lock JAGUAR XJ6 1997 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1997, Model line: XJ6, Model: JAGUAR XJ6 1997 2.GPages: 227, PDF Size: 7.2 MB

Page 97 of 227

13Allow the bellcrank to return to the idle

position and test the adjustment once again

until the correct adjustment has been attained.

11 Electronic Fuel Injection

(EFI) system-

general information

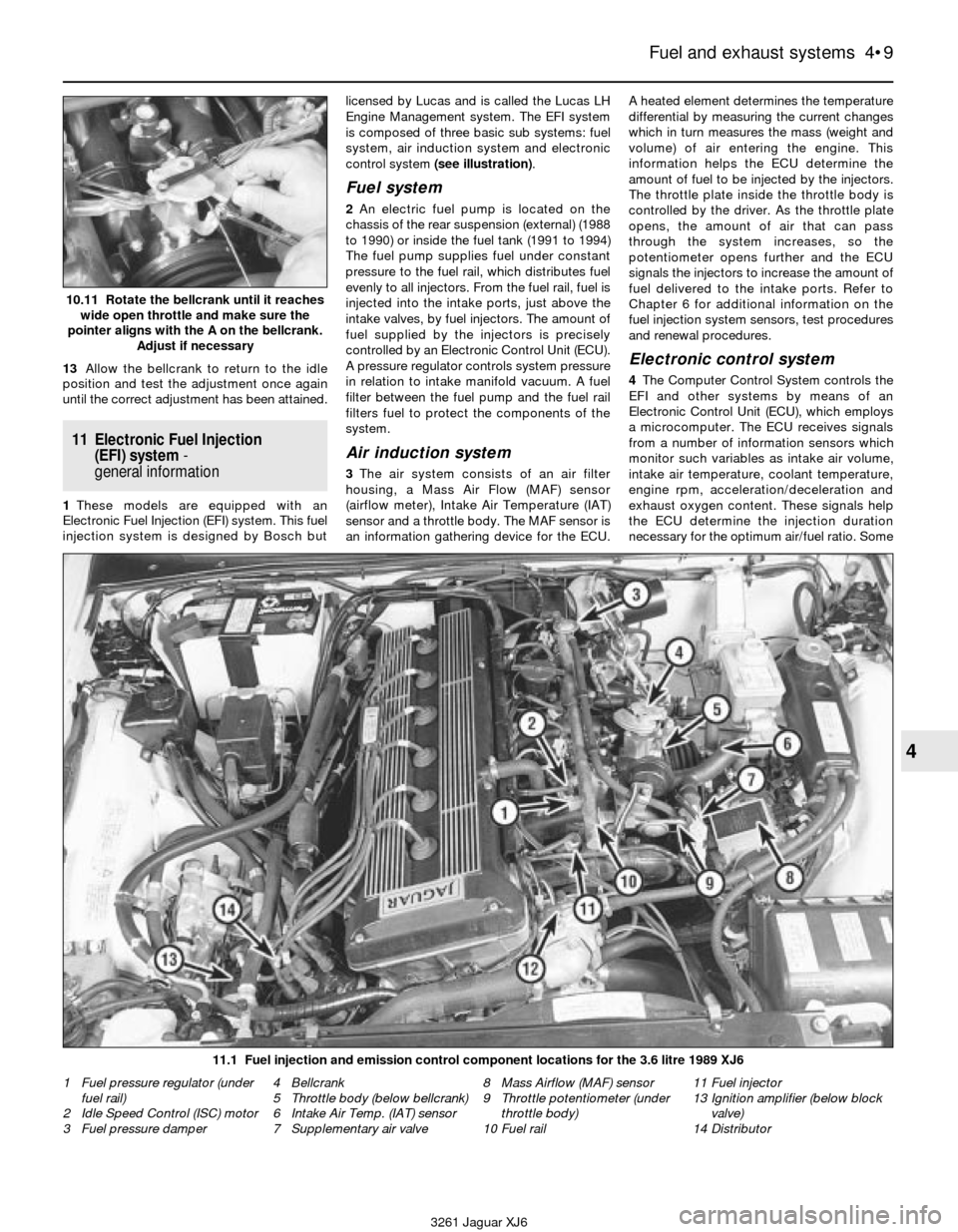

1These models are equipped with an

Electronic Fuel Injection (EFI) system. This fuel

injection system is designed by Bosch butlicensed by Lucas and is called the Lucas LH

Engine Management system. The EFI system

is composed of three basic sub systems: fuel

system, air induction system and electronic

control system (see illustration).

Fuel system

2An electric fuel pump is located on the

chassis of the rear suspension (external) (1988

to 1990) or inside the fuel tank (1991 to 1994)

The fuel pump supplies fuel under constant

pressure to the fuel rail, which distributes fuel

evenly to all injectors. From the fuel rail, fuel is

injected into the intake ports, just above the

intake valves, by fuel injectors. The amount of

fuel supplied by the injectors is precisely

controlled by an Electronic Control Unit (ECU).

A pressure regulator controls system pressure

in relation to intake manifold vacuum. A fuel

filter between the fuel pump and the fuel rail

filters fuel to protect the components of the

system.

Air induction system

3The air system consists of an air filter

housing, a Mass Air Flow (MAF) sensor

(airflow meter), Intake Air Temperature (IAT)

sensor and a throttle body. The MAF sensor is

an information gathering device for the ECU.A heated element determines the temperature

differential by measuring the current changes

which in turn measures the mass (weight and

volume) of air entering the engine. This

information helps the ECU determine the

amount of fuel to be injected by the injectors.

The throttle plate inside the throttle body is

controlled by the driver. As the throttle plate

opens, the amount of air that can pass

through the system increases, so the

potentiometer opens further and the ECU

signals the injectors to increase the amount of

fuel delivered to the intake ports. Refer to

Chapter 6 for additional information on the

fuel injection system sensors, test procedures

and renewal procedures.

Electronic control system

4The Computer Control System controls the

EFI and other systems by means of an

Electronic Control Unit (ECU), which employs

a microcomputer. The ECU receives signals

from a number of information sensors which

monitor such variables as intake air volume,

intake air temperature, coolant temperature,

engine rpm, acceleration/deceleration and

exhaust oxygen content. These signals help

the ECU determine the injection duration

necessary for the optimum air/fuel ratio. Some

Fuel and exhaust systems 4•9

4

10.11 Rotate the bellcrank until it reaches

wide open throttle and make sure the

pointer aligns with the A on the bellcrank.

Adjust if necessary

11.1 Fuel injection and emission control component locations for the 3.6 litre 1989 XJ6

3261 Jaguar XJ6 1 Fuel pressure regulator (under

fuel rail)

2 Idle Speed Control (ISC) motor

3 Fuel pressure damper4 Bellcrank

5 Throttle body (below bellcrank)

6 Intake Air Temp. (IAT) sensor

7 Supplementary air valve8 Mass Airflow (MAF) sensor

9 Throttle potentiometer (under

throttle body)

10 Fuel rail11 Fuel injector

13 Ignition amplifier (below block

valve)

14 Distributor

Page 98 of 227

of these sensors and their corresponding

ECU-controlled relays are not contained

within EFI components, but are located

throughout the engine compartment. For

further information regarding the ECU and its

relationship to the engine electrical and

ignition system, see Chapter 6.

