JAGUAR XJ6 1994 2.G Repair Manual

Manufacturer: JAGUAR, Model Year: 1994, Model line: XJ6, Model: JAGUAR XJ6 1994 2.GPages: 521, PDF Size: 17.35 MB

Page 61 of 521

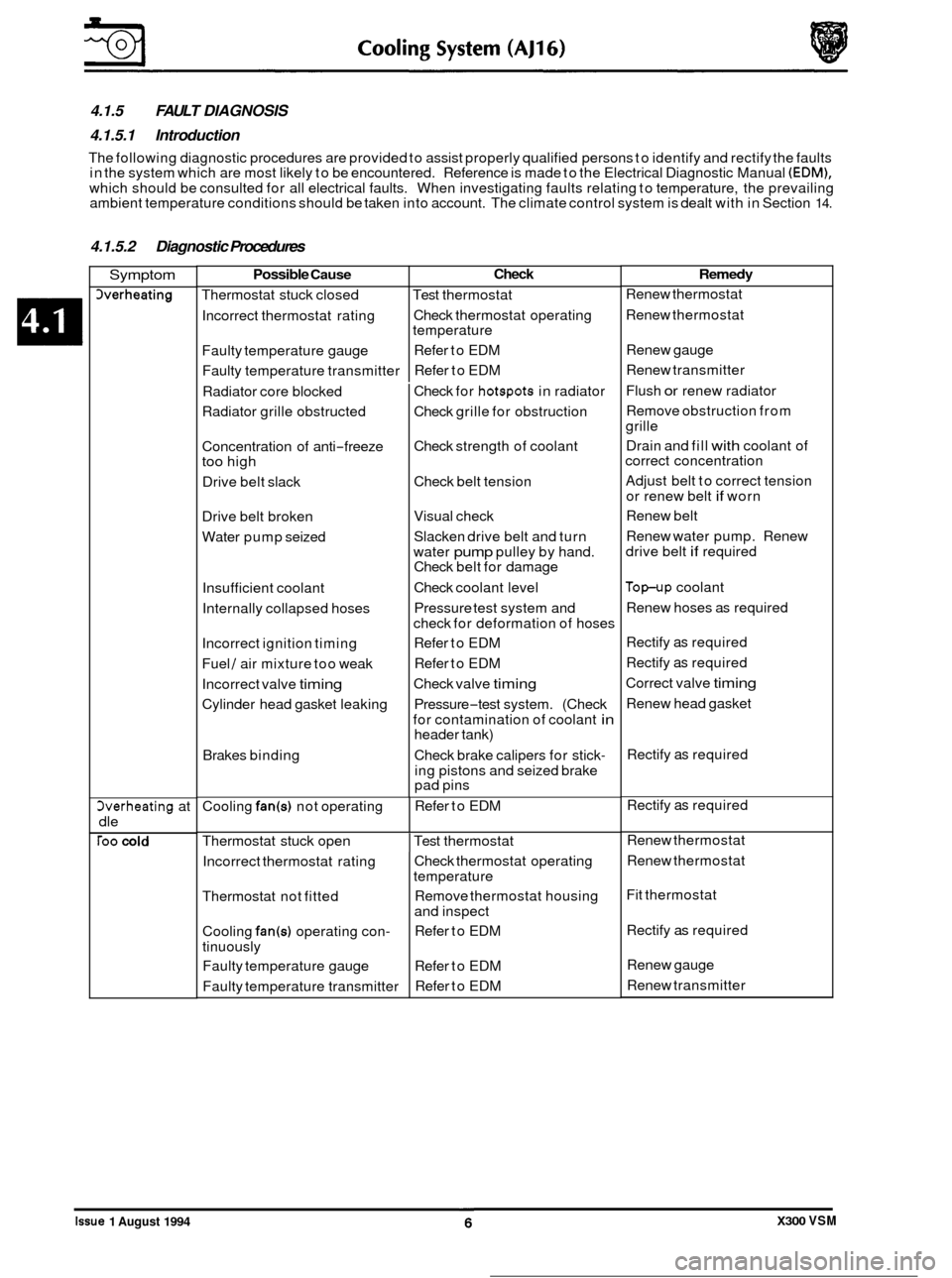

4.1.5 FAULT DIAGNOSIS

4.1.5.1 Introduction

The following diagnostic procedures are provided to assist properly qualified persons to identify and rectify the faults

in the system which are most likely to be encountered. Reference is made to the Electrical Diagnostic Manual (EDM),

which should be consulted for all electrical faults. When investigating faults relating to temperature, the prevailing

ambient temperature conditions should be taken into account. The climate control system is dealt with in Section 14.

Possible Cause

Thermostat stuck closed

Incorrect thermostat rating

Faulty temperature gauge

Faulty temperature transmitter

4.1.5.2 Diagnostic Procedures

Check

Test thermostat

Check thermostat operating

temperature

Refer to EDM

Refer to EDM

Symptom

herheating

Cooling fan(s) not operating 3verheating at

dle

roo cold

Refer to EDM

Incorrect thermostat rating

Thermostat not fitted

Cooling

fan(s) operating con-

tinuously Faulty temperature gauge

Faulty temperature transmitter

Radiator

core blocked

Radiator grille obstructed

Check thermostat operating

temperature

Remove thermostat housing

and inspect

Refer to EDM

Refer to EDM

Refer to EDM

Concentration of

anti

-freeze too high

Drive belt slack

Drive belt broken

Water pump seized

Insufficient coolant

Internally collapsed hoses

Incorrect ignition timing

Fuel

/ air mixture too weak

Incorrect valve

timing

Cylinder head gasket leaking

Brakes binding Check

for

hotspots in radiator

Check grille for obstruction

Check strength of coolant

Check belt tension

Visual check

Slacken drive belt and turn

water

pump pulley by hand.

