torque JAGUAR XJ6 1994 2.G Owner's Guide

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 158 of 521

Powertrain Automatic Transmission (V12 & AJ16 Supercharged)

Light throttle D1 -D2 D2 - D3 D3 - D4

Normal mile 1 h 8- 10 18-20 25 - 39

kmlh 13- 15 28 - 33 40 - 46

sport mile 1 h 10 - 12 20 - 23 30 - 34

kmlh 16- 19 32 - 37 48-55

Up to Detent D1- D2 D2 - D3

Normal mile I h 34 - 37 60-66

kmlh 54 - 59 97 - 107

8.2.1.2 Shift Speeds

0

D4 - TCC on

45 - 51

72

-83

47

- 55

76

-88

D3

- D4

86

-94

138

- 151

4,O Liter Supercharged

sport mile I h 43 - 47 74 - 81 103 - 113

kmlh 69 - 76

118- 130

166 - 182

Maximum shift speeds (through detent)

Normal 1 Sport mile I h

kmlh

D1 -D2 D2 - D3 D3 - TCC on

47 - 50 81 -84

116 - 128

75

- 80 130 - 134

187 - 205

TCC

-Torque converter clutch

m: Road speeds shown above are for a vehicle with an axle ratio of 3,58:1, and standard tyres (2251 65ZR15). For

a vehicle with optional sports tyres

(225 / 55ZR16) (lattice wheels), these speeds must be reduced by 2,4%.

Zero throttle 1 TCCoffinD4 1 D4 - D3 D3 - D2

X300 VSM 3 Issue 1 August 1994

D2 - D1

Normal mile 1 h

kmth

sport mile 1 h

kmlh

I 36 - 40 15- 17

10- 12 -

58-64 24 - 27 16- 19 -

36 - 40 18 - 20 12 - 14

9-9

58-64 29 - 32 20 - 22 14 - 15

Up to

detent D4 - D3 03 - D2

Normal mile 1 h 67-74 3-44

kmlh 107-118 63-70

sport mile 1 h 81 -89 57 - 63

kmlh 130- 144 92 - 101

Kick-down available (through detent) TCC4 - D3 D3 - 02

Normal 1 Sport mile I h 103- 113 67 -74

kmlh 165 - 183 107 - 118 D2

- D1

9-9

14

- 15

27

- 29

43 - 47

D2

- D1

36 - 40

58-64

Page 159 of 521

Automatic Transmission (V12 & AJ16 Supercharged)

Light throttle D1 -D2

Normal mile 1 h -

km/h -

sport mile / h 10- 12

kmlh 16- 18

Up to detent

Normal mile I h

kmlh

sport mile

1 h

km/h

Maximum shift speeds (through detent)

Normal I Sport mile / h

kmlh

6,O Liier

D2 - D3

D3 - D4

D4 - TCC on

20 - 23 29 - 33

48 - 55

32

- 37 46 - 52

77 -88

23 - 26 32 - 37 51 -59

36

- 41 51 -59 82 - 94

D1 -D2

D2 - D3 D3 - D4

35

- 40 61 -70 83-91

56

- 64 98- 112 133 - 164

43 - 49 73 - 79 99 -107

68

-78 117 - 127 158 - 172

D1 -D2 D2 - D3

D3 - TCC on

48-53 81 -89

116- 124

77

- 85 130- 149

186 - 198

Zero throttle

Normal mile 1 h

kmlh

sport mile

1 h

km/h

TCC off in 04 D4 - D3 D3 - D2 D2 - D1

- 36 - 40 15 - 17 10 - 12

16

- 19 58 - 64 24 - 27

36

- 40 18 - 20 12-14 6-7

58

- 64 29 - 32 19 - 22 10- 12

-

0

0

Up to detent

Normal mile I h

kmlh

sport mile

/ h

km/h

mile I h

kmlh

'Kick-down' available (through detent)

Normal 1 Sport

TCC -Torque converter clutch

m: Road speeds shown above are for a vehicle with an axle ratio of 3,58:1, and standard tyres (2251 65ZR15). For

a vehicle with optional sports tyres

(225 155ZR16) (lattice wheels), these speeds must be reduced by 2,4%.

