JEEP CHEROKEE 1995 Service Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 301 of 2198

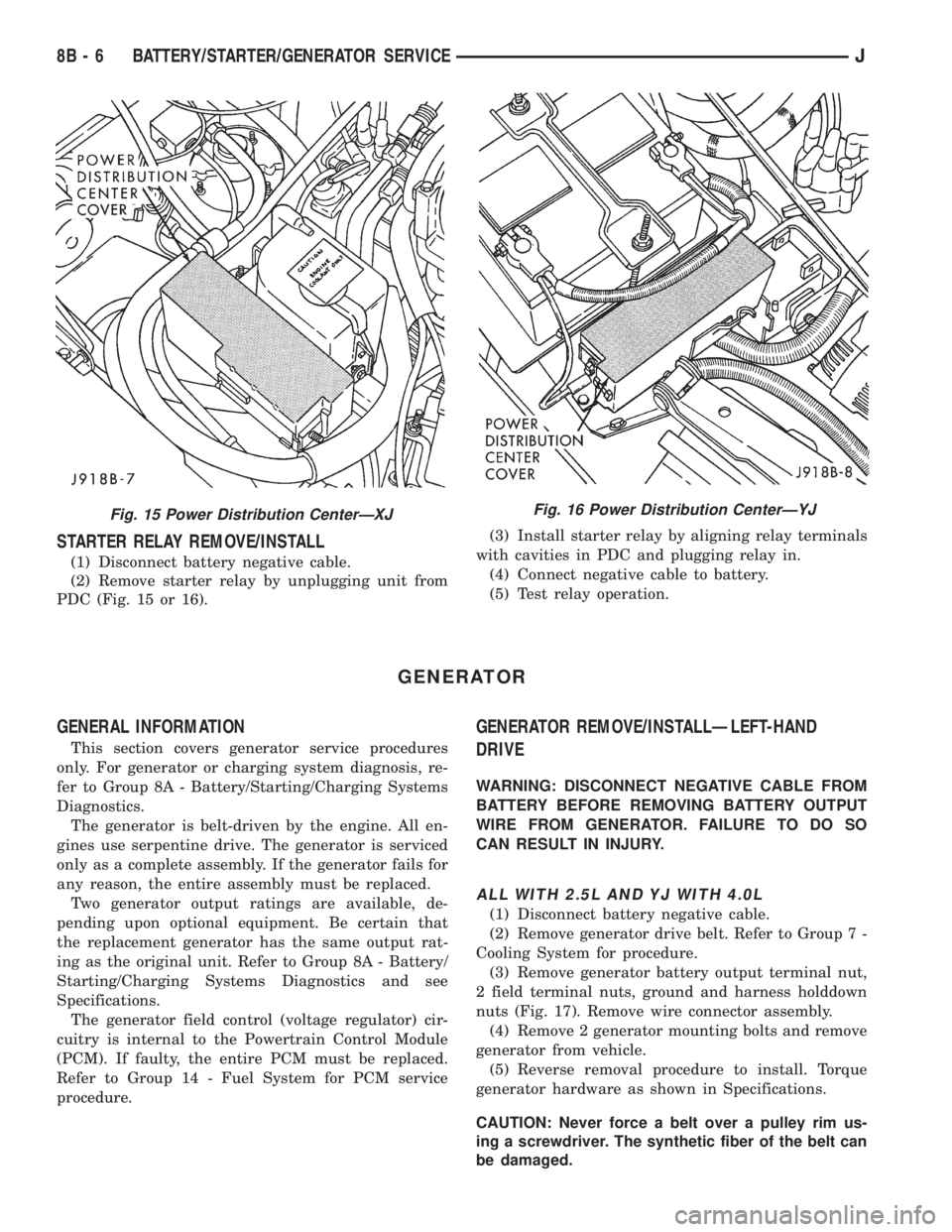

STARTER RELAY REMOVE/INSTALL

(1) Disconnect battery negative cable.

(2) Remove starter relay by unplugging unit from

PDC (Fig. 15 or 16).(3) Install starter relay by aligning relay terminals

with cavities in PDC and plugging relay in.

(4) Connect negative cable to battery.

(5) Test relay operation.

GENERATOR

GENERAL INFORMATION

This section covers generator service procedures

only. For generator or charging system diagnosis, re-

fer to Group 8A - Battery/Starting/Charging Systems

Diagnostics.

The generator is belt-driven by the engine. All en-

gines use serpentine drive. The generator is serviced

only as a complete assembly. If the generator fails for

any reason, the entire assembly must be replaced.

Two generator output ratings are available, de-

pending upon optional equipment. Be certain that

the replacement generator has the same output rat-

ing as the original unit. Refer to Group 8A - Battery/

Starting/Charging Systems Diagnostics and see

Specifications.

The generator field control (voltage regulator) cir-

cuitry is internal to the Powertrain Control Module

(PCM). If faulty, the entire PCM must be replaced.

Refer to Group 14 - Fuel System for PCM service

procedure.

GENERATOR REMOVE/INSTALLÐLEFT-HAND

DRIVE

WARNING: DISCONNECT NEGATIVE CABLE FROM

BATTERY BEFORE REMOVING BATTERY OUTPUT

WIRE FROM GENERATOR. FAILURE TO DO SO

CAN RESULT IN INJURY.

ALL WITH 2.5L AND YJ WITH 4.0L

(1) Disconnect battery negative cable.

(2) Remove generator drive belt. Refer to Group 7 -

Cooling System for procedure.