12 Electronic Fuel Injection

(EFI) system- check

2

1Check the earth wire connections for

tightness. Check all wiring and electrical

connectors that are related to the system.

Loose electrical connectors and poor grounds

can cause many problems that resemble

more serious malfunctions.

2Check to see that the battery is fully

charged, as the control unit and sensors

depend on an accurate supply voltage in

order to properly meter the fuel.

3Check the air filter element - a dirty or

partially blocked filter will severely impede

performance and economy (see Chapter 1).

4If a blown fuse is found, renew it and see if

it blows again. If it does, search for a shorted

wire in the harness related to the system.

5Check the air intake duct from the MAF

sensor to the intake manifold for leaks, which

will result in an excessively lean mixture. Also

check the condition of the vacuum hoses

connected to the intake manifold.

6Remove the air intake duct from the throttle

body and check for carbon and residue build-

up. If it’s dirty, clean with aerosol carburettor

cleaner (make sure the can says it’s safe for

use with oxygen sensors and catalytic

converters) and a toothbrush.

7With the engine running, place a

stethoscope against each injector, one at a

time, and listen for a clicking sound, indicating

operation (see illustration).8If there is a problem with an injector,

purchase a special injector test light (noid

light) and refit it into the injector electrical

connector (see illustration). Start the engine

and make sure that each injector connector

flashes the noid light. This will test for the

proper voltage signal to the injector.Caution:

If the engine will not start and the noid

light indicates that each injector is

receiving the proper signal, there is a good

possibility that the injector(s) is stuck open

and allowing fuel into the combustion

chamber in excessive amounts. If the spark

plugs are fouled, detach the primary (low

voltage) wires from the ignition coil, disable

the fuel pump by removing the fuel pump

relay (see Section 2), remove the spark plugs

and crank the engine over. If fuel sprays from

the spark plug holes, the engine is flooded

and the fuel must be removed from the

combustion chambers.

9With the engine OFF and the fuel injector

electrical connectors disconnected, measure

the resistance of each injector (see

illustration). Each injector should measure

about 2.0 to 3.0 ohms. If not, the injector is

probably faulty.10The remainder of the system checks

should be left to a Jaguar service department

or other qualified repair workshop, as there is

a chance that the control unit may be

damaged if not performed properly.

13 Electronic Fuel Injection

(EFI) system- component

check and renewal

3

Warning: Petrol is extremely

flammable, so take extra

precautions when you work on

any part of the fuel system. See

the Warning in Section 2.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

Throttle body

Check

1Verify that the throttle linkage operates

smoothly.

2Start the engine, detach each vacuum hose

and, using your finger, check the vacuum at

each port on the throttle body with the engine

at idle and above idle. The vacuum available

from the throttle body is ported. Raise the

engine rpm and watch as vacuum increases.

It may be necessary to use a vacuum gauge.

Refer to Chapter 2B for additional information

concerning vacuum checks.

Renewal

Warning: Wait until the engine is

completely cool before

beginning this procedure.

3Detach the cable from the negative terminal

of the battery (see the Cautionat the

beginning of this Section).

4Drain the radiator (see Chapter 1).

4•10 Fuel and exhaust systems

12.9 Using an ohmmeter, measure the

resistance across both terminals

of the injector

3261 Jaguar XJ6 12.7 Use a stethoscope or a screwdriver to determine if the

injectors are working properly - they should make a steady

clicking sound that rises and falls with engine speed changes

12.8 Refit the “noid” light into the fuel injector electrical

connector and check to see that it blinks with the engine running

Page 99 of 227

5Remove the air cleaner (see Chapter 1) and

the air cleaner housing (see Section 9).

6Remove the air intake duct.

7Detach the electrical connector from the

MAF sensor (see illustration).

8Remove the clamp that retains the MAF

sensor to the air intake duct (see illustration)

and lift the MAF sensor assembly from the

engine compartment.

9Detach the throttle cable from the bellcrank

(see Section 10), then remove the bellcrank

assembly from the throttle body (see

illustration).

10Detach the kickdown cable from the

bellcrank and set the cable and brackets

aside (see Chapter 7).

11Clearly label, then detach, all vacuum and

coolant hoses from the throttle body.

12Disconnect the electrical connector from

the throttle potentiometer.

13Remove the four throttle body mounting

bolts and detach the throttle body from the

intake manifold.

14Using a soft brush and carburettor

cleaner, thoroughly clean the throttle body

casting, then blow out all passages with

compressed air.

Caution: Do not clean the throttle position

sensor with any solvents or sprays. Just

wipe it off with a clean, soft cloth.

15Refitting of the throttle body is the reverse

of removal.

16Be sure to tighten the throttle body

mounting bolts to the torque listed in this

Chapter’s Specifications.

Adjustment

17Remove the air intake duct to expose the

throttle body and butterfly valve.

18Make sure the throttle body is clean and

free of burrs, nicks or carbon build-up (see

illustration).

19Measure the clearance between the

butterfly valve (throttle plate) and the wall of

the throttle body (see illustration). It should

be 0.05 mm (0.002 inch). 20If the gap is incorrect, loosen the throttle

stop locknut (see illustration)and turn the

throttle stop screw until the correct clearance

is attained.

21Refit the air intake duct and surrounding

components.

Idle Speed Control (ISC) motor

Note:The minimum idle speed is pre-set at

the factory and should not require adjustment

under normal operating conditions; however ifthe throttle body has been replaced or you

suspect the minimum idle speed has been

tampered with (for example, if the idle speed

screw was removed from the throttle body)

have the vehicle checked by a dealer service

department or a qualified automotive repair

workshop.Check

22Start the engine and allow it to reach

normal operating temperature. Switch on the

Fuel and exhaust systems 4•11

4

13.9 Remove the bellcrank assembly bolts

(arrowed) and separate it from the

throttle body13.18 The area inside the throttle body

near the throttle plate suffers from sludge

build-up because the PCV hose vents

crankcase vapour into the intake duct

13.19 Measure clearance between the

butterfly valve and the throttle body

3261 Jaguar XJ6 13.7 Push up on the clip and remove the harness connector from

the MAF sensor

13.8 Remove the air intake duct clamp from the

MAF sensor housing

13.20 Adjust the butterfly angle by

loosening the locknut on the throttle stop

and turning the adjustment bolt

Page 106 of 227

sure you have the correct activation code

before disconnecting the battery.

2Disconnect the electrical connectors and

the coil wire from the coil.

