length JAGUAR XJ6 1997 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1997, Model line: XJ6, Model: JAGUAR XJ6 1997 2.GPages: 227, PDF Size: 7.2 MB

Page 24 of 227

3Inspect each of the new plugs for defects. If

there are any signs of cracks in the porcelain

insulator of a plug, don’t use it.

4Check the electrode gaps of the new plugs.

Check the gap by inserting the wire gauge of

the proper thickness between the electrodes

at the tip of the plug (see illustration). The

gap between the electrodes should be

identical to that listed in this Chapter’s

Specifications or on the VECI label (as

applicable). If the gap is incorrect, use the

notched adjuster on the feeler gauge body to

bend the curved side electrode slightly (see

illustration).

5If the side electrode is not exactly over the

centre electrode, use the notched adjuster to

align them.Caution: If the gap of a new plug must be

adjusted, bend only the base of the earth

electrode - do not touch the tip.

Removal

6To prevent the possibility of mixing up

spark plug leads, work on one spark plug at a

time. Remove the lead and boot from one

spark plug. Grasp the boot - not the lead - as

shown, give it a half twisting motion and pull

straight up (see illustration).

7If compressed air is available, blow any dirt

or foreign material away from the spark plug

area before proceeding (a common bicycle

pump will also work).

8Remove the spark plug (see illustration).9Whether you are replacing the plugs at this

time or intend to re-use the old plugs,

compare each old spark plug with the chart

shown on the inside back cover of this manual

to determine the overall running condition of

the engine.

Refitting

10Prior to refitting, apply a coat of anti-seize

compound to the plug threads (see

illustration). It’s often difficult to insert spark

plugs into their holes without cross-threading

them. To avoid this possibility, fit a short piece

of 3/8-inch internal diameter (ID) rubber hose

over the end of the spark plug (see Haynes

Hint). The flexible hose acts as a universal

joint to help align the plug with the plug hole.

Should the plug begin to cross-thread, the

hose will slip on the spark plug, preventing

thread damage. Tighten the plug to the torque

listed in this Chapter’s Specifications. In the

absence of a torque wrench, tighten each

plug until you feel it seat, and then by a further

quarter-turn only. Do not overtighten the

spark plugs.

11Attach the plug lead to the new spark

plug, again using a twisting motion on the

boot until it is firmly seated on the end of the

spark plug.

12Follow the above procedure for the

remaining spark plugs, replacing them one at

a time to prevent mixing up the spark plug

leads.

1•8Every 7500 miles or 6 months

4.4a Spark plug manufacturers

recommend using a wire-type gauge when

checking the gap - if the wire does not

slide between the electrodes with a slight

drag, adjustment is required4.4b To change the gap, bend the side

electrode only, as indicated by the arrows,

and be very careful not to crack or chip the

porcelain insulator surrounding the

centre electrode4.6 When removing the spark plug leads,

grasp only the boot and use a

twisting/pulling motion

4.8 Use a spark plug socket with a long

extension to unscrew the spark plugs

3261 Jaguar XJ6

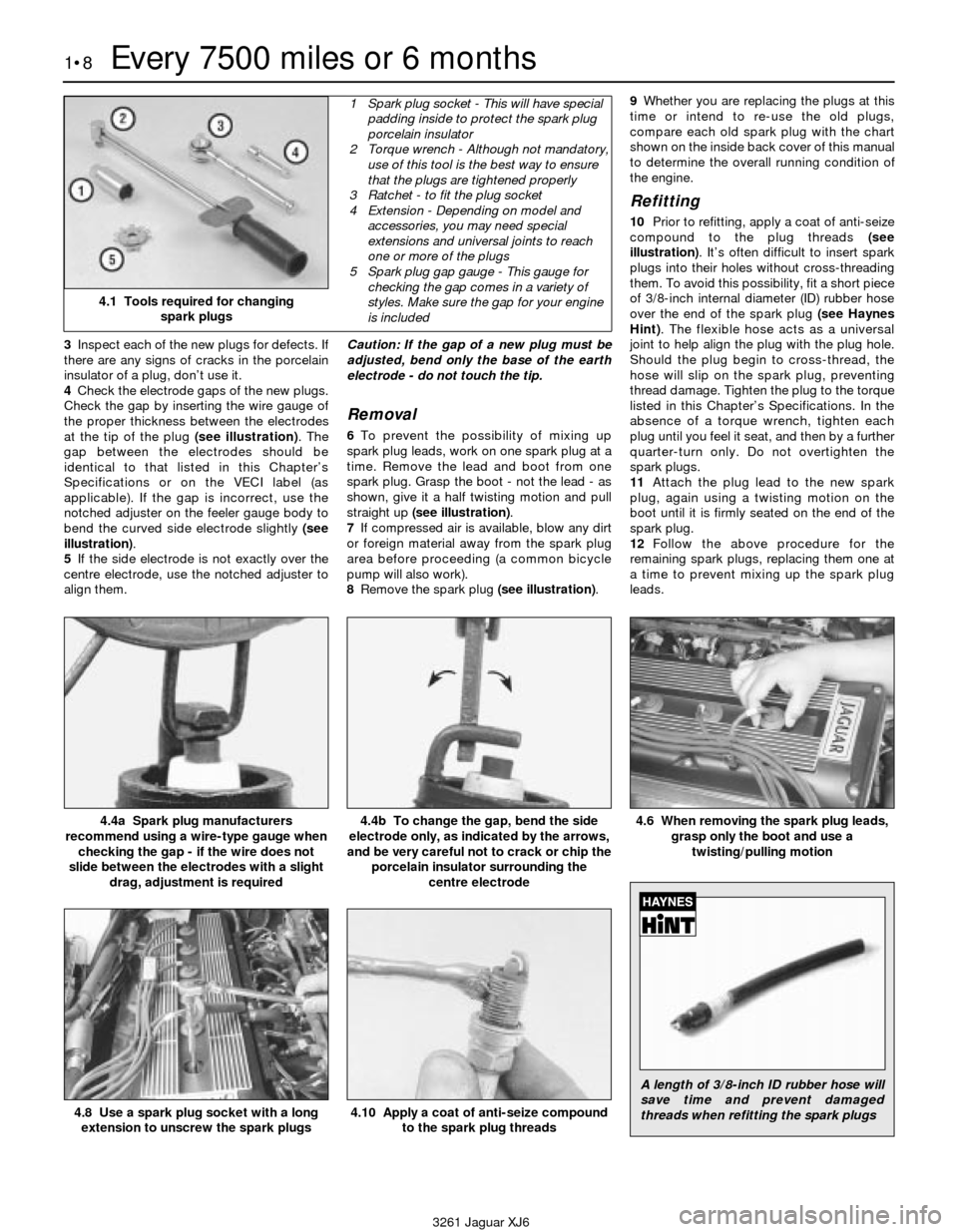

4.1 Tools required for changing

spark plugs

1 Spark plug socket - This will have special

padding inside to protect the spark plug

porcelain insulator

2 Torque wrench - Although not mandatory,

use of this tool is the best way to ensure

that the plugs are tightened properly

3 Ratchet - to fit the plug socket

4 Extension - Depending on model and

accessories, you may need special

extensions and universal joints to reach

one or more of the plugs

5 Spark plug gap gauge - This gauge for

checking the gap comes in a variety of

styles. Make sure the gap for your engine

is included

4.10 Apply a coat of anti-seize compound

to the spark plug threads

A length of 3/8-inch ID rubber hose will

save time and prevent damaged

threads when refitting the spark plugs

Page 26 of 227

never ingest it. Wear protective safety glasses

when working near the battery. Keep children

away from the battery.

5Note the external condition of the battery. If

the positive terminal and cable clamp on your

vehicle’s battery is equipped with a rubber

protector, make sure it isn’t torn or damaged.

It should completely cover the terminal. Look

for any corroded or loose connections, cracks

in the case or cover or loose hold-down

clamps. Also check the entire length of each

cable for cracks and frayed conductors.

6If corrosion, which looks like white, fluffy

deposits (see illustration)is evident,

particularly around the terminals, the battery

should be removed for cleaning. Loosen the

cable clamp bolts, being careful to remove the

ground cable first, and slide them off the

terminals (see illustration). Then disconnect

the hold-down clamp bolt and nut, remove the

clamp and lift the battery from the engine

compartment.

7Clean the cable clamps thoroughly with a

battery brush or a terminal cleaner and a

solution of warm water and baking soda (see

illustration). Wash the terminals and the top

of the battery case with the same solution but

make sure that the solution doesn’t get into

the battery. When cleaning the cables,

terminals and battery top, wear safety

goggles and rubber gloves to prevent any

solution from coming in contact with your

eyes or hands. Wear old clothes too - evendiluted, sulphuric acid splashed onto clothes

will burn holes in them. If the terminals have

been extensively corroded, clean them up

with a terminal cleaner (see illustration).

Thoroughly wash all cleaned areas with plain

water.

8Make sure the battery tray is in good

condition and the hold-down clamp bolt or

nut is tight. If the battery is removed from the

tray, make sure no parts remain in the bottom

of the tray when the battery is reinstalled.

When reinstalling the hold-down clamp bolt or

nut, do not over-tighten it.

9Information on removing and refitting the

battery can be found in Chapter 5. Information

on jump starting can be found at the front of

this manual.

