lock JAGUAR XJ6 1994 2.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 124 of 521

Manual Transmission & Clutch (AJ16)

GEARSHIFT LEVER KNOB, RENEW

:RY 37.16.11

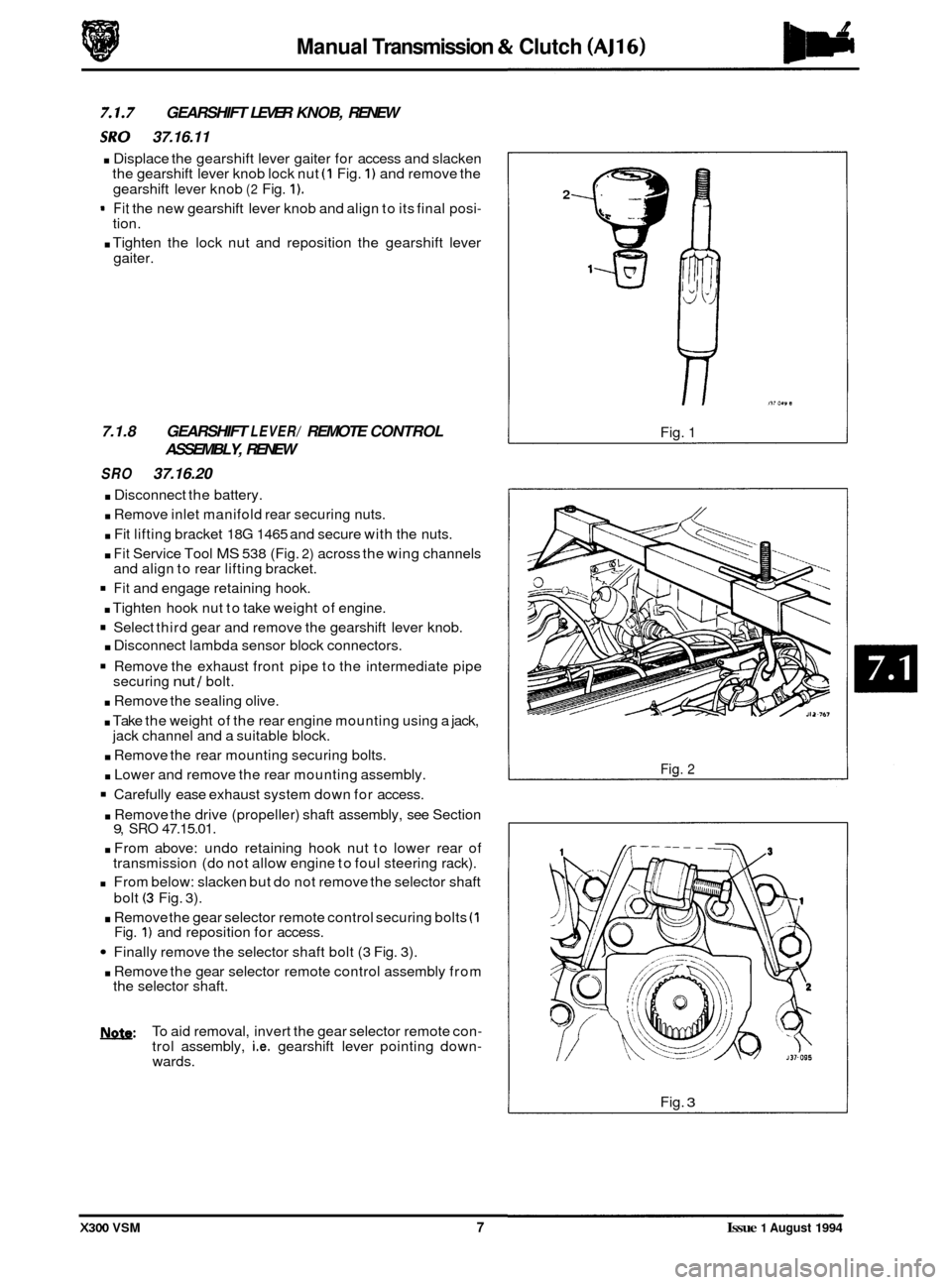

. Displace the gearshift lever gaiter for access and slacken

the gearshift lever knob lock nut (1 Fig. 1) and remove the

gearshift lever knob

(2 Fig. 1).

- Fit the new gearshift lever knob and align to its final posi- tion.

. Tighten the lock nut and reposition the gearshift lever

gaiter.

7.1.8 GEARSHIFT LEVER/ REMOTE CONTROL

ASSEMBLY, RENEW

SRO 37.16.20

. Disconnect the battery.

. Remove inlet manifold rear securing nuts.

. Fit lifting bracket 18G 1465 and secure with the nuts.

. Fit Service Tool MS 538 (Fig. 2) across the wing channels

and align to rear lifting bracket.

