manual transmission JAGUAR XJ6 1994 2.G User Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 48 of 521

Engine (V12)

3.2.1 ENGINE, GENERAL

The twelve cylinder, vee formation engine has a capacity of 6.0 liters. Each cylinder bank has a single overhead

camshaft and two valves percylinder. The engine has a fully mapped engine management system with digital ignition

and two ignition coils.

This section describes the service procedures to be carried out with the engine in situ.

It also covers the renewal of

the engine / transmission unit.

For information relating

tostrip-down, inspedion,fault diagnosis, renovation and rebuild work, referto the VI2 Engine

Service Manual.

X300 VSM 1 Issue 1 August 1994

Page 49 of 521

3.2.2 ENGINE - GEARBOX/ TRANSMISSION

ASSEMBLY, RENEW

SRO 12.37.01/90

The engine /transmission unit on the V12 6.0 liter model is mounted on three engine mounting / bracket assemblies

fitted to the front crossmember on either side of the engine bay. The engine/ transmission rear mount is a mounting

bracket and spring assembly fitted and secured to body underframe longitudinal members. For access to remove the

engine carry

out the following procedures:

WARNING: WHEN WORKING WITHIN THE ENGINE COMPARTMENT, KEEP CLEAR OF THE RADIATOR COOLING

FANS AS THEY COULD START WITHOUT WARNING, EVEN IF THE ENGINE IS NOT RUNNING.

. Remove the hood, see SRO 76.16.01, section 13.

. Remove the two air cleaner assemblies, see SRO’s 19.10.01 & 19.10.02.

. Remove the engine cover, see SRO 12.29.93 (V12 Engine Service Manual).

Depressurize the fuel system, see SRO 19.50.02, section 5.1.

In line with the relevant SRO’s and sections, remove all appropriate obstructing parts, including their fixing and

. Disconnect all mechanical and isolate all electrical linkages leading to and from the engine.

. De-gas the air conditioning system, see section 14, Charge Recovery (System depressurization).

Disconnect

the battery.

mounting arrangements.

CAUTION: Do

not vent refrigerant directly to the atmosphere and always use Jaguar approved recovery/recycle/ra charge equipment.

Drain the engine oil, see 3.2.3 this section.

Drain the coolant, see SRO 26.10.01, section 4.1.

WARNING: DO NOT REMOVE THE HEADER TANK PRESSURE CAP WHILE THE ENGINE IS HOT. IF THE CAP MUST

BE REMOVED, PROTECT THE HANDS AGAINST ESCAPING STEAM AND SLOWLY TURN THE CAP ANTI- CLOCKWISE UNTIL THE EXCESS PRESSURE CAN ESCAPE. LEAVE THE CAP IN THIS POSITION UNTIL ALL

STEAM AND PRESSURE HAS ESCAPED AND THEN REMOVE THE CAP COMPLETELY.

Before

lifting the complete engine/transmission unit with an engine hoist from the engine bay, ensure that two engine

lifting brackets (tool 18G. 1465) are secured equallyspaced to the inlet manifold studs. The four engine lifting brackets

should be positioned towards the front and the rear of the assembly. Ensure the front of thevehicle is jacked

up secure- ly on stands when removing the assembly.

X300 VSM Issue 1 August 1994 2

Page 114 of 521

Manual Transmission & Clutch (AJ16)

SECTlON CONTENTS

Sub-section Title SRO Page

i to iv ............ Preliminary Pages ................................................................ i to iii

7.1.1 ............. Manual Transmission. Description ...................................................... 1

7.1.2 ............. Manual Transmission Assembly, Renew ............................ 37.20.0 1 ............. 2

7.1.3

............. Front OilSeal. Renew .......................................... 37.23.06 ............. 5

7.1.4

............. Rear OilSeal. Renew ........................................... 37.23.01 ............. 6

7.1.5 ............. Gearshift Lever, Renew ......................................... 37.16.04 ............. 6

7.1.6 ............. Gearshift Lever Draught Excluder, Renew ......................... 37.16.05 ............. 6

7.1.7. ............ Gearshift Lever Knob. Renew .................................... 37.16.11 ............. 7

7.1.8. ............ Gearshifi Lever/ Remote Control Assembly, Renew .................. 37.16.20 ............. 7

7.1.9 ............. Gear Selector Shaft - Rear, Overhaul .............................. 37.16.4 1 ............. 9

7.1.10.

........... Reverse Lamp Switch. Renew .................................... 37.27.01 ............. 9

7.1.11 ............ Layshaft Front Seal. Renew ...................................... 37.23.07 ............. 9

7.1.12.

........... Clutch. Description .................................................................. 10

7.1.14.

........... Clutch Assembly, Renew ........................................ 33.10.01 ............ 14

7.1.15. ........... Clutch Master Cylinder, Renew .................................. 33.20.01 ............ 76

7.1.16. ........... Clutch Slave Cylinder, Renew ................................... 33.35.01 ............ 17

7.1.17.