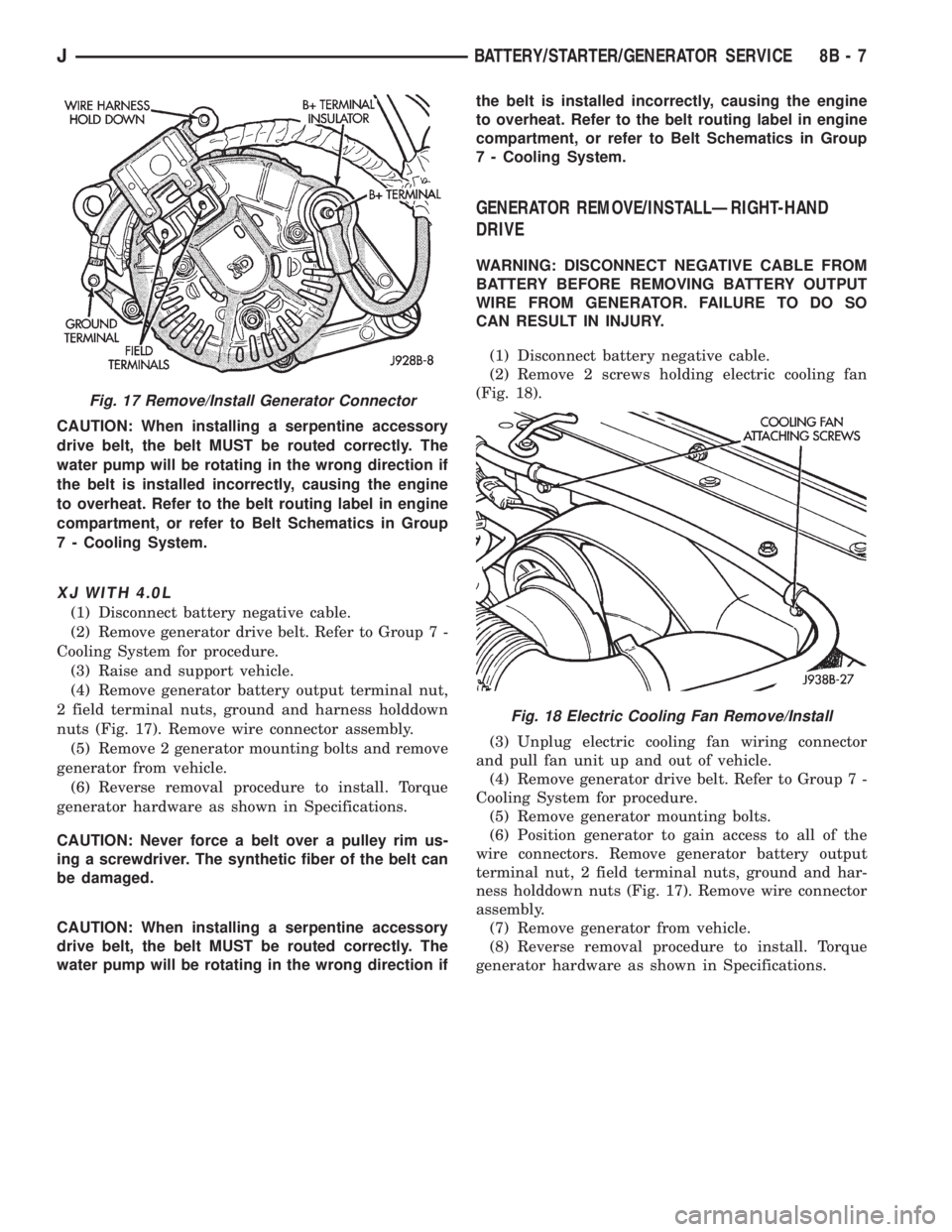

(3) Remove generator battery output terminal nut,

2 field terminal nuts, ground and harness holddown

nuts (Fig. 17). Remove wire connector assembly.

(4) Remove 2 generator mounting bolts and remove

generator from vehicle.

(5) Reverse removal procedure to install. Torque

generator hardware as shown in Specifications.

CAUTION: Never force a belt over a pulley rim us-

ing a screwdriver. The synthetic fiber of the belt can

be damaged.

Fig. 15 Power Distribution CenterÐXJFig. 16 Power Distribution CenterÐYJ

8B - 6 BATTERY/STARTER/GENERATOR SERVICEJ

Page 302 of 2198

CAUTION: When installing a serpentine accessory

drive belt, the belt MUST be routed correctly. The

water pump will be rotating in the wrong direction if

the belt is installed incorrectly, causing the engine

to overheat. Refer to the belt routing label in engine

compartment, or refer to Belt Schematics in Group

7 - Cooling System.

XJ WITH 4.0L

(1) Disconnect battery negative cable.

(2) Remove generator drive belt. Refer to Group 7 -

Cooling System for procedure.

(3) Raise and support vehicle.

(4) Remove generator battery output terminal nut,

2 field terminal nuts, ground and harness holddown

nuts (Fig. 17). Remove wire connector assembly.

(5) Remove 2 generator mounting bolts and remove

generator from vehicle.

(6) Reverse removal procedure to install. Torque

generator hardware as shown in Specifications.

CAUTION: Never force a belt over a pulley rim us-

ing a screwdriver. The synthetic fiber of the belt can

be damaged.

CAUTION: When installing a serpentine accessory

drive belt, the belt MUST be routed correctly. The

water pump will be rotating in the wrong direction ifthe belt is installed incorrectly, causing the engine

to overheat. Refer to the belt routing label in engine

compartment, or refer to Belt Schematics in Group

7 - Cooling System.

GENERATOR REMOVE/INSTALLÐRIGHT-HAND

DRIVE

WARNING: DISCONNECT NEGATIVE CABLE FROM

BATTERY BEFORE REMOVING BATTERY OUTPUT

WIRE FROM GENERATOR. FAILURE TO DO SO

CAN RESULT IN INJURY.

(1) Disconnect battery negative cable.

(2) Remove 2 screws holding electric cooling fan

(Fig. 18).

(3) Unplug electric cooling fan wiring connector

and pull fan unit up and out of vehicle.

(4) Remove generator drive belt. Refer to Group 7 -

Cooling System for procedure.

(5) Remove generator mounting bolts.

(6) Position generator to gain access to all of the

wire connectors. Remove generator battery output

terminal nut, 2 field terminal nuts, ground and har-

ness holddown nuts (Fig. 17). Remove wire connector

assembly.

(7) Remove generator from vehicle.

(8) Reverse removal procedure to install. Torque

generator hardware as shown in Specifications.