Fit and engage retaining hook.

. Tighten hook nut to take weight of engine.

Select third gear and remove the gearshift lever knob.

. Disconnect lambda sensor block connectors.

Remove the exhaust front pipe to the intermediate pipe

securing nut / bolt.

. Remove the sealing olive.

. Take the weight of the rear engine mounting using a jack,

. Remove the rear mounting securing bolts.

. Lower and remove the rear mounting assembly.

Carefully ease exhaust system down for access.

jack channel

and a suitable block.

. Remove the drive (propeller) shaft assembly, see Section 9, SRO 47.15.01.

. From above: undo retaining hook nut to lower rear of

transmission (do not allow engine to foul steering rack).

From below: slacken but do not remove the selector shaft

bolt

(3 Fig. 3).

. Remove the gear selector remote control securing bolts (1 Fig. 1) and reposition for access.

Finally remove the selector shaft bolt (3 Fig. 3).

. Remove the gear selector remote control assembly from

the selector shaft.

b: To aid removal, invert the gear selector remote con- trol assembly, i.e. gearshift lever pointing down- wards.

2

Fig. 1

Fig. 2

Fig. 3

X300 VSM 7 Issue 1 August 1994

Page 140 of 521

Automatic Transmission (AJ16)

Both types of automatic transmission comprise a hydrodynamic torque converter driving an epicyclic gear train which

provides four forward ratios and reverse. Gearshift selection is made by a hydraulic (or electronichydraulic) trans- mission control unit. Six gearshift positions are provided:

Position

'P' (Park) -the driven wheels are mechanically locked at the transmission.

Position

'R' (Reverse) - reverse gear selected.

Position

'N' (Neutral) - engine disconnected from drive-line and wheels.

Position 'D' (Drive)

- all four speed ranges are selected automatically with lock-up available in top gear only.

Position

'3' - automatic selection of the lowest three speed ranges only.

Position '2'

- automatic selection of the lowest two speed ranges only; the transmission is prevented from shift- ing up to the third and top speed ranges.

Immediate selection of a lower ratio is also available, within mapped limits, by 'kick

-down' (pressing the accelerator

pedal down beyond the normal full throttle position) for example when overtaking.

A brake pedal/gearshift interlock is incorporated in the shift lever mechanism. Theshift lever may only be movedfrom

the 'P' (Park) position if the ignition key switch is in position 'll', and the foot brake is applied. The ignition key cannot

be removed from the ignition switch unless the shift lever is in the 'P' (Park) position. Once the ignition key has been

removed, the shift lever is locked in the Park position. The gearshift interlock may be over-ridden manually in the event

of an electrical failure or when it is required to move the vehicle manually for access, ie for removal of the propeller

shaft.

8.1.1.1

Gearshift selection causes the appropriate gear to be selected through a cable operated shift lever on the side of the

Gear Selection (ZF 4HP 22)

transmission unit. When a gea; is selected, the shift points are determined by accelerator pedal position through a

throttle cable connection and by pressures equivalent to road speed derived from a centrifugal governor on the output

shaft.

Gearshift speed and quality are controlled by the hydraulic control unit located in the lower part of the transmission

housing. The control unit contains selector valve, control pistons and pressure valves.

The hydraulic control unit can be overridden by 'kickdown'. This is actuated by the final travel of the accelerator pedal

and causes the next lower gear to be selected.

8.1.1.2

Gearshift selection causes the appropriate gear to be selected through a cable operated shift lever on the side of the

transmission unit; the shift lever also operates a rotary switch attached to the side of the transmission unit. When a

gear is selected, the rotary switch provides an output or combination of outputs to the TCM, which continuously moni

- tors the gear selected in addition to output shaft speed and transmission oil temperature. Information from the Engine

Control Module (ECM) representing engine speed, load and throttle position is also fed to the TCM to enable the most

suitable gear to be selected.

Gear selection and gearshift speeds are controlled by the manually operated selector valve, a solenoid operated pres

- sure regulator and three solenoid valves. On receipt of signalsfrom the TCM, the three solenoid valves MVI, MV2 and

MV3, in various combinations with the safety valve, determine the appropriate gear range. The TCM, on receipt of

information of engine state and road speed, determines the shift speed.

The Performance Mode switch, located on the shift lever surround, provides two alternative shift speed patterns:

1. 'Normal (Economy) Mode' - designed for everyday use.

2. 'Sport Mode'

- gear shift takes place at higher road speeds to enhance performance.

The 'kick

-down' switch, located beneath the accelerator pedal, is actuated by the final travel of the pedal and signals

to the TCM that the next lower gear is to be selected.