D4 - D3 D3 - D2 D2 - D1

67 - 75 37 - 41 7-9

108

- 119 59 - 66 11 - 14

84

-92 60 - 66

27 - 29

134

- 148 96 - 106

43 - 47

TCC4

- D3 03 - D2 D2 - D1

103 - 113 67 -75 36 - 40

164

- 181 108 - 119 58 - 64

0

0

Issue 1 August 1994 4 X300 VSM

Page 183 of 521

-5 Driveshafts & Final Drive

0

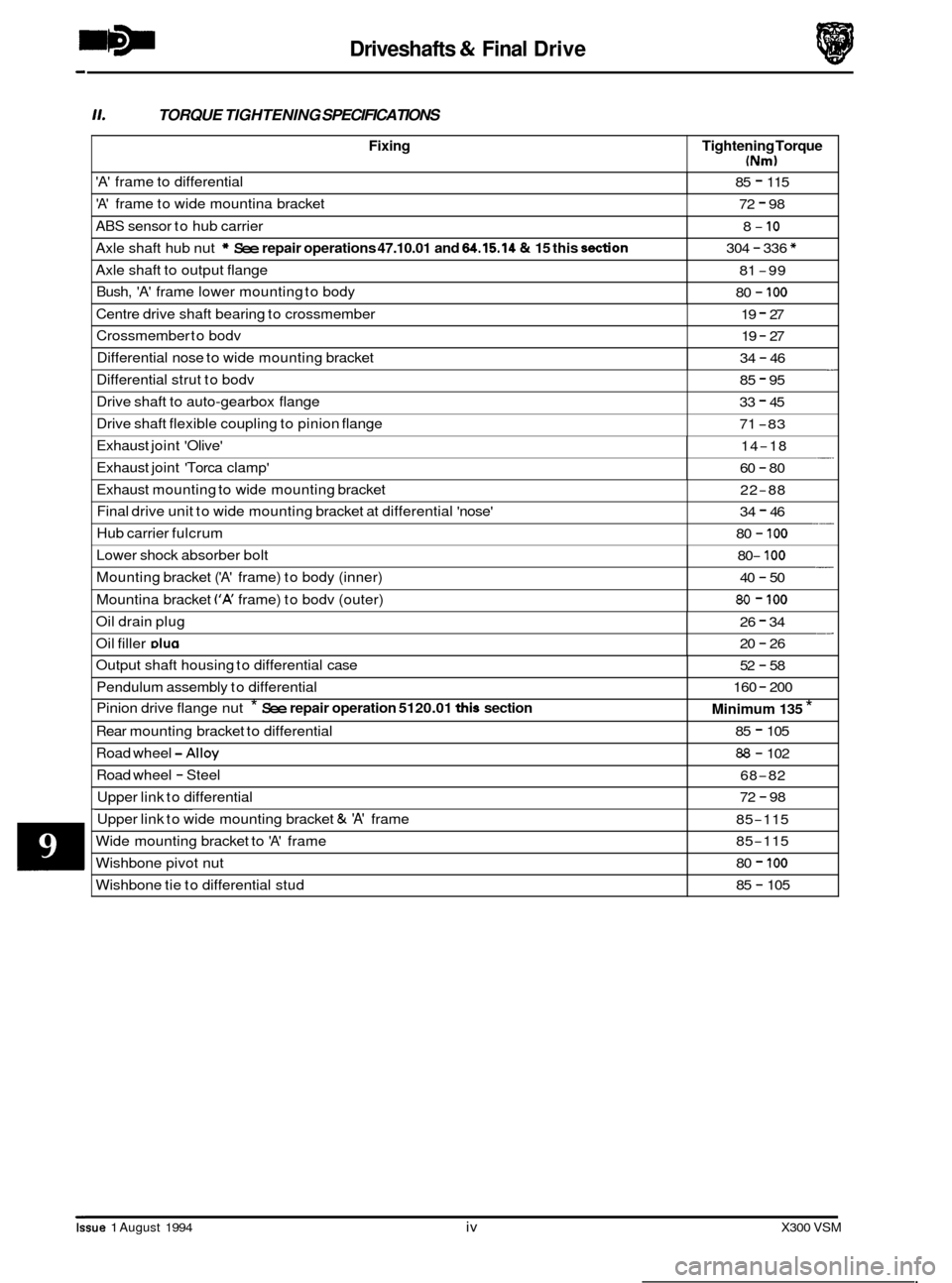

Fixing

11. TORQUE TIGHTENING SPECIFICATIONS

Tightening Torque

(Nm)

'A' frame to differential 85 - 115

'A' frame to wide mountina bracket 72 - 98

ABS sensor to hub carrier

Axle shaft hub nut

* See repair operations 47.10.01 and 64.15.14 & 15 this don

8- 10

304 - 336 *

Axle shaft to output flange

Bush,

'A' frame lower mounting to body

81 -99

80

- 100

Centre drive shaft bearing to crossmember 19 - 27

Crossmember to bodv 19 - 27

Differential nose to wide mounting bracket - 34 - 46

Issue 1 August 1994 iv X300 VSM

Differential strut to bodv 85 - 95

Drive shaft to auto-gearbox flange

Drive shaft flexible coupling to pinion flange 33 - 45

71

-83

Exhaust joint 'Olive'

Exhaust joint 'Torca clamp' -. 14-18

60

- 80

Exhaust mounting to wide mounting bracket

Final drive unit to wide mounting bracket at differential 'nose'

Hub carrier fulcrum 22-88

34

- 46

80

- 100 ___

Lower shock absorber bolt

Mounting bracket

('A' frame) to body (inner)

Mountina bracket

('A' frame) to bodv (outer)

- 80- 100

40 - 50

80 - 100

Oil drain plug __ 26 - 34

Oil filler DIU~ 20 - 26

Output shaft housing to differential case

Pendulum assembly to differential

Pinion drive flange nut

* See repair operation 5120.01 this section

Road wheel -Alloy

Road wheel - Steel

Upper link to differential

Rear

mounting bracket to differential

52 - 58

160

- 200

Minimum 135 *

85 - 105

88 - 102

68

-82

72

- 98 ~~~~~

Upper

link to wide mounting bracket & 'A' frame

Wide mounting bracket to

'A' frame

85-115

85

-115

Wishbone pivot nut

Wishbone tie to differential stud 80 - 100

85 - 105

Page 189 of 521

Driveshafts & Final Drive

9.3

SRO 51.10.24

Disconnect vehicle battery ground lead.