Check belt for damage

Check coolant level

Pressure test system and

check for deformation of hoses

Refer to EDM

Refer to EDM

Check valve

timing

Pressure-test system. (Check

for contamination of coolant

in header tank)

Check brake calipers for stick

-

ing pistons and seized brake

pad pins

Thermostat stuck open

I Test thermostat

Remedy

Renew thermostat

Renew thermostat

Renew gauge

Renew transmitter

Flush

or renew radiator

Remove obstruction from

grille

Drain and fill

with coolant of

correct concentration

Adjust belt to correct tension

or renew belt

if worn

Renew belt

Renew water pump. Renew

drive belt

if required

Top-up coolant

Renew hoses as required

Rectify

as required

Rectify

as required

Correct valve

timing

Renew head gasket

Rectify

as required

Rectify

as required

Renew thermostat

Renew thermostat

Fit thermostat

Rectify

as required

Renew gauge

Renew transmitter

0

e

0

0

Issue 1 August 1994 X300 VSM

Page 62 of 521

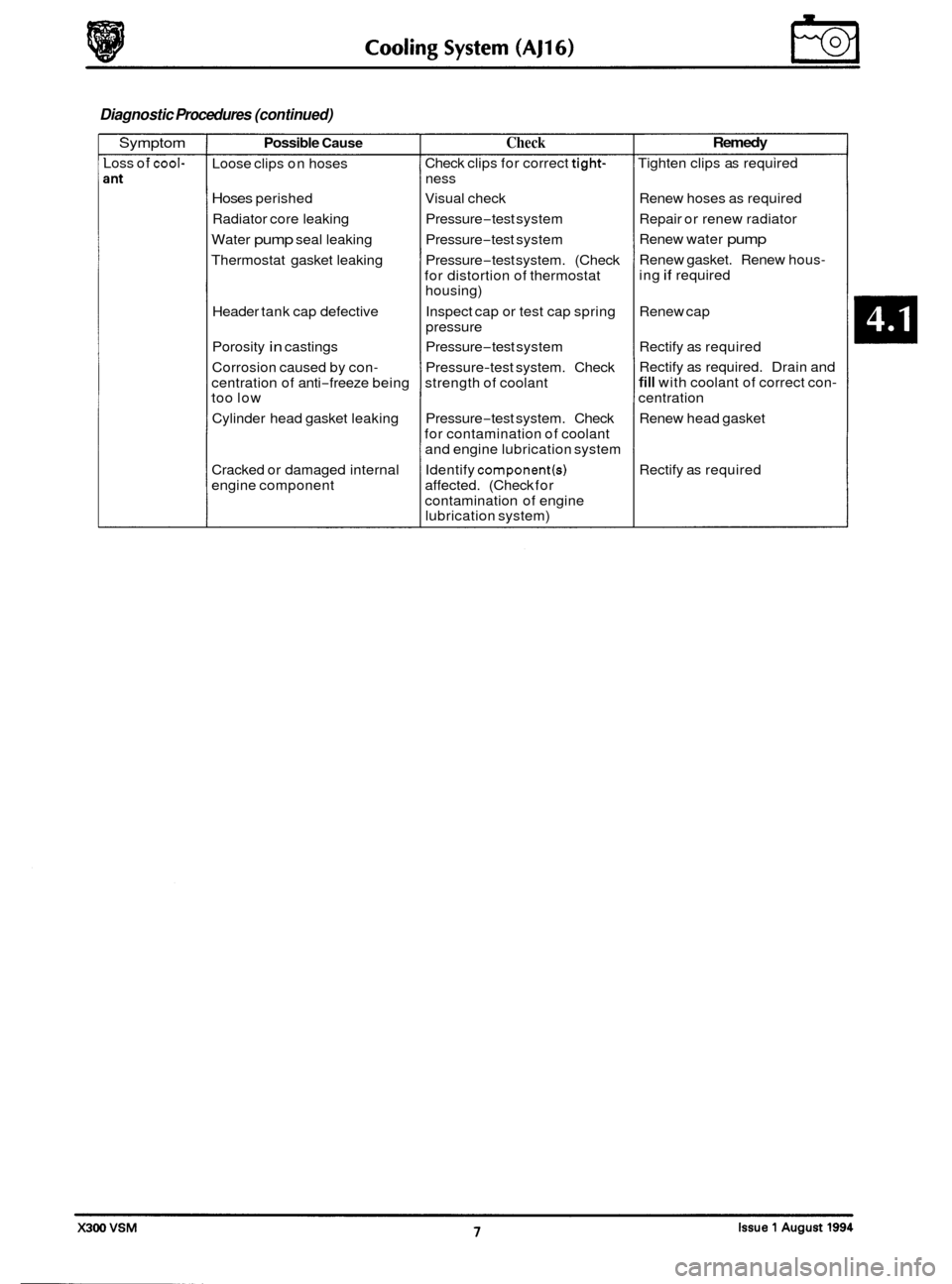

Diagnostic Procedures (continued)

Symptom

Loss of cool-

Possible Cause Check

Loose clips on hoses

Hoses perished Visual check

Radiator core leaking Pressure

-test system

Water

pump seal leaking Pressure-test system

Thermostat gasket leaking Pressure

-test system. (Check

for distortion of thermostat

housing)

Inspect cap or test cap spring

pressure

Pressure

-test system. Check

strength of coolant

Pressure

-test system. Check

for contamination of coolant

and engine lubrication system

Identify

component(s)

contamination of engine

lubrication system)