Gear Selection (ZF 4 HP 24 E)

X300 VSM 3 Issue 1 August 1994

Page 144 of 521

Automatic Transmission (AJI 6)

8.1.3 TRANSMISSION CONTROL MODULE, RENEW

0 (4, OL)

SRO 44.15.32

. Raise the trunk lid and disconnect the battery.

. Remove the passenger side dash liner for access.

Displace and remove the air conditioning footwell outlet

duct.

. Release and remove the footwell carpet securing fastener:

displace and reposition the carpet for access.

Release the Transmission Control Module

(TCM) bracket

to body bracket securing nut

(1 Fig. 1).

. DisplacetheTCM mounting brackettang (2 Fig. 1)fromthe

body bracket and mounting stud.

= Reposition the TCM, release the TCM multi-pin plug lever

lock and disconnect the multi

-pin plug (3 Fig. 1).

. Release and remove the TCM mounting bracket securing

bolts and remove the TCM.

= Fit and align the new TCM to the mounting bracket.

. Fit and tighten the TCM securing bolts.

. Connect the TCM harness multi-pin plug and secure the

Position the TCM to body mounting bracket, ensuring that

Fit and tighten the TCM securing nut.

. Position the footwell carpet and fit the carpet fastener.

. Fit and align the footwell outlet duct to air conditioning

. Position and fit the duct fastener to the blower motor slot.

. Refit the dash liner.

. Reconnect the battery.

multi-pin plug lever lock.

the tang locates

in the bracket slot and stud.

unit.