Cleaning

10Corrosion on the hold-down components,

battery case and surrounding areas can be

removed with a solution of water and baking

soda. Thoroughly rinse all cleaned areas with

plain water.

11Any metal parts of the vehicle damaged

by corrosion should be covered with a zinc-

based primer, then painted.

Charging

Warning: When batteries are

being charged, hydrogen gas,

which is very explosive and

flammable, is produced. Do notsmoke or allow open flames near a

charging or a recently charged battery.

Wear eye protection when near the battery

during charging. Also, make sure the

charger is unplugged before connecting or

disconnecting the battery from the

charger.

12Slow-rate charging is the best way to

restore a battery that’s discharged to the

point where it will not start the engine. It’s also

a good way to maintain the battery charge in a

vehicle that’s only driven a few miles between

starts. Maintaining the battery charge is

particularly important in the winter when the

battery must work harder to start the engine

and electrical accessories that drain the

battery are in greater use.

13It’s best to use a one or two-amp battery

charger (sometimes called a “trickle” charger).

They are the safest and put the least strain on

the battery. They are also the least expensive.

For a faster charge, you can use a higher

amperage charger, but don’t use one rated

more than 1/10th the amp/hour rating of the

battery. Rapid boost charges that claim to

restore the power of the battery in one to two

hours are hardest on the battery and can

damage batteries not in good condition. This

type of charging should only be used in

emergency situations.

14The average time necessary to charge a

battery should be listed in the instructions that

come with the charger. As a general rule, a

trickle charger will charge a battery in 12 to 16

hours.

7 Hose and fluid leak check

1

1Visually inspect the engine joint faces,

gaskets and seals for any signs of water or oil

leaks. Pay particular attention to the areas

around the camshaft cover, cylinder head, oil

filter and sump joint faces. Bear in mind that,

over a period of time, some very slight

seepage from these areas is to be expected -

what you are really looking for is any indication

of a serious leak (see Haynes Hint). Should a

1•10Every 7500 miles or 6 months

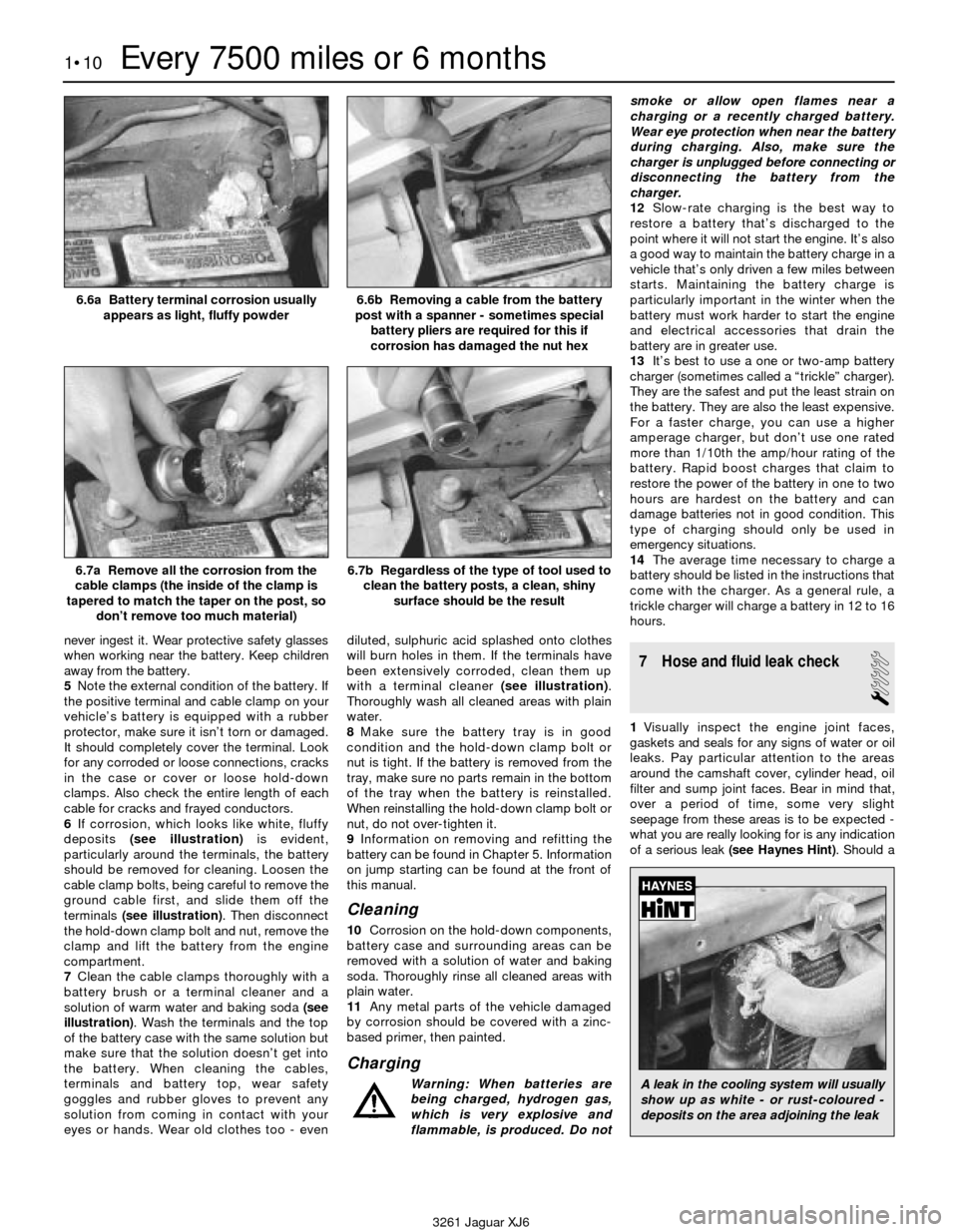

6.6a Battery terminal corrosion usually

appears as light, fluffy powder6.6b Removing a cable from the battery

post with a spanner - sometimes special

battery pliers are required for this if

corrosion has damaged the nut hex

6.7a Remove all the corrosion from the

cable clamps (the inside of the clamp is

tapered to match the taper on the post, so

don’t remove too much material)6.7b Regardless of the type of tool used to

clean the battery posts, a clean, shiny

surface should be the result

3261 Jaguar XJ6

A leak in the cooling system will usually

show up as white - or rust-coloured -

deposits on the area adjoining the leak

Page 27 of 227

leak be found, renew the offending gasket or

oil seal by referring to the appropriate

Chapters in this manual.

2Also check the security and condition of all

the engine-related pipes and hoses. Ensure

that all cable ties or securing clips are in place

and in good condition. Clips which are broken

or missing can lead to chafing of the hoses,

pipes or wiring, which could cause more

serious problems in the future.

3Carefully check the radiator hoses and

heater hoses along their entire length. Renew

any hose which is cracked, swollen or

deteriorated. Cracks will show up better if

the hose is squeezed. Pay close attention

to the hose clips that secure the hoses to the

cooling system components. Hose clips can

pinch and puncture hoses, resulting in cooling

system leaks.

4Inspect all the cooling system components

(hoses, joint faces etc.) for leaks. A leak in the

cooling system will usually show up as white-

or rust-coloured deposits on the area

adjoining the leak. Where any problems of this

nature are found on system components,

renew the component or gasket with

reference to Chapter 3.

5From within the engine compartment,

check the security of all fuel hose attachments

and pipe unions, and inspect the fuel hoses

and vacuum hoses for kinks, chafing and

deterioration.

6Also check the condition of the power

steering fluid hoses and pipes.

8 Automatic transmission

fluid level check

1

1The level of the automatic transmission fluid

should be carefully maintained. Low fluid level

can lead to slipping or loss of drive, while

overfilling can cause foaming, loss of fluid and

transmission damage.

2The transmission fluid level should only be

checked when the transmission is at its

normal operating temperature.

Caution: If the vehicle has just been driven

for a long time at high speed or in city

traffic in hot weather, or if it has been

pulling a trailer, an accurate fluid level

reading cannot be obtained. Allow the fluid

to cool down for about 30 minutes.

3If the vehicle has not been driven, park the

vehicle on level ground, set the handbrake,

then start the engine and bring it to operating

temperature. While the engine is idling,

depress the brake pedal and move the

selector lever through all the gear ranges,

beginning and ending in Park.