Check

clips for correct

tight-

ness

Header tank cap defective

Porosity

in castings Pressure-test system

Corrosion caused by con

-

centration of anti-freeze being

too low

Cylinder head gasket leaking

Cracked or damaged internal

engine component affected. (Check for

Remedy

Tighten clips as required

Renew hoses as required

Repair or renew radiator

Renew water

pump

Renew gasket. Renew hous-

ing if required

Renew cap

Rectify as required

Rectify as required. Drain and

fill with coolant of correct con-

centration

Renew head gasket

Rectify as required

Page 63 of 521

8

Page 64 of 521

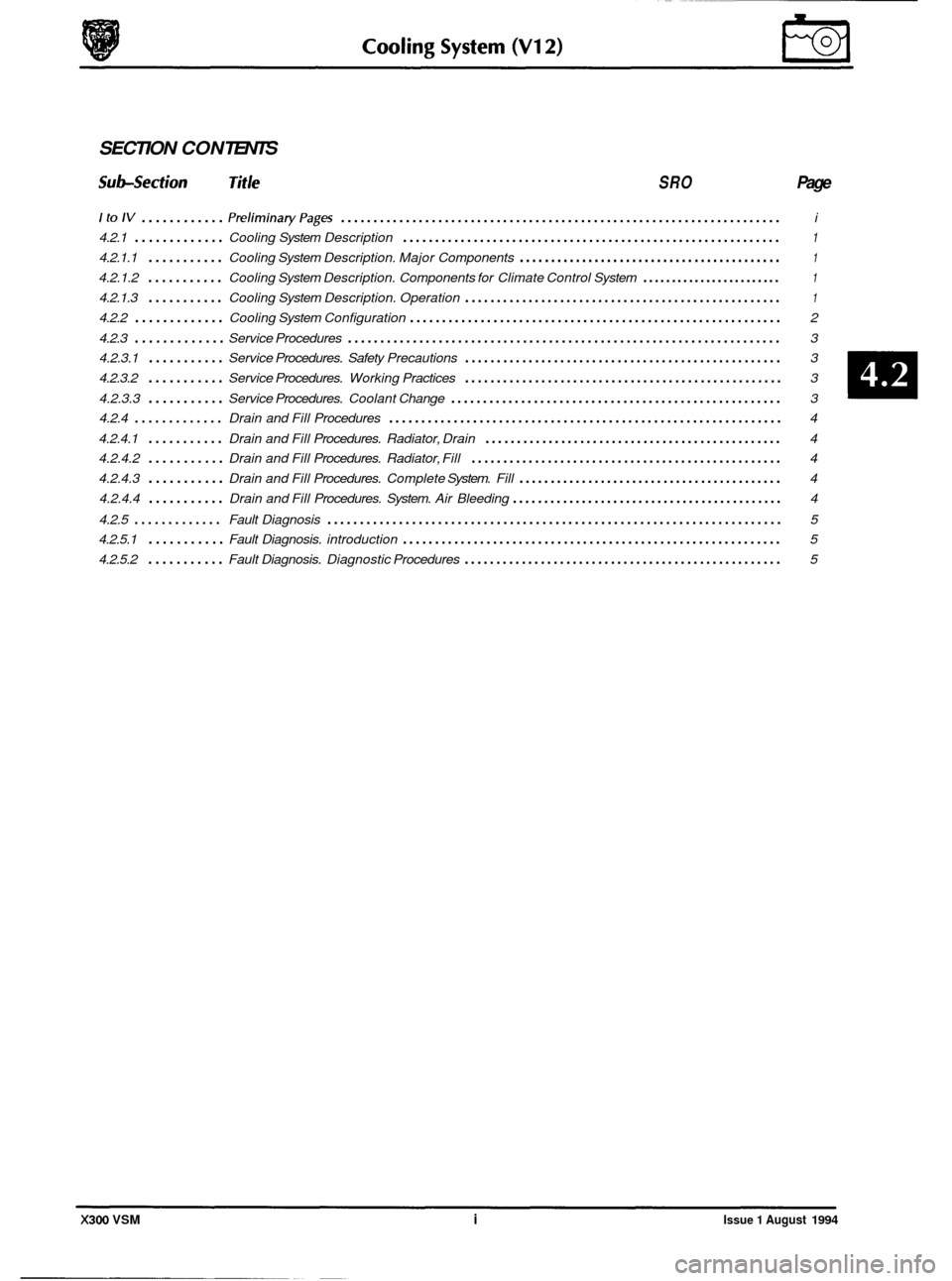

SECTION CON TENTS

Subsection Titie SRO Page

it0 IV ............ Preliminarypages .................................................................... i

4.2.1 ............. Cooling System Description ........................................................... 1

4.2.1.1 ........... Cooling System Description. Major Components .......................................... 1

4.2.1.2 ........... Cooling System Description. Components for Climate Control System ........................ 1

4.2.1.3 ........... Cooling System Description. Operation .................................................. 1

4.2.2 ............. Cooling System Configuration .......................................................... 2

4.2.3

............. Service Procedures ................................................................... 3

4.2.3.1

........... Service Procedures. Safety Precautions .................................................. 3

4.2.3.2

........... Service Procedures. Working Practices .................................................. 3

4.2.3.3

........... Service Procedures. Coolant Change .................................................... 3

4.2.4

............. Drain and Fill Procedures ............................................................. 4

4.2.4.1

........... Drain and Fill Procedures. Radiator, Drain ............................................... 4

4.2.4.2

........... Drain and Fill Procedures. Radiator, Fill ................................................. 4

* 4.2.4.3 ........... Drain and Fill Procedures. Complete System. Fill .......................................... 4

4.2.4.4

........... Drain and Fill Procedures. System. Air Bleeding ........................................... 4

4.2.5

............. Fault Diagnosis ...................................................................... 5

4.2.5.1

........... Fault Diagnosis. introduction ........................................................... 5

4.2.5.2

........... Fault Diagnosis. Diagnostic Procedures .................................................. 5

