ignition JAGUAR XJ6 1994 2.G Service Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 357 of 521

15.6

15.6.1

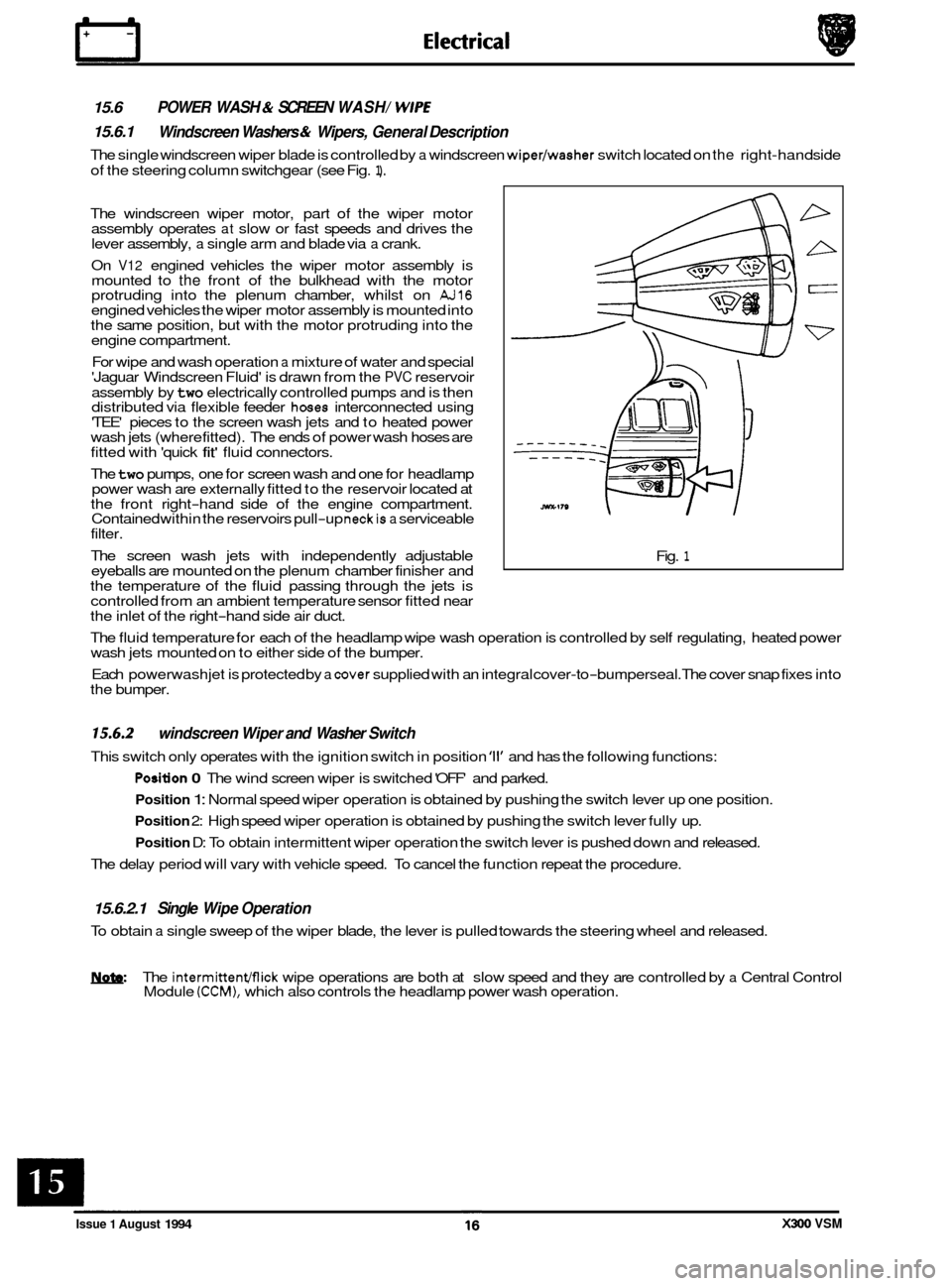

The single windscreen wiper blade is controlled by a windscreen wiper/washer switch located on the right-hand side

of the steering column switchgear (see Fig.

1).

POWER WASH & SCREEN WASH/ WlPE

Windscreen Washers & Wipers, General Description

The windscreen wiper motor, part of the wiper motor

assembly operates at slow or fast speeds and drives the

lever assembly, a single arm and blade via a crank.

On

V12 engined vehicles the wiper motor assembly is

mounted to the front of the bulkhead with the motor

protruding into the plenum chamber, whilst on AJ16 engined vehicles the wiper motor assembly is mounted into

the same position, but with the motor protruding into the

engine compartment.

For wipe and wash operation

a mixture of water and special

'Jaguar Windscreen Fluid' is drawn from the PVC reservoir

assembly by

two electrically controlled pumps and is then

distributed via flexible feeder hoses interconnected using

'TEE' pieces to the screen wash jets and to heated power

wash jets (where fitted). The ends of power wash hoses are

fitted with 'quick

fit' fluid connectors.

The

two pumps, one for screen wash and one for headlamp

power wash are externally fitted to the reservoir located at

the front right

-hand side of the engine compartment.

Contained within the reservoirs pull-up neckis a serviceable

filter.