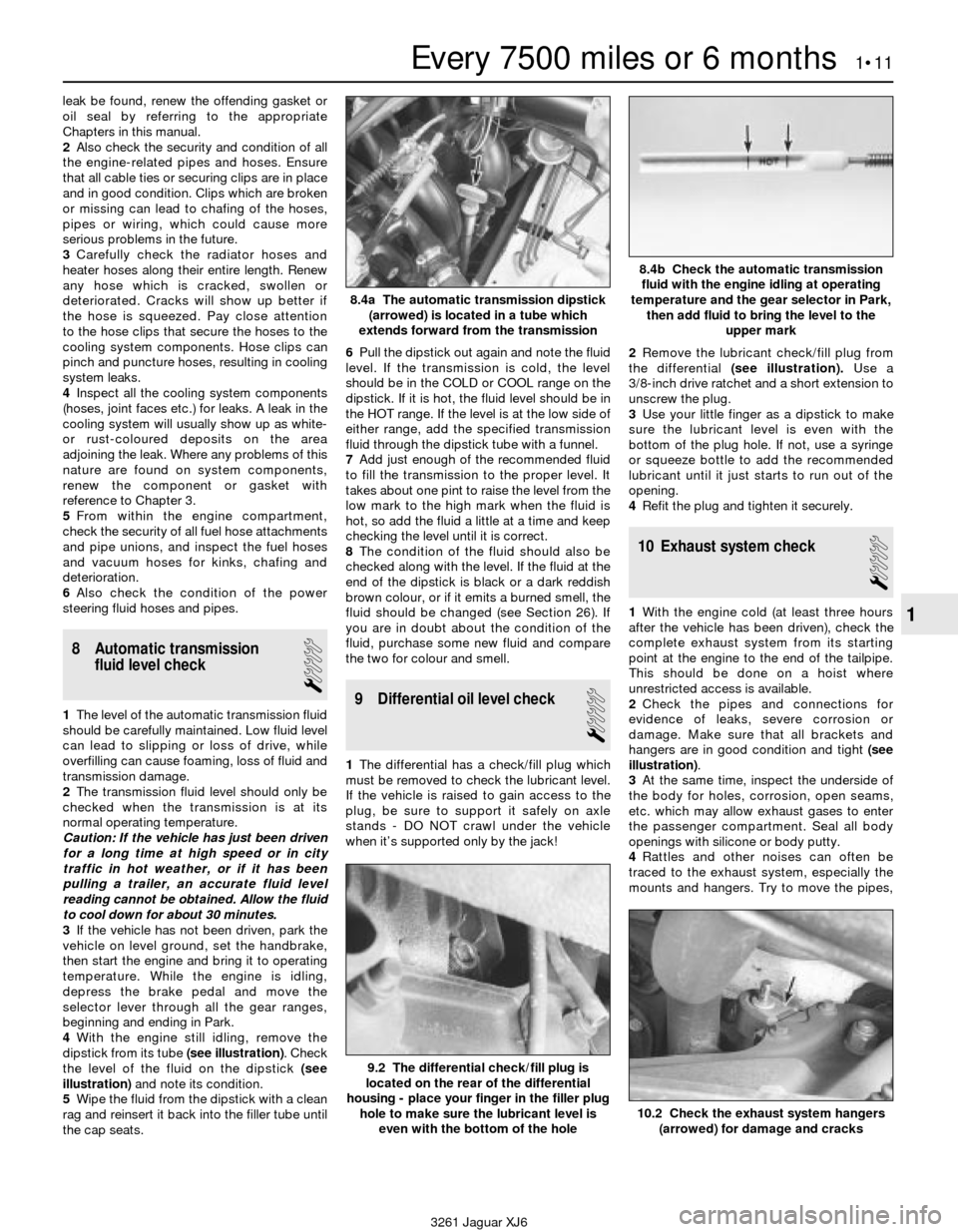

4With the engine still idling, remove the

dipstick from its tube (see illustration). Check

the level of the fluid on the dipstick (see

illustration)and note its condition.

5Wipe the fluid from the dipstick with a clean

rag and reinsert it back into the filler tube until

the cap seats.6Pull the dipstick out again and note the fluid

level. If the transmission is cold, the level

should be in the COLD or COOL range on the

dipstick. If it is hot, the fluid level should be in

the HOT range. If the level is at the low side of

either range, add the specified transmission

fluid through the dipstick tube with a funnel.

7Add just enough of the recommended fluid

to fill the transmission to the proper level. It

takes about one pint to raise the level from the

low mark to the high mark when the fluid is

hot, so add the fluid a little at a time and keep

checking the level until it is correct.

8The condition of the fluid should also be

checked along with the level. If the fluid at the

end of the dipstick is black or a dark reddish

brown colour, or if it emits a burned smell, the

fluid should be changed (see Section 26). If

you are in doubt about the condition of the

fluid, purchase some new fluid and compare

the two for colour and smell.9 Differential oil level check

1

1The differential has a check/fill plug which

must be removed to check the lubricant level.

If the vehicle is raised to gain access to the

plug, be sure to support it safely on axle

stands - DO NOT crawl under the vehicle

when it’s supported only by the jack!2Remove the lubricant check/fill plug from

the differential (see illustration).Use a

3/8-inch drive ratchet and a short extension to

unscrew the plug.

3Use your little finger as a dipstick to make

sure the lubricant level is even with the

bottom of the plug hole. If not, use a syringe

or squeeze bottle to add the recommended

lubricant until it just starts to run out of the

opening.

4Refit the plug and tighten it securely.

10 Exhaust system check

1

1With the engine cold (at least three hours

after the vehicle has been driven), check the

complete exhaust system from its starting

point at the engine to the end of the tailpipe.

This should be done on a hoist where

unrestricted access is available.

2Check the pipes and connections for

evidence of leaks, severe corrosion or

damage. Make sure that all brackets and

hangers are in good condition and tight (see

illustration).

3At the same time, inspect the underside of

the body for holes, corrosion, open seams,

etc. which may allow exhaust gases to enter

the passenger compartment. Seal all body

openings with silicone or body putty.

4Rattles and other noises can often be

traced to the exhaust system, especially the

mounts and hangers. Try to move the pipes,

Every 7500 miles or 6 months 1•11

1

9.2 The differential check/fill plug is

located on the rear of the differential

housing - place your finger in the filler plug

hole to make sure the lubricant level is

even with the bottom of the hole

10.2 Check the exhaust system hangers

(arrowed) for damage and cracks

3261 Jaguar XJ6

8.4a The automatic transmission dipstick

(arrowed) is located in a tube which

extends forward from the transmission

8.4b Check the automatic transmission

fluid with the engine idling at operating

temperature and the gear selector in Park,

then add fluid to bring the level to the

upper mark

Page 31 of 227

hand tools to remove. Simply slide back the

locking collars and remove the inlet and outlet

fuel lines (see illustration). Detach the filter

mounting bracket and discard the old filter in

a proper container.

5Note the direction of the arrow on the

outside of the filter; it should be pointed

towards the front of the car. Make sure the

new filter is installed so that it’s facing the

proper direction. Note:Always refit new

copper washers where equipped.

6Refit the inlet and outlet fittings then tighten

the filter mounting bracket. Reconnect the

battery cable, start the engine and check for

leaks.

19 Ignition system check

2

1The spark plug leads should be checked

whenever new spark plugs are installed.

2Begin this procedure by making a visual

check of the spark plug leads while the engine

is running. In a darkened garage (make sure

there is adequate ventilation) start the engine

and observe each plug lead. Be careful not to

come into contact with any moving engine

parts. If there is a break in the lead, you will

see arcing or a small spark at the damaged

area. If arcing is noticed, make a note to

obtain new leads, then allow the engine to

cool and check the distributor cap and rotor.

3The spark plug leads should be inspected

one at a time to prevent mixing up the order,

which is essential for proper engine operation.

Each original plug lead should be numbered

to help identify its location. If the number is

illegible, a piece of tape can be marked with

the correct number and wrapped around the

plug lead.

4Disconnect the plug lead from the spark

plug. A removal tool can be used for this

purpose or you can grasp the rubber boot,

twist the boot half a turn and pull the boot

free. Do not pull on the lead itself.

5Check inside the boot for corrosion, which

will look like a white crusty powder.6Push the lead and boot back onto the end

of the spark plug. It should fit tightly onto the

end of the plug. If it doesn’t, remove the lead

and use pliers to carefully crimp the metal

connector inside the lead boot until the fit is

snug.

7Using a clean rag, wipe the entire length of

the lead to remove built-up dirt and grease.

Once the lead is clean, check for burns,

cracks and other damage. Do not bend the

lead sharply, because the conductor might

break.

8Disconnect the spark plug lead from the

distributor cap. Again, pull only on the rubber

boot. Check for corrosion and a tight fit.

Reinsert the lead in the distributor cap.

9Inspect the remaining spark plug leads,

making sure that each one is securely

fastened at the distributor and spark plug

when the check is complete.10If new spark plug leads are required,

purchase a set for your specific engine model.

Remove and replace the leads one at a time

to avoid mix-ups in the firing order.