. Support the vehicle at the rear.

OUTPUT SHAFT END FLOAT, CHECK

Mount a dial test indicator (DTI) to the differential housing with the probe resting on the output shaft flange (DTI probe must be parallel to the output shaft center line and NOT at an angle).

. Push the wheel 1 shaft assembly inwards and zero the DTI; pull outwards and note the reading.

. If the end float exceeds 0,15 mm; firstly verify the shim preload and if this is found to be correct, renew the output

shaft bearing. See 51.10.22. this section, for shim check and renew operations.

9.4

SRO 51.20.19

rn Disconnect vehicle battery ground lead.

See operation 51.10.22. this section, for process detail, less bearing 1 oil seal renew.

OUTPUT SHAFT HOUSING ‘0’ RING, RENEW

Prior to removal of shaft assembly check output shaft end float in accordance with operation 51.10.24.

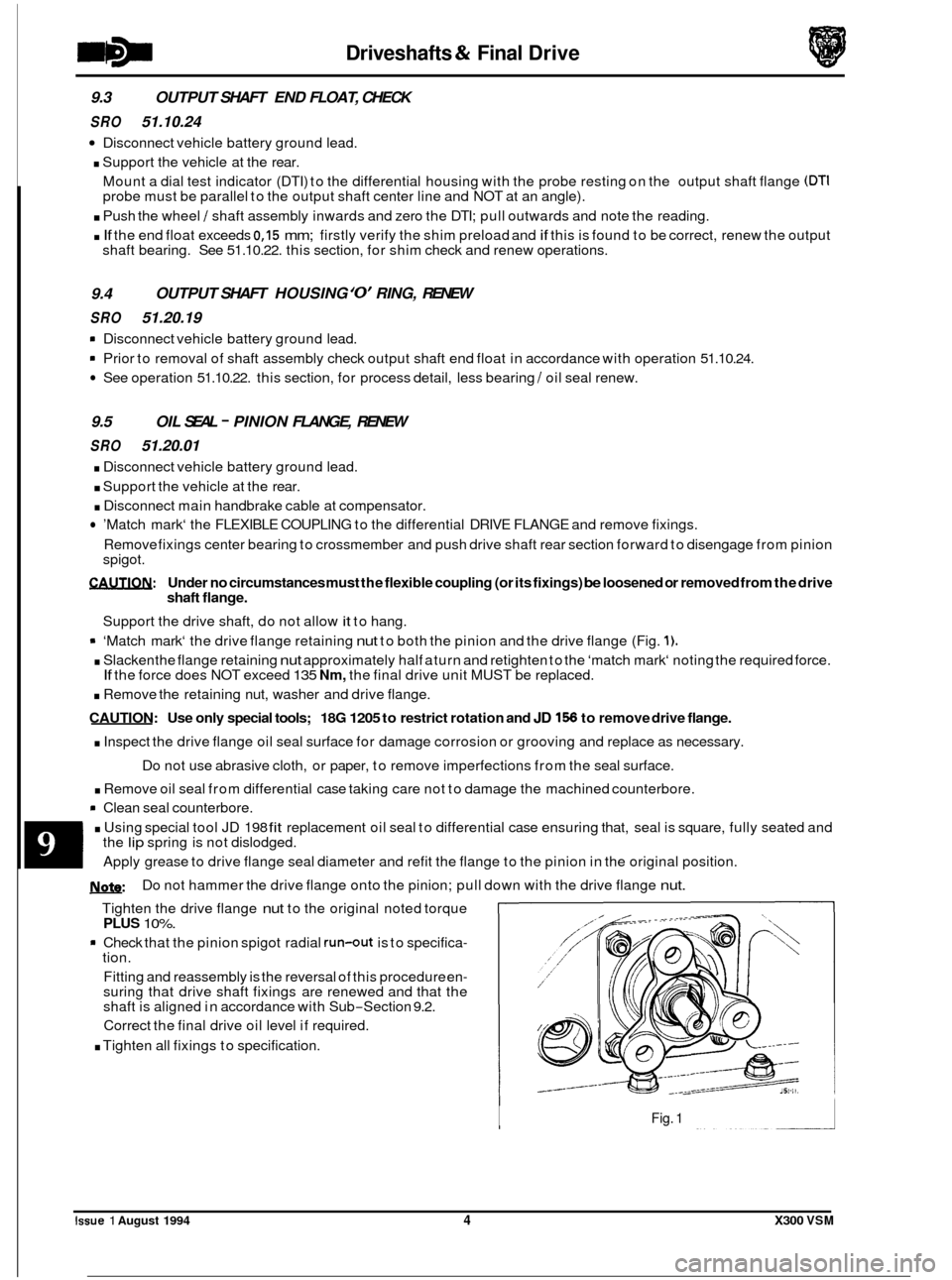

9.5 OIL SEAL - PINION FLANGE, RENEW

SRO 51.20.01

. Disconnect vehicle battery ground lead.