The screen wash jets with independently adjustable

eyeballs are mounted on the plenum chamber finisher and

the temperature of the fluid passing through the jets is

controlled from an ambient temperature sensor fitted near

the inlet of the right

-hand side air duct. Fig.

1

The

fluid temperature for each of the headlamp wipe wash operation is controlled by self regulating, heated power

wash jets mounted on to either side of the bumper.

Each powerwash jet is protected by

a cover supplied with an integral cover-to-bumperseal. The cover snap fixes into

the bumper.

15.6.2

This switch only operates with the ignition switch in position '11' and has the following functions:

windscreen Wiper and Washer Switch

Position 0 The wind screen wiper is switched 'OFF' and parked.

Position 1: Normal speed wiper operation is obtained by pushing the switch lever up one position.

Position 2: High speed wiper operation is obtained by pushing the switch lever fully up.

Position D: To obtain intermittent wiper operation the switch lever is pushed down and released.

The delay period will vary with vehicle speed. To cancel the function repeat the procedure.

15.6.2.1 Single Wipe Operation

To obtain a single sweep of the wiper blade, the lever is pulled towards the steering wheel and released.

W The intermittenmick wipe operations are both at slow speed and they are controlled by a Central Control

Module (CCM), which also controls the headlamp power wash operation.

Issue 1 August 1994 X300 VSM

Page 358 of 521

15.6.2.2 Programmed Wash / Wipe Operation

The end of the switch lever must be pressed inwards for the windscreen wash and wipe operation. Wash / wipe con- tinues for as long as the lever is pressed.

When released, the windscreen wiper stops immediately and the wiper blades sweep for

a further three wipes.

On pressing the end of the switch lever inward and then releasing

it, the windscreen washers operate for approximately

two seconds before stopping, whilst the wiper blade continues for a further three wipes.

N&: If the end of the switch lever is pressed while the washer fluid warning light is illuminated, the windscreen

washers, but not the wiper blade continues to operate.

0

15.6.2.3 Headlamp Power Wash Operation (where fitfed)

The headlamp power wash operates only when the programmed washer/ wipe function is selected and the side lights

are 'ON'

The headlamp power wash does not operate if the windscreen washer reservoir fluid lever is low. This is indicated

by the washer fluid level warning light illuminating.

&&: The headlamp power wash only operates on the 1st and every 6th succeeding cycle of the programme wash /wipe switch, after the ignition switch has been turned to position '11'.

X300 VSM 17 Issue 1 August 1994

Page 374 of 521

Black

Black

Black All

models

All Models

All Models

Black

Black All

Models

All Models

Black/

White Stripe

Black/

White Stripe

Black Non

Aircon.

