switch faulty.

4. Mechanical mechanism fault.

5. SCM faulty.

1.

2. Renew motor.

3. Renew switch pack.

4.

5. SCM faulty.

Harness

wiring or connector fault.

Examine wiring and connectors between SCM

- switch

pack and SCM

- motors.

Identify and repair mechanical faults.

Seat lumbar pump only inoperative

1.

2.

3. Motor faulty.

4. Switch faulty.

5. Mechanical mechanism

fault.

1.

2.

3. Renew motor.

4. Renew switch.

5. No

power supply to SCM.

Harness wiring or connector fault.

Check fuses in

'A' post base fuse boxes.

Examine wiring and connectors between SCM

- switch

pack and SCM

- motors.

Identify and repair mechanical faults.

Seat heaters only inoperative

1.

2.

3. Heater element faulty.

4. Heater thermostat faulty.

5. Heater switch faulty.

6. Body processor signal fault.

1.

2.

3.

4. Renew faulty switch.

5.

No power supply to SCM.

Wiring harness or connectors faulty.

Check fuses in

'A' post base fuse boxes.

Examine harness and connectors between SCM

- heater

circuit and SCM

- BPU.

Locate and renew faulty heater and thermostat unit.

Refer to BPU fault diagnosis.

X300 EDM 15.4 - 17 Issue 1 August 1994

Page 215 of 327

Electrical IT

Fault:

Possible causes:

Remedy:

Fault: Possible causes:

Remedy:

Fault:

Possible causes:

Remedy:

Fault:

Possible causes:

Remedy:

Fault:

Possible causes:

Remedy: Steering

column positional adjustment inoperative

1. No power supply.

2. Wiring harness or connector fault.

3. Switch faulty.

4. Mechanical failure.

1. 2. Examine harness and connectors between S 1 CM -

3. Renew switch.

4.

Check fuses in 'A' post base fuse boxes.

fuse,

S I C CM - joy-stick switch and SI C CM - motors.

Identify and repair mechanical faults.

Steering column positional adjustment restricted

1. Wiring harness or connector fault.

2. Motor faulty.

3. Switch faulty.

4.

1.

2. Renew faulty motor.

3. Renew faulty switch.

4.

M echa n ica I mechanism fa i I u re.

Examine harness and connectors between

S 1 C CM -

motors and SI C CM and switch.

Identify and repair mechanical faults.

Rear view mirror positional adjustment inoperative or restricted

1. No power supply.

2.

3. Motor faulty.

4. Switch faulty.

5. Mechanical mechanism failure.

1.

2.

3. Renew faulty motor.

4. Renew faulty switch.

5.

Wiring harness or connector fault.

Check fuses in

'A' post base fuse boxes.

Examine harness and connectors between

S 1 C CM -

motors and SI C CM and switch.

Identify and repair mechanical faults.

Recall / Memory set facility inoperative or incorrect

1. Wiring harness or connector fault.

2. Potentiometers out of range or faulty.

3. Switches faulty.

1. Examine harness and connectors between SCM, S I C

CM and switches.

2. PDU only to check.

3. Renew faulty switches.

Exit \Entry facility inoperative or incorrect

1. Wiring harness or connector fault.

2. Potentiometers out of range or faulty.

3. Switch faulty.

1. Examine harness and connectors between SCM, S 1 C

CM and switches.

2.. PDU only to check.

3. Renew faulty switches. ~

Issue 1 August 1994 15.4 - 18 X300 EDM

Page 216 of 327

15.4.9 PIN-POINT TESTS

The following tests give detailed information on component fault diagnosis. Refer to sub-section 15.4.9.16 for key to

schematic diagrams.

