JEEP CHEROKEE 1995 Service Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: CHEROKEE, Model: JEEP CHEROKEE 1995Pages: 2198, PDF Size: 82.83 MB

Page 331 of 2198

REMOVALÐ2.5L OR 4.0L ENGINE

(1) Disconnect the negative battery cable at the

battery.

(2) Disconnect coil secondary cable at coil.

(3) Remove distributor cap from distributor (2

screws). Do not remove cables from cap. Do not re-

move rotor.

(4) Disconnect the distributor wiring harness from

the main engine harness.

(5) Remove the cylinder number 1 spark plug.

(6) Hold a finger over the open spark plug hole.

Rotate the engine at the vibration dampener bolt un-

til compression (pressure) is felt.

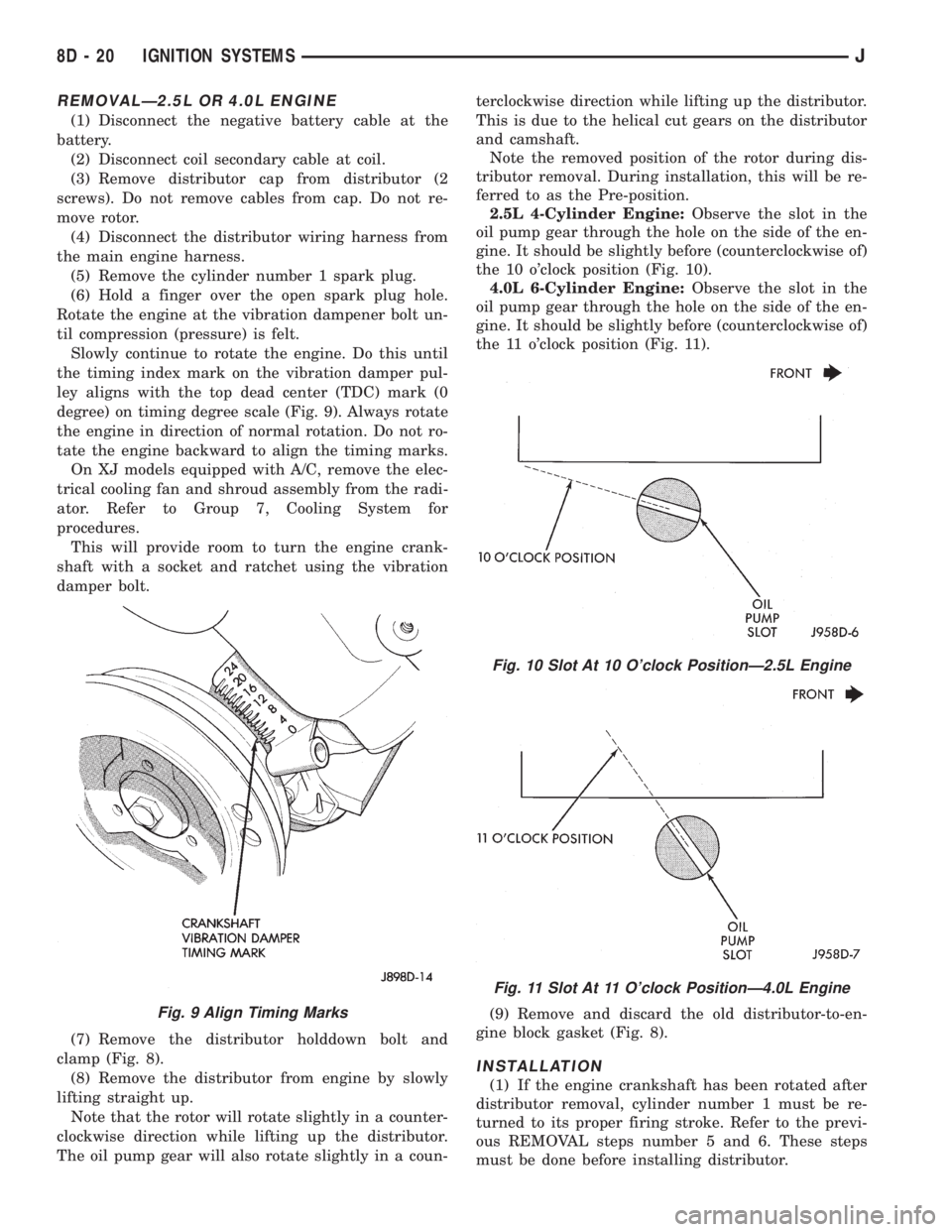

Slowly continue to rotate the engine. Do this until

the timing index mark on the vibration damper pul-

ley aligns with the top dead center (TDC) mark (0

degree) on timing degree scale (Fig. 9). Always rotate

the engine in direction of normal rotation. Do not ro-

tate the engine backward to align the timing marks.