Models

only

Non Power

Wash Models

only

Optional

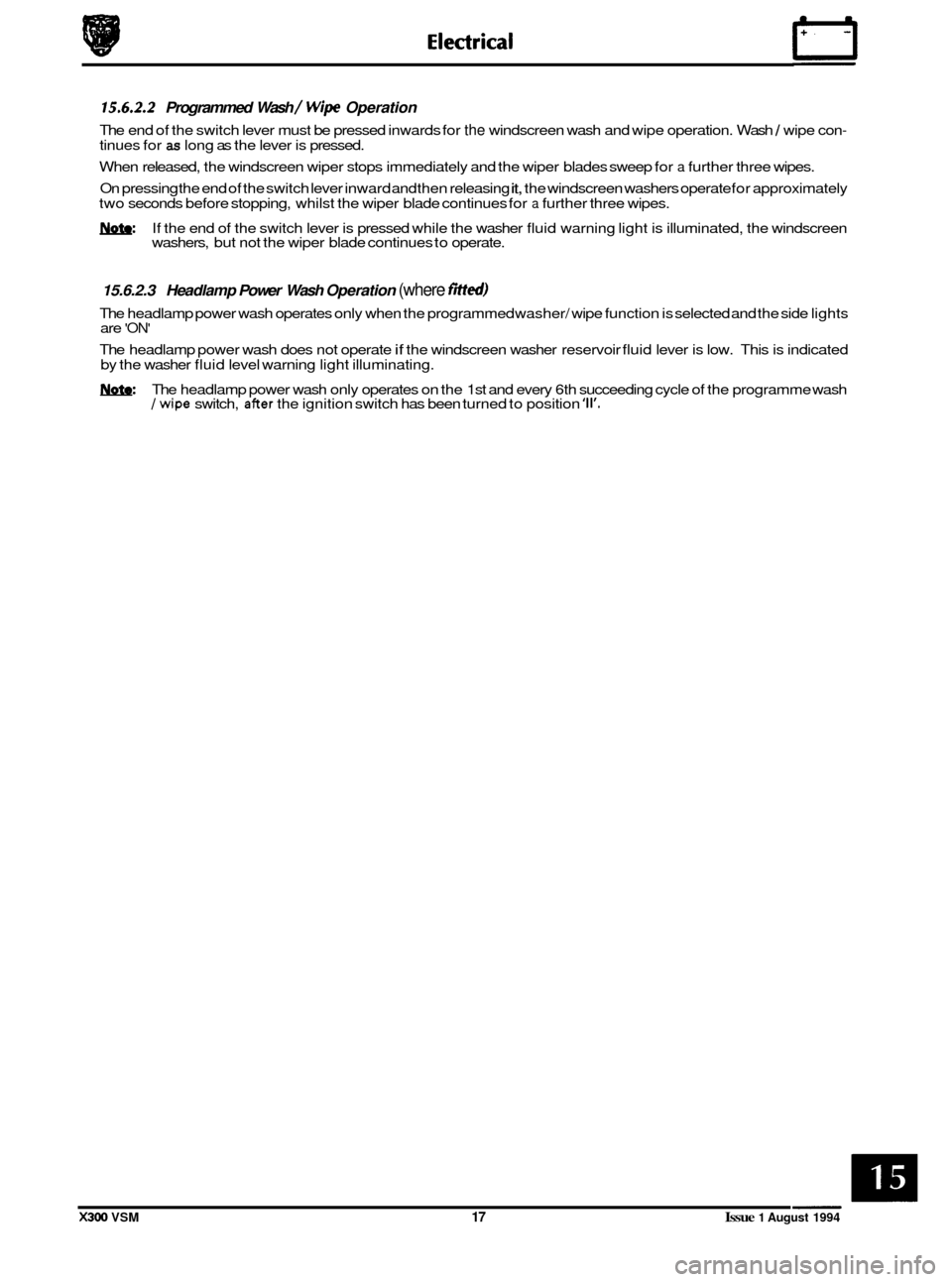

0 Key to Fig. 1, hgine Compartment Relays, page 14.

Number v12 Color

All Models

SRO

B6.55.04

Rdaw

Horn

Location

Engine

compartment,

inside the left

hand side fuse box.

Engine

compartment,

behind left hand head

lamp assembly.

see starter

motor

solenoid. All

Models

1 ~~

All

Models 5 Starter Motor

Solenoid

4 All Models

All Models 18.30.34 Air-conditionin

g Water Pump

Wiper Motor

On

/Off

2 see starter

motor

solenoid.

see starter

motor

solenoid. All

Models

3 Wiper Fast /

Slow

18.30.71 Engine

compartment, behind right

hand head

lamp assembly. 8 EMS Engine

Management

System

Control

Black

I

All Models 9 Ignition Coil

PI Main Relay see

EMS

control.

see EMS

control. Black

I

All

Models 8

Air Pump 7 see EMS

control.

see EMS

control. Black

Air Injection

Black Air Con

- Model Air

Injection

only

All Models

18.30.34

86.55.08 Air

Conditioning

Compressor

Clutch

Relay Case

Engine

compartment,

on the right

hand side inner

wing valance.

Relay

Case Non Power

Wash

Models

only

11

10

12

Power Wash

Screen Wash Optional

All Models

All Models

Black

All Models

Ignition Relay

Engine

compartment,

inside

right

hand fuse box.

X300 VSM 33 Issue 1 August 1994

Page 376 of 521

I SRO I Rdw* AJ16 v12

Automatic Automatic

Models only Models only

Automatic Automatic

Models only Models only

UK

& ROW -

Manual Seat

only

UK

& ROW -

Manual Seat

onh/

UK & ROW -

Manual Seat

only

Manual Seat

only

UK

& Manual -

Seat only

UK

& Manual -

Seat only

UK

& ROW -

Optional

Optional

Optional Optional

Keylock

Number

13

14

15

16

34

35

17

36

37

38

Driver's Seat Height

Control (Upward)

Driver's Seat Height

Control (Downward)

Passenger Seat

Height Control (Upward)

Passenger Seat

Height Control

(Downward)

Driver's Seat Heater

All Models

All Models

All Models

Passenger Seat

Heater

RH Front

Screen

Heater

LH Front Screen

Heater

Ignition All Models

25

All Models 26

All Models 23

Ignition

Air

-conditioning

Isolate

LH Blower

RH Blower

LH Blower

high

speed

RH Blower high

speed

Deadlock front

lefthear right All

Models All Models

20

Below gear selector 'J' gate.

Not NAS or

Japan

UK

& Europe

only

All Models

All Models

USA

&

Canada only

All Models

All Models

All Models

All Models

Below

gear selector

'J' gate.

Not NAS or

30

UK & Europe 31

All Models 28

All Models 29

USA & 27

All Models 24

All Models 33

All Models 22

All Models 32

Japan

only

Canada only

On

seat panel below

driver's seat.

86.55.78

86.55.74

On seat panel below

driver's seat.

Deadlock front

righthear left

Door Lock

Door Unlock

Driver's Door

Unlock

Mirror Heater

Puddle Lamps

Cigar Lighter

Fuel Flap Lock On

seat panel below

passenger's seat.

On seat panel below

passenger's seat.

On seat panel below

driver's seat.

On seat panel below

passenger's seat.

Left hand side footwell on

front

'A' post, behind cover.

Left hand side footwell on

front

'A' post, behind cover.

Fuse box assembly

RH side heelboard.

Fuse box assembly

LH side heelboard.

Behind

RH side heelboard.

Behind

RH side heelboard.

Behind RH side heelboard.

Behind

RH side heelboard.

Behind

RH side heelboard.

Behind LH side heelboard.

Behind LH side heelboard.

Behind LH side heelboard.