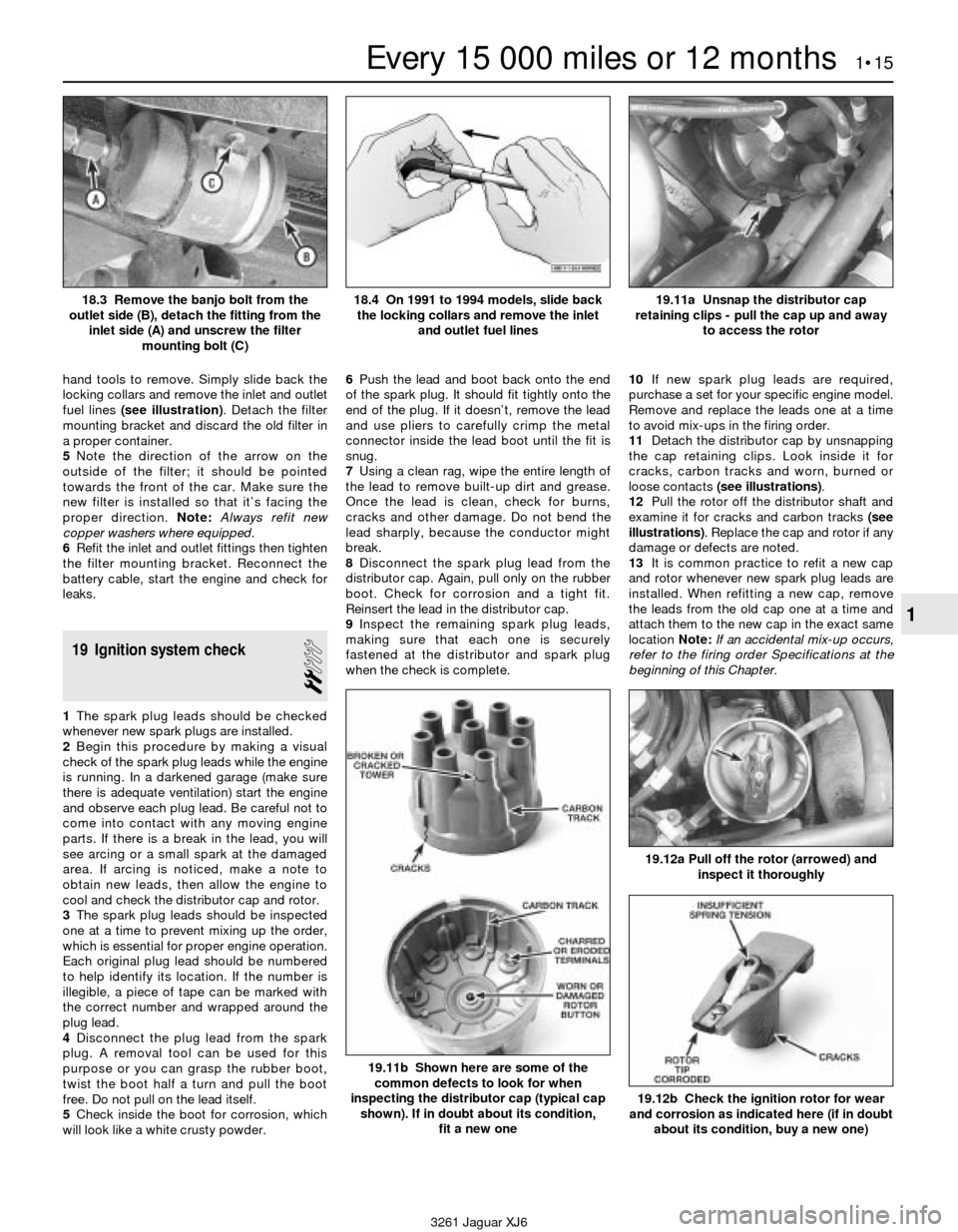

11Detach the distributor cap by unsnapping

the cap retaining clips. Look inside it for

cracks, carbon tracks and worn, burned or

loose contacts (see illustrations).

12Pull the rotor off the distributor shaft and

examine it for cracks and carbon tracks (see

illustrations). Replace the cap and rotor if any

damage or defects are noted.

13It is common practice to refit a new cap

and rotor whenever new spark plug leads are

installed. When refitting a new cap, remove

the leads from the old cap one at a time and

attach them to the new cap in the exact same

location Note:If an accidental mix-up occurs,

refer to the firing order Specifications at the

beginning of this Chapter.

Every 15 000 miles or 12 months 1•15

1

19.11a Unsnap the distributor cap

retaining clips - pull the cap up and away

to access the rotor

19.11b Shown here are some of the

common defects to look for when

inspecting the distributor cap (typical cap

shown). If in doubt about its condition,

fit a new one

19.12a Pull off the rotor (arrowed) and

inspect it thoroughly

19.12b Check the ignition rotor for wear

and corrosion as indicated here (if in doubt

about its condition, buy a new one)

3261 Jaguar XJ6 18.3 Remove the banjo bolt from the

outlet side (B), detach the fitting from the

inlet side (A) and unscrew the filter

mounting bolt (C)

18.4 On 1991 to 1994 models, slide back

the locking collars and remove the inlet

and outlet fuel lines

Page 32 of 227

20 Crankcase ventilation

system check

1

Refer to Chapter 6.

21 Drivebelt check and renewal

2

Check

1The drivebelts, or V-belts as they are

sometimes called, are located at the front of

the engine and play an important role in the

overall operation of the vehicle and its

components. Due to their function and

material make-up, the belts are prone to

failure after a period of time and should be

inspected and adjusted periodically to prevent

major engine damage.

2The number of belts used on a particular

vehicle depends on the accessories installed.

The main belt transmits power from the

crankshaft to the water pump, alternator and

the power steering pump. The second belt

transmits power from the crankshaft to the air

conditioning compressor.

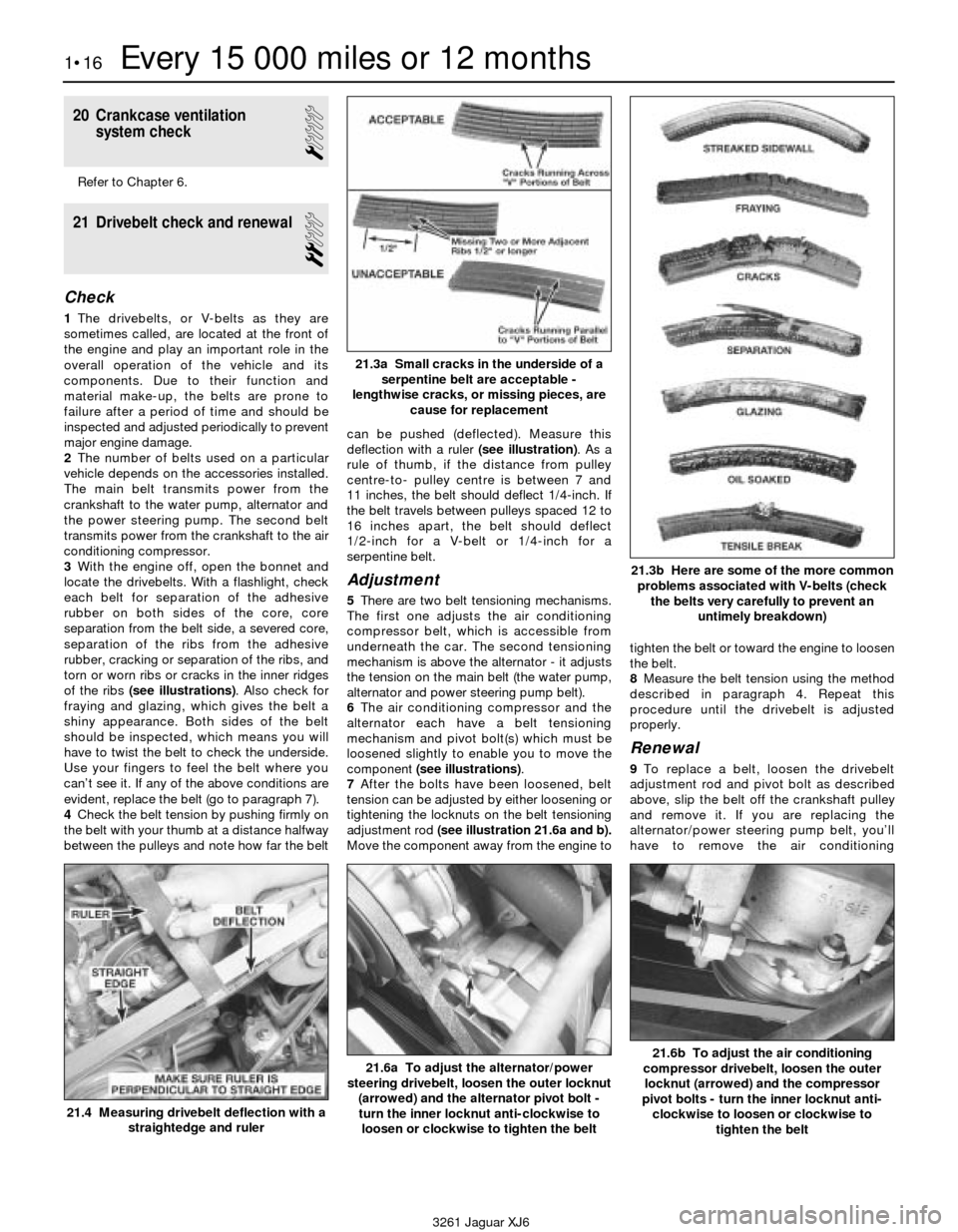

3With the engine off, open the bonnet and

locate the drivebelts. With a flashlight, check

each belt for separation of the adhesive

rubber on both sides of the core, core

separation from the belt side, a severed core,

separation of the ribs from the adhesive

rubber, cracking or separation of the ribs, and

torn or worn ribs or cracks in the inner ridges

of the ribs (see illustrations). Also check for

fraying and glazing, which gives the belt a

shiny appearance. Both sides of the belt

should be inspected, which means you will

have to twist the belt to check the underside.

Use your fingers to feel the belt where you

can’t see it. If any of the above conditions are

evident, replace the belt (go to paragraph 7).