3Using an ohmmeter, check the coil

resistance:

a) Measure the resistance between the

positive and negative terminals (see

illustration). Compare your reading with

the specified coil primary resistance listed

in this Chapter’s Specifications.

b) Measure the resistance between the

positive terminal and the high tension (HT)

terminal(see illustration). Compare your

reading with the specified coil secondary

resistance listed in this Chapter’s

Specifications.

4If either of the above tests yield resistance

values outside the specified amount, renew

the coil.

Renewal

5Detach the battery negative cable.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery. 6Label and disconnect the electrical wires

from the coil terminals.

7Remove the coil mounting fasteners (see

illustration).

8Refitting is the reverse of removal.

9 Distributor-

removal and refitting

2

Note:The timing on this ignition system cannot

be adjusted by turning the distributor. Ignition

timing is maintained by the ECU at all times. In

the event the distributor must be removed from

the engine, be sure to follow the precautions

described in this section and mark the engine

and distributor with paint to ensure correct

refitting. If the distributor is not marked, and the

crankshaft is turned while the distributor is out of

the engine, have the distributor installed by a

dealer service department. The distributor must

be installed using a special alignment tool.

Removal

1Detach the battery negative cable. Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

2Disconnect the electrical connectors from

the distributor.

3Look for a raised “1” on the distributor cap.

This marks the location for the number one

cylinder spark plug lead terminal. If the cap

does not have a mark for the number one

terminal, locate the number one spark plug

and trace the wire back to the terminal on the

cap.

4Remove the distributor cap (see Chapter 1)

and rotate the engine until the rotor is pointing

toward the number one spark plug terminal.

5Make a mark on the edge of the distributor

base directly below the rotor tip and in line

with it. Also, mark the distributor base and the

engine block to ensure that the distributor is

installed correctly (see illustrations).

6Remove the distributor hold-down bolt,

then pull the distributor out to remove it.

Caution: DO NOT turn the crankshaft while

the distributor is out of the engine, or the

alignment marks will be useless.

5•4 Engine electrical systems

8.3a To check the primary resistance of

the coil, measure the resistance between

the positive and the negative terminals8.3b To check the secondary resistance of

the coil, measure the resistance between

the positive terminal and the HT terminal8.7 Remove the nuts from the coil

mounting bracket (arrowed)

3261 Jaguar XJ6

9.5a Paint or scribe a mark (arrowed) on the edge of the

distributor housing below the rotor tip to ensure that the rotor is

pointing in the same direction when the distributor is reinstalled9.5b Paint or scribe another mark across the cylinder head and

the distributor body (arrowed) to ensure that the distributor is

aligned correctly when it is reinstalled

Page 107 of 227

Refitting

7Insert the distributor into the engine in

exactly the same relationship to the block that

it was in when removed.

8If the distributor does not seat completely,

recheck the alignment marks between the

distributor base and the block to verify that

the distributor is in the same position it was in

before removal. Also check the rotor to see if

it’s aligned with the mark you made on the

edge of the distributor base.

9Refit the distributor hold-down bolt(s).

10The remainder of refitting is the reverse of

removal.

10 Charging system- general

information and precautions

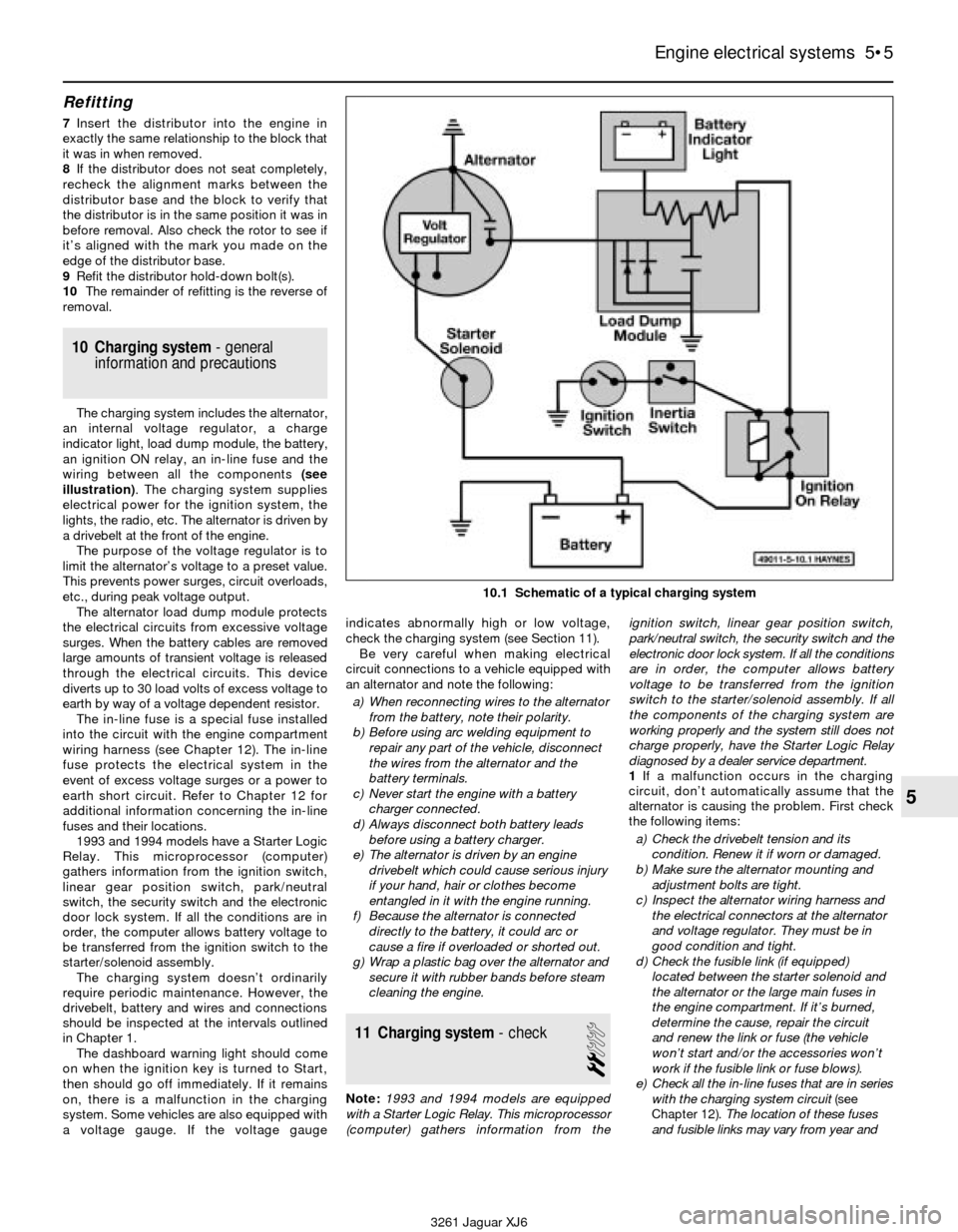

The charging system includes the alternator,

an internal voltage regulator, a charge

indicator light, load dump module, the battery,

an ignition ON relay, an in-line fuse and the

wiring between all the components (see

illustration). The charging system supplies

electrical power for the ignition system, the

lights, the radio, etc. The alternator is driven by

a drivebelt at the front of the engine.