Behind LH side heelboard.

Behind LH side heelboard.

Behind

RH side heelboard.

Behind LH side heelboard.

Behind

RH side heelboard.

Behind LH side heelboard.

Color

Blue

Blue

Violet

Violet

Violet Violet Blue Blue

Blue

Blue

Blue

Blue

Blue

Blue

Blue Blue

Blue

Violet

Violet

Violet

Violet

Violet

Violet Blue

Blue

Violet All

Models All Models

All Models All Models

All Models All Models

18

X300 VSM 35 Issue 1 August 1994

Page 398 of 521

0

Engine Bay Fuse Box - right-hand side

Fuse No. Fuse Colour Code

- F1

F2 Red

F3

F4 Red

F5 Red

-

F6 Tan

F7 Clear

F8 Red

F9 -

FIO Tan

F12 Red

F13 Red

F14 Red F15

-

F16 Red

F17 Light Green

F18 Red

Value

(amps)

10

10

10

5

25

10

-

5

20

10

10

10

10

30

10

Circuit

Not used

Main beam headlamp

- right-hand side

Not used

Lowered beam

headlamD - riaht-hand side ."

Side light -front right-hand side

Turn indicator

-front right-hand side

Side repeater flasher

- right-hand side

Engine control module

(ECM)

Air pump (6 cyl. - where fitted)

Ignition coils

(VIZ)

Air conditioning clutch

Not used

Generator

Front lighting control module

- right-hand

Air conditioning clutch

Windshield wash

J headlamp power wash heaters and relays

Engine management system relay supply

Injectors

Engine management system

Starter relay Ignition coil sensing and air pump relay (6

cyl.)

Fuel injection relay

Engine management sensing

(VIZ)

Windshield washer pump

Lambda heaters

Idle speed control valve

Not used

Air pump control

Solenoid vacuum valve

(VIZ)

Water pump (supercharged)

Headlamp power wash pump

Front fog lamp

- right-hand side (where fitted)