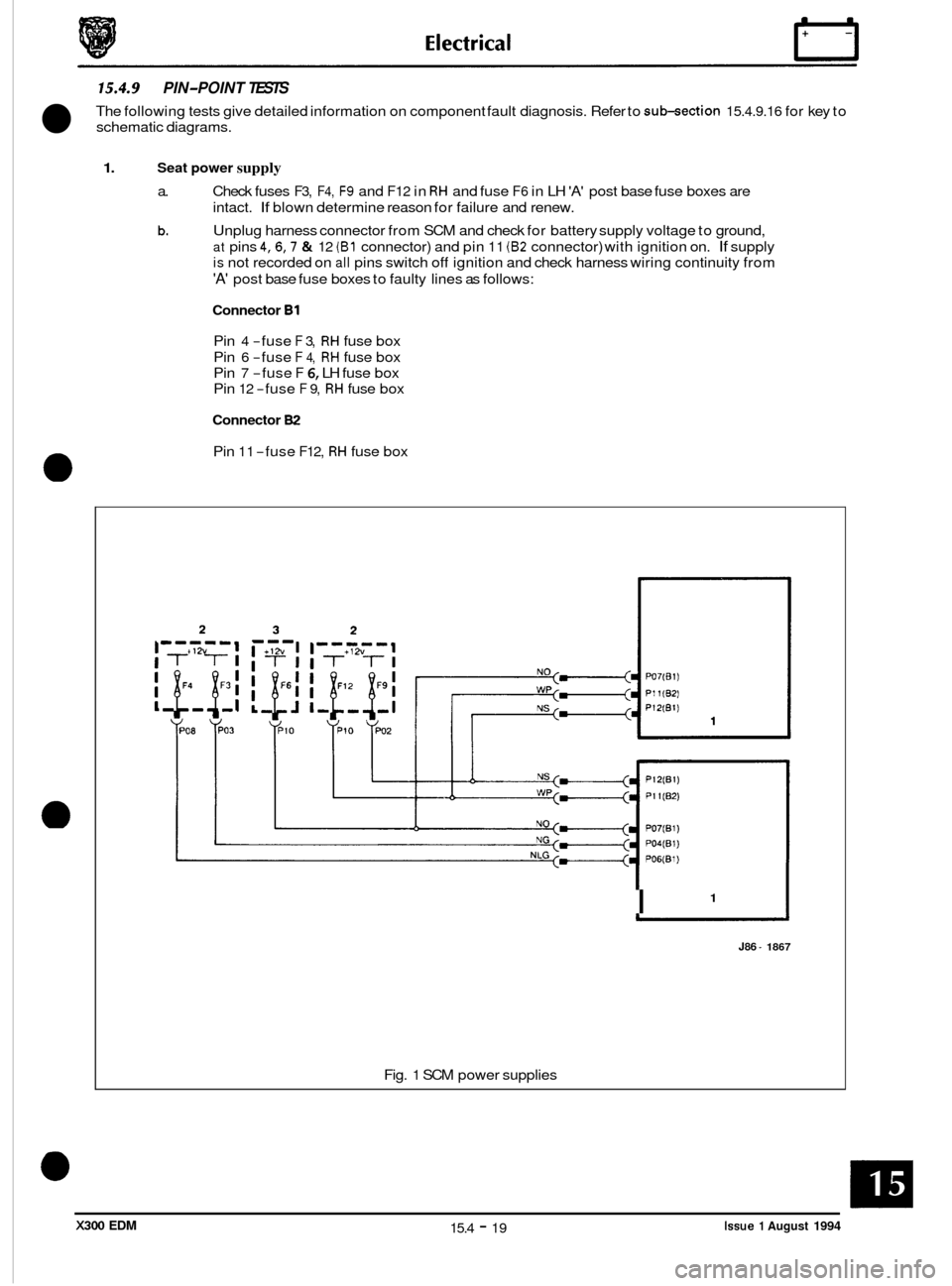

1. Seat power supply

a.

b.

Check fuses F3, F4, F9 and F12 in RH and fuse F6 in LH 'A' post base fuse boxes are

intact.

If blown determine reason for failure and renew.