. Support the vehicle at the rear.

. Disconnect main handbrake cable at compensator.

’Match mark‘ the FLEXIBLE COUPLING to the differential DRIVE FLANGE and remove fixings.

Remove fixings center bearing to crossmember and push drive shaft rear section forward to disengage from pinion

spigot.

CAUTION: Under no circumstances must the flexible coupling (or its fixings) be loosened or removed from the drive

shaft flange.

Support the drive shaft, do not allow it to hang.

9 ‘Match mark‘ the drive flange retaining nut to both the pinion and the drive flange (Fig. 1).

. Slacken the flange retaining nut approximately half a turn and retighten to the ‘match mark‘ noting the required force.

. Remove the retaining nut, washer and drive flange.

CAUTION: Use only special tools; 18G 1205 to restrict rotation and JD 156 to remove drive flange.

. Inspect the drive flange oil seal surface for damage corrosion or grooving and replace as necessary.

. Remove oil seal from differential case taking care not to damage the machined counterbore.

rn Clean seal counterbore.

. Using special tool JD 198 fit replacement oil seal to differential case ensuring that, seal is square, fully seated and

If the force does NOT exceed 135 Nm, the final drive unit MUST be replaced.

Do not use abrasive cloth, or paper, to remove imperfections from the seal surface.

the

lip spring is not dislodged.

Apply grease to drive flange seal diameter and refit the flange to the pinion in the original position.

U: Do not hammer the drive flange onto the pinion; pull down with the drive flange nut.

Tighten the drive flange nut to the original noted torque PLUS 10%.

* Check that the pinion spigot radial run-out is to specifica- tion.

Fitting and reassembly is the reversal of this procedure en

- suring that drive shaft fixings are renewed and that the

shaft is aligned in accordance with Sub-Section 9.2.

Correct the final drive oil level if required.

. Tighten all fixings to specification.

Fig. 1

0

Issue 1 August 1994 4 X300 VSM

Page 192 of 521

Driveshafts & Final Drive

. Remove upper link assembly from differential and wide mounting bracket / 'A' frame.

. Release fixings, 'A' frame to differential, 'A' frame to wishbone tie and wide mounting bracket to 'A' frame.

. Remove wishbone tie assembly, rear mounting bracket and pendulum assembly.

. Release fixings differential nose to wide mounting bracket.

. Assembly and fitting is the reversal of this procedure, taking note of the following:

Drive shaft must be aligned in accordance with Sub

-Section 9.2.

Renew all self locking nuts.

Renew all bolts that were originally fitted with thread locking adhesive.

Replace all locking wire and split pins (cotter pins).

Tighten all fixings to the specified torque.

Correct the final drive oil level

if required.

Check and adjust rear wheel camber setting as required.