Fig. 17 Remove/Install Generator Connector

Fig. 18 Electric Cooling Fan Remove/Install

JBATTERY/STARTER/GENERATOR SERVICE 8B - 7

Page 303 of 2198

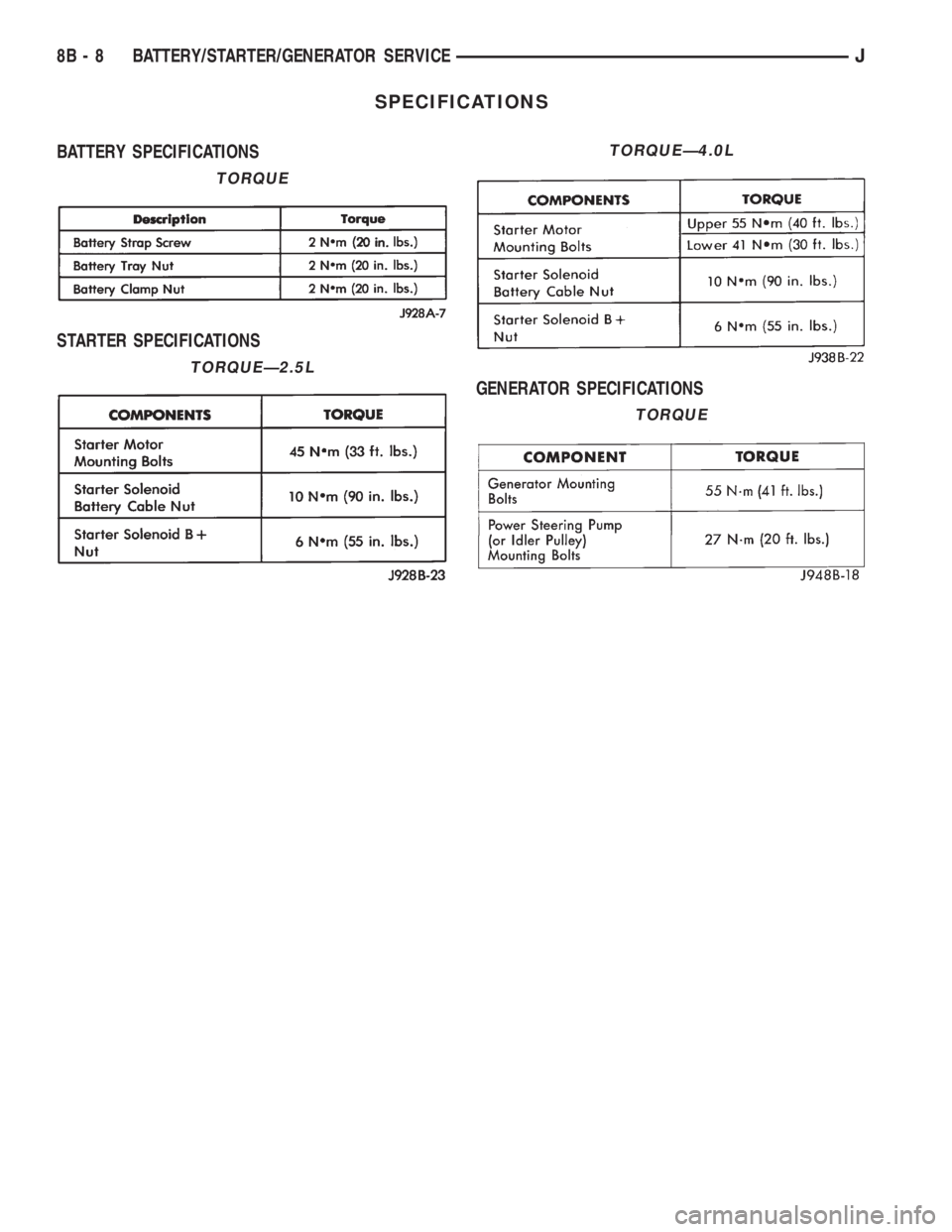

SPECIFICATIONS

BATTERY SPECIFICATIONS

STARTER SPECIFICATIONS

GENERATOR SPECIFICATIONS

TORQUE

TORQUEÐ2.5L

TORQUEÐ4.0L

TORQUE

8B - 8 BATTERY/STARTER/GENERATOR SERVICEJ

Page 304 of 2198

OVERHEAD CONSOLE

CONTENTS

page page

DIAGNOSIS............................. 2

GENERAL INFORMATION.................. 1SERVICE PROCEDURES................... 5

GENERAL INFORMATION

An overhead console featuring an electronic com-

pass and thermometer is an available option for XJ

(Cherokee) models. Following are general descrip-

tions of major components used in the overhead con-

sole. Refer to Group 8W - Wiring Diagrams for

complete circuit descriptions and diagrams.

COMPASS

The compass will display the direction in which the

vehicle is pointed using the eight major compass

headings (Examples: north is N, northeast is NE). It

does not display the headings in actual degrees. The

display is turned on or off using the COMP/TEMP

button to the left of the display.

The self-calibrating compass unit requires no ad-

justing in normal use. The only calibration that may

prove necessary is to drive the vehicle in 3 complete

circles, on level ground, in not less than 48 seconds.

This will reorient the unit to its vehicle.

The unit also will compensate for magnetism the

body of the vehicle may acquire during normal use.

However, avoid placing anything magnetic directly on

the roof of the vehicle. Magnetic mounts for an an-

tenna, a repair order hat or a funeral procession flag

can exceed the compensating ability of the compass

unit if placed on the roof panel. Magnetic bit drivers

used on the fasteners that hold the assembly to the

roof header can also affect compass operation.

If the vehicle roof should become magnetized, the

demagnetizing and calibration procedures may be re-

quired to restore proper operation.

THERMOMETER

The thermometer displays the outside ambient

temperature. The temperature displayed can be

changed from Fahrenheit to Celsius using the US/

METRIC button. The displayed temperature is not

an instant reading of conditions, but an average tem-

perature. It may take the unit several minutes to re-

act to a major temperature change such as driving

out of a heated garage into winter temperatures.

When the ignition switch is turned OFF, the lastdisplayed temperature reading stays in memory.

When the ignition switch is turned ON again, the

thermometer will display the memory temperature

for one minute; then update the display to the cur-

rent average temperature reading within five min-

utes.

READING AND COURTESY LAMPS

All reading and courtesy lamps in the overhead

console are activated by the door jamb switches.

When all doors and the liftgate are closed, the lamps

can be individually activated by depressing the corre-

sponding lens. When a door and/or the liftgate is

open, depressing the lamp lens switches will not turn

the lamps off. Refer to Group 8L - Lamps, for diag-

nosis and service of these lamps.

KEYLESS ENTRY RECEIVER

The overhead console houses the keyless entry re-

ceiver. Refer to Group 8P - Power Locks, for diagno-

sis and service of this component.

REMOTE GARAGE DOOR OPENER STORAGE

A compartment in the overhead console is designed

to hold most remote garage door opener transmitters.

The transmitter is mounted within the compartment

with an adhesive-backed hook and loop fastener

patch. Then one to three pegs are selected and

mounted on a post on the inside of the storage com-

partment door. The pegs may be stacked, if neces-

sary. The peg(s) selected must be long enough to

activate the button of the transmitter each time the

storage compartment door is depressed.

SUNGLASSES STORAGE

A flocked storage compartment for sunglasses is in-

cluded in the overhead console. This compartment

features a push/push-type latch and a viscous damp-

ening system for a fluid opening motion.