0

0

Issue 1 August 1994 X300 VSM AI-95MY 15

Page 399 of 521

Specification

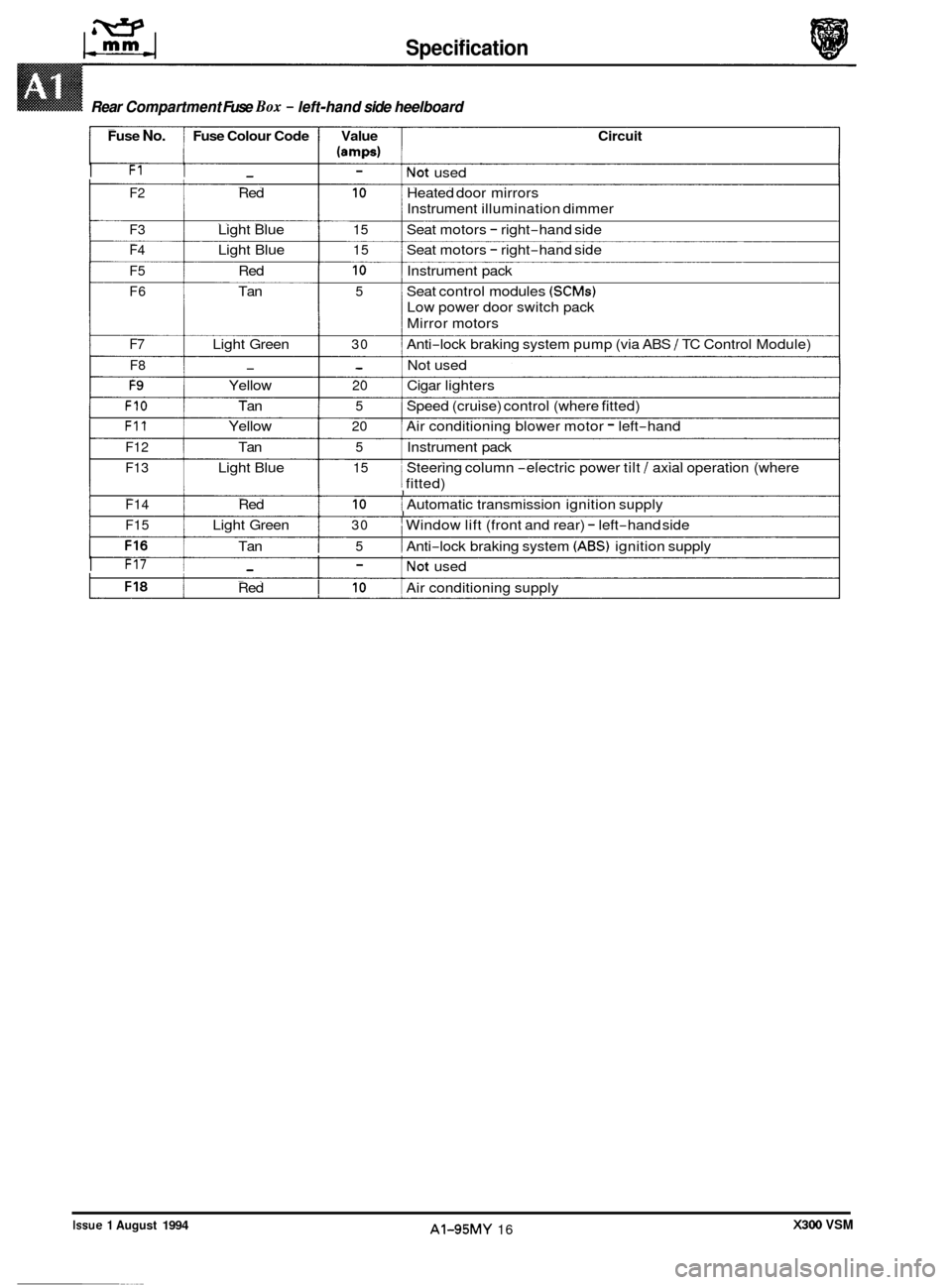

Rear Compartment Fuse Box - left-hand side heelboard

Fuse No. Fuse Colour Code Value Circuit

(amps)

I F1 I - I - lNot used

F2 Red 10 Heated door mirrors

F3 Light Blue 15 Seat motors - right-hand side

F4 Light Blue 15 Seat motors - right-hand side

F5 Red 10 Instrument pack

F6 Tan 5 Seat control modules (SCMs)

Low power door switch pack

Mirror motors

Instrument

illumination dimmer

F7 Light Green 30 Anti-lock braking system pump (via ABS / TC Control Module)

F8 - - Not used

F9 Yellow 20 Cigar lighters

FIO Tan 5 Speed (cruise) control (where fitted)

F11 Yellow 20 Air conditioning blower motor - left-hand

F12 Tan 5 Instrument pack

F13 Light Blue 15 Steering column -electric power tilt / axial operation (where

j fitted) 1 I I F14 Red 10 i Automatic transmission ignition supply I I I F15 Light Green 30 I Window lift (front and rear) - left-hand side