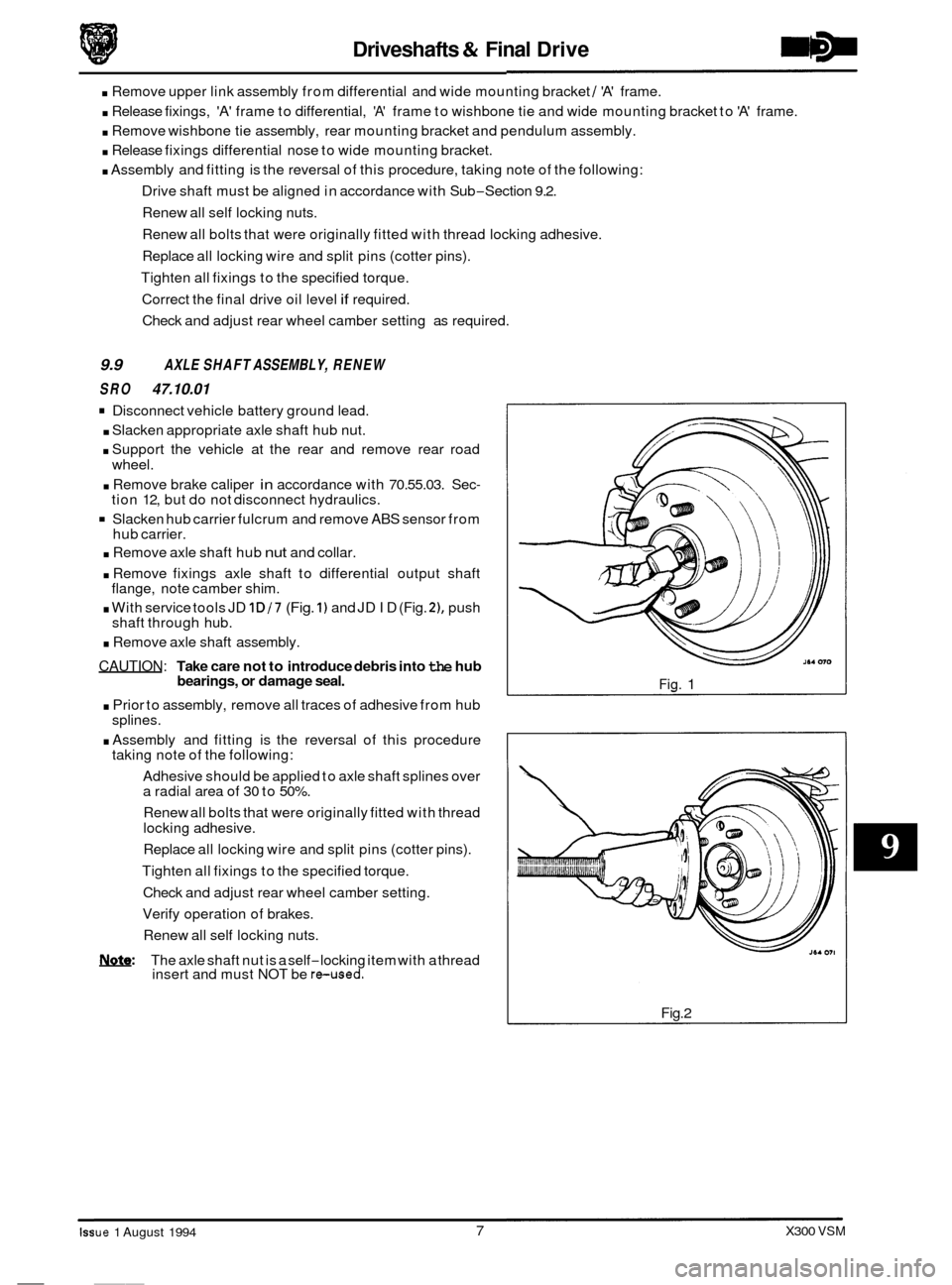

9.9 AXLE SHAFT ASSEMBLY, RENEW

SRO

47.10.01

Disconnect vehicle battery ground lead.

. Slacken appropriate axle shaft hub nut.

. Support the vehicle at the rear and remove rear road

. Remove brake caliper in accordance with 70.55.03. Sec-

wheel.

tion 12, but do not disconnect hydraulics.

Slacken hub carrier fulcrum and remove ABS sensor from

hub carrier.

. Remove axle shaft hub nut and collar.

. Remove fixings axle shaft to differential output shaft

flange, note camber shim.

. With service tools JD 1D/7 (Fig. 1) and JD ID (Fig. 21, push

shaft through hub.

. Remove axle shaft assembly.

CAUTION: Take care not to introduce debris into the hub

bearings, or damage seal.

. Prior to assembly, remove all traces of adhesive from hub

. Assembly and fitting is the reversal of this procedure

Adhesive should be applied to axle shaft splines over

a radial area of

30 to 50%.

Renew all bolts that were originally fitted with thread

locking adhesive.

Replace all locking wire and split pins (cotter pins).

Tighten all fixings to the specified torque.

Check and adjust rear wheel camber setting.

Verify operation of brakes.

Renew all self locking nuts.

splines.

taking

note of the following:

0

NQ&: The axle shaft nut is a self-locking item with a thread

insert and must NOT be reused.