JOVERHEAD CONSOLE 8C - 1

Page 305 of 2198

DIAGNOSIS

COMPASS/DISPLAY SELF-DIAGNOSTIC TEST

This self-diagnostic test is used to determine that

the compass and all of its display segments are oper-

ating properly electrically. Initiate the self-diagnostic

test as follows:

(1) With the ignition switch in the OFF position,

simultaneously press and hold the COMP/TEMP but-

ton and the US/METRIC button.

(2) Turn ignition switch to the ON position.

(3) Continue to hold both buttons until the display

performs a walking segment test. In this test all of

the compass points are displayed, along with various

number combinations. These combinations verify that

all display segments are functional. If any segment

should fail to light during the test, the unit is faulty

and requires replacement. To repeat the test, momen-

tarily depress and release the COMP/TEMP button

one time.

(4) Momentarily depress and release the US/MET-

RIC button one time and all segments will light si-

multaneously for about 2 seconds. If any segment

should fail to light during the test, the unit is faulty

and requires replacement. To repeat the test, momen-

tarily depress and release the COMP/TEMP button

one time.

(5) Momentarily depress and release the US/MET-

RIC button one time or turn the ignition switch to

OFF to exit the self-diagnostic mode and return to

normal operation.

If the compass functions, but accuracy is sus-

pect, it may be necessary to perform a variation

adjustment. This procedure allows the unit to

accommodate variations in the earth's mag-

netic field strength based on geographic loca-

tion. See Compass Variation Adjustment, in this

group.

If the compass display has blanked out and

only CAL appears, demagnetizing may be nec-

essary to remove excessive residual magnetic

fields from the vehicle. See Compass Demagne-

tizing, in this group.

THERMOMETER DIAGNOSIS

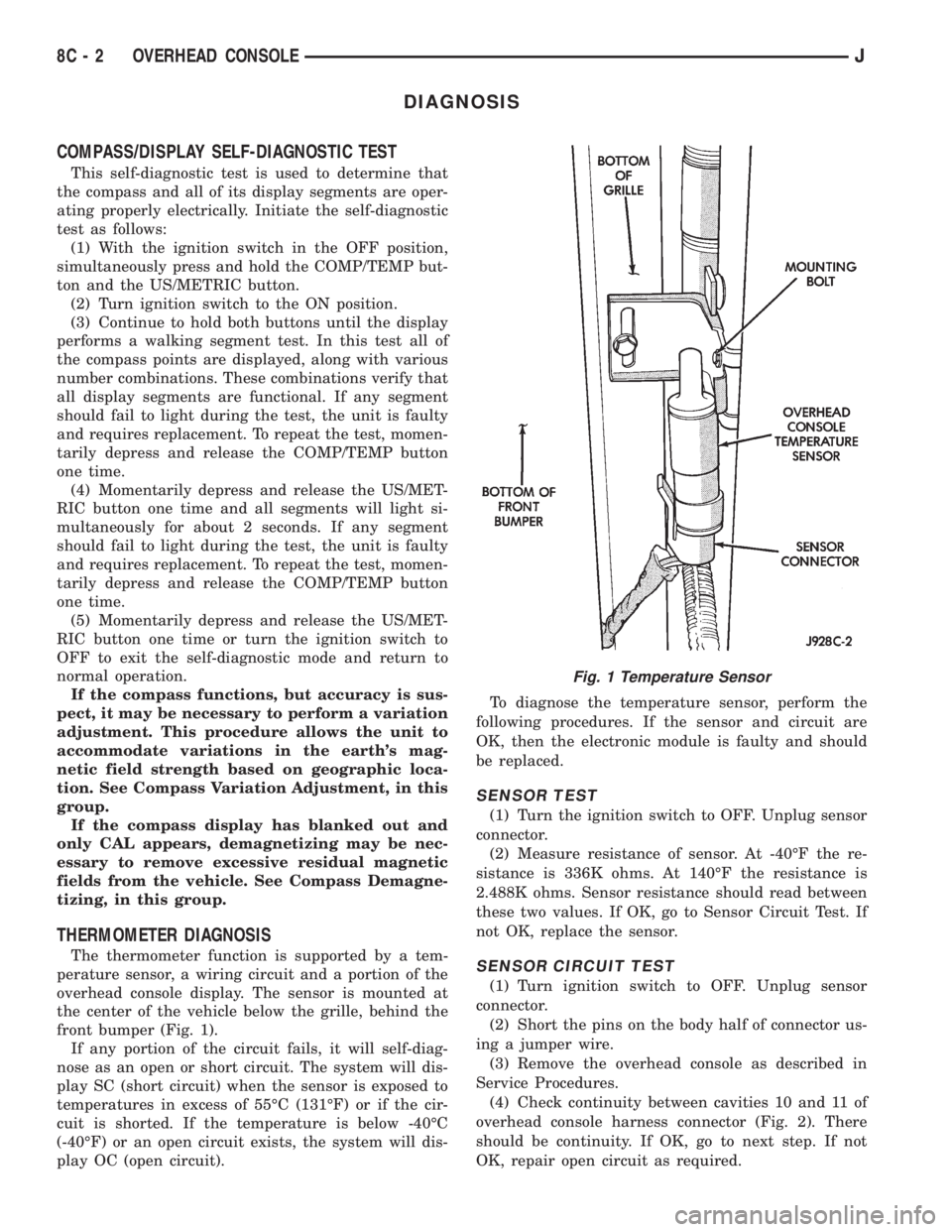

The thermometer function is supported by a tem-

perature sensor, a wiring circuit and a portion of the

overhead console display. The sensor is mounted at

the center of the vehicle below the grille, behind the

front bumper (Fig. 1).

If any portion of the circuit fails, it will self-diag-

nose as an open or short circuit. The system will dis-

play SC (short circuit) when the sensor is exposed to

temperatures in excess of 55ÉC (131ÉF) or if the cir-

cuit is shorted. If the temperature is below -40ÉC

(-40ÉF) or an open circuit exists, the system will dis-

play OC (open circuit).To diagnose the temperature sensor, perform the

following procedures. If the sensor and circuit are

OK, then the electronic module is faulty and should

be replaced.

SENSOR TEST

(1) Turn the ignition switch to OFF. Unplug sensor

connector.

(2) Measure resistance of sensor. At -40ÉF the re-

sistance is 336K ohms. At 140ÉF the resistance is

2.488K ohms. Sensor resistance should read between

these two values. If OK, go to Sensor Circuit Test. If

not OK, replace the sensor.

SENSOR CIRCUIT TEST

(1) Turn ignition switch to OFF. Unplug sensor

connector.