1

i

J44-703 U

Fig. 1

Issue 1 August 1994 X300 VSM 7

Page 156 of 521

Automatic Transmission (V12 & AJl6 Supercharged) Pomrtrain

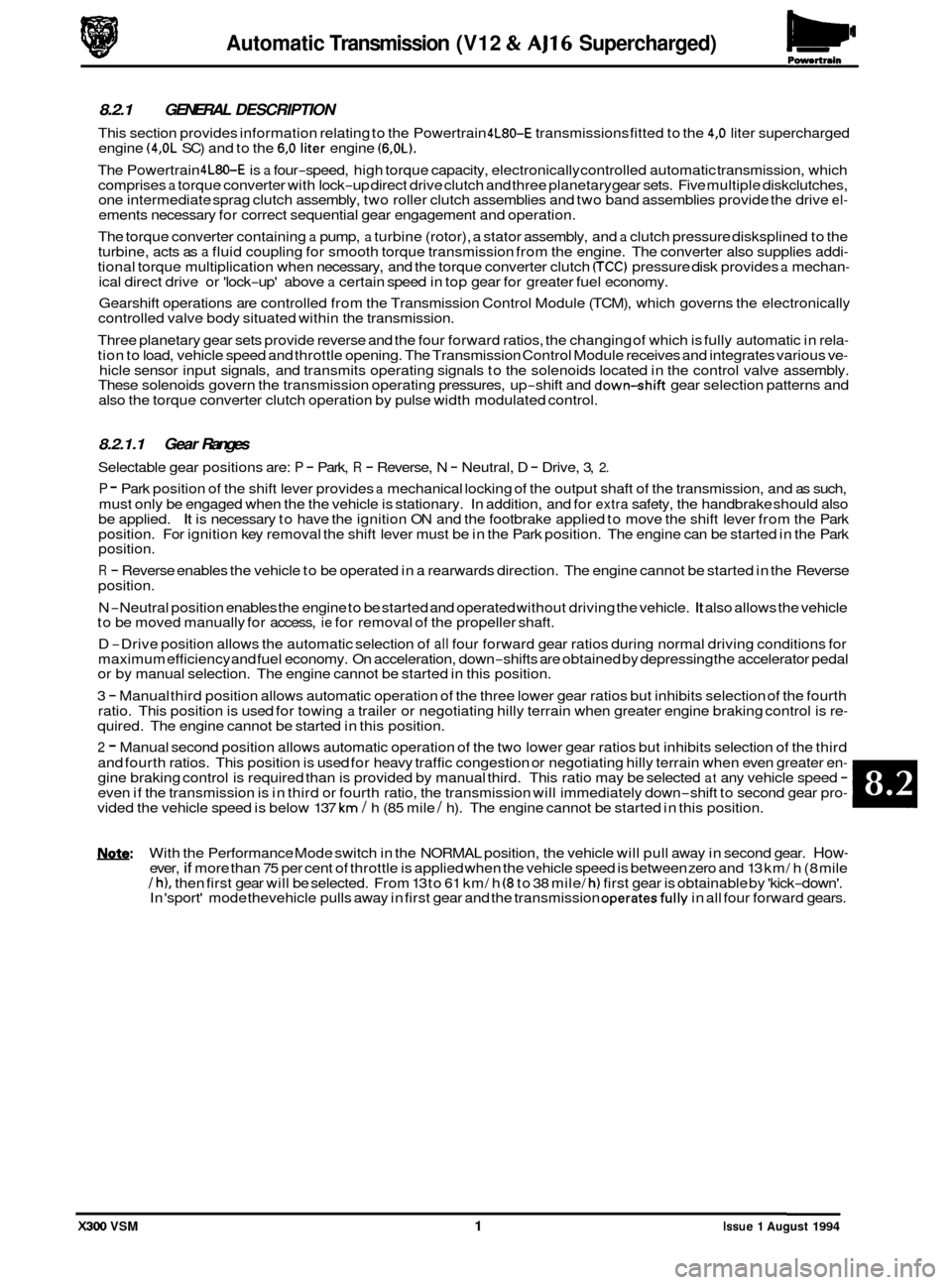

8.2.1 GENERAL DESCRIPTION

This section provides information relating to the Powertrain 4L80-E transmissions fitted to the 4,O liter supercharged

engine (4,OL SC) and to the 6,O liter engine (6,OL).

The Powertrain 4L80-E is a four-speed, high torque capacity, electronically controlled automatic transmission, which

comprises a torque converter with lock-up direct drive clutch and three planetary gear sets. Five multiple diskclutches,

one intermediate sprag clutch assembly, two roller clutch assemblies and two band assemblies provide the drive el- ements necessary for correct sequential gear engagement and operation.

The torque converter containing

a pump, a turbine (rotor), a stator assembly, and a clutch pressure disksplined to the

turbine, acts as a fluid coupling for smooth torque transmission from the engine. The converter also supplies addi- tional torque multiplication when necessary, and the torque converter clutch (TCC) pressure disk provides a mechan- ical direct drive or 'lock-up' above a certain speed in top gear for greater fuel economy.

Gearshift operations are controlled from the Transmission Control Module (TCM), which governs the electronically

controlled valve body situated within the transmission.

Three planetary gear sets provide reverse and the four forward ratios, the changing of which is fully automatic in rela

- tion to load, vehicle speed and throttle opening. The Transmission Control Module receives and integrates various ve- hicle sensor input signals, and transmits operating signals to the solenoids located in the control valve assembly.

These solenoids govern the transmission operating pressures, up-shift and down-shift gear selection patterns and

also the torque converter clutch operation by pulse width modulated control.

8.2.1.1 Gear Ranges

Selectable gear positions are: P - Park, R - Reverse, N - Neutral, D - Drive, 3, 2.

P - Park position of the shift lever provides a mechanical locking of the output shaft of the transmission, and as such,

must only be engaged when the the vehicle is stationary. In addition, and for

extra safety, the handbrake should also

be applied. It is necessary to have the ignition ON and the footbrake applied to move the shift lever from the Park

position. For ignition key removal the shift lever must be in the Park position. The engine can be started in the Park

position.

R - Reverse enables the vehicle to be operated in a rearwards direction. The engine cannot be started in the Reverse

position.

N

-Neutral position enables the engine to be started and operated without driving the vehicle. It also allows the vehicle

to be moved manually for access, ie for removal of the propeller shaft.

D

-Drive position allows the automatic selection of all four forward gear ratios during normal driving conditions for

maximum efficiency and fuel economy. On acceleration, down-shifts are obtained by depressing the accelerator pedal

or by manual selection. The engine cannot be started in this position.

3

- Manual third position allows automatic operation of the three lower gear ratios but inhibits selection of the fourth

ratio. This position is used for towing a trailer or negotiating hilly terrain when greater engine braking control is re- quired. The engine cannot be started in this position.

2 - Manual second position allows automatic operation of the two lower gear ratios but inhibits selection of the third

and fourth ratios. This position is used for heavy traffic congestion or negotiating hilly terrain when even greater en

- gine braking control is required than is provided by manual third. This ratio may be selected at any vehicle speed - even if the transmission is in third or fourth ratio, the transmission will immediately down-shift to second gear pro- vided the vehicle speed is below 137 km / h (85 mile / h). The engine cannot be started in this position.

N.g!b: With the Performance Mode switch in the NORMAL position, the vehicle will pull away in second gear. How- ever, if more than 75 per cent of throttle is applied when the vehicle speed is between zero and 13 km/ h (8 mile / h), then first gear will be selected. From 13 to 61 km/ h (8 to 38 mile/ h) first gear is obtainable by 'kick-down'.

In 'sport' mode thevehicle pulls away in first gear and the transmission operatesfully in all four forward gears.

X300 VSM 1 Issue 1 August 1994

Page 157 of 521

Automatic Transmission (V12 & AJ16 Supercharged) Powertrain

1.

2.

3.

4.

5. 6.

7.

8.

9. 10.

11.

12.

13.

Torque converter

Turbine shaft

Pressure disk

Converter turbine

Converter stator

Variable force motor

solenoid

Fluid pan

Filter

Interior detent lever

Manual shaft

Control valve

Front band

Parking lock actuator

3 4667 i JU-134

14.