Unplug harness connector from SCM and check for battery supply voltage to ground,

at pins 4,6,7 & 12 (B1 connector) and pin 11 (82 connector) with ignition on. If supply

is not recorded on all pins switch off ignition and check harness wiring continuity from

'A' post base fuse boxes to faulty lines as follows:

Connector B1

Pin 4 -fuse F 3, RH fuse box

Pin

6 -fuse F 4, RH fuse box

Pin

7 -fuse F 6, LH fuse box

Pin

12 -fuse F 9, RH fuse box

Connector 82

Pin 11 -fuse F12, RH fuse box

1 I

J86 - 1867

Fig. 1 SCM power supplies

Issue 1 August 1994 15.4 - 19 X300 EDM

Page 217 of 327

n E I ectr ical

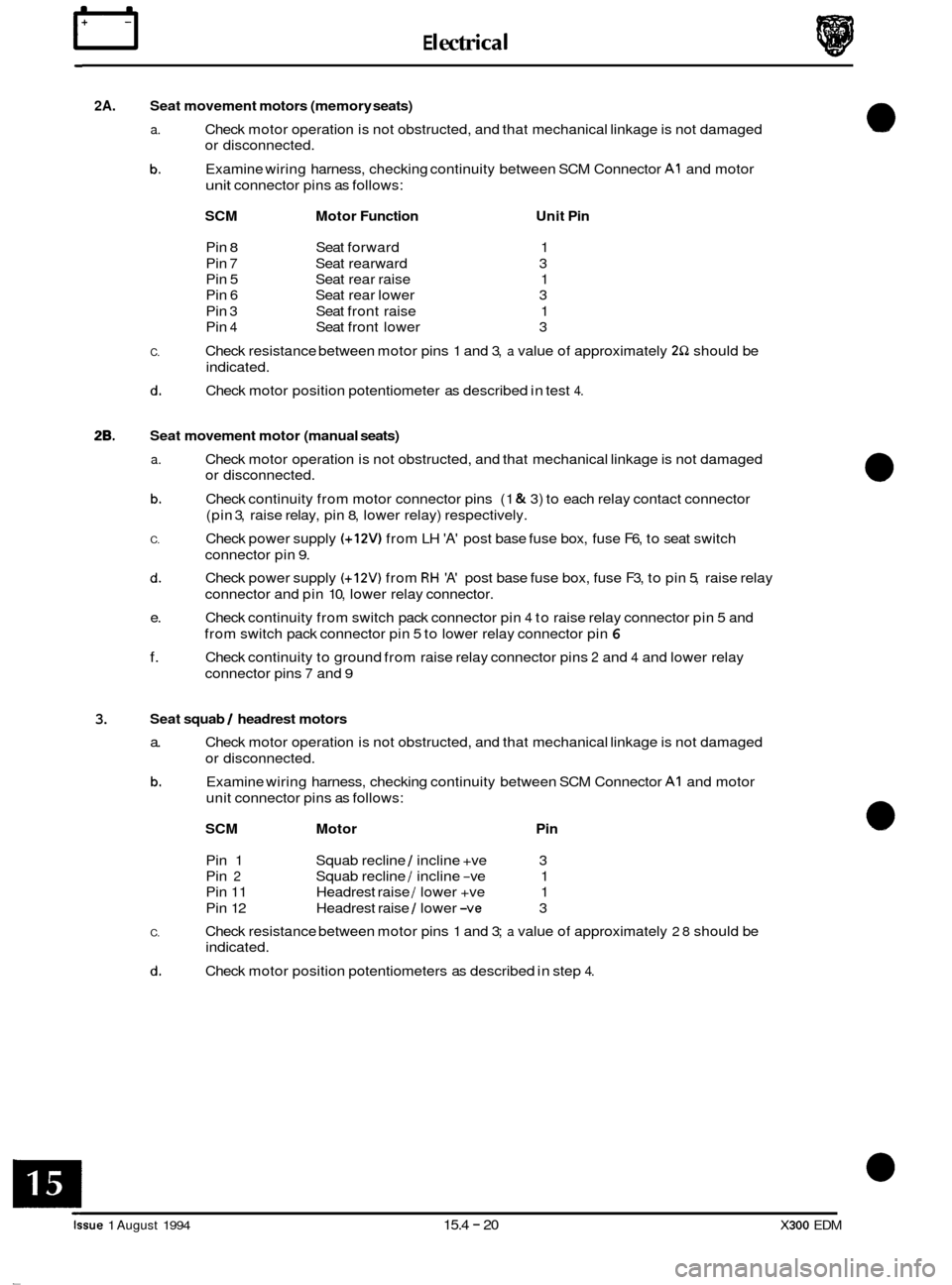

2A. Seat movement motors (memory seats)

a.

b.