Fig. 1

Fig.2

- Iss ue 1 August 1994

__~

7 X300 VSM

Page 198 of 521

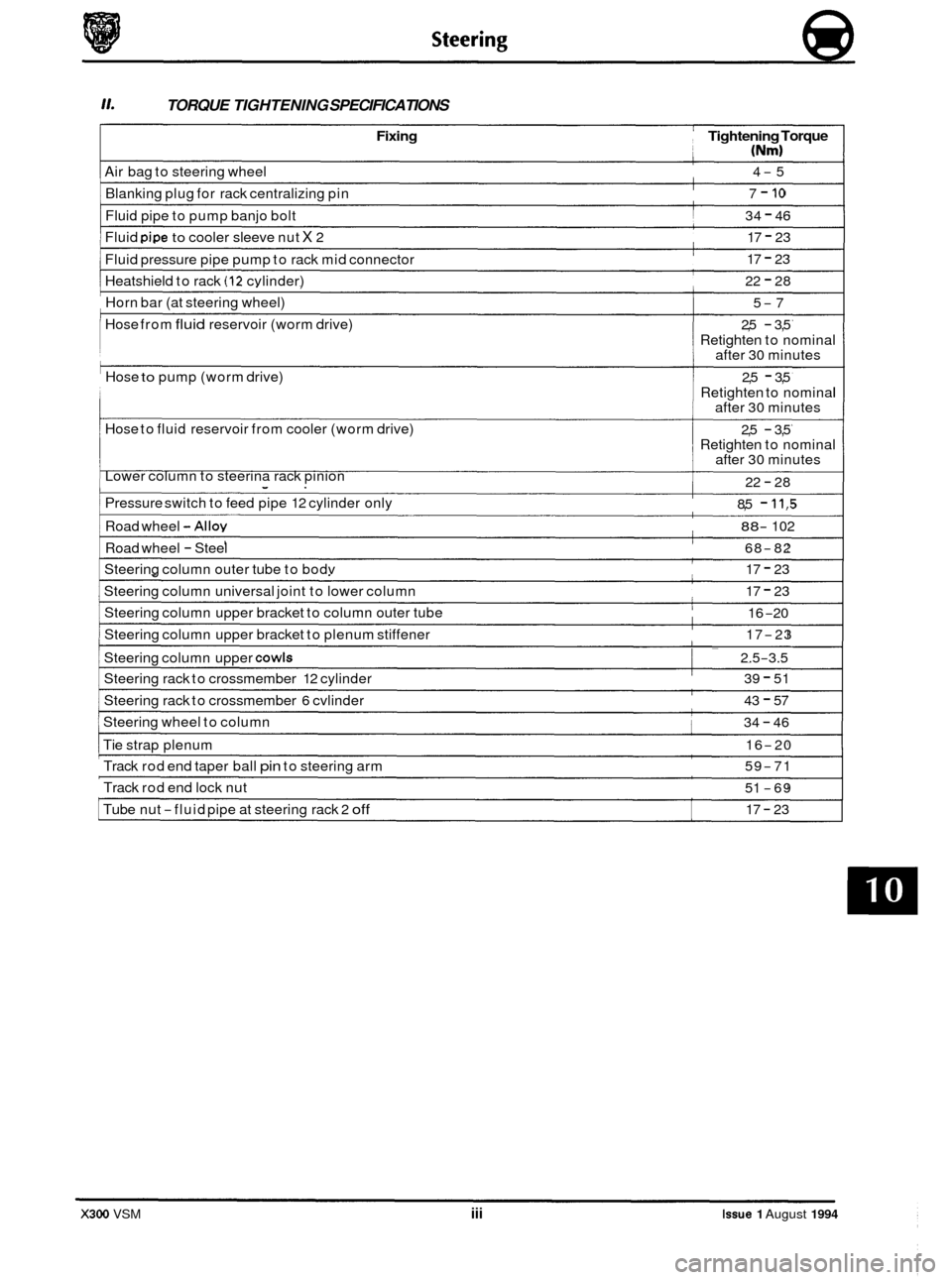

TORQUE TIGHTENING SPECIFICATIONS

Fixing Tightening Torque

(Nm)

Air bag to steering wheel

Blanking plug for rack centralizing pin 4-5

7

- 10

Fluid pipe to pump banjo bolt

Fluid

pipe to cooler sleeve nut X 2 34

- 46

17

- 23

Fluid pressure pipe pump to rack mid connector

Heatshield to rack

(12 cvlinder)

17 - 23

22

- 28

Horn bar (at steering wheel)

Hose from

fluid reservoir (worm drive)

Hose

to pump (worm drive)

Hose to fluid reservoir from cooler (worm drive)

Lower column to steerina rack pinion

5-7

2,5

- 3,5

Retighten to nominal

after 30 minutes

Retighten to nominal

after

30 minutes

Retighten to nominal

after

30 minutes

2,5 - 3,5

2,5

- 3,5

22

- 28

Pressure switch to feed pipe 12 cylinder only 8,5 - 11,5

Road wheel -Alloy 88- 102

Road wheel - Steel 68-82

Steering column outer tube to bodv 17 - 23

Steering column universal joint to lower column

Steering column upper bracket to column outer tube

Steering column upper bracket to plenum stiffener 17 - 23

16

-20

17

-23 ~~

I Steering

column upper COWIS I ~ 2.5-3.5

Steering

rack to crossmember 12 cylinder

Steering rack to crossmember

6 cvlinder

39 - 51

43

- 57

Steering wheel to column 34 - 46

Tie strap plenum 16-20

Track rod end taper ball pin to steering arm

Track rod end lock nut 59-71

51

-69

17

- 23 Tube nut -fluid pipe at steering rack 2 off

X300 VSM iii Issue 1 August 1994

Page 212 of 521

Suspension Systems

Not illustrated

1. SERVICE TOOLS & EQUIPMENT (continued)

JD199

0

Fixing

To be issued

Tightening Torque

(Nm)

JD199-1 Not i II ustrated

Description US98

LM Multi - purpose grease

Molib Alloy

PI907 No1

Molykote 11 1

Lower damper bolt

Wishbone to crossmember fulcrum shaft

Stabilizer mounting bushes

& rear damper top

guide bush

Caliper to carrier bolts

/ guide pins

Description

Notes

Adaptor Remover / Renewer

Suspension Bushes (Bottom Front

Wishbone Inner)

____~ ~ Spring

Compressor Rear Suspension

Damper Retaining Tie Rear

Suspension

Adaptor

Replacer Rear Hub Pivot

Bearing Cup

Driver Handle

Adaptor Remover

Main Shaft Pilot

Bearing Outer Track

Impulse Extractor (slide Hammer)

UNF. Basic Tool

Notes

Issue 1 August 1994 X300 VSM iii

Page 216 of 521

may include:

0

0

Loose or worn wheel bearings.