15.

16.

17.

18.

19.

20. 21.

22.

23.

24. 25.

Rear band

Sun gear shaft

Sun gear

Parking lock pawl

Transmission case

Output shaft

Rear extension housing

Rear internal gear

Output planetary carrier

assembly Reaction planetary

carrier assembly

'LO' roller clutch

Main shaft

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

Intermediate clutch Intermediate sprag clutch

Direct clutch

Forward clutch

Overdrive planetary carrier

assembly

Overdrive roller clutch

Overrun clutch

Fourth clutch

Pump assembly

Converter pump

Stator roller clutch

Output speed sensor

Fig.1 Powertrain 4L8O-E automatic transmission

0

0

0

Issue 1 August 1994 2 X300 VSM

Page 163 of 521

Automatic Transmission (V12 & AJ16 Supercharged) Powertrain

8.2.6

SRO 44.15.40

. Open the hood and fit a suitable fender cover.

. Raise the vehicle on a ramp.

. Slacken the underfloor catalyst to downpipe clamps se-

. Displace and reposition the olive clamps on the pipes.

INPUT SPEED SENSOR, RENEW (6,OL)

curing bolts.

Slacken the underfloor catalyst

to intermediate silencer

clamps securing bolts.

9 Displace the underfloor catalyst assembly rearwards to

disconnect from the downpipes.

Displace and remove the olives from the downpipes.

Using a wire brush, clean the olives and downpipe joints.

. Place a suitable piece of wood between the underfloor

. Reposition the edge of the transmission tunnel insulation

. Release and remove the input speed sensor securing bolt.

. Reposition the speed sensor protection cover for access,

noting that the cover remains captive on the harness.

Disconnect the speed sensor harness multi

-pin plug.

- Displace and remove the speed sensor from the trans- mission case.

Clean the transmission case area.

. Fit a new ‘0 ring seal to a new input speed sensor.

. Lubricate the ‘0 ring seal.

. Fit and fully seat the speed sensor to the transmission

. Reconnect the harness multi-pin plug.

Reposition and align the protection cover.

. Fit and tighten the speed sensor securing bolt.

Reposition the insulation foam to its original position.

Remove the block of wood from between the underfloor

. Apply sealant to the downpipe joints and olives. See Ser-

Fit and seat the olives to the downpipes.

Reposition the olive clamps.

Tighten the underfloor catalyst to downpipe clamps secur-

Align the intermediate silencers to the underfloor catalyst

. Tighten the clamp securing bolts.

. Lower the vehicle on the ramp.

Remove the fender cover and close the hood.

catalyst

and the body for access.

foam for access.

0

case.

catalyst and the floor.

vice Materials

in the preliminary pages, this Section.

Reconnect the underfloor catalyst to the downpipes.

0

ing bolts.

assembly.

lppl

0

X300 VSM issue 1 August 1994 8

Page 164 of 521

Powertwin Automatic Transmission (V12 & AJ16 Supercharged)

8.2.7

SRO 44.15.41

OUTPUT SPEED SENSOR, RENEW (6,OL)

. Open the hood and fit a suitable fender cover.

. Raise the vehicle on a ramp.

. Slacken the underfloor catalyst to downpipe clamps se-

Displace and reposition the olive clamps on the pipes.

. Slacken the underfloor catalyst to intermediate silencer

. Displace the underfloor catalyst assembly rearwards to

. Displace and remove the olives from the downpipes.

. Using a wire brush, clean the olives and downpipe joints.

Place a suitable piece of wood between the underfloor

catalyst and the body for access.

. Reposition the edge of the transmission tunnel insulation

foam for access.

. Release and remove the output speed sensor securing

bolt.

Reposition the speed sensor protection cover for access,

noting that the cover remains captive on the harness.

. Disconnect the speed sensor harness multi-pin plug.

. Displace and remove the speed sensor from the trans-

. Clean the transmission case sensor area.

. Fit a new '0' ring seal to a new output speed sensor.

. Lubricate the '0' ring seal.

Fit and fully seat the speed sensor to the transmission

. Reconnect the harness multi-pin plug.

Reposition and align the protection cover.

. Fit and tighten the speed sensor securing bolt.

Reposition the insulation foam to its original position.

Remove the block of wood from between the underfloor

catalyst and the floor.

. Apply sealant to the downpipe joints and olives. See Ser- vice Materials in the preliminary pages, this Section.

. Fit and seat the olives to the downpipes.

. Reconnect the underfloor catalyst to the downpipes.

= Reposition the olive clamps.

. Tighten the underfloor catalyst to downpipe clamps secur-

= Align the intermediate silencers to the underfloor catalyst

. Tighten the clamp securing bolts.