The purpose of the voltage regulator is to

limit the alternator’s voltage to a preset value.

This prevents power surges, circuit overloads,

etc., during peak voltage output.

The alternator load dump module protects

the electrical circuits from excessive voltage

surges. When the battery cables are removed

large amounts of transient voltage is released

through the electrical circuits. This device

diverts up to 30 load volts of excess voltage to

earth by way of a voltage dependent resistor.

The in-line fuse is a special fuse installed

into the circuit with the engine compartment

wiring harness (see Chapter 12). The in-line

fuse protects the electrical system in the

event of excess voltage surges or a power to

earth short circuit. Refer to Chapter 12 for

additional information concerning the in-line

fuses and their locations.

1993 and 1994 models have a Starter Logic

Relay. This microprocessor (computer)

gathers information from the ignition switch,

linear gear position switch, park/neutral

switch, the security switch and the electronic

door lock system. If all the conditions are in

order, the computer allows battery voltage to

be transferred from the ignition switch to the

starter/solenoid assembly.

The charging system doesn’t ordinarily

require periodic maintenance. However, the

drivebelt, battery and wires and connections

should be inspected at the intervals outlined

in Chapter 1.

The dashboard warning light should come

on when the ignition key is turned to Start,

then should go off immediately. If it remains

on, there is a malfunction in the charging

system. Some vehicles are also equipped with

a voltage gauge. If the voltage gaugeindicates abnormally high or low voltage,

check the charging system (see Section 11).

Be very careful when making electrical

circuit connections to a vehicle equipped with

an alternator and note the following:

a) When reconnecting wires to the alternator

from the battery, note their polarity.

b) Before using arc welding equipment to

repair any part of the vehicle, disconnect

the wires from the alternator and the

battery terminals.

c) Never start the engine with a battery

charger connected.

d) Always disconnect both battery leads

before using a battery charger.

e) The alternator is driven by an engine

drivebelt which could cause serious injury

if your hand, hair or clothes become

entangled in it with the engine running.

f) Because the alternator is connected

directly to the battery, it could arc or

cause a fire if overloaded or shorted out.

g) Wrap a plastic bag over the alternator and

secure it with rubber bands before steam

cleaning the engine.

11 Charging system- check

2

Note:1993 and 1994 models are equipped

with a Starter Logic Relay. This microprocessor

(computer) gathers information from theignition switch, linear gear position switch,

park/neutral switch, the security switch and the

electronic door lock system. If all the conditions

are in order, the computer allows battery

voltage to be transferred from the ignition

switch to the starter/solenoid assembly. If all

the components of the charging system are

working properly and the system still does not

charge properly, have the Starter Logic Relay

diagnosed by a dealer service department.

1If a malfunction occurs in the charging

circuit, don’t automatically assume that the

alternator is causing the problem. First check

the following items:

a) Check the drivebelt tension and its

condition. Renew it if worn or damaged.

b) Make sure the alternator mounting and

adjustment bolts are tight.

c) Inspect the alternator wiring harness and

the electrical connectors at the alternator

and voltage regulator. They must be in

good condition and tight.

d) Check the fusible link (if equipped)

located between the starter solenoid and

the alternator or the large main fuses in

the engine compartment. If it’s burned,

determine the cause, repair the circuit

and renew the link or fuse (the vehicle

won’t start and/or the accessories won’t

work if the fusible link or fuse blows).

e) Check all the in-line fuses that are in series

with the charging system circuit (see

Chapter 12).The location of these fuses

and fusible links may vary from year and

Engine electrical systems 5•5

5

10.1 Schematic of a typical charging system

3261 Jaguar XJ6

Page 108 of 227

model but the designations are the same.

Refer to the wiring diagrams at the end of

Chapter 12.

f) Start the engine and check the alternator

for abnormal noises (a shrieking or

squealing sound indicates a bad bushing).

g) Check the specific gravity of the battery

electrolyte. If it’s low, charge the battery

(doesn’t apply to maintenance free

batteries).

h) Make sure that the battery is fully charged

(one bad cell in a battery can cause

overcharging by the alternator).

i) Disconnect the battery cables (negative

first, then positive). Caution:If the stereo

in your vehicle is equipped with an anti-

theft system, make sure you have the

correct activation code before

disconnecting the battery. Inspect the

battery posts and the cable clamps for

corrosion. Clean them thoroughly if

necessary (see Chapter 1). Reconnect the

positive cable, then the negative cable.