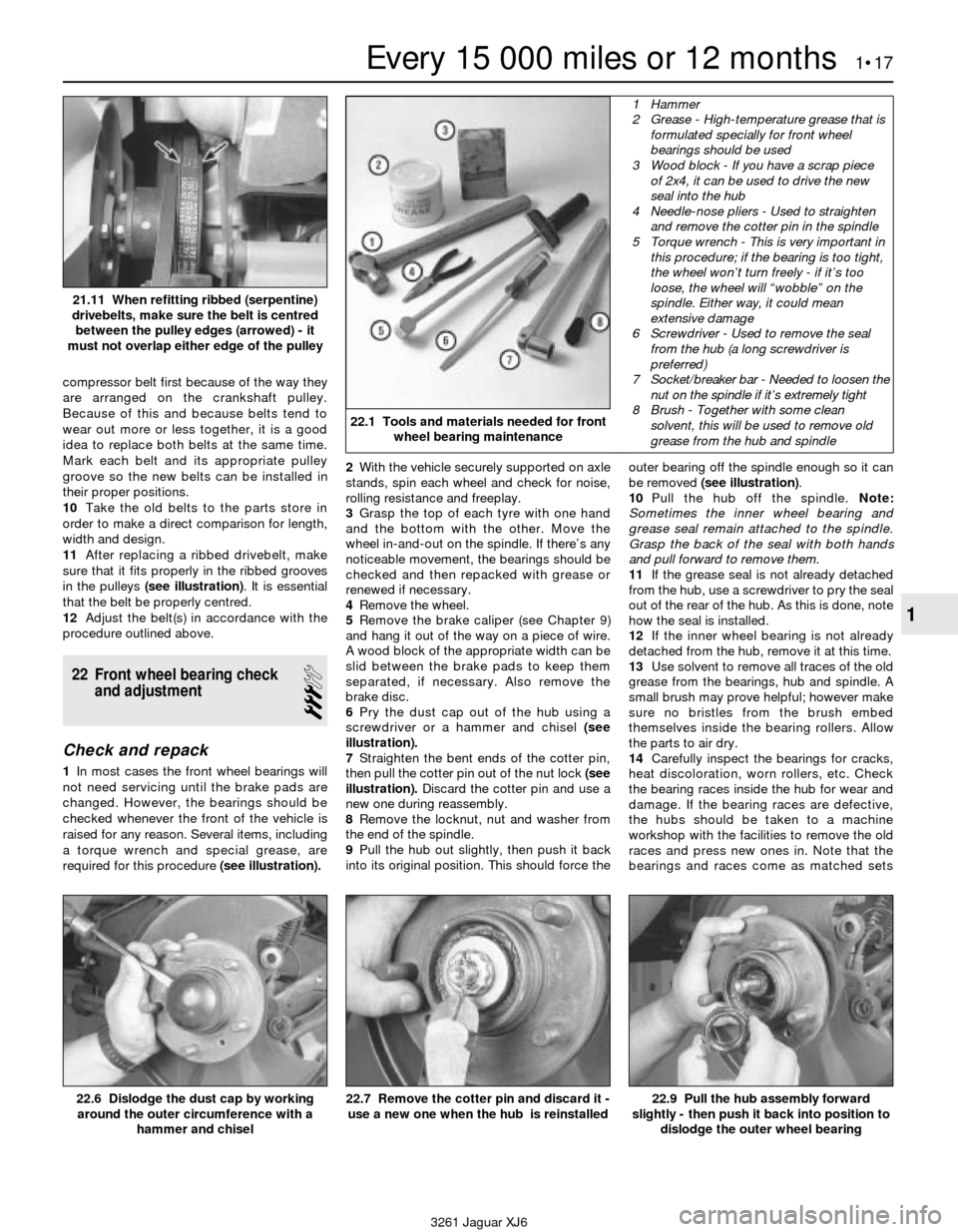

4Check the belt tension by pushing firmly on

the belt with your thumb at a distance halfway

between the pulleys and note how far the beltcan be pushed (deflected). Measure this

deflection with a ruler (see illustration). As a

rule of thumb, if the distance from pulley

centre-to- pulley centre is between 7 and

11 inches, the belt should deflect 1/4-inch. If

the belt travels between pulleys spaced 12 to

16 inches apart, the belt should deflect

1/2-inch for a V-belt or 1/4-inch for a

serpentine belt.

Adjustment

5There are two belt tensioning mechanisms.

The first one adjusts the air conditioning

compressor belt, which is accessible from

underneath the car. The second tensioning

mechanism is above the alternator - it adjusts

the tension on the main belt (the water pump,

alternator and power steering pump belt).

6The air conditioning compressor and the

alternator each have a belt tensioning

mechanism and pivot bolt(s) which must be

loosened slightly to enable you to move the

component (see illustrations).

7After the bolts have been loosened, belt

tension can be adjusted by either loosening or

tightening the locknuts on the belt tensioning

adjustment rod (see illustration 21.6a and b).

Move the component away from the engine totighten the belt or toward the engine to loosen

the belt.

8Measure the belt tension using the method

described in paragraph 4. Repeat this

procedure until the drivebelt is adjusted

properly.

Renewal

9To replace a belt, loosen the drivebelt

adjustment rod and pivot bolt as described

above, slip the belt off the crankshaft pulley

and remove it. If you are replacing the

alternator/power steering pump belt, you’ll

have to remove the air conditioning

1•16Every 15 000 miles or 12 months

21.3a Small cracks in the underside of a

serpentine belt are acceptable -

lengthwise cracks, or missing pieces, are

cause for replacement

21.3b Here are some of the more common

problems associated with V-belts (check

the belts very carefully to prevent an

untimely breakdown)

21.4 Measuring drivebelt deflection with a

straightedge and ruler

21.6a To adjust the alternator/power

steering drivebelt, loosen the outer locknut

(arrowed) and the alternator pivot bolt -

turn the inner locknut anti-clockwise to

loosen or clockwise to tighten the belt21.6b To adjust the air conditioning

compressor drivebelt, loosen the outer

locknut (arrowed) and the compressor

pivot bolts - turn the inner locknut anti-

clockwise to loosen or clockwise to

tighten the belt

3261 Jaguar XJ6

Page 33 of 227

compressor belt first because of the way they

are arranged on the crankshaft pulley.

Because of this and because belts tend to

wear out more or less together, it is a good

idea to replace both belts at the same time.

Mark each belt and its appropriate pulley

groove so the new belts can be installed in

their proper positions.

10Take the old belts to the parts store in

order to make a direct comparison for length,

width and design.

11After replacing a ribbed drivebelt, make

sure that it fits properly in the ribbed grooves

in the pulleys (see illustration). It is essential

that the belt be properly centred.

12Adjust the belt(s) in accordance with the

procedure outlined above.