Lower the vehicle on the ramp.

. Remove the fender cover and close the hood.

curing

bolts.

cl amps securing bolts.

disconnect from the downpipes.

mission case.

case.

0

ing bolts.

assembly.

Issue 1 August 1994 X300 VSM 9

Page 171 of 521

Automatic Transmission (V12 & AJ16 Supercharged) Powertrain

8.2.15 FlUlD PAN, RENEW (6,Ol)

SRO 44.24.04

Open the hood and fit a suitable fender cover.

. Raise the vehicle on a ramp.

. Slacken the underfloor catalyst to downpipe clamps se-

. Displace and reposition the olive clamps on the pipes.

. Slacken the underfloor catalyst to intermediate silencer

Displace the underfloor catalyst assembly rearwards to

. Displace and remove the olives from the downpipes.

. Using a wire brush, clean the olives and downpipe joints.

m Place a suitable piece of wood between the underfloor

Drain the transmission lubrication system, see Sub-sec-

Release and remove the fluid pan securing bolts.

Drain the residual fluid from the fluid pan.

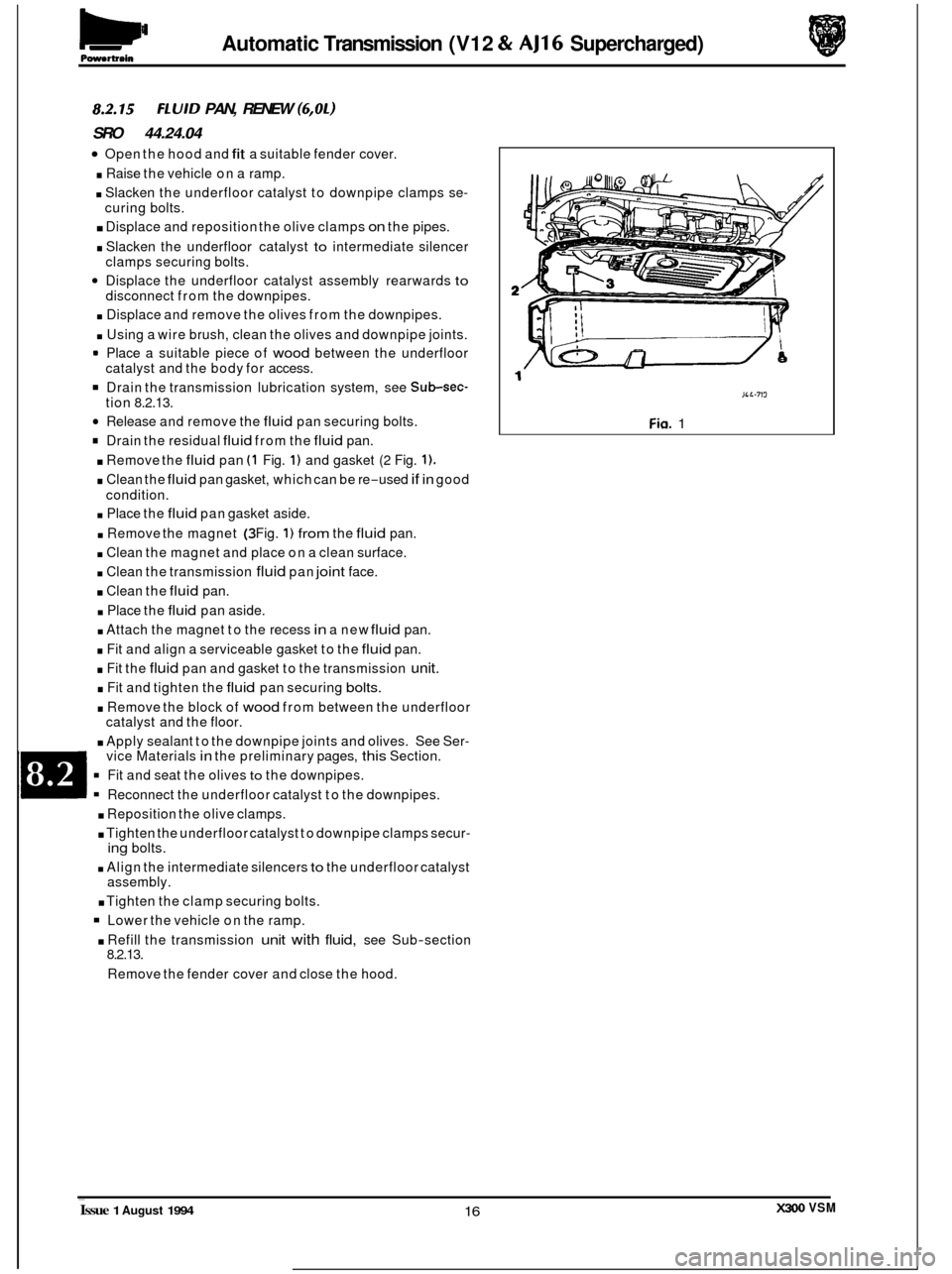

. Remove the fluid pan (1 Fig. 1) and gasket (2 Fig. 1).