(2) Short the pins on the body half of connector us-

ing a jumper wire.

(3) Remove the overhead console as described in

Service Procedures.

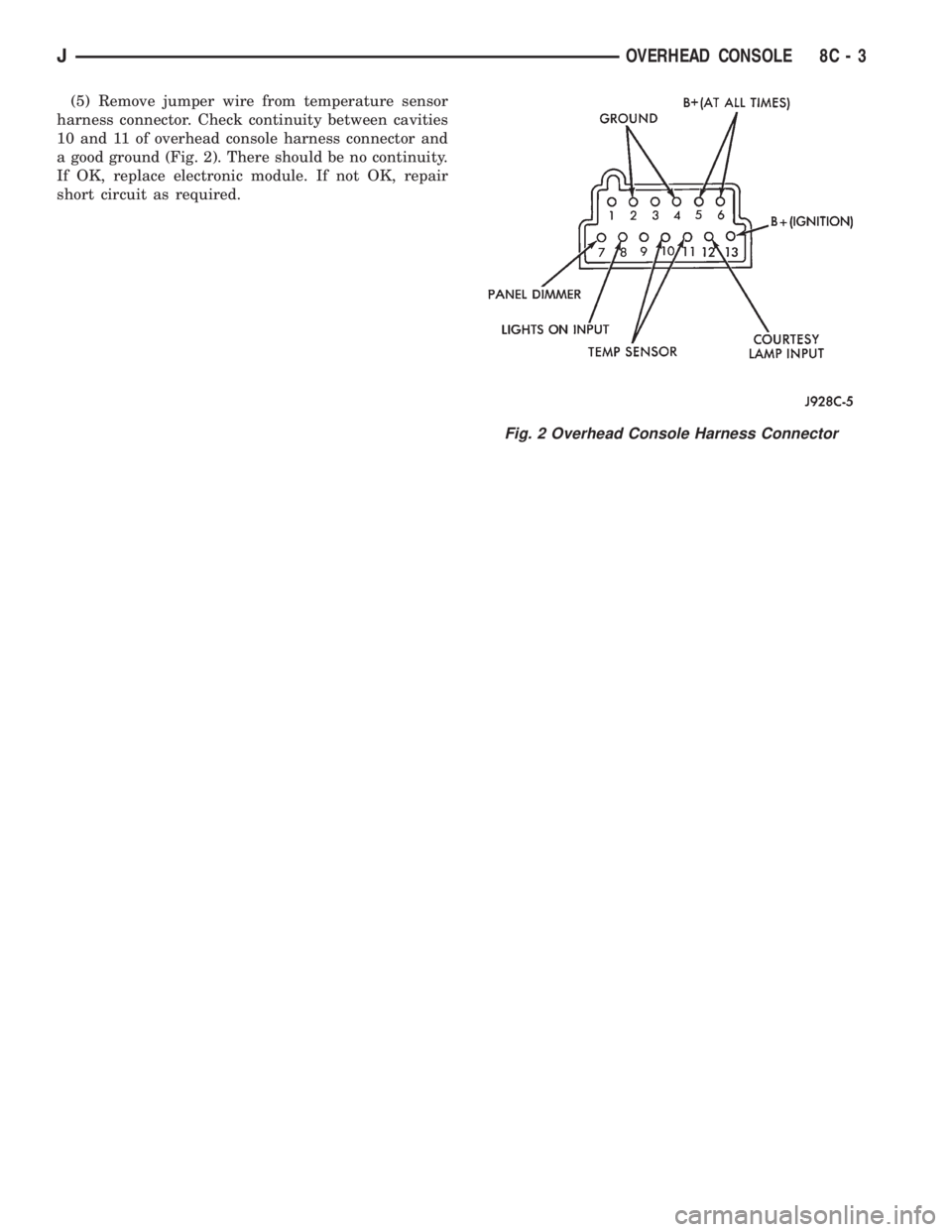

(4) Check continuity between cavities 10 and 11 of

overhead console harness connector (Fig. 2). There

should be continuity. If OK, go to next step. If not

OK, repair open circuit as required.

Fig. 1 Temperature Sensor

8C - 2 OVERHEAD CONSOLEJ

Page 306 of 2198

(5) Remove jumper wire from temperature sensor

harness connector. Check continuity between cavities

10 and 11 of overhead console harness connector and

a good ground (Fig. 2). There should be no continuity.

If OK, replace electronic module. If not OK, repair

short circuit as required.