Check motor operation is not obstructed, and that mechanical linkage is not damaged

or disconnected.

Examine wiring harness, checking continuity between SCM Connector

A1 and motor

unit connector pins as follows:

SCM Motor Function Unit Pin

Pin 8 Seat forward 1

Pin

7 Seat rearward 3

Pin 5 Seat rear raise 1

Pin

6 Seat rear lower 3

Pin 3 Seat front raise 1

Pin

4 Seat front lower 3

Check resistance between motor pins 1 and 3, a value of approximately 2S2 should be

indicated.

Check motor position potentiometer as described in test

4.

C.

d.

28. Seat movement motor (manual seats)

a.

b.

C.

d.

Check motor operation is not obstructed, and that mechanical linkage is not damaged

or disconnected.

Check continuity from motor connector pins (1

& 3) to each relay contact connector

(pin

3, raise relay, pin 8, lower relay) respectively.

Check power supply

(+12V) from LH 'A' post base fuse box, fuse F6, to seat switch

connector pin

9.

Check power supply (+12V) from RH 'A' post base fuse box, fuse F3, to pin 5, raise relay

connector and pin 10, lower relay connector.

Check continuity from switch pack connector pin

4 to raise relay connector pin 5 and

from switch pack connector pin 5 to lower relay connector pin

6

Check continuity to ground from raise relay connector pins 2 and 4 and lower relay

connector pins

7 and 9

e.

f.

3. Seat squab 1 headrest motors

a.

b.

Check motor operation is not obstructed, and that mechanical linkage is not damaged

or disconnected.

Examine wiring harness, checking continuity between SCM Connector

A1 and motor

unit connector pins as follows:

SCM Motor Pin

Pin 1 Squab recline 1 incline +ve 3

Pin 2 Squab recline 1 incline -ve 1

Pin 11 Headrest raise

1 lower +ve 1

Pin 12 Headrest raise

1 lower -ve 3

Check resistance between motor pins 1 and 3; a value of approximately 28 should be

indicated.

Check motor position potentiometers as described in step

4.

C.

d.

Issue 1 August 1994 15.4 - 20 X300 EDM

Page 218 of 327

E I ect r ical

0

0

0

J86-1868

Fig. 1 Seat Motors

11

J86 - 1870

Fig. 2 Seat Motors (Manual)