. Clean the fluid pan gasket, which can be re-used if in good

. Place the fluid pan gasket aside.

. Remove the magnet (3 Fig. 1) from the fluid pan.

. Clean the magnet and place on a clean surface.

. Clean the transmission fluid pan joint face.

. Clean the fluid pan.

. Place the fluid pan aside.

. Attach the magnet to the recess in a new fluid pan.

. Fit and align a serviceable gasket to the fluid pan.

. Fit the fluid pan and gasket to the transmission unit.

. Fit and tighten the fluid pan securing bolts.

. Remove the block of wood from between the underfloor

catalyst and the floor.

. Apply sealant to the downpipe joints and olives. See Ser- vice Materials in the preliminary pages, this Section.

Fit and seat the olives to the downpipes.

Reconnect the underfloor catalyst to the downpipes.

. Reposition the olive clamps.

. Tighten the underfloor catalyst to downpipe clamps secur-

. Align the intermediate silencers to the underfloor catalyst

. Tighten the clamp securing bolts.

Lower the vehicle on the ramp.

. Refill the transmission unit with fluid, see Sub-section

curing

bolts.

clamps securing bolts.

disconnect from the downpipes.

catalyst and the body for access.

tion 8.2.13.

condition.

ing bolts.

assembly.

8.2.13. Remove the fender cover and close the hood.

JLL-719

Fin. 1 ~

Issue 1 August 1994 X300 VSM 16

Page 173 of 521

Automatic Transmission (V12 & AJ16 Supercharged) Powertrain

8.2.17 FLUID PAN GASKET RENEW (6,OL)

SRO 44.24.05

Open the hood and fit a suitable fender cover.

. Raise the vehicle on a ramp.

. Slacken the underfloor catalyst to downpipe clamp secur-

. Displace and reposition the olive clamps on the pipes.

. Slacken the underfloor catalyst to intermediate silencer

. Displace the underfloor catalyst assembly rearwards to

ing

bolts.

clamps securing bolts.

disconnect from the downpipes.

Displace and remove the olives from the downpipes.

Using a wire brush, clean the olives and downpipe joints.

. Place a suitable piece of wood between the underfloor

Drain the transmission lubrication system, see Sub-sec-

Release and remove the fluid pan securing bolts.