Tan

I 5 1 Anti-lock braking system (ABS) ignition supply

I F17 1 - I - lNot used

Red

I 10 I Air conditioning supply

Rear Compartment Fuse Box - left-hand side heelboard ~~

X300 VSM Issue 1 August 1994 AI-95MY 16

0

0

0

Page 406 of 521

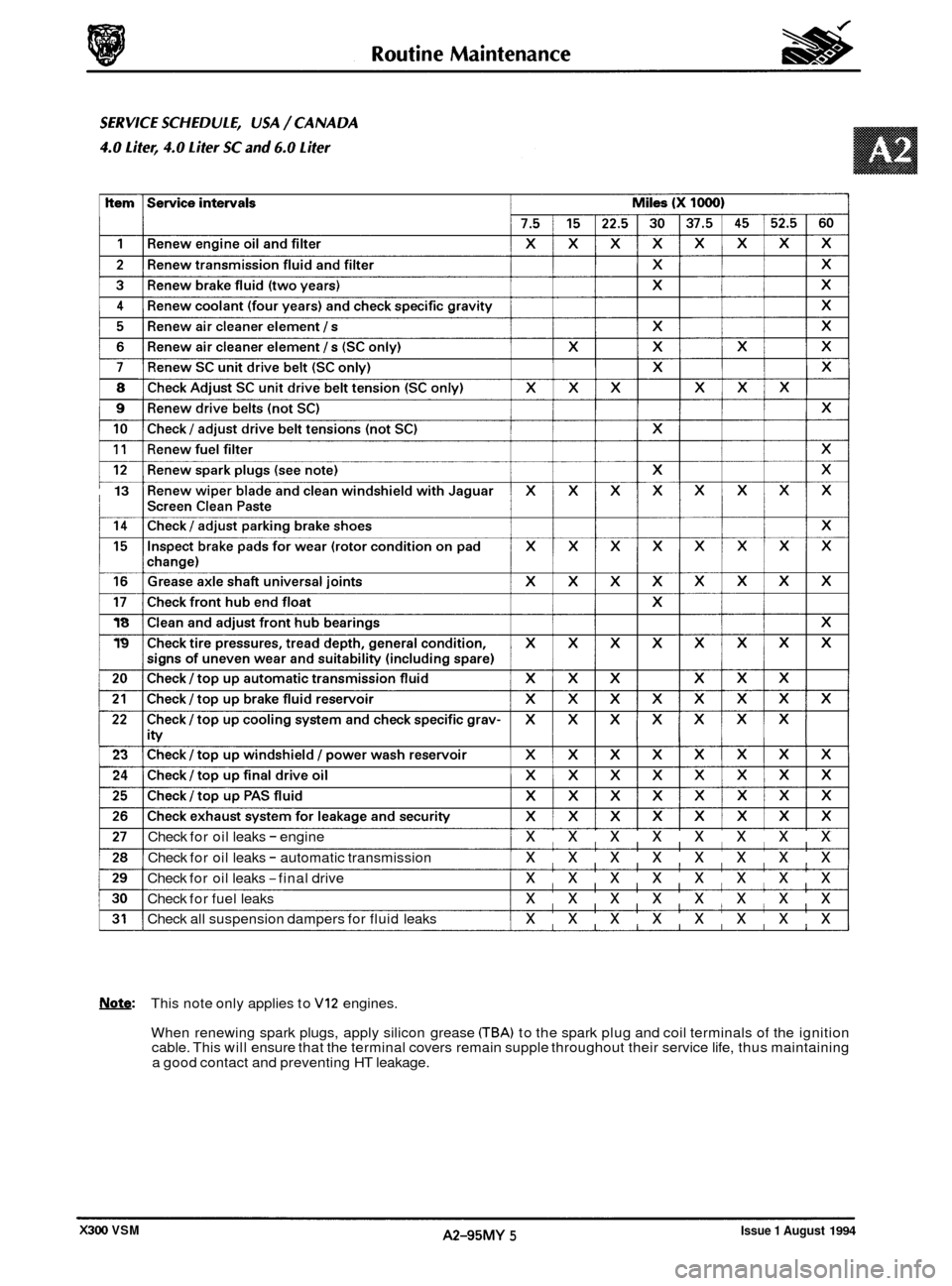

Routine Maintenance

SERVICE SCHEDULE - UK, EUROPe ROW

3.2 Liter, 4.0 Liter, 4.0 Liter SC and 6.0 Liter

0

0

Note: This note only applies to VI2 engines.

When renewing spark plugs, apply silicon grease

(TBA) to the spark plug and coil terminals of the ignition

cable. This will ensure that the terminal covers remain supple throughout their service life, thus maintaining

a good contact and preventing HT leakage.

A2-95MY 3 Issue 1 August 1994 X300 VSM

Page 408 of 521

j

8

9

10

13 I

18

19

23

24

Check for oil leaks - engine xxxxxxxx

Check for oil leaks - automatic transmission xxxxxxxx

Check for oil leaks -final drive xxxxxxxx

Check for fuel leaks xxxxxxxx

Check all suspension dampers for fluid leaks xxxxxxxx

Note: This note only applies to VI2 engines.

When renewing spark plugs, apply silicon grease

CTBA) to the spark plug and coil terminals of the ignition

cable. This will ensure that the terminal covers remain supple throughout their service life, thus maintaining

a good contact and preventing HT leakage.

Issue 1 August 1994 A2-95MY 5 X300 VSM

Page 412 of 521

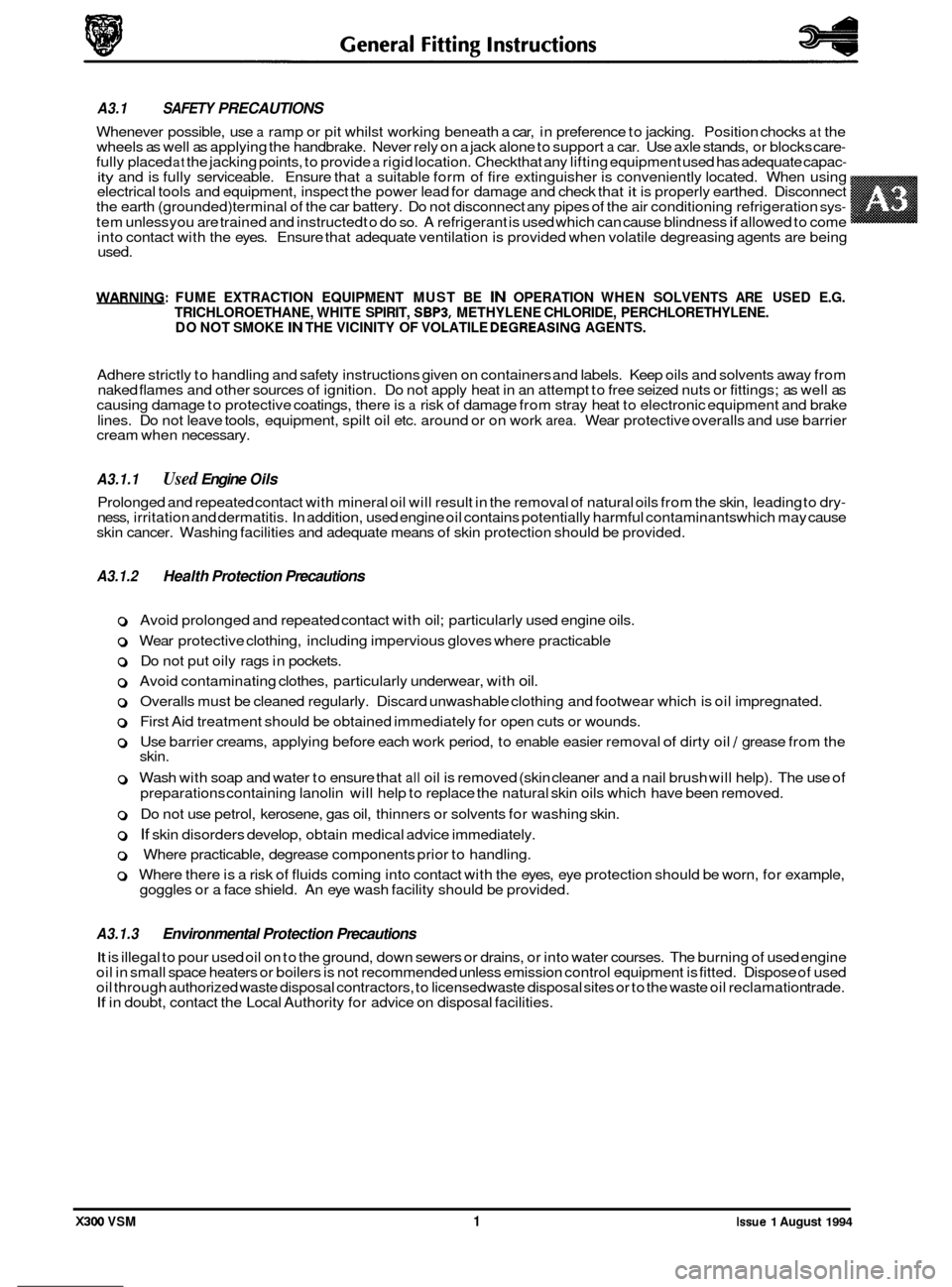

used.