On XJ models equipped with A/C, remove the elec-

trical cooling fan and shroud assembly from the radi-

ator. Refer to Group 7, Cooling System for

procedures.

This will provide room to turn the engine crank-

shaft with a socket and ratchet using the vibration

damper bolt.

(7) Remove the distributor holddown bolt and

clamp (Fig. 8).

(8) Remove the distributor from engine by slowly

lifting straight up.

Note that the rotor will rotate slightly in a counter-

clockwise direction while lifting up the distributor.

The oil pump gear will also rotate slightly in a coun-terclockwise direction while lifting up the distributor.

This is due to the helical cut gears on the distributor

and camshaft.

Note the removed position of the rotor during dis-

tributor removal. During installation, this will be re-

ferred to as the Pre-position.

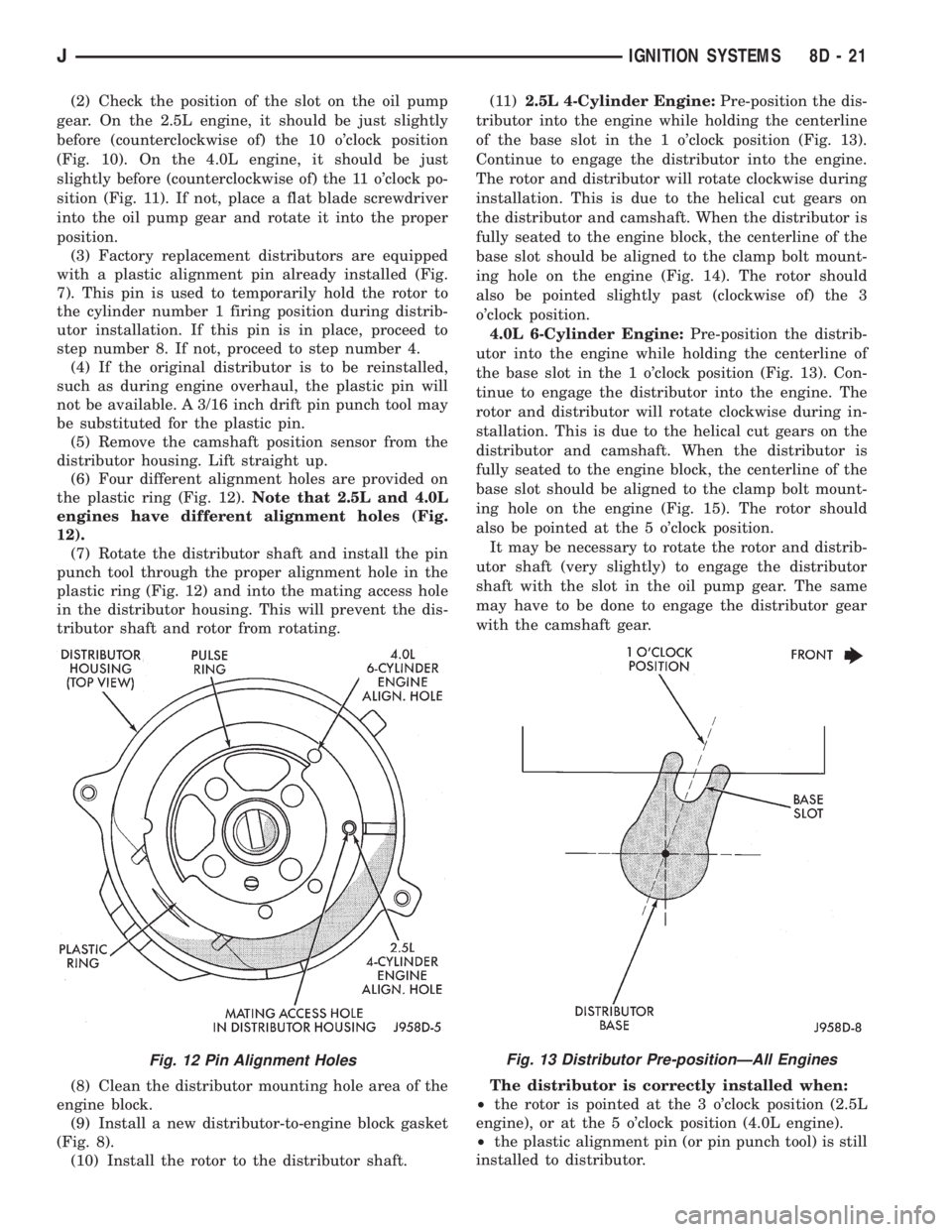

2.5L 4-Cylinder Engine:Observe the slot in the

oil pump gear through the hole on the side of the en-

gine. It should be slightly before (counterclockwise of)

the 10 o'clock position (Fig. 10).