........... Clutch Slave Cylinder, Overhaul ................................. 33.35.07 ............ 17

7.1.18. ........... Clutch Hydraulic System. Bleed .................................. 33.15.01 ............ 18

7 . 1 . 7 3 ............ Clutch. Fault Diagnosis .............................................................. 11

X300 VSM i Issue 1 August 1994

Page 116 of 521

Manual Transmission & clutch (AJ16)

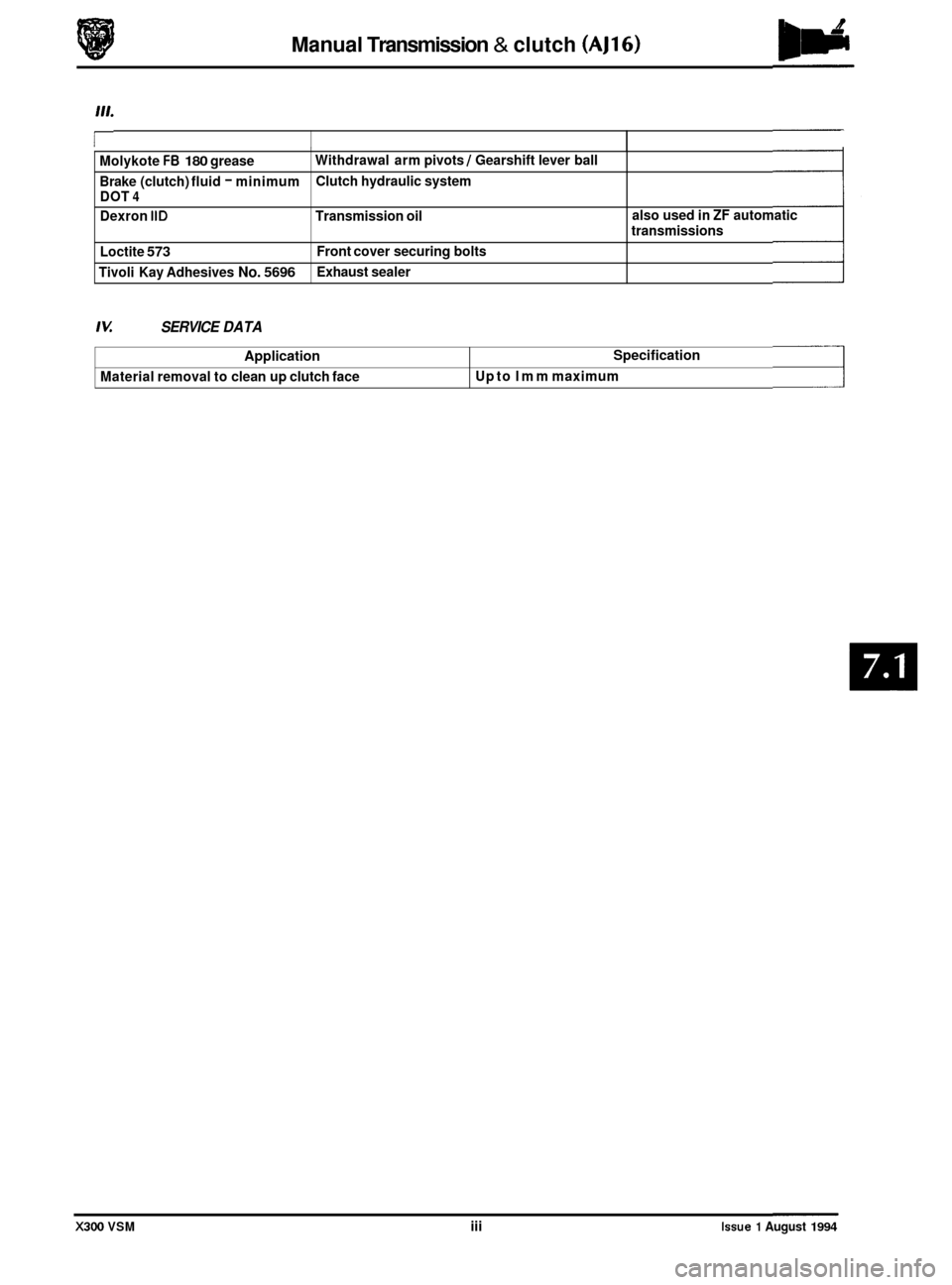

I Molykote FB 180 grease

Brake (clutch) fluid

- minimum

DOT 4

Dexron IID Transmission oil

Loctite

573

Tivoli Kay Adhesives No. 5696

Withdrawal arm pivots / Gearshift lever ball

Clutch hydraulic system

Front cover securing bolts

Exhaust sealer also used

in

ZF automatic

transmissions

Application

Material removal to clean up clutch face

IU SERVICE DATA

Specification

Up to lmm maximum

X300 VSM iii Issue 1 August 1994

Page 118 of 521

Manual Transmission & Clutch (AJ16)