X300 VSM i Issue 1 August 1994

Page 65 of 521

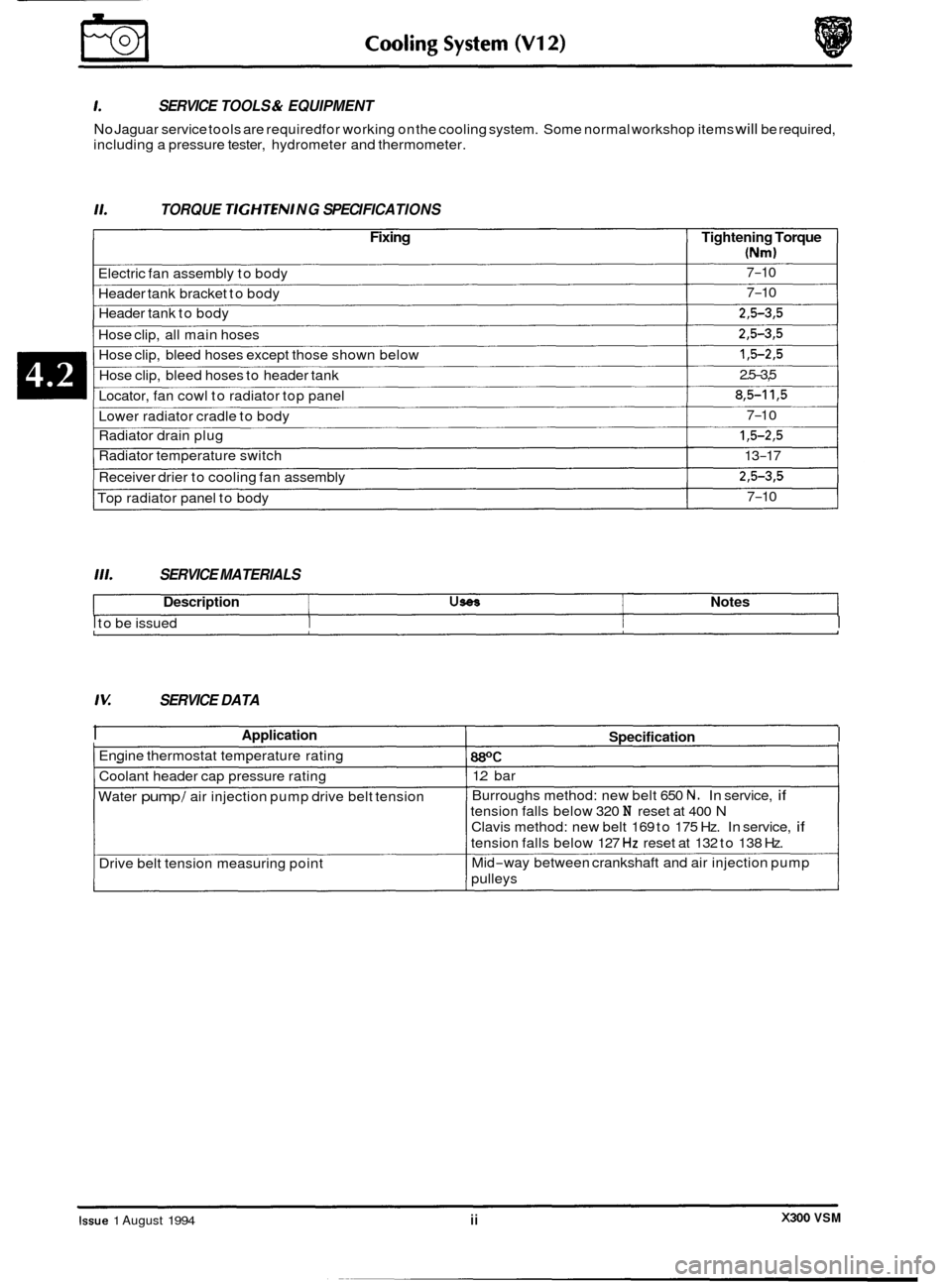

Lower radiator cradle to body

Radiator drain plug

1,5-2,5

Radiator temperature switch 13-17

Receiver drier to cooling fan assembly

Top radiator panel to body 7

-1 0

2,5-3,5

7-10

111. SERVICE

MATERIALS

Description USeS Notes

I to be issued I I I

0

SERVICE TOOLS & EQUIPMENT

No Jaguar service tools are required for working on the cooling system. Some normal workshop items will be required,

including a pressure tester, hydrometer and thermometer.

TORQUE TIGHTEN/ NG SPECI FICA TIONS

Fixing Tightening Torque

(Nm)

Electric fan assembly to body

Header tank bracket to body 7-10

7-10

Header tank to body

2,5-3,5

Hose clip, bleed hoses except those shown below 13-2.5

Hose clip, all main hoses 2,5-3,5

Hose clip, bleed hoses to header tank

Locator, fan cowl to radiator top panel 2.5-3,5

8,5-11,5

0

0

/U SERVICE

DATA

I Application

I Engine thermostat temperature rating

I Coolant header cap pressure rating

Water

pump / air injection pump drive belt tension

Drive belt tension measuring point

Specification I

88OC I

1.2 bar

Burroughs method: new belt 650

N. In service, if

tension falls below 320 N reset at 400 N

Clavis method: new belt 169 to 175 Hz. In service, if

tension falls below 127 Hz reset at 132 to 138 Hz.

Mid

-way between crankshaft and air injection pump

pulleys

X300 VSM Issue 1 August 1994 ii

Page 66 of 521

Cooling System (V12

4.2.1 COOLING SYSTEM DESCRIPTION I

4.2.1.1 Major Components

o Engine crossflow radiator, incorporating a concentric tube cooler for the power steering fluid mounted in the

left

-hand radiator side tank. Vehicles with automatic transmission have a six-plate transmission fluid cooler

mounted in the right

-hand radiator side tank. A double-action temperature switch, for controlling the electric

radiator cooling fans, is mounted in the left

-hand radiator side tank.