4.0L 6-Cylinder Engine:Observe the slot in the

oil pump gear through the hole on the side of the en-

gine. It should be slightly before (counterclockwise of)

the 11 o'clock position (Fig. 11).

(9) Remove and discard the old distributor-to-en-

gine block gasket (Fig. 8).

INSTALLATION

(1) If the engine crankshaft has been rotated after

distributor removal, cylinder number 1 must be re-

turned to its proper firing stroke. Refer to the previ-

ous REMOVAL steps number 5 and 6. These steps

must be done before installing distributor.

Fig. 9 Align Timing Marks

Fig. 10 Slot At 10 O'clock PositionÐ2.5L Engine

Fig. 11 Slot At 11 O'clock PositionÐ4.0L Engine

8D - 20 IGNITION SYSTEMSJ

Page 332 of 2198

(2) Check the position of the slot on the oil pump

gear. On the 2.5L engine, it should be just slightly

before (counterclockwise of) the 10 o'clock position

(Fig. 10). On the 4.0L engine, it should be just

slightly before (counterclockwise of) the 11 o'clock po-

sition (Fig. 11). If not, place a flat blade screwdriver

into the oil pump gear and rotate it into the proper

position.

(3) Factory replacement distributors are equipped

with a plastic alignment pin already installed (Fig.

7). This pin is used to temporarily hold the rotor to

the cylinder number 1 firing position during distrib-

utor installation. If this pin is in place, proceed to

step number 8. If not, proceed to step number 4.

(4) If the original distributor is to be reinstalled,

such as during engine overhaul, the plastic pin will

not be available. A 3/16 inch drift pin punch tool may

be substituted for the plastic pin.

(5) Remove the camshaft position sensor from the

distributor housing. Lift straight up.