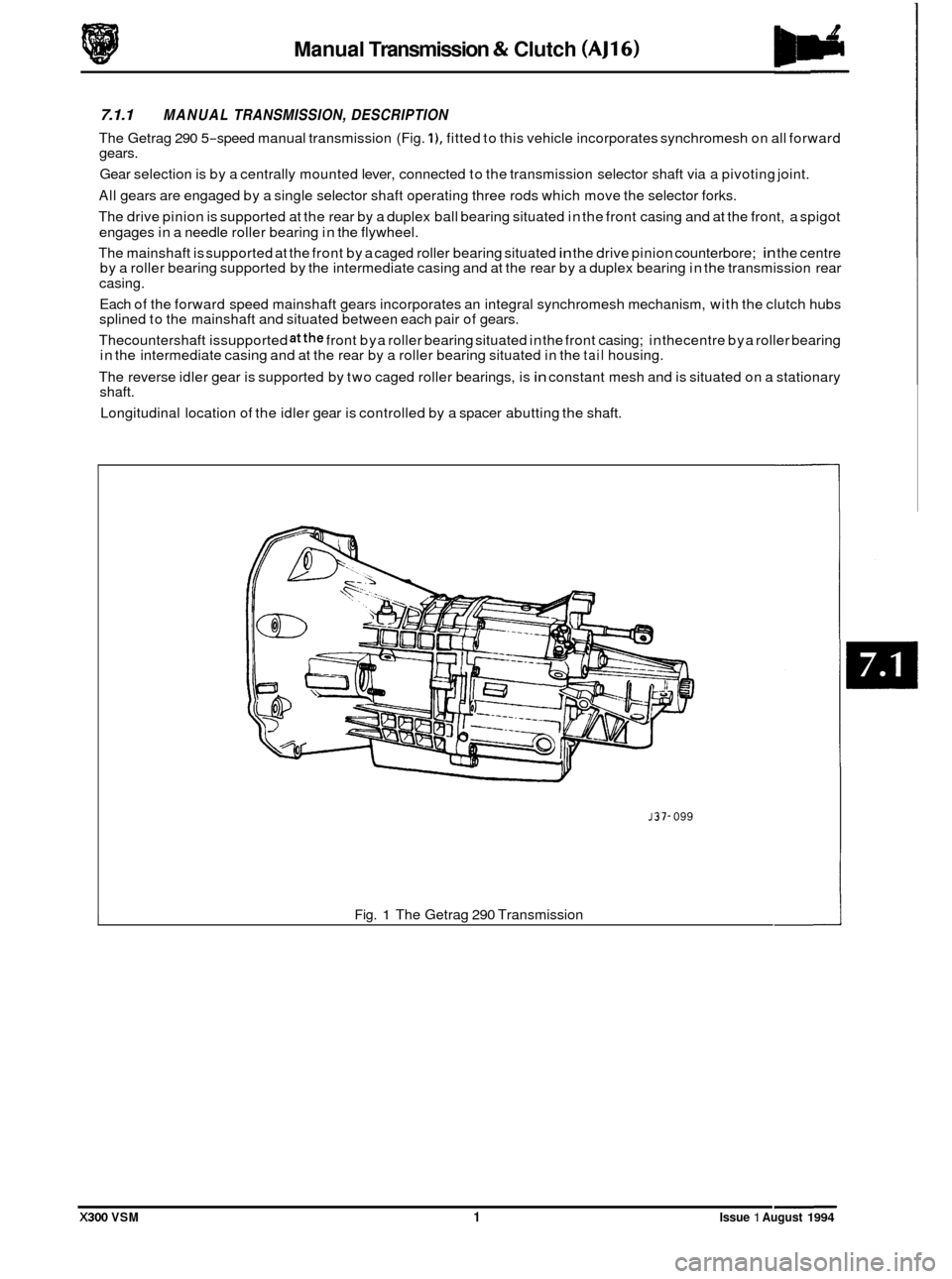

7.1.1 MANUAL TRANSMISSION, DESCRIPTION

The Getrag 290 5-speed manual transmission (Fig. I), fitted to this vehicle incorporates synchromesh on all forward

gears.

Gear selection is by a centrally mounted lever, connected to the transmission selector shaft via a pivoting joint.

All gears are engaged by a single selector shaft operating three rods which move the selector forks.

The drive pinion is supported at the rear by a duplex ball bearing situated in the front casing and at the front, a spigot

engages in a needle roller bearing in the flywheel.

The mainshaft is supported at the front by a caged roller bearing situated

in the drive pinion counterbore; in the centre

by a roller bearing supported by the intermediate casing and at the rear by a duplex bearing in the transmission rear

casing.

Each of the forward speed mainshaft gears incorporates an integral synchromesh mechanism, with the clutch hubs

splined to the mainshaft and situated between each pair of gears.

Thecountershaft issupported

atthe front bya roller bearing situated in the front casing; in thecentre bya roller bearing

in the intermediate casing and at the rear by a roller bearing situated in the tail housing.

The reverse idler gear is supported by two caged roller bearings, is

in constant mesh and is situated on a stationary

shaft.

Longitudinal location of the idler gear is controlled by a spacer abutting the shaft.

J37- 099

Fig. 1 The Getrag 290 Transmission

X300 VSM 1 Issue 1 August 1994

Page 119 of 521

Manual Transmission & Clutch (AJ16)