Fig. 2 Overhead Console Harness Connector

JOVERHEAD CONSOLE 8C - 3

Page 307 of 2198

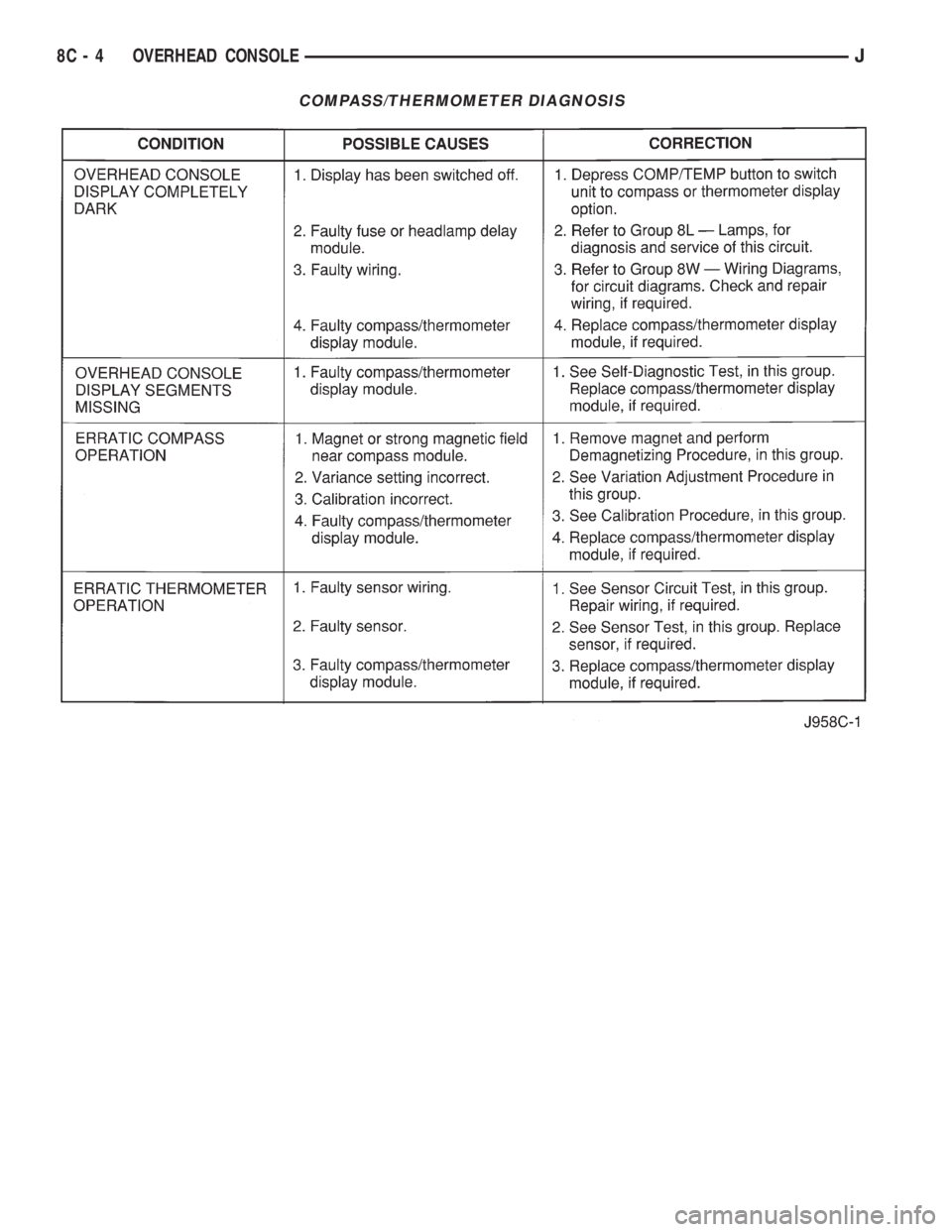

COMPASS/THERMOMETER DIAGNOSIS

8C - 4 OVERHEAD CONSOLEJ

Page 308 of 2198

SERVICE PROCEDURES

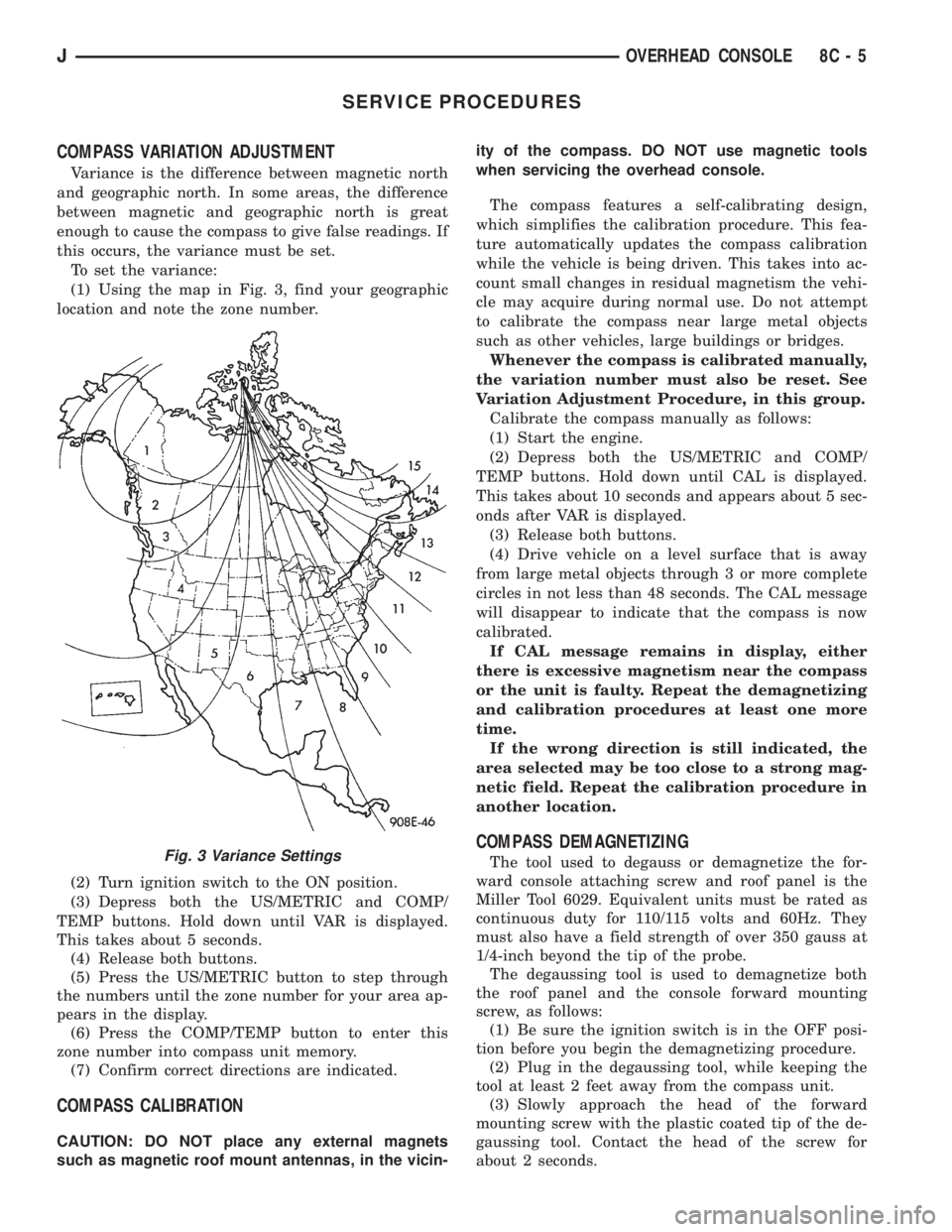

COMPASS VARIATION ADJUSTMENT

Variance is the difference between magnetic north

and geographic north. In some areas, the difference

between magnetic and geographic north is great

enough to cause the compass to give false readings. If

this occurs, the variance must be set.

To set the variance:

(1) Using the map in Fig. 3, find your geographic

location and note the zone number.

(2) Turn ignition switch to the ON position.

(3) Depress both the US/METRIC and COMP/

TEMP buttons. Hold down until VAR is displayed.

This takes about 5 seconds.

(4) Release both buttons.

(5) Press the US/METRIC button to step through

the numbers until the zone number for your area ap-

pears in the display.

(6) Press the COMP/TEMP button to enter this

zone number into compass unit memory.

(7) Confirm correct directions are indicated.

COMPASS CALIBRATION

CAUTION: DO NOT place any external magnets

such as magnetic roof mount antennas, in the vicin-ity of the compass. DO NOT use magnetic tools

when servicing the overhead console.