Loose or worn suspensions or steering components.

0 Worn or damaged drive shaft slip yoke joint.

0 Front disc rotor runout.

o Loose engine or transmission supports.

0 Driveline alignment.

0 Engine driven accessories.

Suspension Systems

11.4 DIAGNOSIS AND TESTING

' 11.4.1 Tire Wear

Tires should be inspected as abnormal or excessive wear may becaused by incorrect wheel alignment, wheelbire im- balance, or incorrect tire pressure.

1 1.4.2 vibration and Roughness

Vibration, roughness, and shimmy conditions may be caused by excessive tire or wheel runout, worn or cupped tires,

or wheel and tire unbalance.

Most of these conditions are due to irregularities in the road surface, hence driving the vehicle on different types of

road surface will often indicate the cause of the condition.

Do not automatically suspect the tires when attempting to diagnose a vibration concern as other sources of vibration

Before investigating any other vibration concerns,

a roaG &est and a customer inter\,.dw (if possible) should be carried

out. This can provide much of the information needed to find the source of vibration.

Drive the vehicle on a road that is preferably smooth and free of undulation and

if vibration is apparent note, the speed at which thevibration occurs, whattype of vibration occurs in each speed range (mechanical or audible), howthevibra- tion is affected by changes in vehicle speed , engine speed and engine torque, and the type of vibration sensitivity

(torque sensitive, vehicle speed sensitive, or speed sensitive).

Some of the condition terms used when describing sources of vibration are explained as follows:

0 Torque Sensitive

This condition can be improved or worsened by accelerating, decelerating, coasting, maintaining

a steady

vehicle speed and application of engine torque.

0 Vehicle Speed Sensitive

This means that the vibration always occurs at the same vehicle speed and is not affected by engine torque,

engine rpm, or transmission gear selection.

B

0 Engine Speed Sensitive

This means that the vibration occurs

at varying vehicle speeds when a different transmission gear is selected.

It can sometimes be isolated by increasing or decreasing engine speed with the transmission in 'NEUTRAL', or

by stall testing with the engine in gear. If the condition is enginesensitive, the condition is not related to tires.

If the road tests indicates that the vibration is related to the tires or wheels,use a 'lire Wear Diagnosis Chart' to

investigate the cause of concern. Should the road test indicate that there is tire whine, but noshake or vibration,

the noise originates from the contact between the tire and the road surface.

X300 VSM 3 Issue 1 August 1994

Page 223 of 521

1. SERVICE TOOLS & EQUIPMENT

Description

Parking brake cable remover

Illustration

Notes

not

illustrated

Pipe connectors to hydraulic module:

M12

M10

Jaguar Number

JD.142

15

- 19

12 - 16

186.672

Description

U-

Molykote 11 1 Caliper to carrier securing bolts

6947017

Notes

JDS.9013

Replacer disc brake

piston seal

I

Brake hose clamp, Girling

Brake pedal hold down tool

11. TORQUE TIGHTENING SPECIFICATIONS

Fixing 1 Tightening Torque

(Nm)

Vacuum booster to pedal box I 21 -29 I

Tandem master cylinder to booster I 21 -29 I

Hvdraulic module to module bracket I 18 - 26 I

Caliper guide pins I 25 - 35 I

Caliper to vertical link I 120 - 160 I

Caliper to hub carrier I 54 - 66 I

111. SERVICE MATERIALS

Iv. SERVICE DATA

Front brake disc run out

Front brake

disc parallelism

Rear brake disc

run out

Rear brake disc parallelism 0.101

mm (0.004 in) max.

0.0127mm (0.0005in) max.

0.101

mm (0.004 in) max.

0.0127mm (0.0005in) max.