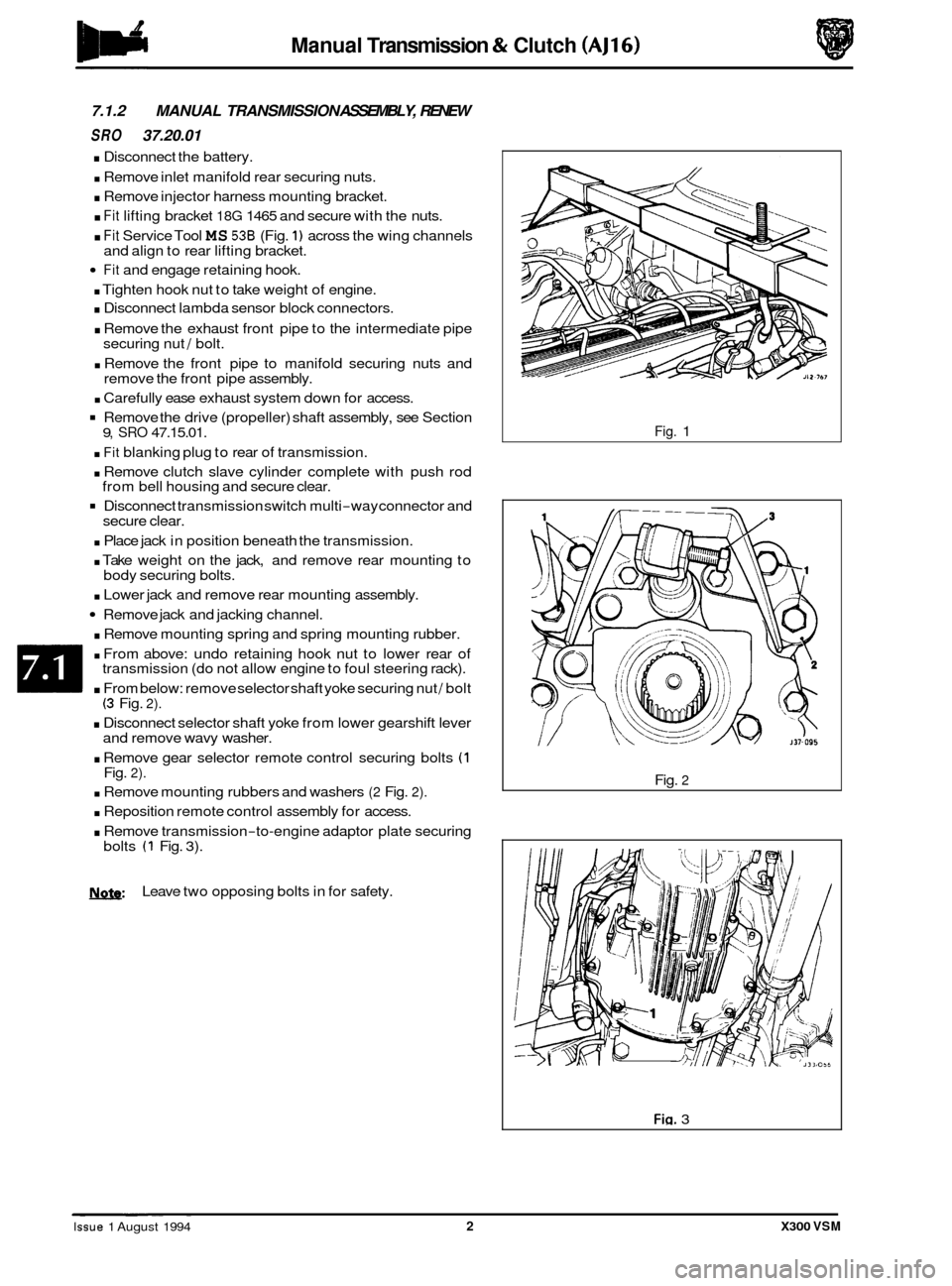

7.1.2 MANUAL TRANSMISSION ASSEMBLY, RENEW

SRO 37.20.01

. Disconnect the battery.

. Remove inlet manifold rear securing nuts.

. Remove injector harness mounting bracket.

. Fit lifting bracket 18G 1465 and secure with the nuts.

. Fit Service Tool MS 536 (Fig. 1) across the wing channels

Fit and engage retaining hook.

. Tighten hook nut to take weight of engine.

. Disconnect lambda sensor block connectors.

. Remove the exhaust front pipe to the intermediate pipe

securing nut / bolt.

. Remove the front pipe to manifold securing nuts and

remove the front pipe assembly.

. Carefully ease exhaust system down for access.

Remove the drive (propeller) shaft assembly, see Section

. Fit blanking plug to rear of transmission.

. Remove clutch slave cylinder complete with push rod

Disconnect transmission switch multi-way connector and

. Place jack in position beneath the transmission.

. Take weight on the jack, and remove rear mounting to

. Lower jack and remove rear mounting assembly.

Remove jack and jacking channel.

. Remove mounting spring and spring mounting rubber.

. From above: undo retaining hook nut to lower rear of

transmission (do not allow engine to foul steering rack).

. From below: remove selector shaft yoke securing nut / bolt (3 Fig. 2).

. Disconnect selector shaft yoke from lower gearshift lever

and remove wavy washer.

. Remove gear selector remote control securing bolts (1 Fig. 2).

. Remove mounting rubbers and washers (2 Fig. 2).

. Reposition remote control assembly for access.

. Remove transmission-to-engine adaptor plate securing

and

align to rear lifting bracket.

9, SRO 47.15.01.

from bell housing and secure clear.

secure clear.

body securing bolts.

bolts

(1 Fig. 3).

N.&: Leave two opposing bolts in for safety.

Fig. 1

Fig.

2

Fig. 3 ~ ~ ~~ ~

Issue 1 August 1994 2 X300 VSM

Page 120 of 521

Manual Transmission & Clutch (AJ16)

. Remove front clamp from unit lift.

. Raise / lower unit with jack, no stands.

. Traverse lift under ramp and take weight of transmission.

. Adjust jacking platform angles to suit transmission.

. Adjust side and rear clamps to suit transmission and tighten clamp wing nuts.

. Fit the safety chain assembly to left hand arm of lift, and secure with peg.

Pass safety chain over transmission and engage in front arm of lift. Tighten the safety chain adjuster.

. Remove remaining transmission to adaptor plate securing bolts and carefully lower transmission from engine.

. Remove transmission from ramp area.

. Remove clutch release bearing assembly from release lever.

. Remove clutch release lever retaining clip and remove lever.

. Remove release lever pivot pin.

Remove transmission switch.

. Remove rear mounting spring retainer securing nut.

. Reposition selector shaft pin cover.

0

Remove rear mounting spring retainer and remove rear mounting assembly.

Remove selector shaft yoke to selector shaft retaining pin and remove the yoke.

. Remove slave cylinder securing studs.

. Remove the transmission from the unit lift.

. Remove transmission drain plug and allow to drain, refit

the drain plug.