X300 EDM 15.4 - 21 Issue 1 August 1994

Page 219 of 327

n E I ect r ica I

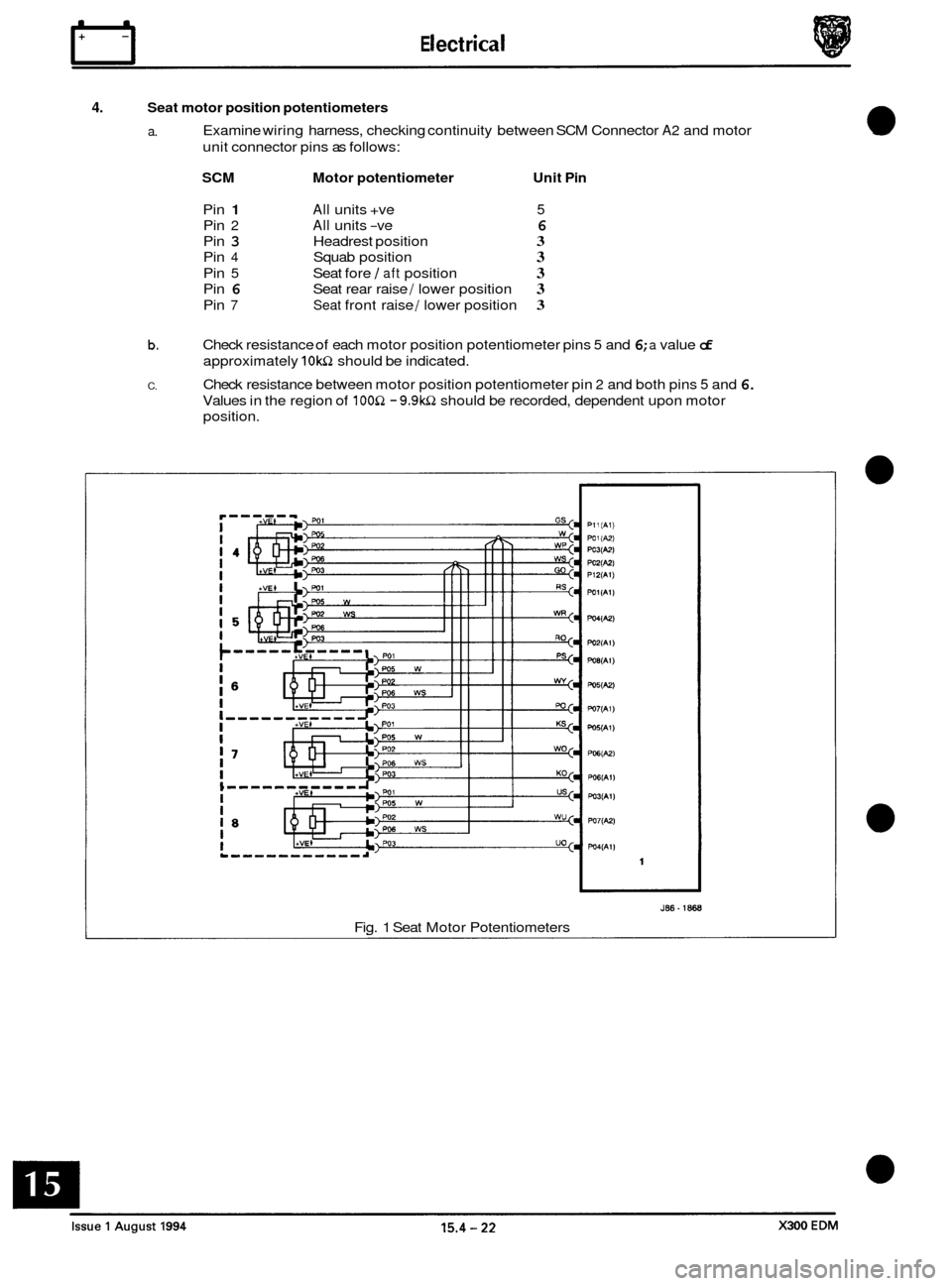

4. Seat motor position potentiometers

a. Examine wiring harness, checking continuity between SCM Connector A2 and motor

unit connector pins as follows:

SCM Motor potentiometer Unit Pin

Pin 1 All units +ve 5

Pin 2 All units -ve 6

Pin 3 Headrest position 3

Pin 4 Squab position 3

Pin 5 Seat fore / aft position 3

Pin 6 Seat rear raise / lower position 3

Pin 7 Seat front raise / lower position 3

b. Check resistance of each motor position potentiometer pins 5 and 6; a value of

approximately IOW1 should be indicated.

Check resistance between motor position potentiometer pin

2 and both pins 5 and 6.

Values in the region of 10051 - 9.9W1 should be recorded, dependent upon motor

position.

C.