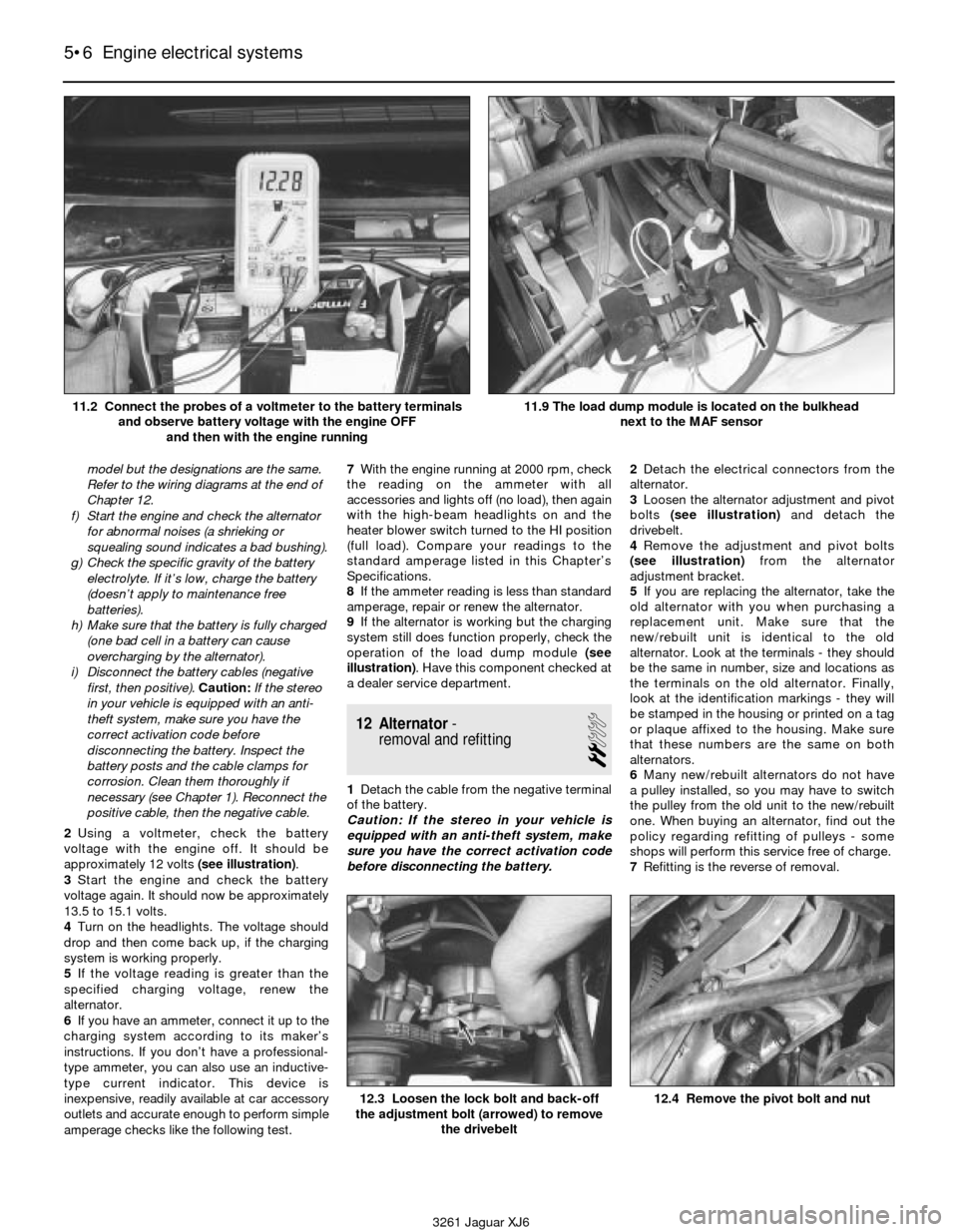

2Using a voltmeter, check the battery

voltage with the engine off. It should be

approximately 12 volts (see illustration).

3Start the engine and check the battery

voltage again. It should now be approximately

13.5 to 15.1 volts.

4Turn on the headlights. The voltage should

drop and then come back up, if the charging

system is working properly.

5If the voltage reading is greater than the

specified charging voltage, renew the

alternator.

6If you have an ammeter, connect it up to the

charging system according to its maker’s

instructions. If you don’t have a professional-

type ammeter, you can also use an inductive-

type current indicator. This device is

inexpensive, readily available at car accessory

outlets and accurate enough to perform simple

amperage checks like the following test.7With the engine running at 2000 rpm, check

the reading on the ammeter with all

accessories and lights off (no load), then again

with the high-beam headlights on and the

heater blower switch turned to the HI position

(full load). Compare your readings to the

standard amperage listed in this Chapter’s

Specifications.

8If the ammeter reading is less than standard

amperage, repair or renew the alternator.

9If the alternator is working but the charging

system still does function properly, check the

operation of the load dump module (see

illustration). Have this component checked at

a dealer service department.

12 Alternator-

removal and refitting

2

1Detach the cable from the negative terminal

of the battery.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.2Detach the electrical connectors from the

alternator.

3Loosen the alternator adjustment and pivot

bolts (see illustration) and detach the

drivebelt.

4Remove the adjustment and pivot bolts

(see illustration)from the alternator

adjustment bracket.

5If you are replacing the alternator, take the

old alternator with you when purchasing a

replacement unit. Make sure that the

new/rebuilt unit is identical to the old

alternator. Look at the terminals - they should

be the same in number, size and locations as

the terminals on the old alternator. Finally,

look at the identification markings - they will

be stamped in the housing or printed on a tag

or plaque affixed to the housing. Make sure

that these numbers are the same on both

alternators.

6Many new/rebuilt alternators do not have

a pulley installed, so you may have to switch

the pulley from the old unit to the new/rebuilt

one. When buying an alternator, find out the

policy regarding refitting of pulleys - some

shops will perform this service free of charge.

7Refitting is the reverse of removal.