The compass features a self-calibrating design,

which simplifies the calibration procedure. This fea-

ture automatically updates the compass calibration

while the vehicle is being driven. This takes into ac-

count small changes in residual magnetism the vehi-

cle may acquire during normal use. Do not attempt

to calibrate the compass near large metal objects

such as other vehicles, large buildings or bridges.

Whenever the compass is calibrated manually,

the variation number must also be reset. See

Variation Adjustment Procedure, in this group.

Calibrate the compass manually as follows:

(1) Start the engine.

(2) Depress both the US/METRIC and COMP/

TEMP buttons. Hold down until CAL is displayed.

This takes about 10 seconds and appears about 5 sec-

onds after VAR is displayed.

(3) Release both buttons.

(4) Drive vehicle on a level surface that is away

from large metal objects through 3 or more complete

circles in not less than 48 seconds. The CAL message

will disappear to indicate that the compass is now

calibrated.

If CAL message remains in display, either

there is excessive magnetism near the compass

or the unit is faulty. Repeat the demagnetizing

and calibration procedures at least one more

time.

If the wrong direction is still indicated, the

area selected may be too close to a strong mag-

netic field. Repeat the calibration procedure in

another location.

COMPASS DEMAGNETIZING

The tool used to degauss or demagnetize the for-

ward console attaching screw and roof panel is the

Miller Tool 6029. Equivalent units must be rated as

continuous duty for 110/115 volts and 60Hz. They

must also have a field strength of over 350 gauss at

1/4-inch beyond the tip of the probe.

The degaussing tool is used to demagnetize both

the roof panel and the console forward mounting

screw, as follows:

(1) Be sure the ignition switch is in the OFF posi-

tion before you begin the demagnetizing procedure.

(2) Plug in the degaussing tool, while keeping the

tool at least 2 feet away from the compass unit.

(3) Slowly approach the head of the forward

mounting screw with the plastic coated tip of the de-

gaussing tool. Contact the head of the screw for

about 2 seconds.Fig. 3 Variance Settings

JOVERHEAD CONSOLE 8C - 5

Page 309 of 2198

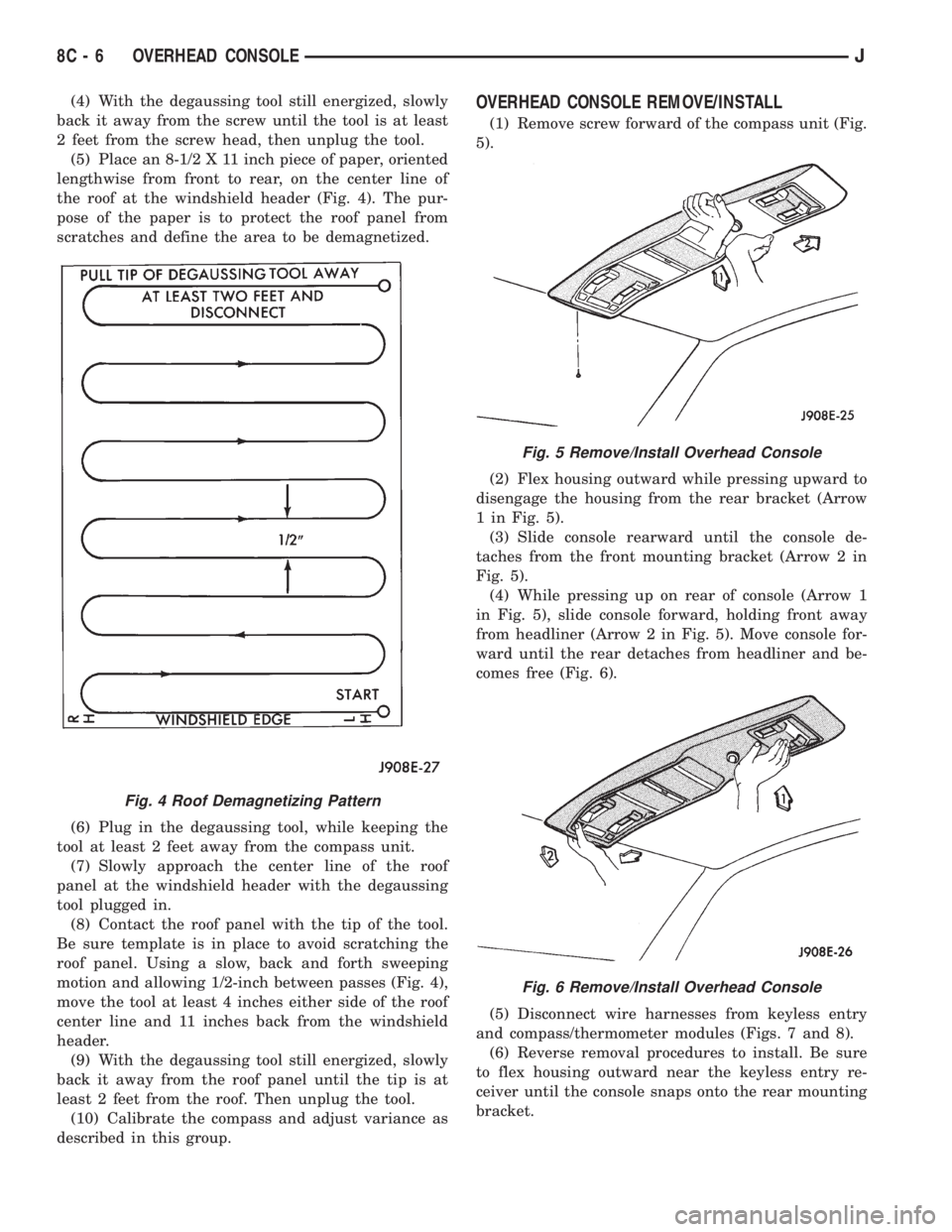

(4) With the degaussing tool still energized, slowly

back it away from the screw until the tool is at least

2 feet from the screw head, then unplug the tool.

(5) Place an 8-1/2 X 11 inch piece of paper, oriented

lengthwise from front to rear, on the center line of

the roof at the windshield header (Fig. 4). The pur-

pose of the paper is to protect the roof panel from

scratches and define the area to be demagnetized.

(6) Plug in the degaussing tool, while keeping the

tool at least 2 feet away from the compass unit.

(7) Slowly approach the center line of the roof

panel at the windshield header with the degaussing

tool plugged in.

(8) Contact the roof panel with the tip of the tool.