0 Engine driven, viscous-coupled, radiator cooling fan

0 Two electrically operated radiator cooling fans, mounted in front of the radiator.

o Coolant circulating pump, belt driven from the engine crankshaft.

0 Coolant header tank with pressure relief cap and coolant level probe.

0 Two engine thermostats, one in each cylinder bank.

4.2.1.2

0 Heater matrix.

0 Electrically operated coolant circulating pump, mounted on the left-hand side of the engine bulkhead.

o Solenoid operated valve, located adjacent to the coolant circulating pump.

Components for Climate Control System

1

4.2.1.3 Operation

The configuration of the cooling system is shown in Sub-section 4.2.2.

The cooling system is pressurized, which allows the system to operate at a higher temperature without overheating.

The header tank is fitted with a pressure relief cap to protect the system against overpressure.

Under cold start conditions, coolant is forced by the engine driven water pump through each cylinder block and cylin

- der head to the thermostat housings. The thermostats are closed to give rapid engine warm up, hence the coolant is

returned via the engine cross pipe to the water pump inlet. When normal engine operating temperature is reached,

the thermostats open and coolant is diverted through the radiator before returning to the water pump inlet.

If the engine driven fan is unable to provide sufficient cooling, the electrically operated fans operate in series and paral

-

lel underthe control of the radiator mounted temperature switch. Under hot operating conditions, the electric fans may

continue to operate after the engine has been switched off. The fans stop automatically when the coolant temperature

has been reduced sufficiently.

The system also provides the coolant supply for the climate control system, which is described in Section 14.

I

I X300 VSM 1 Issue 1 August 1994

Page 67 of 521

Cooling System (VI 2)

0

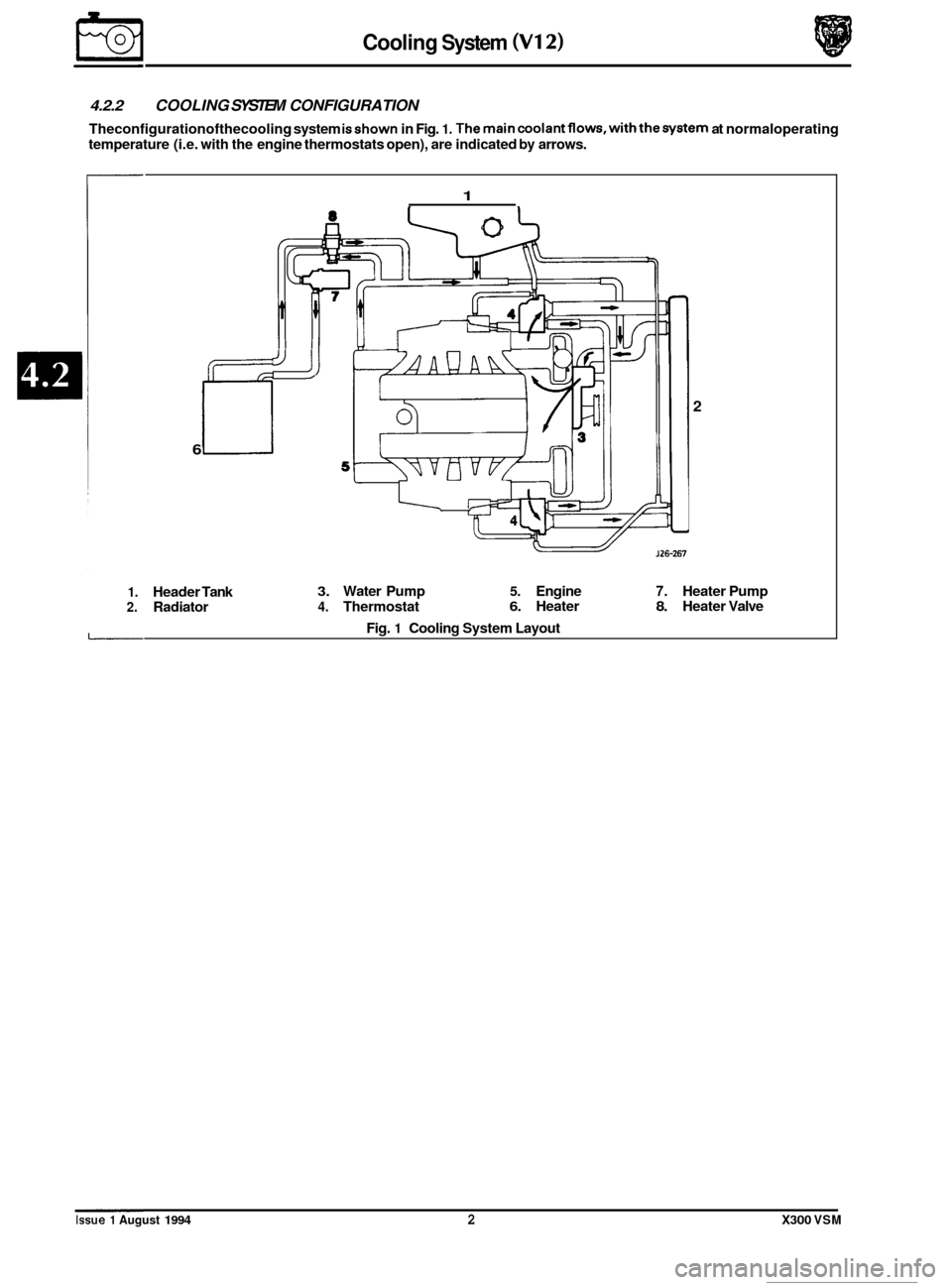

4.2.2 COOLING SYSTEM CONFIGURATION

Theconfigurationofthecooling system isshown in Fig. 1. Themaincoolantflows,withthesystem at normaloperating

temperature (i.e. with the engine thermostats open), are indicated

by arrows.