22 Front wheel bearing check

and adjustment

3

Check and repack

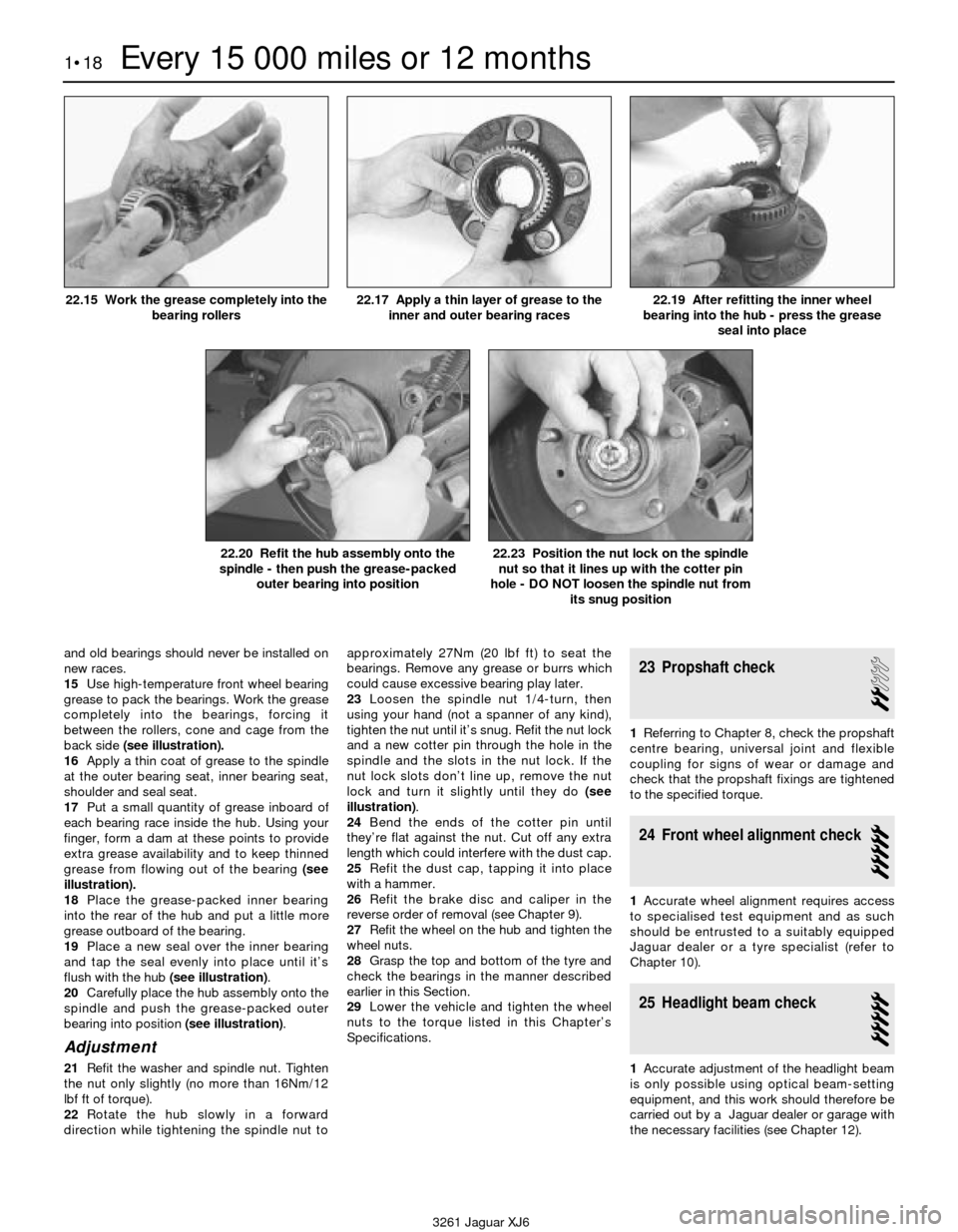

1In most cases the front wheel bearings will

not need servicing until the brake pads are

changed. However, the bearings should be

checked whenever the front of the vehicle is

raised for any reason. Several items, including

a torque wrench and special grease, are

required for this procedure (see illustration).2With the vehicle securely supported on axle

stands, spin each wheel and check for noise,

rolling resistance and freeplay.

3Grasp the top of each tyre with one hand

and the bottom with the other. Move the

wheel in-and-out on the spindle. If there’s any

noticeable movement, the bearings should be

checked and then repacked with grease or

renewed if necessary.

4Remove the wheel.

5Remove the brake caliper (see Chapter 9)

and hang it out of the way on a piece of wire.

A wood block of the appropriate width can be

slid between the brake pads to keep them

separated, if necessary. Also remove the

brake disc.

6Pry the dust cap out of the hub using a

screwdriver or a hammer and chisel (see

illustration).

7Straighten the bent ends of the cotter pin,

then pull the cotter pin out of the nut lock (see

illustration).Discard the cotter pin and use a

new one during reassembly.

8Remove the locknut, nut and washer from

the end of the spindle.

9Pull the hub out slightly, then push it back

into its original position. This should force theouter bearing off the spindle enough so it can

be removed (see illustration).

10Pull the hub off the spindle. Note:

Sometimes the inner wheel bearing and

grease seal remain attached to the spindle.

Grasp the back of the seal with both hands

and pull forward to remove them.

11If the grease seal is not already detached

from the hub, use a screwdriver to pry the seal

out of the rear of the hub. As this is done, note

how the seal is installed.

12If the inner wheel bearing is not already

detached from the hub, remove it at this time.

13Use solvent to remove all traces of the old

grease from the bearings, hub and spindle. A

small brush may prove helpful; however make

sure no bristles from the brush embed

themselves inside the bearing rollers. Allow

the parts to air dry.

14Carefully inspect the bearings for cracks,

heat discoloration, worn rollers, etc. Check

the bearing races inside the hub for wear and

damage. If the bearing races are defective,

the hubs should be taken to a machine

workshop with the facilities to remove the old

races and press new ones in. Note that the

bearings and races come as matched sets

Every 15 000 miles or 12 months 1•17

1

22.1 Tools and materials needed for front

wheel bearing maintenance

1 Hammer

2 Grease - High-temperature grease that is

formulated specially for front wheel

bearings should be used

3 Wood block - If you have a scrap piece

of 2x4, it can be used to drive the new

seal into the hub

4 Needle-nose pliers - Used to straighten

and remove the cotter pin in the spindle

5 Torque wrench - This is very important in

this procedure; if the bearing is too tight,

the wheel won’t turn freely - if it’s too

loose, the wheel will “wobble” on the

spindle. Either way, it could mean

extensive damage

6 Screwdriver - Used to remove the seal

from the hub (a long screwdriver is

preferred)

7 Socket/breaker bar - Needed to loosen the

nut on the spindle if it’s extremely tight

8 Brush - Together with some clean

solvent, this will be used to remove old

grease from the hub and spindle

22.6 Dislodge the dust cap by working

around the outer circumference with a

hammer and chisel

22.7 Remove the cotter pin and discard it -

use a new one when the hub is reinstalled22.9 Pull the hub assembly forward

slightly - then push it back into position to

dislodge the outer wheel bearing

3261 Jaguar XJ6 21.11 When refitting ribbed (serpentine)

drivebelts, make sure the belt is centred

between the pulley edges (arrowed) - it

must not overlap either edge of the pulley

Page 34 of 227

and old bearings should never be installed on

new races.

15Use high-temperature front wheel bearing

grease to pack the bearings. Work the grease

completely into the bearings, forcing it

between the rollers, cone and cage from the

back side (see illustration).

16Apply a thin coat of grease to the spindle

at the outer bearing seat, inner bearing seat,

shoulder and seal seat.

17Put a small quantity of grease inboard of

each bearing race inside the hub. Using your

finger, form a dam at these points to provide

extra grease availability and to keep thinned

grease from flowing out of the bearing (see

illustration).

18Place the grease-packed inner bearing

into the rear of the hub and put a little more

grease outboard of the bearing.

19Place a new seal over the inner bearing

and tap the seal evenly into place until it’s

flush with the hub (see illustration).

20Carefully place the hub assembly onto the

spindle and push the grease-packed outer

bearing into position (see illustration).

Adjustment

21Refit the washer and spindle nut. Tighten

the nut only slightly (no more than 16Nm/12

lbf ft of torque).

22Rotate the hub slowly in a forward

direction while tightening the spindle nut toapproximately 27Nm (20 lbf ft) to seat the

bearings. Remove any grease or burrs which

could cause excessive bearing play later.

23Loosen the spindle nut 1/4-turn, then

using your hand (not a spanner of any kind),

tighten the nut until it’s snug. Refit the nut lock

and a new cotter pin through the hole in the

spindle and the slots in the nut lock. If the

nut lock slots don’t line up, remove the nut

lock and turn it slightly until they do (see

illustration).

24Bend the ends of the cotter pin until

they’re flat against the nut. Cut off any extra

length which could interfere with the dust cap.

25Refit the dust cap, tapping it into place

with a hammer.

26Refit the brake disc and caliper in the

reverse order of removal (see Chapter 9).

27Refit the wheel on the hub and tighten the

wheel nuts.

28Grasp the top and bottom of the tyre and

check the bearings in the manner described

earlier in this Section.

29Lower the vehicle and tighten the wheel

nuts to the torque listed in this Chapter’s

Specifications.

23 Propshaft check

2

1Referring to Chapter 8, check the propshaft

centre bearing, universal joint and flexible

coupling for signs of wear or damage and

check that the propshaft fixings are tightened

to the specified torque.

24 Front wheel alignment check

5

1Accurate wheel alignment requires access

to specialised test equipment and as such

should be entrusted to a suitably equipped

Jaguar dealer or a tyre specialist (refer to

Chapter 10).

25 Headlight beam check

5

1Accurate adjustment of the headlight beam

is only possible using optical beam-setting

equipment, and this work should therefore be

carried out by a Jaguar dealer or garage with

the necessary facilities (see Chapter 12).

1•18Every 15 000 miles or 12 months

22.15 Work the grease completely into the

bearing rollers22.17 Apply a thin layer of grease to the

inner and outer bearing races22.19 After refitting the inner wheel

bearing into the hub - press the grease

seal into place

22.20 Refit the hub assembly onto the

spindle - then push the grease-packed

outer bearing into position22.23 Position the nut lock on the spindle

nut so that it lines up with the cotter pin

hole - DO NOT loosen the spindle nut from

its snug position

3261 Jaguar XJ6

Page 56 of 227

3261 Jaguar XJ6

2B

Chapter 2 Part B

Engine removal and overhaul procedures

General

Cylinder compression pressure @ 300 rpm, warm

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.6 to 11.3 bar (150 to 160 psi)

High compression models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.3 to 12.1 bar (160 to 170 psi)

Maximum variation between cylinders . . . . . . . . . . . . . . . . . . . . . . . . 0.8 bar (10 psi)

Oil pressure (engine warm)

At idle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.1 bar (30 psi) minimum

At 4000 rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.9 bar (70 psi) minimum

Cylinder head

Resurfacing limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.25 mm (0.010 inch) maximum

Minimum thickness (see text)

3.6 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129.6 mm (5.101 inches)

3.2 and 4.0 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129.7 mm (5.108 inches)

Valves and related components

Valve stem-to-guide clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.038 to 0.076 mm (0.0015 to 0.0030 inch)

Valve springs, free length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.13 mm (1.580 inches)

Valve lifter

Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33.34 to 33.35 mm (1.3126 to 1.3130 inches)

Lifter-to-bore clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.02 to 0.05 mm (0.0008 to 0.0020 inch)

Crankshaft and connecting rods

Connecting rod journal

Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52.97 to 52.99 mm (2.0856 to 2.0861 inches)