Be sure template is in place to avoid scratching the

roof panel. Using a slow, back and forth sweeping

motion and allowing 1/2-inch between passes (Fig. 4),

move the tool at least 4 inches either side of the roof

center line and 11 inches back from the windshield

header.

(9) With the degaussing tool still energized, slowly

back it away from the roof panel until the tip is at

least 2 feet from the roof. Then unplug the tool.

(10) Calibrate the compass and adjust variance as

described in this group.OVERHEAD CONSOLE REMOVE/INSTALL

(1) Remove screw forward of the compass unit (Fig.

5).

(2) Flex housing outward while pressing upward to

disengage the housing from the rear bracket (Arrow

1 in Fig. 5).

(3) Slide console rearward until the console de-

taches from the front mounting bracket (Arrow 2 in

Fig. 5).

(4) While pressing up on rear of console (Arrow 1

in Fig. 5), slide console forward, holding front away

from headliner (Arrow 2 in Fig. 5). Move console for-

ward until the rear detaches from headliner and be-

comes free (Fig. 6).

(5) Disconnect wire harnesses from keyless entry

and compass/thermometer modules (Figs. 7 and 8).

(6) Reverse removal procedures to install. Be sure

to flex housing outward near the keyless entry re-

ceiver until the console snaps onto the rear mounting

bracket.

Fig. 4 Roof Demagnetizing Pattern

Fig. 5 Remove/Install Overhead Console

Fig. 6 Remove/Install Overhead Console

8C - 6 OVERHEAD CONSOLEJ

Page 310 of 2198

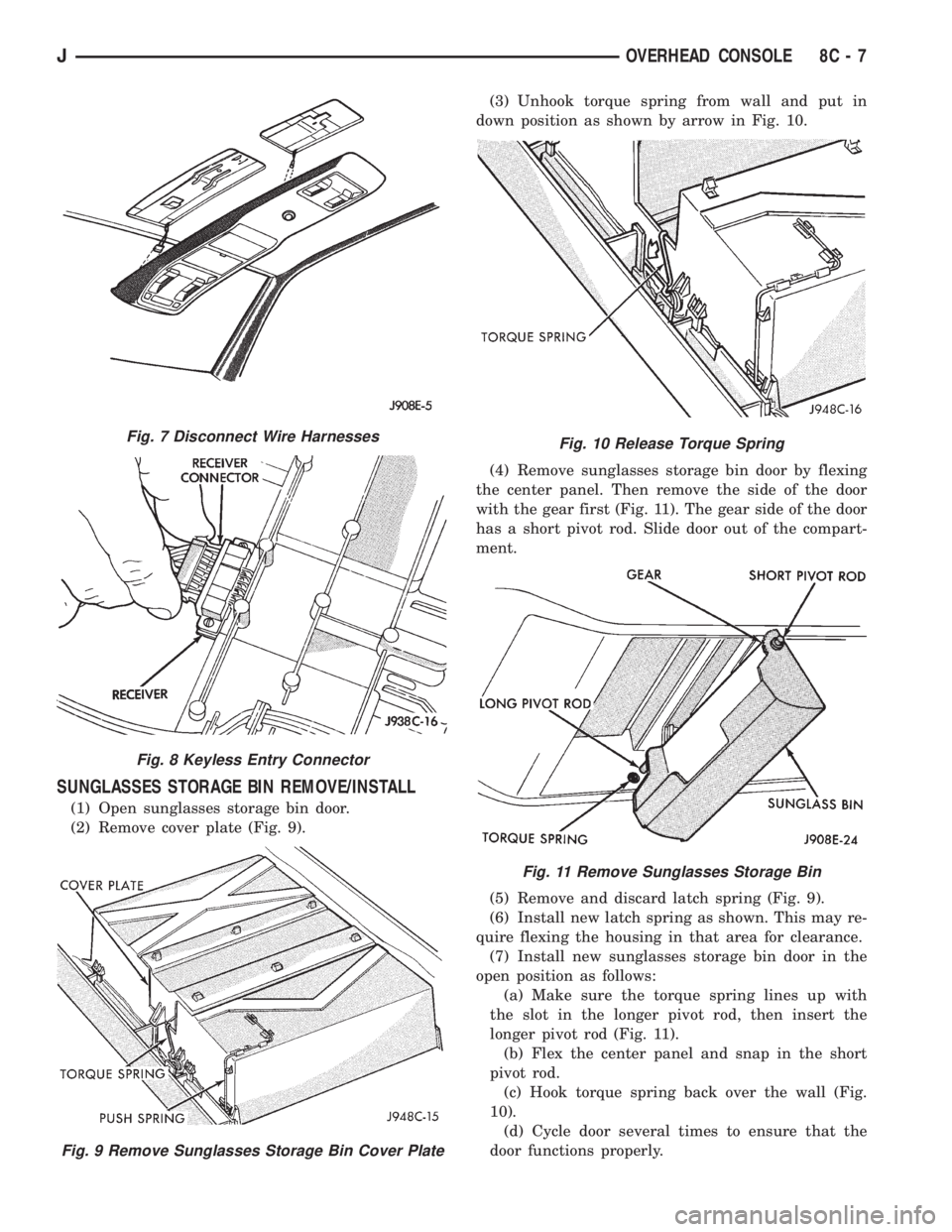

SUNGLASSES STORAGE BIN REMOVE/INSTALL

(1) Open sunglasses storage bin door.

(2) Remove cover plate (Fig. 9).(3) Unhook torque spring from wall and put in

down position as shown by arrow in Fig. 10.

(4) Remove sunglasses storage bin door by flexing

the center panel. Then remove the side of the door

with the gear first (Fig. 11). The gear side of the door

has a short pivot rod. Slide door out of the compart-

ment.

(5) Remove and discard latch spring (Fig. 9).

(6) Install new latch spring as shown. This may re-

quire flexing the housing in that area for clearance.

(7) Install new sunglasses storage bin door in the

open position as follows:

(a) Make sure the torque spring lines up with

the slot in the longer pivot rod, then insert the

longer pivot rod (Fig. 11).

(b) Flex the center panel and snap in the short

pivot rod.

(c) Hook torque spring back over the wall (Fig.

10).

(d) Cycle door several times to ensure that the

door functions properly.

Fig. 7 Disconnect Wire Harnesses

Fig. 8 Keyless Entry Connector

Fig. 9 Remove Sunglasses Storage Bin Cover Plate

Fig. 10 Release Torque Spring

Fig. 11 Remove Sunglasses Storage Bin

JOVERHEAD CONSOLE 8C - 7