5•6 Engine electrical systems

12.3 Loosen the lock bolt and back-off

the adjustment bolt (arrowed) to remove

the drivebelt12.4 Remove the pivot bolt and nut

3261 Jaguar XJ6 11.2 Connect the probes of a voltmeter to the battery terminals

and observe battery voltage with the engine OFF

and then with the engine running

11.9 The load dump module is located on the bulkhead

next to the MAF sensor

Page 113 of 227

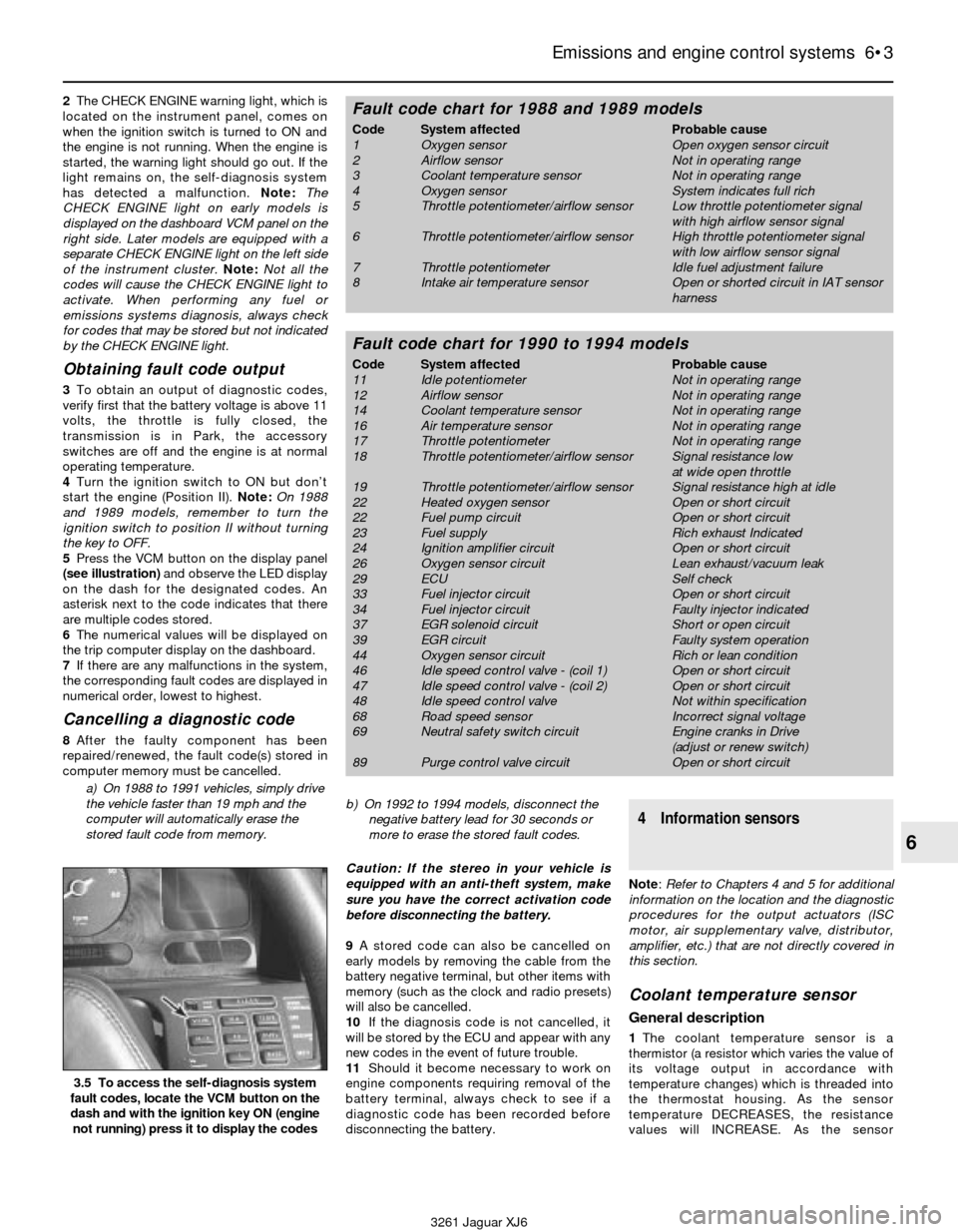

2The CHECK ENGINE warning light, which is

located on the instrument panel, comes on

when the ignition switch is turned to ON and

the engine is not running. When the engine is

started, the warning light should go out. If the

light remains on, the self-diagnosis system

has detected a malfunction. Note: The

CHECK ENGINE light on early models is

displayed on the dashboard VCM panel on the

right side. Later models are equipped with a

separate CHECK ENGINE light on the left side

of the instrument cluster.Note:Not all the

codes will cause the CHECK ENGINE light to

activate. When performing any fuel or

emissions systems diagnosis, always check

for codes that may be stored but not indicated

by the CHECK ENGINE light.

Obtaining fault code output

3To obtain an output of diagnostic codes,

verify first that the battery voltage is above 11

volts, the throttle is fully closed, the

transmission is in Park, the accessory

switches are off and the engine is at normal

operating temperature.

4Turn the ignition switch to ON but don’t

start the engine (Position II). Note:On 1988

and 1989 models, remember to turn the

ignition switch to position II without turning

the key to OFF.

5Press the VCM button on the display panel

(see illustration)and observe the LED display

on the dash for the designated codes. An

asterisk next to the code indicates that there

are multiple codes stored.

6The numerical values will be displayed on

the trip computer display on the dashboard.

7If there are any malfunctions in the system,

the corresponding fault codes are displayed in

numerical order, lowest to highest.

Cancelling a diagnostic code

8After the faulty component has been

repaired/renewed, the fault code(s) stored in

computer memory must be cancelled.

a) On 1988 to 1991 vehicles, simply drive

the vehicle faster than 19 mph and the

computer will automatically erase the

stored fault code from memory.b) On 1992 to 1994 models, disconnect the

negative battery lead for 30 seconds or

more to erase the stored fault codes.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

9A stored code can also be cancelled on

early models by removing the cable from the

battery negative terminal, but other items with

memory (such as the clock and radio presets)

will also be cancelled.

10If the diagnosis code is not cancelled, it

will be stored by the ECU and appear with any

new codes in the event of future trouble.

11Should it become necessary to work on

engine components requiring removal of the

battery terminal, always check to see if a

diagnostic code has been recorded before

disconnecting the battery.

4 Information sensors

Note: Refer to Chapters 4 and 5 for additional

information on the location and the diagnostic

procedures for the output actuators (ISC

motor, air supplementary valve, distributor,

amplifier, etc.) that are not directly covered in

this section.

Coolant temperature sensor

General description

1The coolant temperature sensor is a

thermistor (a resistor which varies the value of

its voltage output in accordance with

temperature changes) which is threaded into

the thermostat housing. As the sensor

temperature DECREASES, the resistance

values will INCREASE. As the sensor

Emissions and engine control systems 6•3

6

3.5 To access the self-diagnosis system

fault codes, locate the VCM button on the

dash and with the ignition key ON (engine

not running) press it to display the codes

3261 Jaguar XJ6

Fault code chart for 1988 and 1989 models

Code System affected Probable cause

1 Oxygen sensor Open oxygen sensor circuit

2 Airflow sensor Not in operating range

3 Coolant temperature sensor Not in operating range

4 Oxygen sensor System indicates full rich

5 Throttle potentiometer/airflow sensor Low throttle potentiometer signal

with high airflow sensor signal

6 Throttle potentiometer/airflow sensor High throttle potentiometer signal

with low airflow sensor signal

7 Throttle potentiometer Idle fuel adjustment failure

8 Intake air temperature sensor Open or shorted circuit in IAT sensor

harness

Fault code chart for 1990 to 1994 models

Code System affected Probable cause

11 Idle potentiometer Not in operating range

12 Airflow sensor Not in operating range

14 Coolant temperature sensor Not in operating range

16 Air temperature sensor Not in operating range

17 Throttle potentiometer Not in operating range

18 Throttle potentiometer/airflow sensor Signal resistance low

at wide open throttle

19 Throttle potentiometer/airflow sensor Signal resistance high at idle

22 Heated oxygen sensor Open or short circuit

22 Fuel pump circuit Open or short circuit

23 Fuel supply Rich exhaust Indicated

24 Ignition amplifier circuit Open or short circuit

26 Oxygen sensor circuit Lean exhaust/vacuum leak

29 ECU Self check

33 Fuel injector circuit Open or short circuit

34 Fuel injector circuit Faulty injector indicated

37 EGR solenoid circuit Short or open circuit

39 EGR circuit Faulty system operation

44 Oxygen sensor circuit Rich or lean condition

46 Idle speed control valve - (coil 1) Open or short circuit

47 Idle speed control valve - (coil 2) Open or short circuit

48 Idle speed control valve Not within specification

68 Road speed sensor Incorrect signal voltage

69 Neutral safety switch circuit Engine cranks in Drive

(adjust or renew switch)

89 Purge control valve circuit Open or short circuit

Page 114 of 227

temperature INCREASES, the resistance

values will DECREASE. A failure in this sensor

circuit should set a Code 3 (1988 and 1989)

or 13 (1990 to 1994). This code indicates a

failure in the coolant temperature sensor

circuit, so in most cases the appropriate

solution to the problem will be either repair of

a connector or wire, or renewal of the sensor.