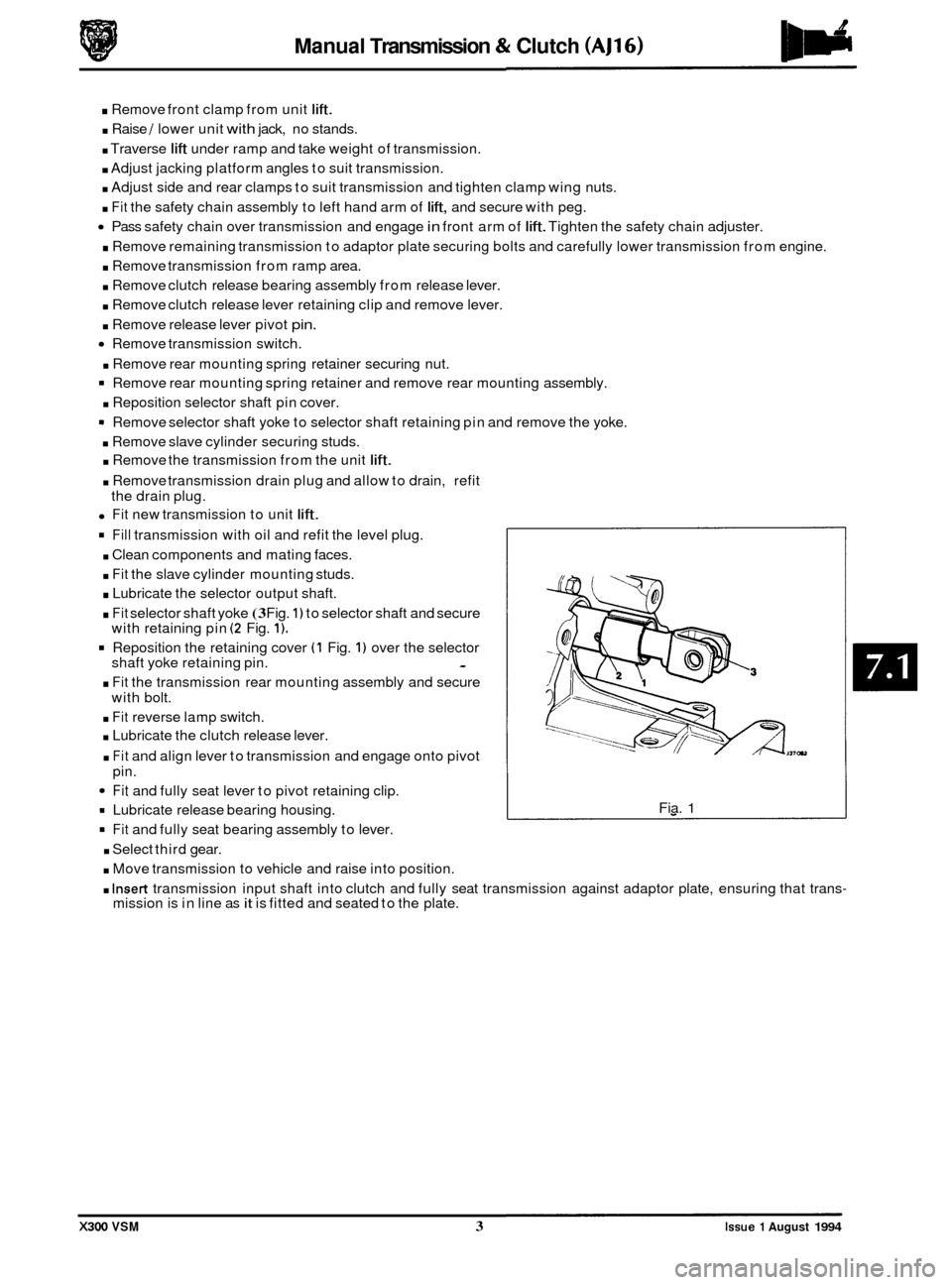

Fit new transmission to unit lift.

Fill transmission with oil and refit the level plug.

. Clean components and mating faces.

. Fit the slave cylinder mounting studs.

. Lubricate the selector output shaft.

. Fit selector shaft yoke (3 Fig. 1) to selector shaft and secure

with retaining pin (2 Fig. 1).

Reposition the retaining cover (1 Fig. 1) over the selector

shaft yoke retaining pin. -

. Fit the transmission rear mounting assembly and secure

with bolt.

. Fit reverse lamp switch.

. Lubricate the clutch release lever.

. Fit and align lever to transmission and engage onto pivot

pin.

Fit and fully seat lever to pivot retaining clip.

= Lubricate release bearing housing.

9 Fit and fully seat bearing assembly to lever.

. Select third gear.

. Move transmission to vehicle and raise into position.

Fia. 1

. Insert transmission input shaft into clutch and fully seat transmission against adaptor plate, ensuring that trans- mission is in line as it is fitted and seated to the plate.