6 rr

1

2

1. Header Tank 3. Water Pump 5. Engine 7. Heater Pump

2. Radiator 4. Thermostat 6. Heater 8. Heater Valve

Fig.

1 Cooling System Layout

Issue 1 August 1994 2 X300 VSM

Page 68 of 521

WARNING: DO NOT REMOVE THE HEADER TANK PRESSURE CAP WHILE THE ENGINE IS HOT. IF THE CAP MUST

BE REMOVED, PROTECT THE HANDS AGAINST ESCAPING STEAM AND SLOWLY TURN THE CAP ANTI- CLOCKWISE UNTIL THE EXCESS PRESSURE CAN ESCAPE. LEAVE THE CAP IN THIS POSITION UNTIL

ALL THE STEAM AND PRESSURE HAS ESCAPED AND THEN REMOVE THE CAP COMPLETELY.

WARNING: WHEN DRAINING THE COOLANT WITH THE ENGINE HOT, PROTECT THE HANDS AGAINST CONTACT

WITH HOT COOLANT.

WARNING

: WHEN WORKING WITHIN THE ENGINE COMPARTMENT, KEEP CLEAR OF THE ENGINE DRIVEN RADI- ATOR COOLING FAN WHEN THE ENGINE IS RUNNING.

4.2.3.2 Working Practices

Whenfilling thesystem with coolant,ensurethatthevehicle isstanding on a level surfaceand thatthecoolant is poured

in slowly so that airlocks are not introduced into the system. Airlocks can seriously affect the operation of the climate

control system and can cause damage to the heater circuit pump.

Hose clips should always be positioned

so that there is proper access for tightening and that the clip does not foul or

interfere with the operation of any components.

4.2.3 SERVICE PROCEDURES

4.2.3.1 Safety Precautions

The anti-freeze specified in Appendix A1 must be used wherever possible. It is designed to afford the maximum cor- rosion protection to all metals found in the engine cooling system, as well as having the frost protection properties

necessary during the winter months. Should it not be available, then anti-freeze conforming to Ford Motor Company

specification

ESBM97B49-A may be used. To provide optimum temperature and corrosion protection, the specified

anti-freeze concentration must always be used. Once coolant has been drained from the system, it must be discarded

and not reused. Anti-freeze is harmful to the environment. Always dispose of used coolant safely and never pour it down a drain connected to the public sewer.

CAUTION: Never fill or topup the system with water only.

CAUTION

: Anti-freeze is harmful to paintwork. Coolant spillages must be wiped up immediately and the affected

area washed to remove all traces of coolant.

CAUTION: To prevent the possibility of damage to the heater circuit

pump, the pump should be electrically isolated if the ignition has to be turned ON while the cooling system is drained.

The drive belt must always be tensioned to the specified value and the tension checked at the correct point on the belt.

This information is given in Sub-section IV in the preliminary pages.

When tightening components, the torque figures given in Sub

-section II in the preliminary pages should always be

used for the fastenings listed.

When fitting a replacement thermostat, ensure that the jiggle-pin is to the top of the thermostat housing.

4.2.3.3 Coolant Change

The coolant must be changed at intervals of four years. The system should be drained from the radiator drain plug,

flushed and filled with fresh coolant. Flushing should be carried out thoroughly to remove all the old coolant from the

engine and heater matrix. (The heatervalve isopen with the ignition OFF). AfterfilIing,checkthecoolant concentration

with a hydrometer. For specified anti-freeze and coolant concentration, see in Appendix Al.

X300 VSM 3 Issue 1 August 1994

Page 69 of 521

€3 Cooling System (V12)