WARNING: FUME EXTRACTION EQUIPMENT MUST BE IN OPERATION WHEN SOLVENTS ARE USED E.G.

TRICHLOROETHANE, WHITE SPIRIT, SBPB, METHYLENE CHLORIDE, PERCHLORETHYLENE.

DO NOT SMOKE IN THE VICINITY OF VOLATILE DEGREASING AGENTS.

Adhere strictly to handling and safety instructions given on containers and labels. Keep oils and solvents away from

naked flames and other sources of ignition. Do not apply heat in an attempt to free seized nuts or fittings; as well as

causing damage to protective coatings, there is

a risk of damage from stray heat to electronic equipment and brake

lines. Do not leave tools, equipment, spilt oil etc. around or on work

area. Wear protective overalls and use barrier

cream when necessary.

0 A3.1.1 Used Engine Oils

Prolonged and repeated contact with mineral oil will result in the removal of natural oils from the skin, leading to dry- ness, irritation and dermatitis. In addition, used engine oil contains potentially harmful contaminants which may cause

skin cancer. Washing facilities and adequate means of skin protection should be provided.

A3.1.2 Health Protection Precautions

0 Avoid prolonged and repeated contact with oil; particularly used engine oils.

o Wear protective clothing, including impervious gloves where practicable

0 Do not put oily rags in pockets.

0 Avoid contaminating clothes, particularly underwear, with oil.

0 Overalls must be cleaned regularly. Discard unwashable clothing and footwear which is oil impregnated.

o First Aid treatment should be obtained immediately for open cuts or wounds.

0 Use barrier creams, applying before each work period, to enable easier removal of dirty oil / grease from the

skin.

0 Wash with soap and water to ensure that all oil is removed (skin cleaner and a nail brush will help). The use of

preparations containing lanolin will help to replace the natural skin oils which have been removed.

o Do not use petrol, kerosene, gas oil, thinners or solvents for washing skin.

0 If skin disorders develop, obtain medical advice immediately.

0 Where practicable, degrease components prior to handling.

0 Where there is a risk of fluids coming into contact with the eyes, eye protection should be worn, for example,

goggles or a face shield. An eye wash facility should be provided.

A3.1.3 Environmental Protection Precautions

A3.1 SAFETY PRECAUTIONS

Whenever possible, use a ramp or pit whilst working beneath a car, in preference to jacking. Position chocks at the

wheels as well as applying the handbrake. Never rely on a jack alone to support a car. Use axle stands, or blocks care- fully placed at the jacking points, to provide a rigid location. Checkthat any lifting equipment used has adequate capac- ity and is fully serviceable. Ensure that a suitable form of fire extinguisher is conveniently located.

When using

electrical tools and equipment, inspect the power lead for damage and check that it is properly earthed. Disconnect

the earth (grounded) terminal of the car battery. Do not disconnect any pipes of the air conditioning refrigeration sys-

tem unless you are trained and instructed to do so. A refrigerant is used which can cause blindness if allowed to come

into contact with the eyes. Ensure that adequate ventilation is provided when volatile degreasing agents are being

It is illegal to pour used oil on to the ground, down sewers or drains, or into water courses. The burning of used engine

oil in small space heaters or boilers is not recommended unless emission control equipment is fitted. Dispose of used

oil through authorized waste disposal contractors, to licensed waste disposal sites or to the waste oil reclamation trade.

If in doubt, contact the Local Authority for advice on disposal facilities.

X300 VSM 1 Issue 1 August 1994

Page 480 of 521

I 03 I Door lock actuators (4 off) 1 part of door assemblv I I

Issue 1 August 1994 X300 VSM 3 I

1 04 I Door lock switches (2 off) I part of door latch assembly I I

1 05 IHoodswitch 1 located above siren I I

1 06 IHorn 1 located on front RH side of en(

1 07 I Inclination sensor I behind luggage compartment LH liner I I

I 08 I Intrusion sensor (LH) I located above LH door behind roof lining I

I 09 I intrusion sensor (RH) 1 located above LH door behind roof lining I

I

1 1 part of door latch assembly I 10 I Key barrel switches (2 off)

1 11 I Key fob transmitter 1 part of key fob I I

I 12 I Key transponder 1 part of key I I

I 13 I Reader exciter coil 1 part of ignition switch I I

I 14 I Reader exciter module 1 part of steering column assembly I I

1 15 I Relays (deadlock) I I I

1 18 I Security active indicator part of central locking switch I I

I 19 I Securitv and lockina control module (SLCM) located in luaaaae compartment behind LH liner I I