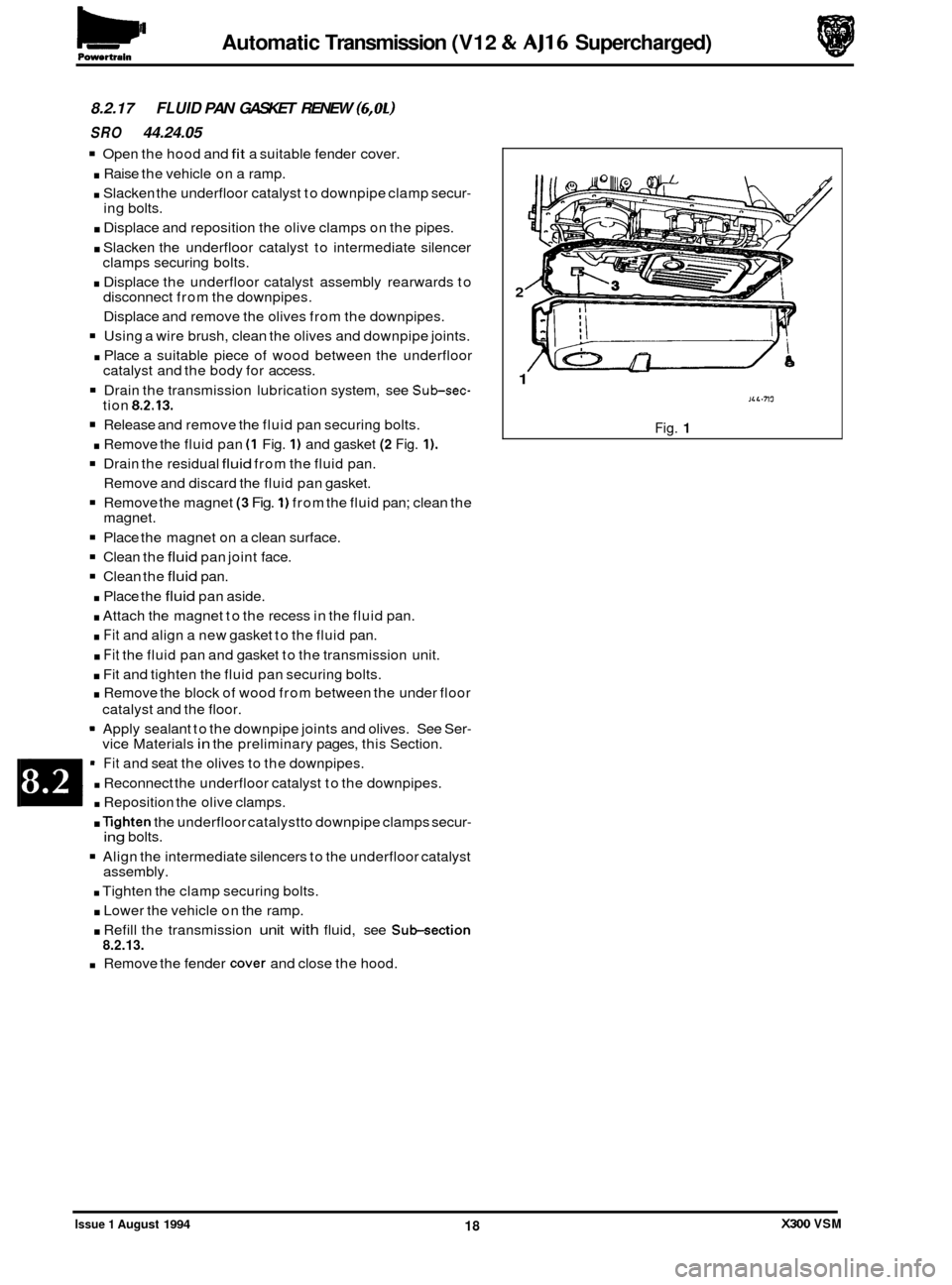

. Remove the fluid pan (1 Fig. 1) and gasket (2 Fig. 1).

Drain the residual fluid from the fluid pan.

Remove and discard the fluid pan gasket.

Remove the magnet (3 Fig. 1) from the fluid pan; clean the

magnet.

Place the magnet on a clean surface.

Clean the fluid pan joint face.

Clean the fluid pan.

. Place the fluid pan aside.

. Attach the magnet to the recess in the fluid pan.

. Fit and align a new gasket to the fluid pan.

. Fit the fluid pan and gasket to the transmission unit.

. Fit and tighten the fluid pan securing bolts.

. Remove the block of wood from between the under floor

catalyst and the floor.

9 Apply sealant to the downpipe joints and olives. See Ser- vice Materials in the preliminary pages, this Section.

= Fit and seat the olives to the downpipes.

. Reconnect the underfloor catalyst to the downpipes.

. Reposition the olive clamps.

. lighten the underfloor catalystto downpipe clamps secur-

Align the intermediate silencers to the underfloor catalyst

. Tighten the clamp securing bolts.

. Lower the vehicle on the ramp.

. Refill the transmission unit with fluid, see Sub-section 8.2.13.

Remove the fender cover and close the hood.

catalyst

and the body for access.

tion

8.2.13.

ing bolts.

assembly.

2

1

JLL.7K

Fig. 1

0

0

0

0

Issue 1 August 1994 18 X300 VSM

Page 175 of 521

Automatic Transmission (V12 & AJ16 Supercharged) Powertrain

8.2.19 TRANSMISSION INTERNAL HARNESS MULTI-

PIN SOCKET '0' RING, RENEW

(4,OL SC AND 6,011

SRO 44.24.20

9 Open the hood and fit a suitable fender cover.

. Raise the vehicle on a ramp.

. Drain the transmission lubrication system, see Sub-sec-

. Remove the fluid pan, see Sub-section 8.2.14 (4,OL SC) or

. Disconnect the external harness multi-pin plug from the

Note: The plug is secured to the socket by its captive lock- ing ring.

= Release and remove the internal harness multi-pin socket

. Displace the internal harness multi-pin socket from the

Remove and discard the '0 ring seal (Fig.1) from the

. Fit and seat a new '0' ring seal to the multi-pin socket.

. Reposition and seat the internal harness multi-pin socket

to the transmission casing.

. Fit and tighten the internal harness multi-pin socket to the

transmission casing securing nut.

Connect the external harness multi-pin plug to the inter- nal harness multi-pin socket; the plug is secured by its

captive locking ring.

Refit the fluid pan, see Sub-section 8.2.14 (4,OL SC) or Sub-section 8.2.15 (6,OL).

. Lower the vehicle on the ramp.

. Refill the transmission unit with fluid, see Sub-section

8.2.13.

. Remove the fender cover and close the hood.

tion

8.2.13.

Sub

-section 8.2.15 (6,OL).

internal harness multi-pin socket.

to transmission casing securing nut.

transmission casing.

multi

-pin socket.

0

0

0

0

X300 VSM Issue 1 August 1994 20