X300 VSM 3 Issue 1 August 1994

Page 121 of 521

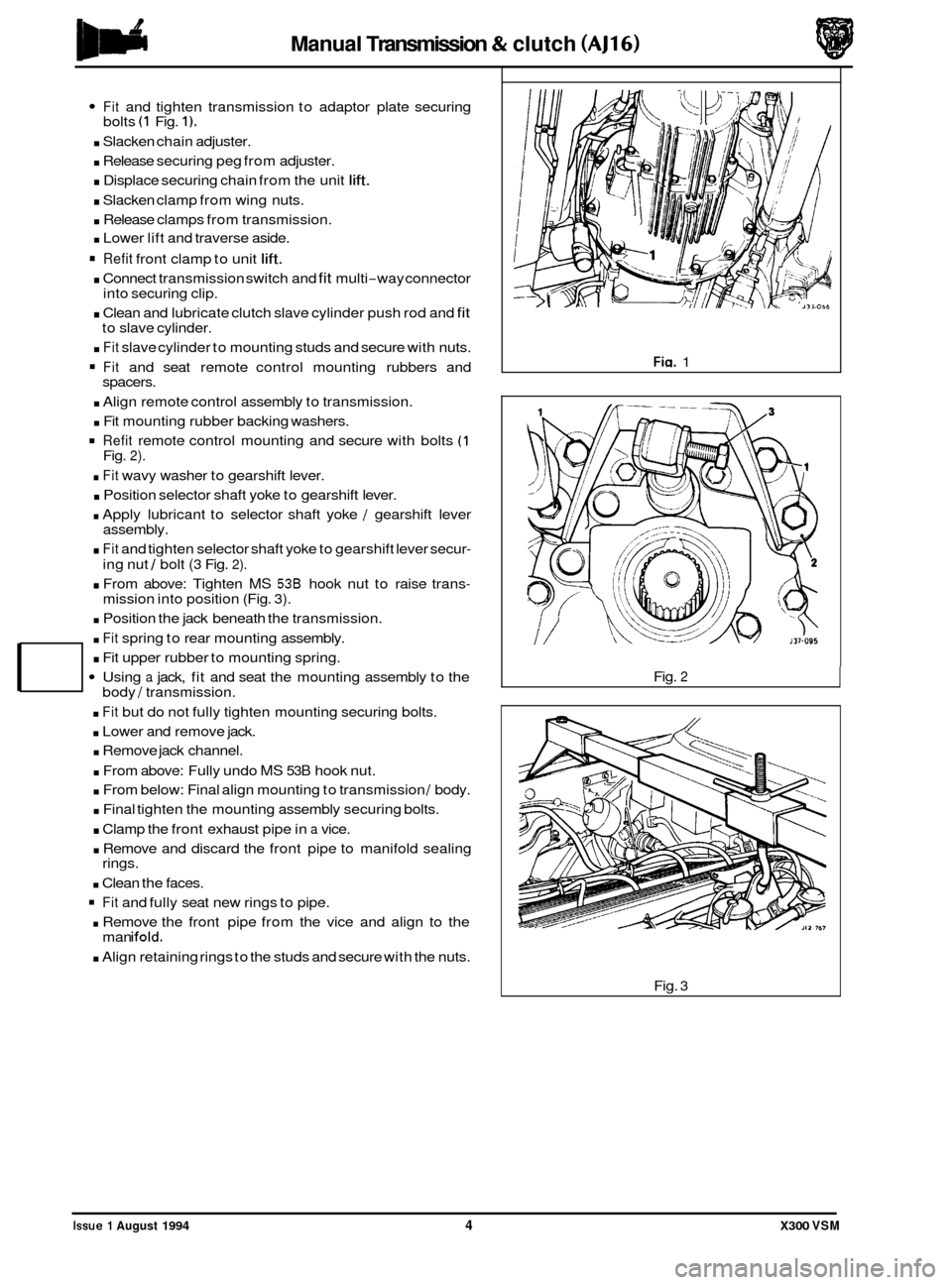

Manual Transmission & clutch (AJ16)

Fit and tighten transmission to adaptor plate securing

. Slacken chain adjuster.

. Release securing peg from adjuster.

. Displace securing chain from the unit lift.

. Slacken clamp from wing nuts.

. Release clamps from transmission.

. Lower lift and traverse aside.

Refit front clamp to unit lift.

. Connect transmission switch and fit multi-way connector

. Clean and lubricate clutch slave cylinder push rod and fit

. Fit slave cylinder to mounting studs and secure with nuts.

Fit and seat remote control mounting rubbers and

. Align remote control assembly to transmission.

. Fit mounting rubber backing washers.

Refit remote control mounting and secure with bolts (1

. Fit wavy washer to gearshift lever.

. Position selector shaft yoke to gearshift lever.

. Apply lubricant to selector shaft yoke / gearshift lever

. Fit and tighten selector shaft yoke to gearshift lever secur-

. From above: Tighten MS 538 hook nut to raise trans-

. Position the jack beneath the transmission.

bolts

(1 Fig. 1).

into

securing clip.

to slave cylinder.

spacers.

Fig.

2).

assembly.

ing nut

/ bolt (3 Fig. 2).

mission into position (Fig. 3).

. Fit spring to rear mounting assembly.

. Fit upper rubber to mounting spring.

Using a jack, fit and seat the mounting assembly to the body / transmission.

. Fit but do not fully tighten mounting securing bolts.

. Lower and remove jack.

. Remove jack channel.

. From above: Fully undo MS 53B hook nut.

. From below: Final align mounting to transmission / body.

. Final tighten the mounting assembly securing bolts.

. Clamp the front exhaust pipe in a vice.

. Remove and discard the front pipe to manifold sealing

. Clean the faces.

Fit and fully seat new rings to pipe.

. Remove the front pipe from the vice and align to the

. Align retaining rings to the studs and secure with the nuts.

rings.

man

ifold.

Fin. 1

Fig.