4.2.4 DRAIN AND FILL PROCEDURES

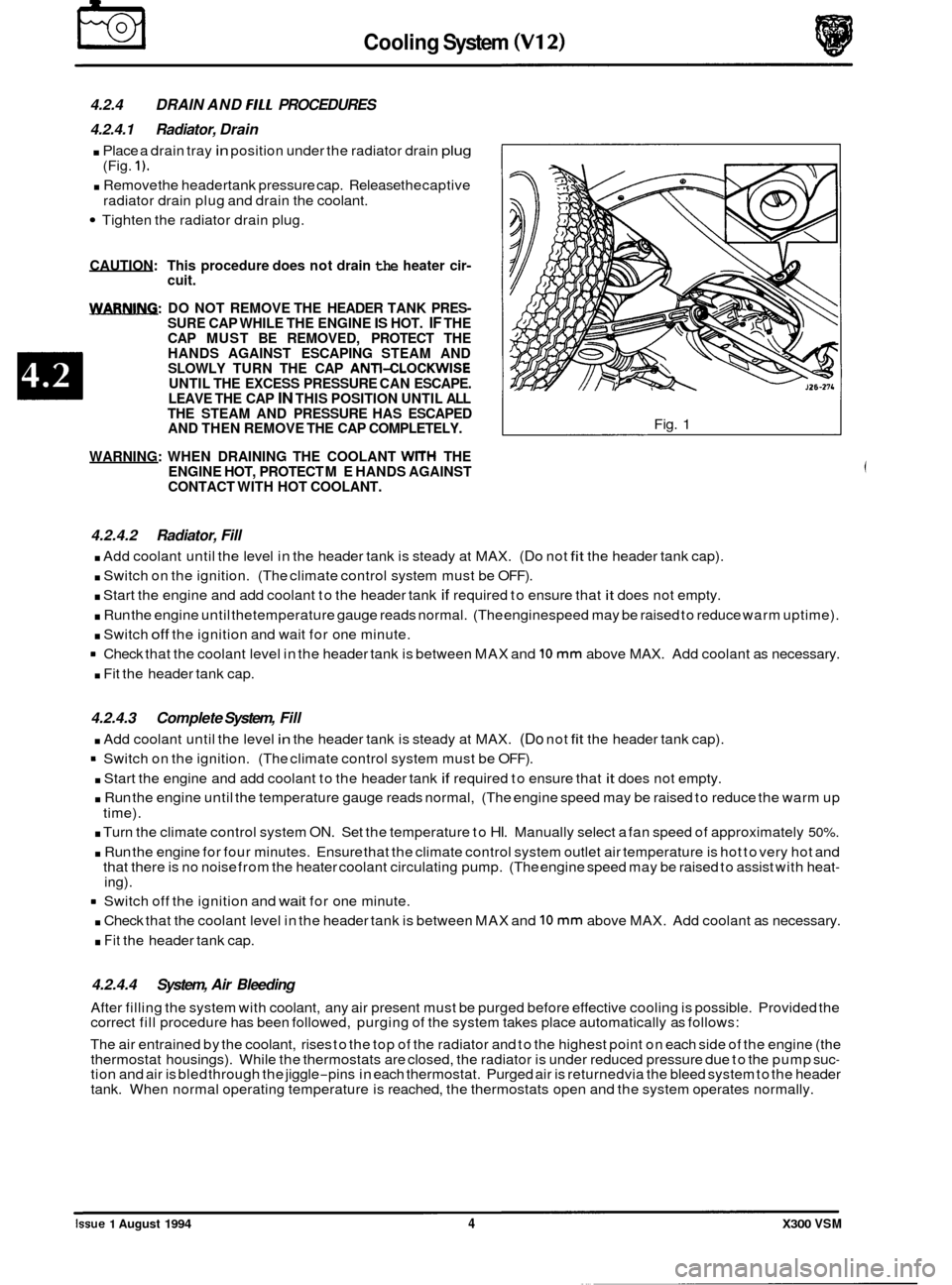

4.2.4.1 Radiator, Drain

. Place a drain tray in position under the radiator drain plug

. Remove the headertank pressure cap. Release thecaptive

Tighten the radiator drain plug.

(Fig.

1).

radiator drain

plug and drain the coolant.

CAUTION: This procedure does not drain the heater cir- cuit.

m: DO NOT REMOVE THE HEADER TANK PRES- SURE CAP WHILE THE ENGINE IS HOT. IF THE

CAP MUST BE REMOVED, PROTECT THE

HANDS AGAINST ESCAPING STEAM AND

SLOWLY TURN THE CAP

ANTI-CLOCKWISE UNTIL THE EXCESS PRESSURE CAN ESCAPE.

LEAVE THE CAP IN THIS POSITION UNTIL ALL

THE STEAM AND PRESSURE HAS ESCAPED

AND THEN REMOVE THE CAP COMPLETELY.

WARNING: WHEN DRAINING THE COOLANT

WITH THE

ENGINE HOT, PROTECT ME HANDS AGAINST

CONTACT WITH HOT COOLANT.

Fig. 1

4.2.4.2 Radiator, Fill

. Add coolant until the level in the header tank is steady at MAX. (Do not fit the header tank cap).

. Switch on the ignition. (The climate control system must be OFF).

. Start the engine and add coolant to the header tank if required to ensure that it does not empty.

. Run the engine until thetemperature gauge reads normal. (The enginespeed may be raised to reduce warm uptime).

. Switch off the ignition and wait for one minute.

Check that the coolant level in the header tank is between MAX and

10 mm above MAX. Add coolant as necessary.

. Fit the header tank cap.

4.2.4.3 Complete System, Fill

. Add coolant until the level in the header tank is steady at MAX. (Do not fit the header tank cap).

= Switch on the ignition. (The climate control system must be OFF).

. Start the engine and add coolant to the header tank if required to ensure that it does not empty.

. Run the engine until the temperature gauge reads normal, (The engine speed may be raised to reduce the warm up

. Turn the climate control system ON. Set the temperature to HI. Manually select a fan speed of approximately 50%.

. Run the engine for four minutes. Ensure that the climate control system outlet air temperature is hot to very hot and

that there is no noise from the heater coolant circulating pump. (The engine speed may be raised to assist with heat- ing).

time).

8 Switch

off the ignition and wait for one minute.

. Check that the coolant level in the header tank is between MAX and 10 mm above MAX. Add coolant as necessary.

. Fit the header tank cap.

4.2.4.4 System, Air Bleeding

After filling the system with coolant, any air present must be purged before effective cooling is possible. Provided the

correct fill procedure has been followed, purging of the system takes place automatically as follows:

The air entrained by the coolant, rises to the top of the radiator and to the highest point on each side of the engine (the

thermostat housings). While the thermostats are closed, the radiator is under reduced pressure due to the pump suc

- tion and air is bled through the jiggle-pins in each thermostat. Purged air is returnedvia the bleed system to the header

tank. When normal operating temperature is reached, the thermostats open and the system operates normally. ~~