J86-18MI

Fig. 1 Seat Motor Potentiometers

Page 220 of 327

Electrical

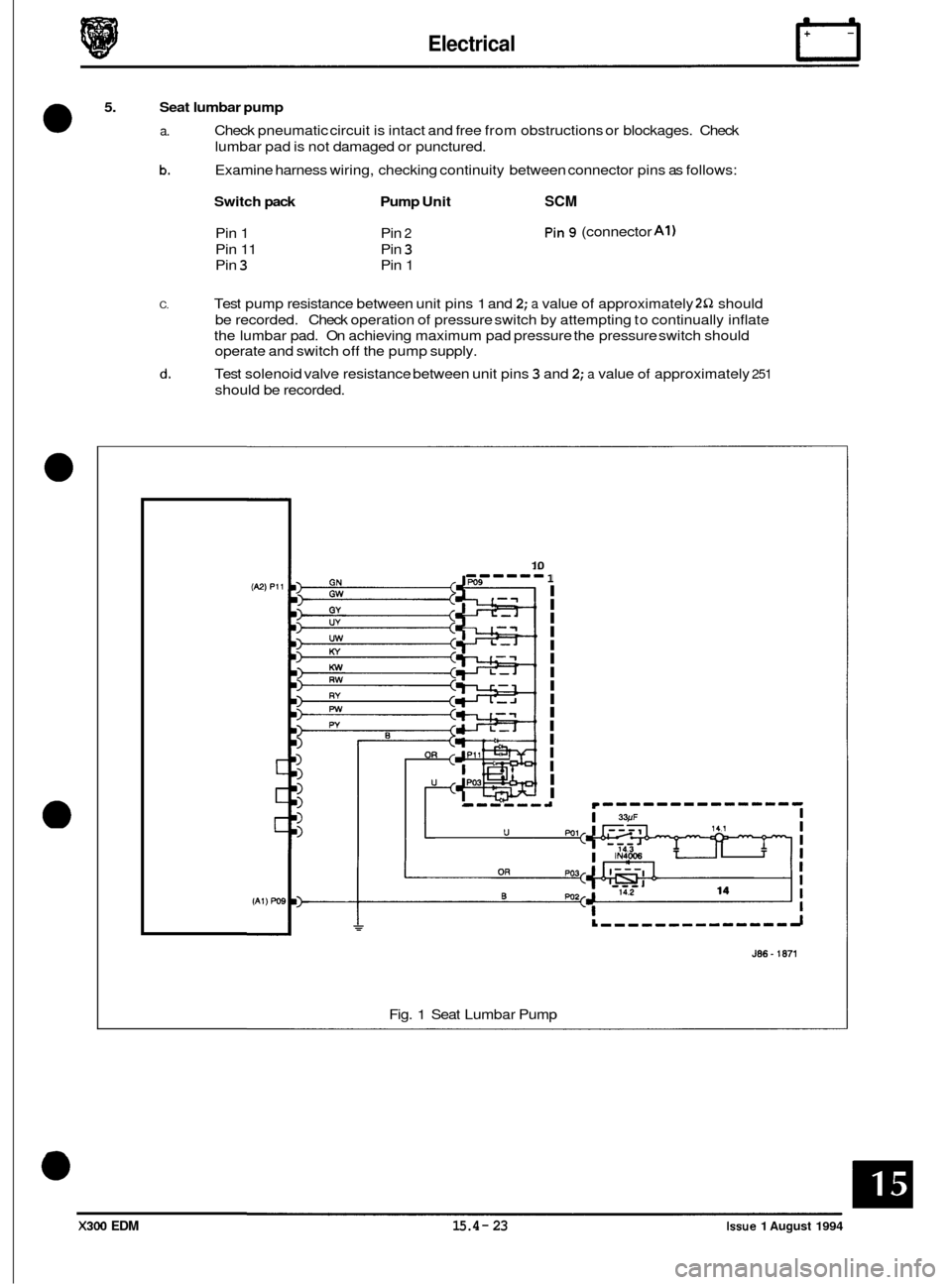

5. Seat lumbar pump

0 a. Check pneumatic circuit is intact and free from obstructions or blockages. Check

lumbar pad is not damaged or punctured.

b. Examine harness wiring, checking continuity between connector pins as follows:

Switch pack Pump Unit SCM

Pin 1

Pin 11

Pin

3

Pin 2

Pin 3

Pin 1

Pin 9 (connector AI)

C. Test pump resistance between unit pins 1 and 2; a value of approximately 2&2 should

be recorded. Check operation

of pressure switch by attempting to continually inflate

the lumbar pad. On achieving maximum pad pressure the pressure switch should

operate and switch

off the pump supply.

Test solenoid valve resistance between unit pins

3 and 2; a value of approximately 251

should be recorded.

d.

P11

10 1 I

I

I

I

I I I I I I I I I

I

I I II

Fig. 1 Seat Lumbar Pump

X300 EDM 15.4 - 23 Issue 1 August 1994