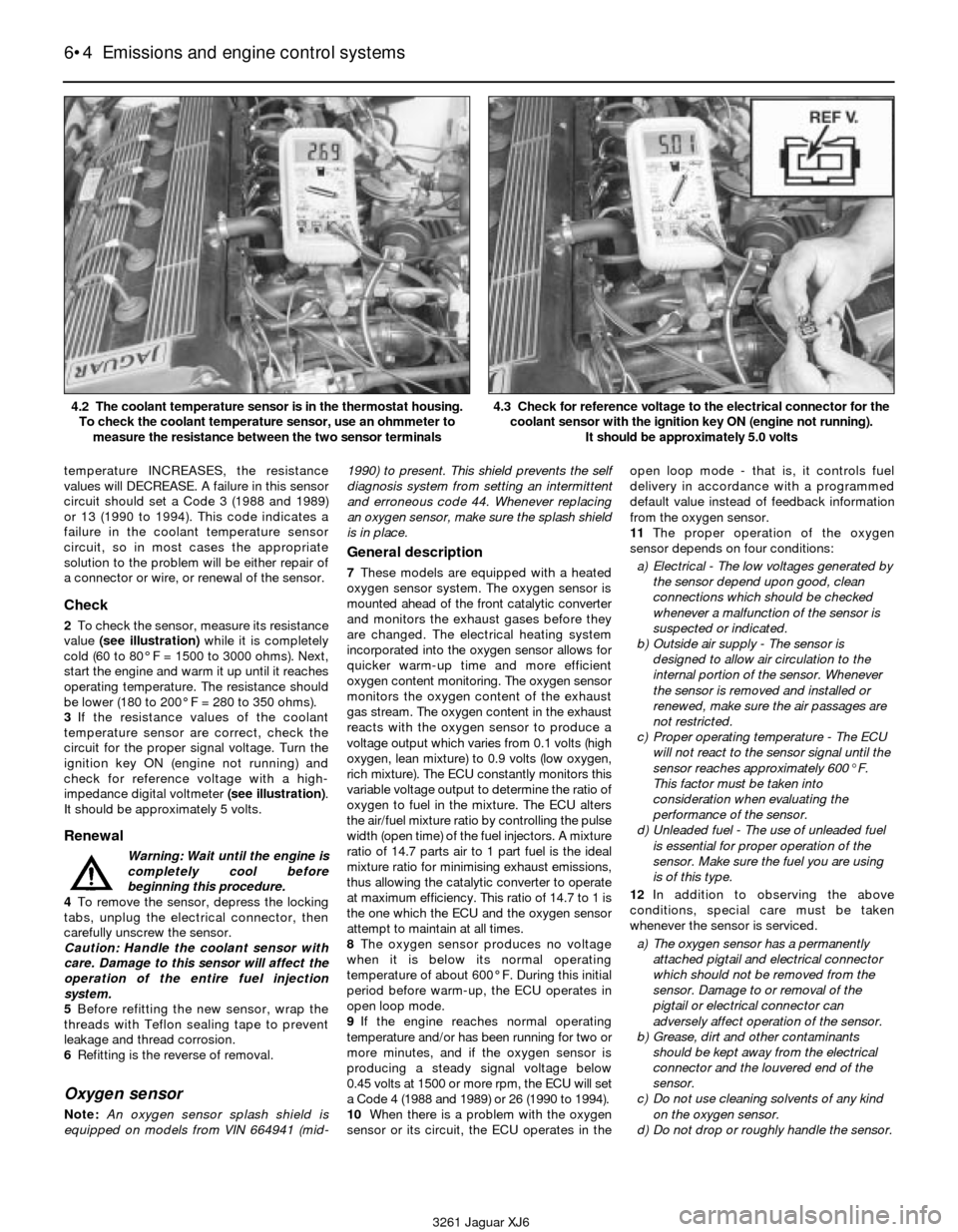

Check

2To check the sensor, measure its resistance

value (see illustration)while it is completely

cold (60 to 80° F = 1500 to 3000 ohms). Next,

start the engine and warm it up until it reaches

operating temperature. The resistance should

be lower (180 to 200° F = 280 to 350 ohms).

3If the resistance values of the coolant

temperature sensor are correct, check the

circuit for the proper signal voltage. Turn the

ignition key ON (engine not running) and

check for reference voltage with a high-

impedance digital voltmeter (see illustration).

It should be approximately 5 volts.

Renewal

Warning: Wait until the engine is

completely cool before

beginning this procedure.

4To remove the sensor, depress the locking

tabs, unplug the electrical connector, then

carefully unscrew the sensor.

Caution: Handle the coolant sensor with

care. Damage to this sensor will affect the

operation of the entire fuel injection

system.

5Before refitting the new sensor, wrap the

threads with Teflon sealing tape to prevent

leakage and thread corrosion.

6Refitting is the reverse of removal.

Oxygen sensor

Note:An oxygen sensor splash shield is

equipped on models from VIN 664941 (mid-1990) to present. This shield prevents the self

diagnosis system from setting an intermittent

and erroneous code 44. Whenever replacing

an oxygen sensor, make sure the splash shield

is in place.

General description

7These models are equipped with a heated

oxygen sensor system. The oxygen sensor is

mounted ahead of the front catalytic converter

and monitors the exhaust gases before they

are changed. The electrical heating system

incorporated into the oxygen sensor allows for

quicker warm-up time and more efficient

oxygen content monitoring. The oxygen sensor

monitors the oxygen content of the exhaust

gas stream. The oxygen content in the exhaust

reacts with the oxygen sensor to produce a

voltage output which varies from 0.1 volts (high

oxygen, lean mixture) to 0.9 volts (low oxygen,

rich mixture). The ECU constantly monitors this

variable voltage output to determine the ratio of

oxygen to fuel in the mixture. The ECU alters

the air/fuel mixture ratio by controlling the pulse

width (open time) of the fuel injectors. A mixture

ratio of 14.7 parts air to 1 part fuel is the ideal

mixture ratio for minimising exhaust emissions,

thus allowing the catalytic converter to operate

at maximum efficiency. This ratio of 14.7 to 1 is

the one which the ECU and the oxygen sensor

attempt to maintain at all times.

8The oxygen sensor produces no voltage

when it is below its normal operating

temperature of about 600° F. During this initial

period before warm-up, the ECU operates in

open loop mode.

9If the engine reaches normal operating

temperature and/or has been running for two or

more minutes, and if the oxygen sensor is

producing a steady signal voltage below

0.45 volts at 1500 or more rpm, the ECU will set

a Code 4 (1988 and 1989) or 26 (1990 to 1994).

10When there is a problem with the oxygen

sensor or its circuit, the ECU operates in theopen loop mode - that is, it controls fuel

delivery in accordance with a programmed

default value instead of feedback information

from the oxygen sensor.

11The proper operation of the oxygen

sensor depends on four conditions:

a) Electrical - The low voltages generated by

the sensor depend upon good, clean

connections which should be checked

whenever a malfunction of the sensor is

suspected or indicated.

b) Outside air supply - The sensor is

designed to allow air circulation to the

internal portion of the sensor. Whenever

the sensor is removed and installed or

renewed, make sure the air passages are

not restricted.

c) Proper operating temperature - The ECU

will not react to the sensor signal until the

sensor reaches approximately 600° F.

This factor must be taken into

consideration when evaluating the

performance of the sensor.

d) Unleaded fuel - The use of unleaded fuel

is essential for proper operation of the

sensor. Make sure the fuel you are using

is of this type.