Issue 1 August 1994 4 X300 VSM

Page 70 of 521

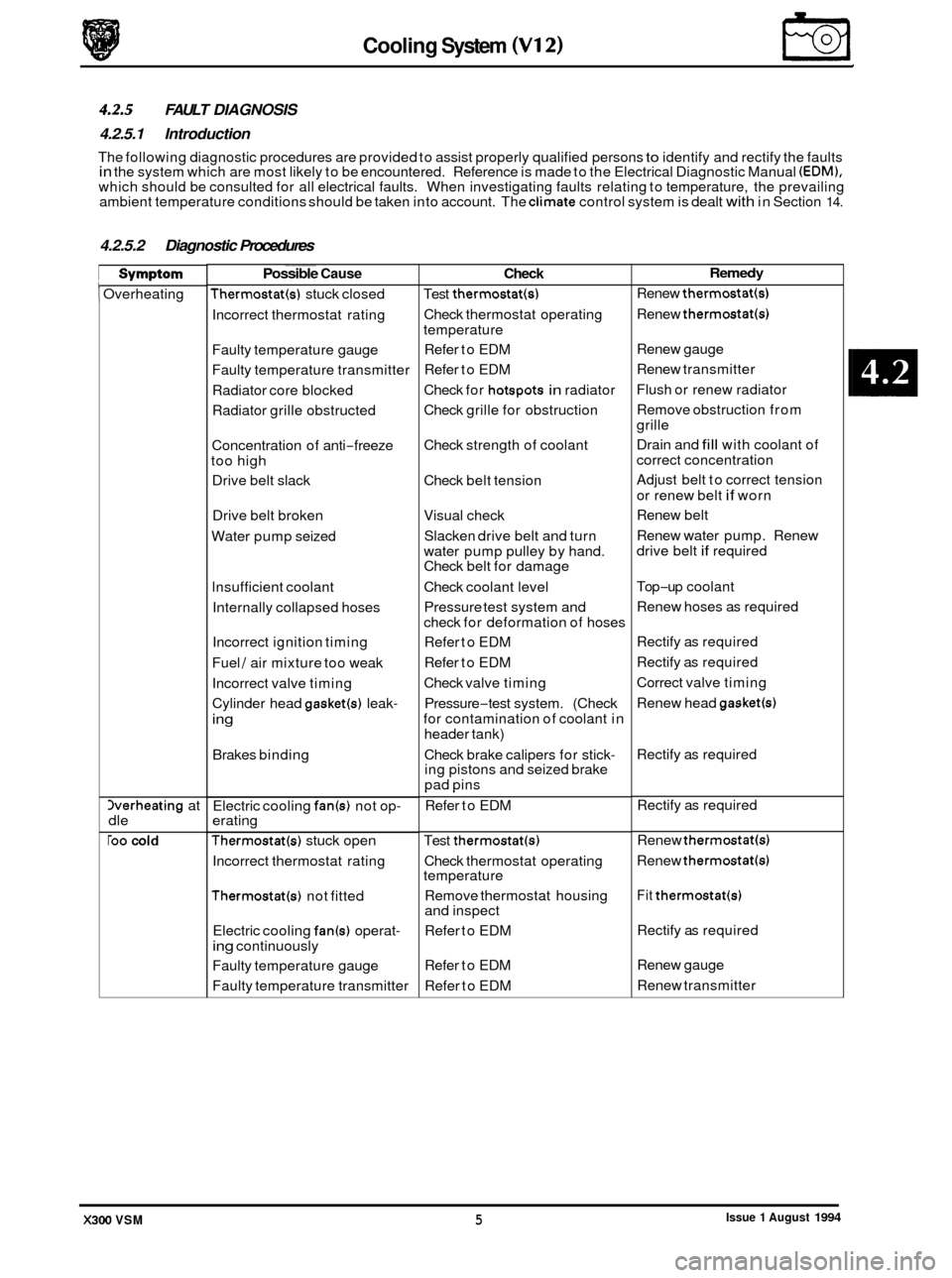

4.2.5.2 Diagnostic Procedures

1

I Symptom ..

Overheating

herheating at

dle

roo cold ~~~

Possible Cause

Thermostat(s) stuck

closed

Incorrect thermostat rating

Faulty temperature gauge

Faulty temperature transmitter

Radiator core blocked

Radiator grille obstructed

Concentration of anti

-freeze

too high

Drive belt slack

Drive belt broken

Water pump seized

lnsuff icient coolant

Internally collapsed hoses

Incorrect ignition timing

Fuel

/ air mixture too weak

Incorrect valve timing

Cylinder head

gasket(s) leak-

ing

Brakes binding

Electric cooling

fan(s) not op- erating

Thermostat(s) stuck open

Incorrect thermostat rating

Thermostatb) not fitted

Electric cooling

fan(s) operat-

ing continuously

Faulty temperature gauge

Faulty temperature transmitter

Check

Cooling System (V12)

4.2.5 FAULT DIAGNOSIS

4.2.5.1 Introduction

The following diagnostic procedures are provided to assist properly qualified persons to identify and rectify the faults in the system which are most likely to be encountered. Reference is made to the Electrical Diagnostic Manual (EDM), which should be consulted for all electrical faults. When investigating faults relating to temperature, the prevailing

ambient temperature conditions should be taken into account. The climate control system is dealt with in Section 14.

Test thermostat(s)

Check thermostat operating

temperature

Refer to EDM

Refer to EDM

Check for

hotspots in radiator

Check grille for obstruction

Check strength of coolant

Check belt tension

Visual check Slacken drive belt and turn

water pump pulley by hand.

Check belt for damage

Check coolant level

Pressure test system and

check for deformation of hoses

Refer to EDM

Refer to EDM

Check valve timing

Pressure

-test system. (Check

for contamination of coolant in

header tank)

Check brake calipers for stick

- ing pistons and seized brake

pad pins

..

Refer to EDM

Test

thermostat(4

Check thermostat operating

temperature

Remove thermostat housing

and inspect

Refer to EDM

Refer to EDM

Refer to EDM

Remedy

Renew thermostat(s)

Renew thermostat(s1

Renew gauge

Renew transmitter

Flush or renew radiator

Remove obstruction from

grille

Drain and

fill with coolant of

correct concentration

Adjust belt to correct tension

or renew belt

if worn

Renew belt

Renew water pump. Renew

drive belt

if required

Top

-up coolant

Renew hoses as required

Rectify as required

Rectify as required

Correct valve timing

Renew head

gasket(s)

Rectify as required

Rectify as required

Renew

thermostat(s1

Renew thermostatb)

Fit thermostat(s)

Rectify as required

Renew gauge

Renew transmitter

Issue 1 August 1994 X300 VSM 5