1 20 ISounder , located on front RH side of engine bay I I

1 25 IValet switch 1 in centre console compartment I I

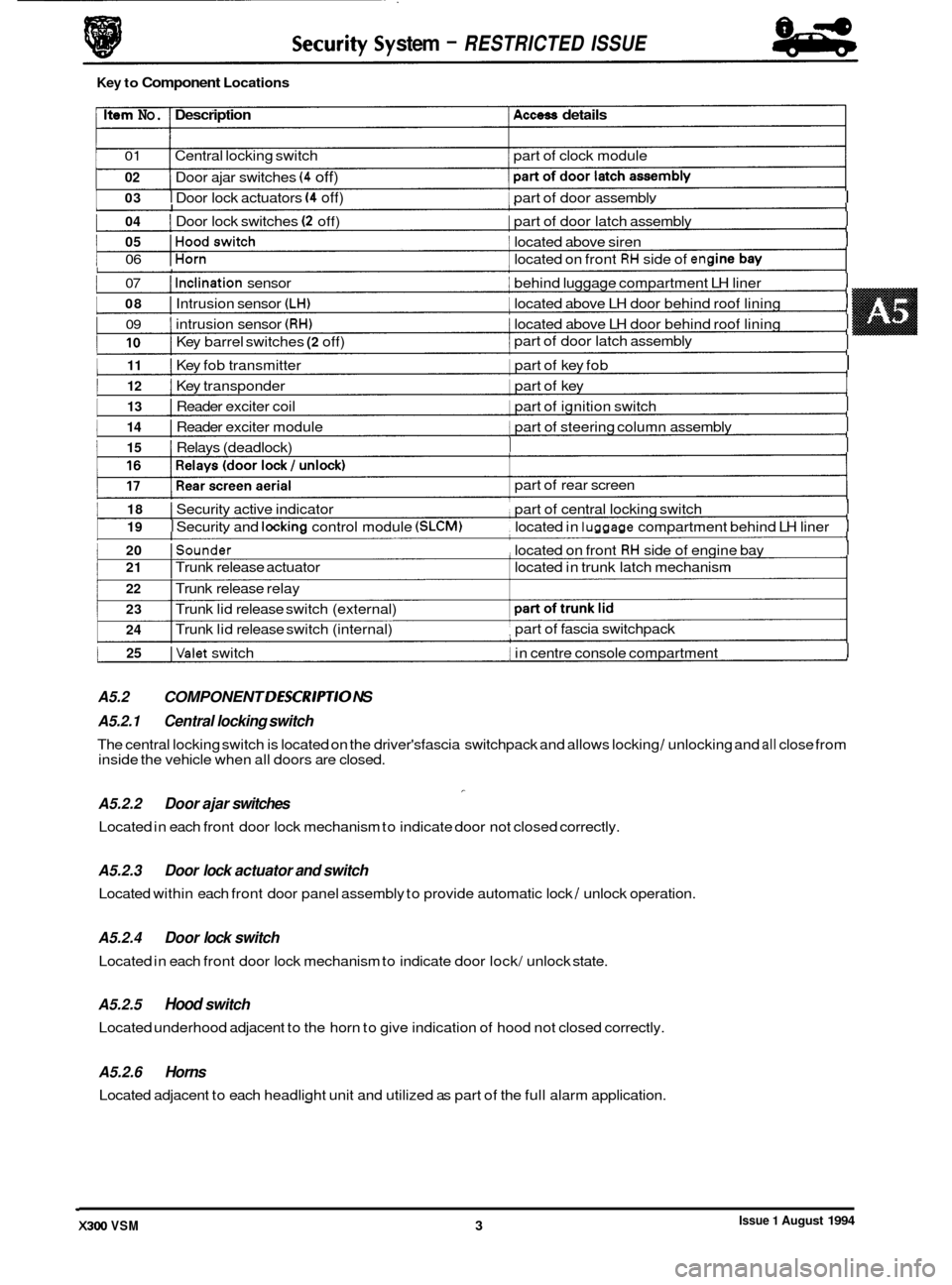

A5.2 COMPONENT DESCR/PT/O NS I

stem - RESTRICTED ISSUE

Key to Component Locations

Item No. Description Access details

01 Central locking switch part of clock module

02

1 I

Door ajar switches (4 off)

I I

part of rear screen

I 21 I Trunk release actuator located in trunk latch mechanism

22 I Trunk release relay

23

24 I Trunk lid release switch (external)

I Trunk lid release switch (internal) part of

fascia switchpack ,

A5.2.1 Central locking switch

A5.2.2 Door ajar switches

Located in each front door lock mechanism to indicate door not closed correctly.

-

The central locking switch is located on the driver'sfascia switchpack and allows locking / unlocking and all close from

inside the vehicle when all doors are closed.

A5.2.3

Located within each front door panel assembly to provide automatic lock / unlock operation.

Door lock actuator and switch

A5.2.4 Door lock switch

Located in each front door lock mechanism to indicate door lock/ unlock state.

A5.2.5 Hood switch

Located underhood adjacent to the horn to give indication of hood not closed correctly.

A5.2.6 Horns

Located adjacent to each headlight unit and utilized as part of the full alarm application.