2

Fig. 3

Issue 1 August 1994 4 X300 VSM

Page 123 of 521

Manual Transmission & Clutch (AJ16)

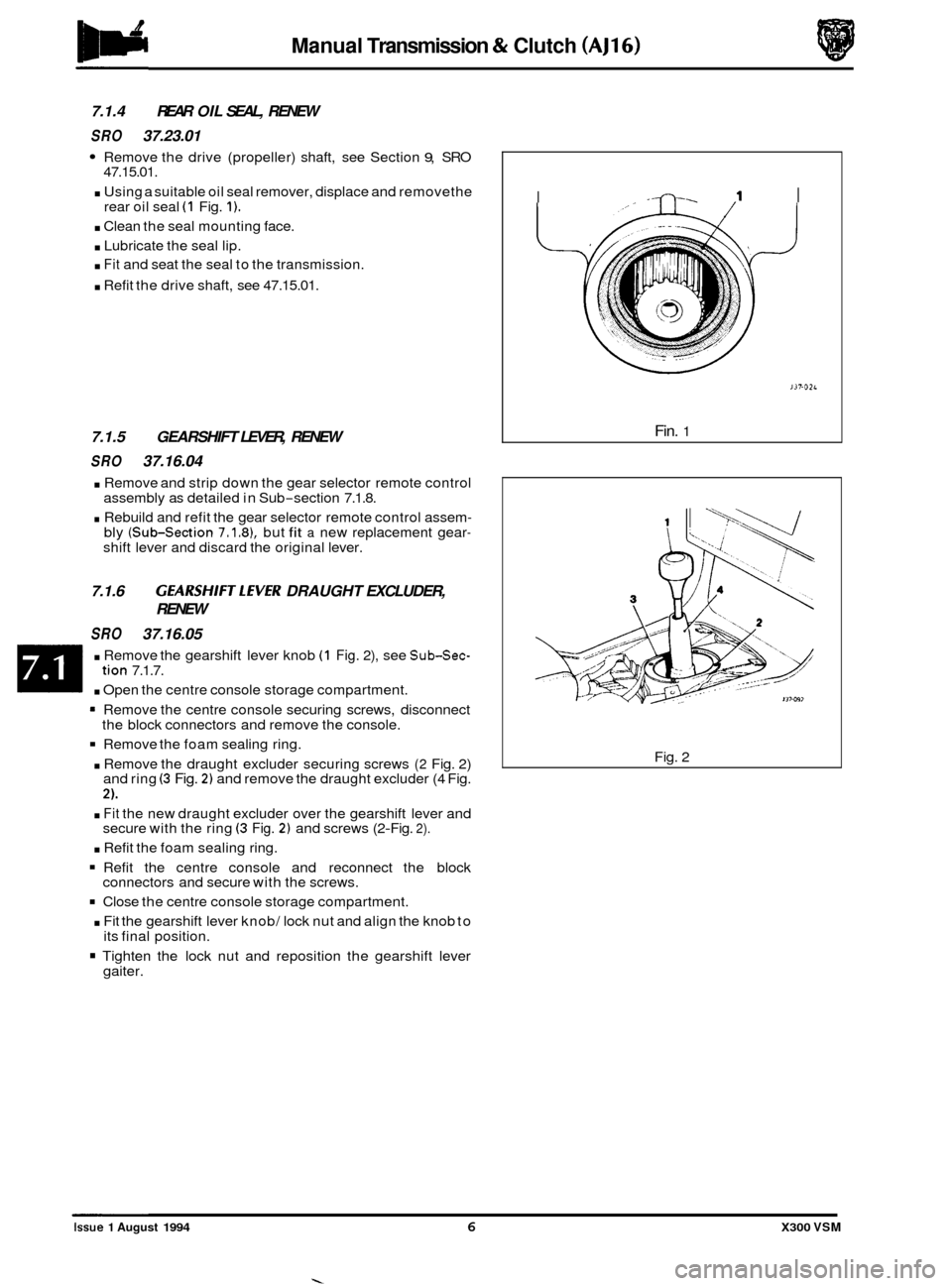

7.1.4 REAR OIL SEAL, RENEW

SRO 37.23.01

Remove the drive (propeller) shaft, see Section 9, SRO

47.15.01.

. Using a suitable oil seal remover, displace and removethe

rear oil seal (1 Fig. 1).

. Clean the seal mounting face.

. Lubricate the seal lip.

. Fit and seat the seal to the transmission.

. Refit the drive shaft, see 47.15.01.

7.1.5 GEARSHIFT LEVER, RENEW

SRO 37.16.04

. Remove and strip down the gear selector remote control

assembly as detailed in Sub-section 7.1.8.

. Rebuild and refit the gear selector remote control assem- bly (Sub-section 7.1.81, but fit a new replacement gear- shift lever and discard the original lever.

7.1.6 GEARSHIFTLEVER DRAUGHT EXCLUDER,

SRO 37.16.05 RENEW

. Remove

the gearshift lever knob (1 Fig. 2), see Sub-Sec-

. Open the centre console storage compartment.

tion 7.1.7.

= Remove the centre console securing screws, disconnect

Remove the foam sealing ring.

. Remove the draught excluder securing screws (2 Fig. 2)

and ring (3 Fig. 2) and remove the draught excluder (4 Fig.

2).

. Fit the new draught excluder over the gearshift lever and

secure with the ring (3 Fig. 2) and screws (2-Fig. 2).

. Refit the foam sealing ring.

Refit the centre console and reconnect the block

Close the centre console storage compartment.

. Fit the gearshift lever knob/ lock nut and align the knob to

Tighten the lock nut and reposition the gearshift lever

the

block connectors and remove the console.

connectors and secure with the screws.

its final position.

gaiter.