Issue 1 August 1994 ii X300 VSM

Page 240 of 521

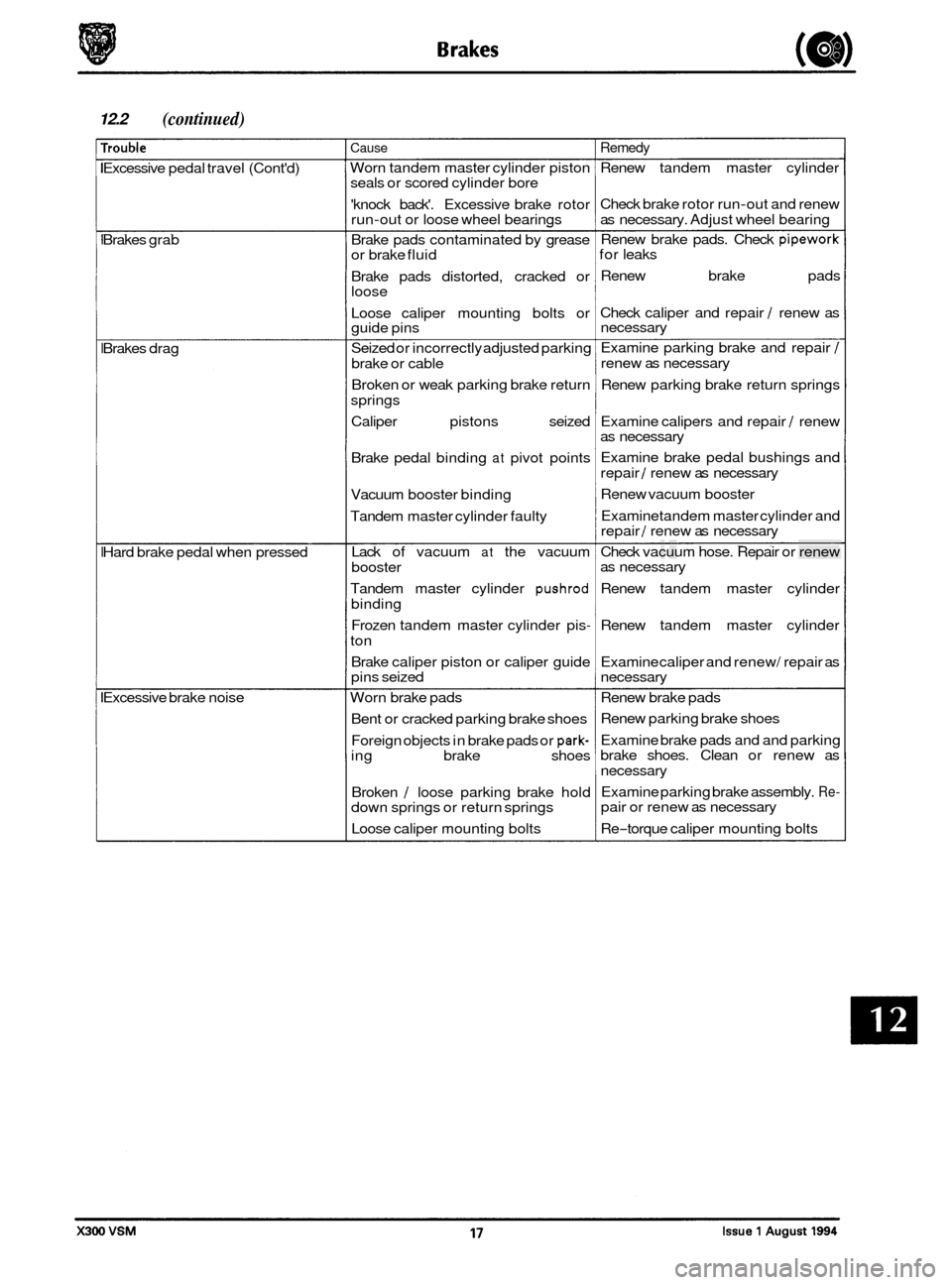

12.2 (continued)

rrouble

Excessive pedal travel (Cont'd)

Brakes grab

Brakes drag

Hard brake pedal when pressed

Excessive brake noise

Cause

Worn tandem master cylinder piston

seals or scored cylinder bore

'knock back'. Excessive brake rotor

run

-out or loose wheel bearings

Brake pads contaminated by grease

or brake fluid

Brake pads distorted, cracked or

loose

Loose caliper mounting bolts or

guide pins

Seized or incorrectly adjusted parking

brake or cable

Broken or weak parking brake return

springs

Caliper pistons seized

Brake pedal binding

at pivot points

Vacuum booster binding

Tandem master cylinder faulty

Lack of vacuum

at the vacuum

booster

Tandem master cylinder

pushrod

binding

Frozen tandem master cylinder pis

-

ton

Brake caliper piston or caliper guide

pins seized

Worn brake pads

Bent or cracked parking brake shoes

Foreign objects in brake pads or

park- ing brake shoes

Broken

/ loose parking brake hold

down springs or return springs

Loose caliper mounting bolts

Remedy

Renew tandem master cylinder

Check brake rotor run

-out and renew

as necessary. Adjust wheel bearing

Renew brake pads. Check

pipework for leaks

Renew brake pads

Check caliper and repair

/ renew as

necessary

Examine parking brake and repair

/

renew as necessary

Renew parking brake return springs

Examine calipers and repair

/ renew

as necessary

Examine brake pedal bushings and

repair

/ renew as necessary

Renew vacuum booster

Examine tandem master cylinder and

repair

/ renew as necessary

Check vacuum hose. Repair or renew

as necessary

Renew tandem master cylinder

Renew tandem master cylinder

Examine caliper and renew/ repair as

necessary

Renew brake pads

Renew parking brake shoes

Examine brake pads and and parking

brake shoes. Clean or renew as

necessary

Examine parking brake assembly.

Re- pair or renew as necessary

Re

-torque caliper mounting bolts