Taper and out-of-round limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.008 mm (0.0003 inch) maximum

Bearing oil clearance

3.6 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.040 to 0.083 mm (0.0016 to 0.0033 inch)

3.2 and 4.0 litre . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.025 to 0.0068 mm (0.0010 to 0.0027 inch)

Connecting rod side clearance (endplay) . . . . . . . . . . . . . . . . . . . . . . . . 0.127 to 0.228 mm (0.005 to 0.009 inch)

Main bearing journal

Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76.217 to 76.233 mm (3.0007 to 3.0012 inches)

Taper and out-of-round limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.008 mm (0.0003 inch) maximum

Bearing oil clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.040 to 0.083 mm (0.0016 to 0.0033 inch)

Crankshaft endplay (standard) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.101 to 0.254 mm (0.004 to 0.010 inch) CHECK ENGINE light . . . . . . . . . . . . . . . . . . . . . . . . . . . See Chapter 6

Crankshaft - inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Crankshaft - refitting and main bearing oil clearance check . . . . . . . 23

Crankshaft - removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cylinder head - cleaning and inspection . . . . . . . . . . . . . . . . . . . . . . 10

Cylinder head - dismantling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Cylinder head - reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Cylinder compression check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Cylinder honing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Engine block - cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Engine block - inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Engine overhaul - dismantling sequence . . . . . . . . . . . . . . . . . . . . . . 8

Engine overhaul - general information . . . . . . . . . . . . . . . . . . . . . . . . 2

Engine overhaul - reassembly sequence . . . . . . . . . . . . . . . . . . . . . . 21Engine rebuilding alternatives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Engine - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Engine removal - methods and precautions . . . . . . . . . . . . . . . . . . . 5

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Initial start-up and running-in after overhaul . . . . . . . . . . . . . . . . . . . 26

Main and connecting big-end bearings - inspection and selection . 20

Pistons/connecting rods - inspection . . . . . . . . . . . . . . . . . . . . . . . . 18

Pistons/connecting rods - refitting and big-end bearing

oil clearance check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Pistons/connecting rods - removal . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Piston rings - refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Rear main oil seal refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Vacuum gauge diagnostic checks . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Valves - servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2B•1

Specifications Contents

Easy,suitable for

novice with little

experienceFairly easy,suitable

for beginner with

some experienceFairly difficult,

suitable for competent

DIY mechanic

Difficult,suitable for

experienced DIY

mechanicVery difficult,

suitable for expert DIY

or professional

Degrees of difficulty

54321

Page 63 of 227

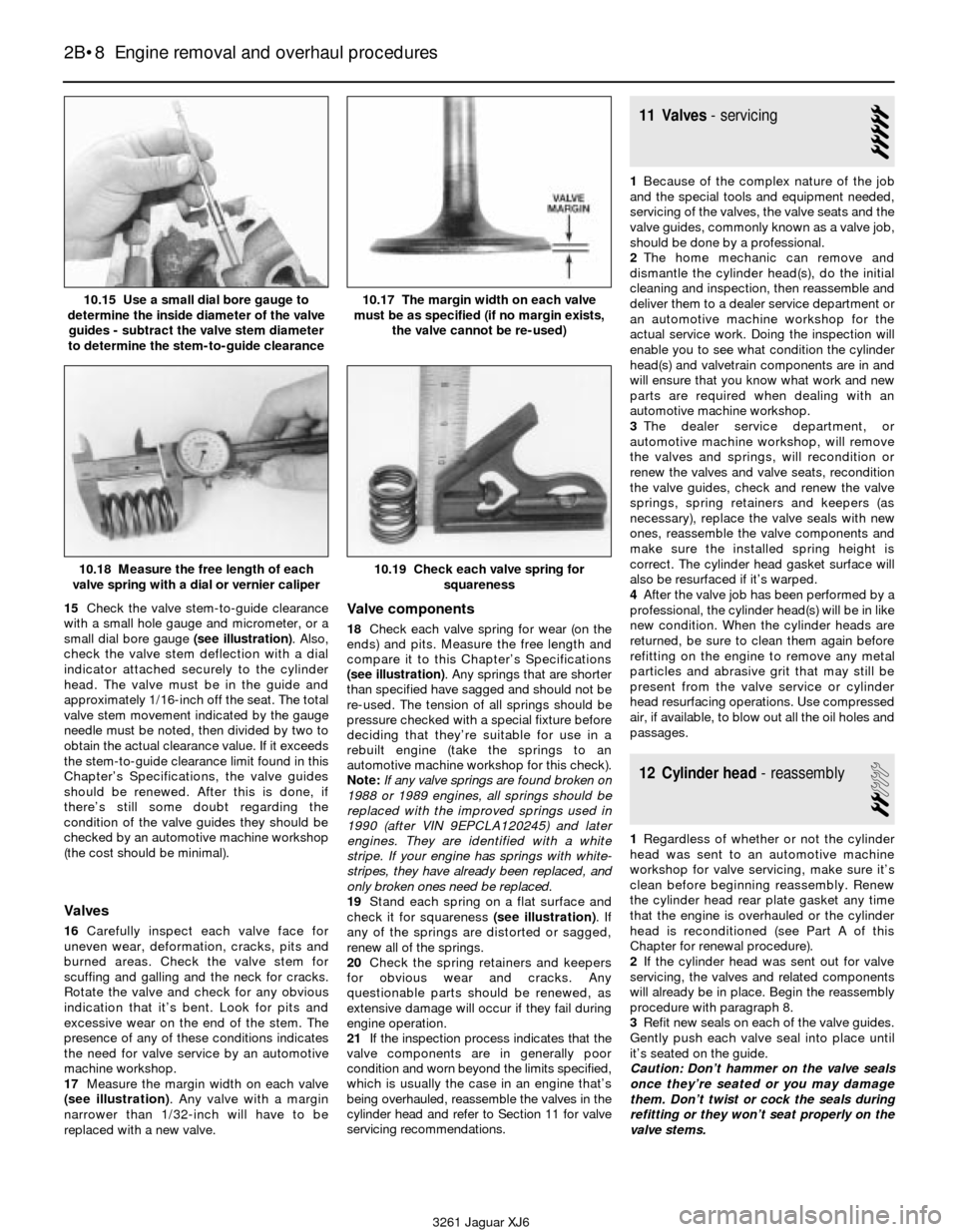

15Check the valve stem-to-guide clearance

with a small hole gauge and micrometer, or a

small dial bore gauge (see illustration). Also,

check the valve stem deflection with a dial

indicator attached securely to the cylinder

head. The valve must be in the guide and

approximately 1/16-inch off the seat. The total

valve stem movement indicated by the gauge

needle must be noted, then divided by two to

obtain the actual clearance value. If it exceeds

the stem-to-guide clearance limit found in this

Chapter’s Specifications, the valve guides

should be renewed. After this is done, if

there’s still some doubt regarding the

condition of the valve guides they should be

checked by an automotive machine workshop

(the cost should be minimal).

Valves

16Carefully inspect each valve face for

uneven wear, deformation, cracks, pits and

burned areas. Check the valve stem for

scuffing and galling and the neck for cracks.

Rotate the valve and check for any obvious

indication that it’s bent. Look for pits and

excessive wear on the end of the stem. The

presence of any of these conditions indicates

the need for valve service by an automotive

machine workshop.

17Measure the margin width on each valve

(see illustration). Any valve with a margin

narrower than 1/32-inch will have to be

replaced with a new valve.

Valve components

18Check each valve spring for wear (on the

ends) and pits. Measure the free length and

compare it to this Chapter’s Specifications

(see illustration). Any springs that are shorter

than specified have sagged and should not be

re-used. The tension of all springs should be

pressure checked with a special fixture before

deciding that they’re suitable for use in a

rebuilt engine (take the springs to an

automotive machine workshop for this check).

Note:If any valve springs are found broken on

1988 or 1989 engines, all springs should be

replaced with the improved springs used in

1990 (after VIN 9EPCLA120245) and later

engines. They are identified with a white

stripe. If your engine has springs with white-

stripes, they have already been replaced, and

only broken ones need be replaced.

19Stand each spring on a flat surface and

check it for squareness (see illustration). If

any of the springs are distorted or sagged,

renew all of the springs.

20Check the spring retainers and keepers

for obvious wear and cracks. Any

questionable parts should be renewed, as

extensive damage will occur if they fail during

engine operation.

21If the inspection process indicates that the

valve components are in generally poor

condition and worn beyond the limits specified,

which is usually the case in an engine that’s

being overhauled, reassemble the valves in the

cylinder head and refer to Section 11 for valve

servicing recommendations.

11 Valves- servicing

5

1Because of the complex nature of the job

and the special tools and equipment needed,

servicing of the valves, the valve seats and the

valve guides, commonly known as a valve job,

should be done by a professional.

2The home mechanic can remove and

dismantle the cylinder head(s), do the initial

cleaning and inspection, then reassemble and

deliver them to a dealer service department or

an automotive machine workshop for the

actual service work. Doing the inspection will

enable you to see what condition the cylinder

head(s) and valvetrain components are in and

will ensure that you know what work and new

parts are required when dealing with an

automotive machine workshop.