I --0-. I

J37.02~

Fin. 1

Fig. 2

0

0

0

Issue 1 August 1994 6 X300 VSM

Page 124 of 521

Manual Transmission & Clutch (AJ16)

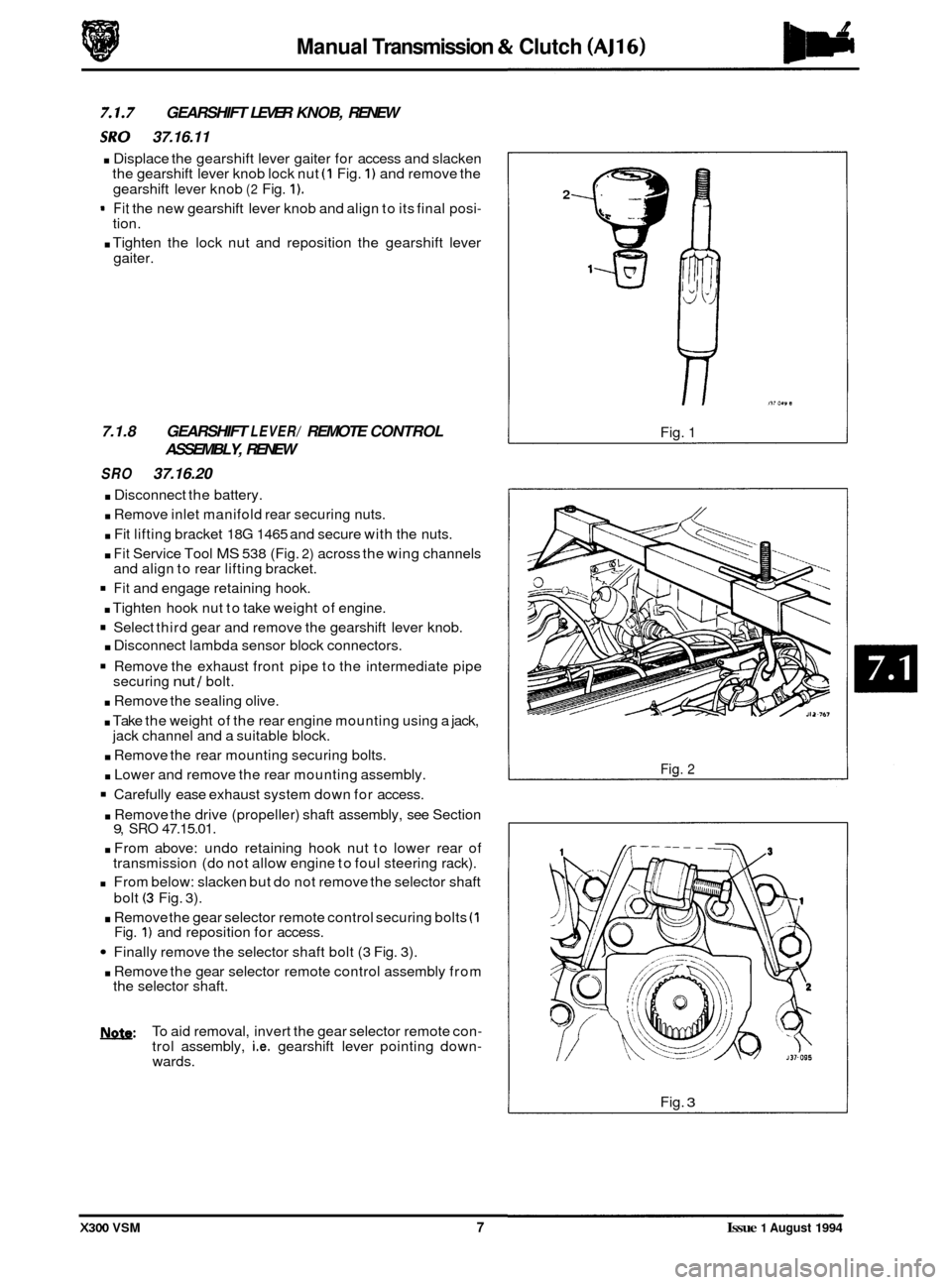

GEARSHIFT LEVER KNOB, RENEW

:RY 37.16.11

. Displace the gearshift lever gaiter for access and slacken

the gearshift lever knob lock nut (1 Fig. 1) and remove the

gearshift lever knob

(2 Fig. 1).

- Fit the new gearshift lever knob and align to its final posi- tion.

. Tighten the lock nut and reposition the gearshift lever

gaiter.

7.1.8 GEARSHIFT LEVER/ REMOTE CONTROL

ASSEMBLY, RENEW

SRO 37.16.20

. Disconnect the battery.

. Remove inlet manifold rear securing nuts.

. Fit lifting bracket 18G 1465 and secure with the nuts.

. Fit Service Tool MS 538 (Fig. 2) across the wing channels

and align to rear lifting bracket.

Fit and engage retaining hook.

. Tighten hook nut to take weight of engine.

Select third gear and remove the gearshift lever knob.

. Disconnect lambda sensor block connectors.

Remove the exhaust front pipe to the intermediate pipe

securing nut / bolt.

. Remove the sealing olive.

. Take the weight of the rear engine mounting using a jack,

. Remove the rear mounting securing bolts.

. Lower and remove the rear mounting assembly.

Carefully ease exhaust system down for access.

jack channel

and a suitable block.

. Remove the drive (propeller) shaft assembly, see Section 9, SRO 47.15.01.

. From above: undo retaining hook nut to lower rear of

transmission (do not allow engine to foul steering rack).

From below: slacken but do not remove the selector shaft

bolt

(3 Fig. 3).

. Remove the gear selector remote control securing bolts (1 Fig. 1) and reposition for access.

Finally remove the selector shaft bolt (3 Fig. 3).

. Remove the gear selector remote control assembly from

the selector shaft.

b: To aid removal, invert the gear selector remote con- trol assembly, i.e. gearshift lever pointing down- wards.

2

Fig. 1

Fig. 2

Fig. 3

X300 VSM 7 Issue 1 August 1994