12In addition to observing the above

conditions, special care must be taken

whenever the sensor is serviced.

a) The oxygen sensor has a permanently

attached pigtail and electrical connector

which should not be removed from the

sensor. Damage to or removal of the

pigtail or electrical connector can

adversely affect operation of the sensor.

b) Grease, dirt and other contaminants

should be kept away from the electrical

connector and the louvered end of the

sensor.

c) Do not use cleaning solvents of any kind

on the oxygen sensor.

d) Do not drop or roughly handle the sensor.

6•4 Emissions and engine control systems

3261 Jaguar XJ6 4.2 The coolant temperature sensor is in the thermostat housing.

To check the coolant temperature sensor, use an ohmmeter to

measure the resistance between the two sensor terminals

4.3 Check for reference voltage to the electrical connector for the

coolant sensor with the ignition key ON (engine not running).

It should be approximately 5.0 volts

Page 118 of 227

5 Air Injector Reactor

(AIR) system

General information

1The air injection reactor system reduces

carbon monoxide and hydrocarbon content

in the exhaust gases by injecting fresh air into

the hot exhaust gases leaving the exhaust

ports. When fresh air is mixed with hot

exhaust gases, oxidation is increased,

reducing the concentration of hydrocarbons

and carbon monoxide and converting them

into harmless carbon dioxide and water.

2The air injection system is composed of an

air pump, diverter valve (bypass), check valve,

air injection manifold, vacuum delay valve,

vacuum control solenoid, air pump magnetic

clutch, air pump clutch relay and hoses (see

illustration). The air pump is driven by a belt

from the crankshaft and supplies compressed

air to the exhaust manifold(s). The check valve

prevents the reverse flow of exhaust gases into

the system. The vacuum-operated (early

models) or electrically-operated (later models)air cut-off valve prevents air from being drawn

into the exhaust when the air pump is switched

off. System vacuum to the air cut-off valve is

controlled by the solenoid vacuum valve in

parallel circuit with the air pump. A delay valve

prevents vacuum loss to the solenoid valve

during wide open throttle operation.

3Injected air is controlled by the computer,

the air pump clutch and the air pump clutch

relay. The AIR system is used during warm-up

(58 to 83° F) to control emissions while the

engine is running rich. The oxygen sensor

feedback system cannot function while the AIR

system is operating. The computer controls

both systems during warm-up and operating

temperatures. If problems occur with the

AIR system relay or circuit, the on-board

diagnosis system will set a code 66.

Check

4Check the condition of the air pump

drivebelt, the injection hoses and the injection

manifold. Make sure that all components are

intact and there are no leaks.

5Check the operation of the air pump clutch

relay (see illustration)and the air pump

clutch. First remove the relay and check forbattery voltage to the relay. Also, check the

relay itself. Refer to the relay checking

procedure in Chapter 12. Extract codes from

the self-diagnosis system (see Section 3) and

check for a code 66, AIR relay malfunction.

6Make sure the electrical connector is

securely fastened to the diverter valve (see

illustration). If everything appears OK but a

fault code still sets, have the system

diagnosed by a dealer service department or

other qualified repair workshop.

Air pump renewal

7Disconnect the cable from the negative

terminal of the battery.

Caution: If the stereo in your vehicle is

equipped with an anti-theft system, make

sure you have the correct activation code

before disconnecting the battery.

8Disconnect the electrical connector from

the air pump clutch.

9Loosen the clips from the air inlet and outlet

hose and separate them from the air injection

pump.

10Loosen the adjuster and pivot bolts (see

illustration)and nuts but do not remove them

from the air injection pump brackets.

6•8 Emissions and engine control systems

3261 Jaguar XJ6 5.2 Schematic of the Air Injection Reactor (AIR) system

5.6 Location of the AIR diverter valve on a 1992 model - check the

hoses for cracking and the electrical connector for security5.10 Loosen the pivot bolt and then the adjustment nut to remove

the drivebelt from the air pump. The adjustment nut has a lock bolt

that must be loosened before the pump will move down the adjuster

5.5 Location of the AIR pump relay on a 1992 model

Page 119 of 227

11Swing the pump toward the engine and

remove the drivebelt from the pump.

12Remove the link arm through-bolt.

13Remove the pivot bolt and front spacer,

rear cone and air injection pump from the

engine compartment.

14Remove the nut securing the front pulley

on the air injection pump.

15Remove the clutch snap-ring and the

clutch.

16Refitting is the reverse of removal.

6 Exhaust Gas Recirculation

(EGR) system

Note 1: Some 1990 models have the EGR

vacuum hose routed incorrectly through the

bulkhead securing straps, thereby restricting

the vacuum signal to the EGR valve. Remove

the EGR vacuum hose from the bulkhead

harness and refit a new hose. Secure it to the

engine compartment using tie-wraps and do

not allow any restrictions in the hose.Note 2: Some models have copper sealing

washers that soften and leak around the EGR

valve causing engine performance and

starting problems. Refit steel washers and

pipe adapters into the EGR system. Contact a

Jaguar dealer for the VIN numbers and years

of the models that are affected by this defect.

1To reduce oxides of nitrogen emissions,

some of the exhaust gases are recirculated

through the EGR valve to the intake manifold

to lower combustion temperatures.

2The EGR system consists of the EGR valve,

an EGR solenoid, an EGR gas temperature

sensor and the transfer pipe (see illustration).

Check

EGR valve

3Start the engine and allow it to idle.

4Detach the vacuum hose from the EGR

valve and attach a hand vacuum pump in its

place (see illustration).

5Apply vacuum to the EGR valve. Vacuum

should remain steady and the engine should

run poorly. Note:This action will raise the

pintle and allow exhaust gases to recirculateinto the intake system and cause rough

running condition at idle.Double-check the

movement of the pintle by checking the

diaphragm using the tip of your finger (see

illustration). If the EGR diaphragm moves

smoothly and holds steady when vacuum is

applied, the EGR valve is working properly.

Warning: Don’t burn yourself. If

the EGR valve is hot, wear a

glove or wait until it cools.

a) If the vacuum doesn’t remain steady and

the engine doesn’t run poorly, renew the

EGR valve and recheck it.

b) If the vacuum remains steady but the

engine doesn’t run poorly, remove the

EGR valve and check the valve and the

intake manifold for blockage. Clean or

renew parts as necessary and recheck.EGR system

6Disconnect the hose from the EGR valve,

refit a vacuum gauge and check for vacuum

to the EGR valve. There should be vacuum

present with the engine warmed to operating

temperature (above 140° F) and between

1000 and 4000 rpm (see illustration).

Emissions and engine control systems 6•9

6

3261 Jaguar XJ6 6.2 Schematic of the EGR system

6.4 Apply vacuum to the EGR valve and confirm that the valve

opens and allows exhaust gases to circulate. Once it is activated,

the EGR valve should hold steady (no loss in vacuum)

6.5 Use a fingertip to move the diaphragm inside the EGR valve6.6 Check for vacuum to the EGR valve from the throttle body