3The dealer service department, or

automotive machine workshop, will remove

the valves and springs, will recondition or

renew the valves and valve seats, recondition

the valve guides, check and renew the valve

springs, spring retainers and keepers (as

necessary), replace the valve seals with new

ones, reassemble the valve components and

make sure the installed spring height is

correct. The cylinder head gasket surface will

also be resurfaced if it’s warped.

4After the valve job has been performed by a

professional, the cylinder head(s) will be in like

new condition. When the cylinder heads are

returned, be sure to clean them again before

refitting on the engine to remove any metal

particles and abrasive grit that may still be

present from the valve service or cylinder

head resurfacing operations. Use compressed

air, if available, to blow out all the oil holes and

passages.

12 Cylinder head- reassembly

2

1Regardless of whether or not the cylinder

head was sent to an automotive machine

workshop for valve servicing, make sure it’s

clean before beginning reassembly. Renew

the cylinder head rear plate gasket any time

that the engine is overhauled or the cylinder

head is reconditioned (see Part A of this

Chapter for renewal procedure).

2If the cylinder head was sent out for valve

servicing, the valves and related components

will already be in place. Begin the reassembly

procedure with paragraph 8.

3Refit new seals on each of the valve guides.

Gently push each valve seal into place until

it’s seated on the guide.

Caution: Don’t hammer on the valve seals

once they’re seated or you may damage

them. Don’t twist or cock the seals during

refitting or they won’t seat properly on the

valve stems.

2B•8 Engine removal and overhaul procedures

10.15 Use a small dial bore gauge to

determine the inside diameter of the valve

guides - subtract the valve stem diameter

to determine the stem-to-guide clearance10.17 The margin width on each valve

must be as specified (if no margin exists,

the valve cannot be re-used)

10.18 Measure the free length of each

valve spring with a dial or vernier caliper10.19 Check each valve spring for

squareness

3261 Jaguar XJ6

Page 64 of 227

4Beginning at one end of the cylinder head,

lubricate and refit the first valve. Apply moly-

base grease or clean engine oil to the valve

stem.

5Place the spring seat or shim(s) over the

valve guide and set the valve spring and

retainer in place.

6Compress the springs with a valve spring

compressor and carefully refit the keepers in

the upper groove, then slowly release the

compressor and make sure the keepers seat

properly. Apply a small dab of grease to each

keeper to hold it in place if necessary (see

Haynes Hint).

7Repeat the procedure for the remaining

valves. Be sure to return the components to

their original locations - don’t mix them up!

13 Pistons/connecting rods-

removal

4

Note :Prior to removing the piston/connecting

rod assemblies, remove the cylinder head(s),

the sump and the oil pump transfer tubes by

referring to Chapter 2A.

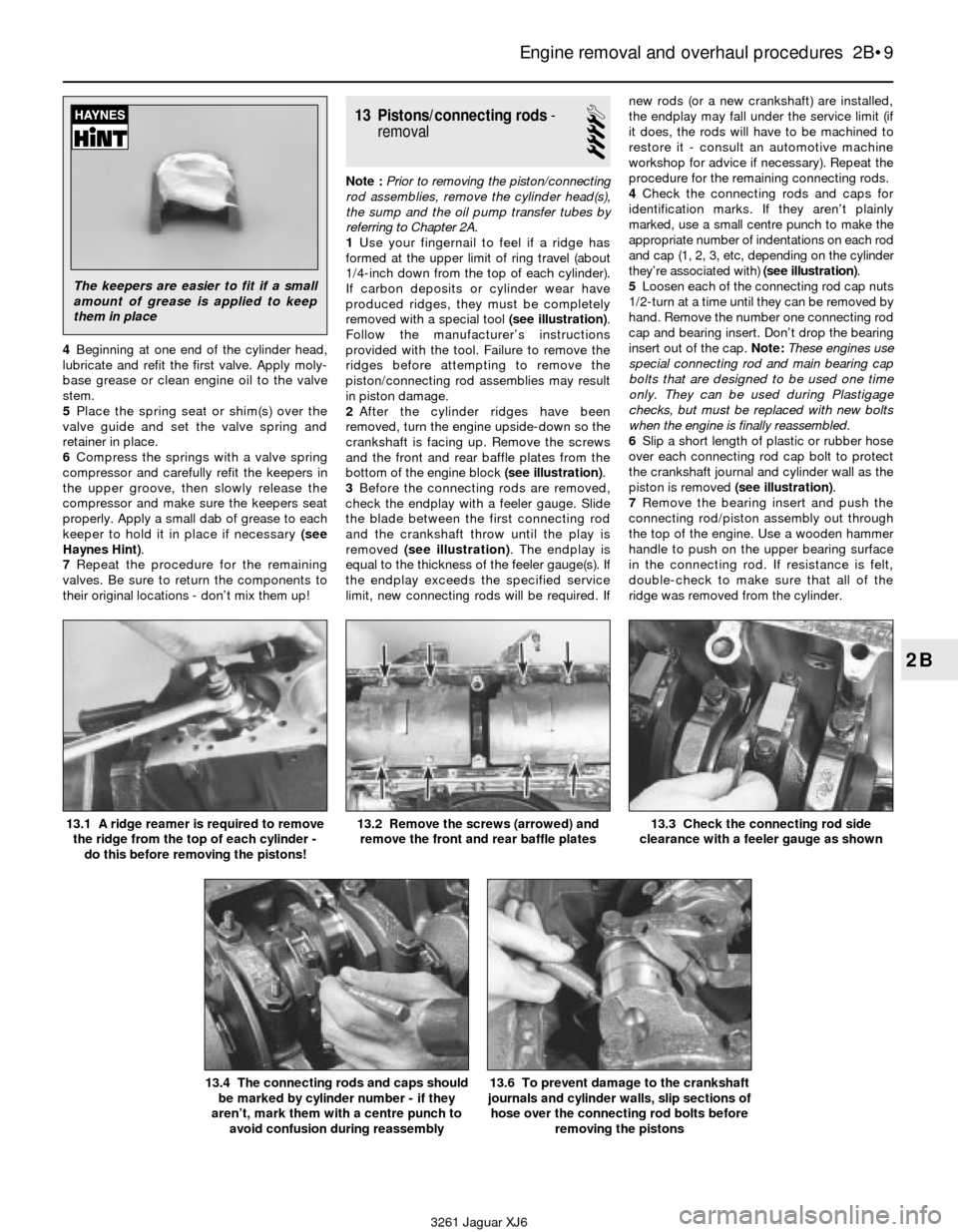

1Use your fingernail to feel if a ridge has

formed at the upper limit of ring travel (about

1/4-inch down from the top of each cylinder).

If carbon deposits or cylinder wear have

produced ridges, they must be completely

removed with a special tool (see illustration).

Follow the manufacturer’s instructions

provided with the tool. Failure to remove the

ridges before attempting to remove the

piston/connecting rod assemblies may result

in piston damage.

2After the cylinder ridges have been

removed, turn the engine upside-down so the

crankshaft is facing up. Remove the screws

and the front and rear baffle plates from the

bottom of the engine block (see illustration).

3Before the connecting rods are removed,

check the endplay with a feeler gauge. Slide

the blade between the first connecting rod

and the crankshaft throw until the play is

removed (see illustration). The endplay is

equal to the thickness of the feeler gauge(s). If

the endplay exceeds the specified service

limit, new connecting rods will be required. Ifnew rods (or a new crankshaft) are installed,

the endplay may fall under the service limit (if

it does, the rods will have to be machined to

restore it - consult an automotive machine

workshop for advice if necessary). Repeat the

procedure for the remaining connecting rods.

4Check the connecting rods and caps for

identification marks. If they aren’t plainly

marked, use a small centre punch to make the

appropriate number of indentations on each rod

and cap (1, 2, 3, etc, depending on the cylinder

they’re associated with) (see illustration).

5Loosen each of the connecting rod cap nuts

1/2-turn at a time until they can be removed by

hand. Remove the number one connecting rod

cap and bearing insert. Don’t drop the bearing

insert out of the cap. Note:These engines use

special connecting rod and main bearing cap

bolts that are designed to be used one time

only. They can be used during Plastigage

checks, but must be replaced with new bolts

when the engine is finally reassembled.

6Slip a short length of plastic or rubber hose

over each connecting rod cap bolt to protect

the crankshaft journal and cylinder wall as the

piston is removed (see illustration).

7Remove the bearing insert and push the

connecting rod/piston assembly out through

the top of the engine. Use a wooden hammer

handle to push on the upper bearing surface

in the connecting rod. If resistance is felt,

double-check to make sure that all of the

ridge was removed from the cylinder.

Engine removal and overhaul procedures 2B•9

2B

13.2 Remove the screws (arrowed) and

remove the front and rear baffle plates13.3 Check the connecting rod side

clearance with a feeler gauge as shown

13.4 The connecting rods and caps should

be marked by cylinder number - if they

aren’t, mark them with a centre punch to

avoid confusion during reassembly13.6 To prevent damage to the crankshaft

journals and cylinder walls, slip sections of

hose over the connecting rod bolts before

removing the pistons

3261 Jaguar XJ6 13.1 A ridge reamer is required to remove

the ridge from the top of each cylinder -

do this before removing the pistons!

The keepers are easier to fit if a small

amount of grease is applied to keep

them in place