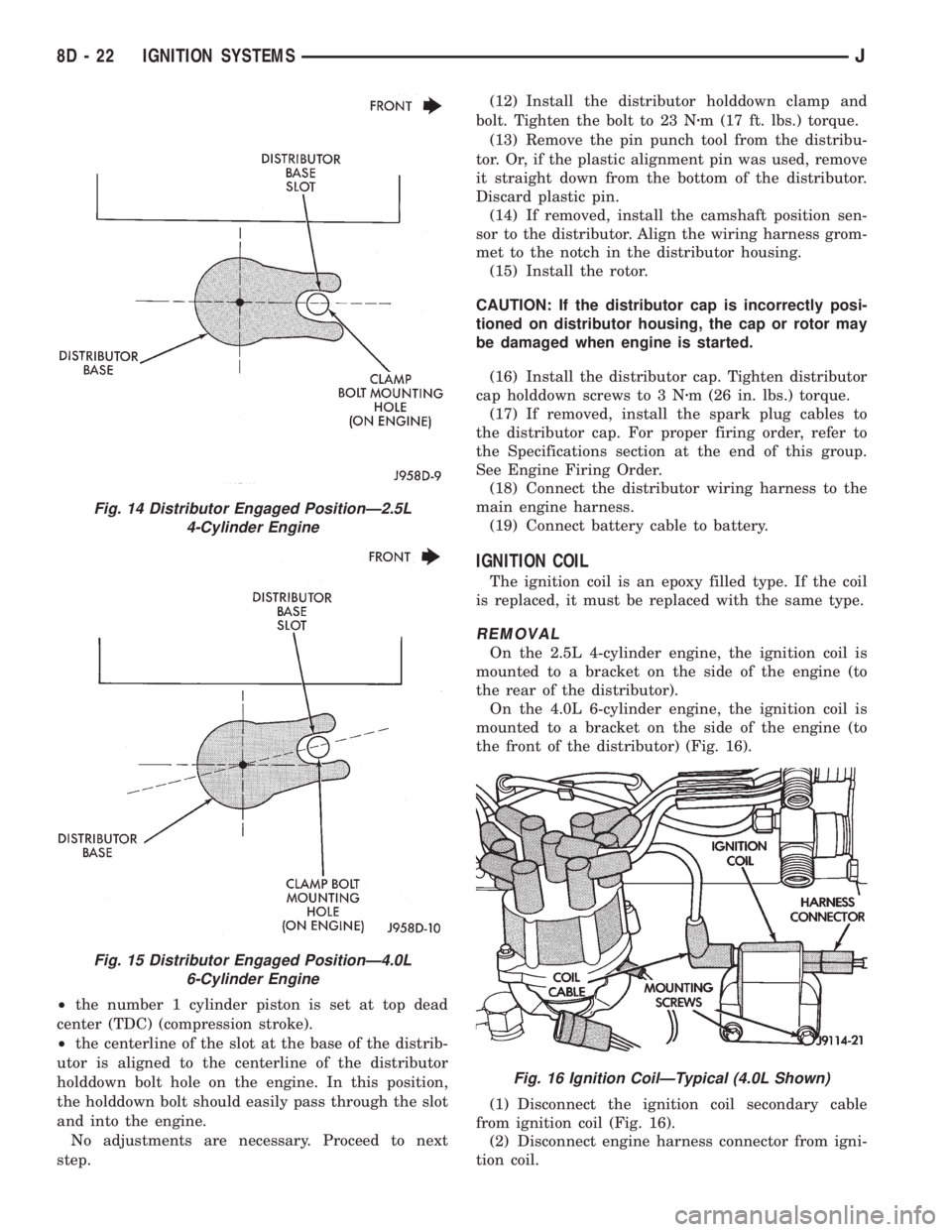

(6) Four different alignment holes are provided on

the plastic ring (Fig. 12).Note that 2.5L and 4.0L

engines have different alignment holes (Fig.

12).

(7) Rotate the distributor shaft and install the pin

punch tool through the proper alignment hole in the

plastic ring (Fig. 12) and into the mating access hole

in the distributor housing. This will prevent the dis-

tributor shaft and rotor from rotating.

(8) Clean the distributor mounting hole area of the

engine block.

(9) Install a new distributor-to-engine block gasket

(Fig. 8).

(10) Install the rotor to the distributor shaft.(11)2.5L 4-Cylinder Engine:Pre-position the dis-

tributor into the engine while holding the centerline

of the base slot in the 1 o'clock position (Fig. 13).

Continue to engage the distributor into the engine.

The rotor and distributor will rotate clockwise during

installation. This is due to the helical cut gears on

the distributor and camshaft. When the distributor is

fully seated to the engine block, the centerline of the

base slot should be aligned to the clamp bolt mount-

ing hole on the engine (Fig. 14). The rotor should

also be pointed slightly past (clockwise of) the 3

o'clock position.

4.0L 6-Cylinder Engine:Pre-position the distrib-

utor into the engine while holding the centerline of

the base slot in the 1 o'clock position (Fig. 13). Con-

tinue to engage the distributor into the engine. The

rotor and distributor will rotate clockwise during in-

stallation. This is due to the helical cut gears on the

distributor and camshaft. When the distributor is

fully seated to the engine block, the centerline of the

base slot should be aligned to the clamp bolt mount-

ing hole on the engine (Fig. 15). The rotor should

also be pointed at the 5 o'clock position.

It may be necessary to rotate the rotor and distrib-

utor shaft (very slightly) to engage the distributor

shaft with the slot in the oil pump gear. The same

may have to be done to engage the distributor gear

with the camshaft gear.

The distributor is correctly installed when:

²the rotor is pointed at the 3 o'clock position (2.5L

engine), or at the 5 o'clock position (4.0L engine).

²the plastic alignment pin (or pin punch tool) is still

installed to distributor.

Fig. 12 Pin Alignment HolesFig. 13 Distributor Pre-positionÐAll Engines

JIGNITION SYSTEMS 8D - 21

Page 333 of 2198

²the number 1 cylinder piston is set at top dead

center (TDC) (compression stroke).

²the centerline of the slot at the base of the distrib-

utor is aligned to the centerline of the distributor

holddown bolt hole on the engine. In this position,

the holddown bolt should easily pass through the slot

and into the engine.

No adjustments are necessary. Proceed to next

step.(12) Install the distributor holddown clamp and

bolt. Tighten the bolt to 23 Nzm (17 ft. lbs.) torque.

(13) Remove the pin punch tool from the distribu-

tor. Or, if the plastic alignment pin was used, remove

it straight down from the bottom of the distributor.

Discard plastic pin.

(14) If removed, install the camshaft position sen-

sor to the distributor. Align the wiring harness grom-

met to the notch in the distributor housing.

(15) Install the rotor.

CAUTION: If the distributor cap is incorrectly posi-

tioned on distributor housing, the cap or rotor may

be damaged when engine is started.

(16) Install the distributor cap. Tighten distributor

cap holddown screws to 3 Nzm (26 in. lbs.) torque.

(17) If removed, install the spark plug cables to

the distributor cap. For proper firing order, refer to

the Specifications section at the end of this group.

See Engine Firing Order.

(18) Connect the distributor wiring harness to the

main engine harness.

(19) Connect battery cable to battery.

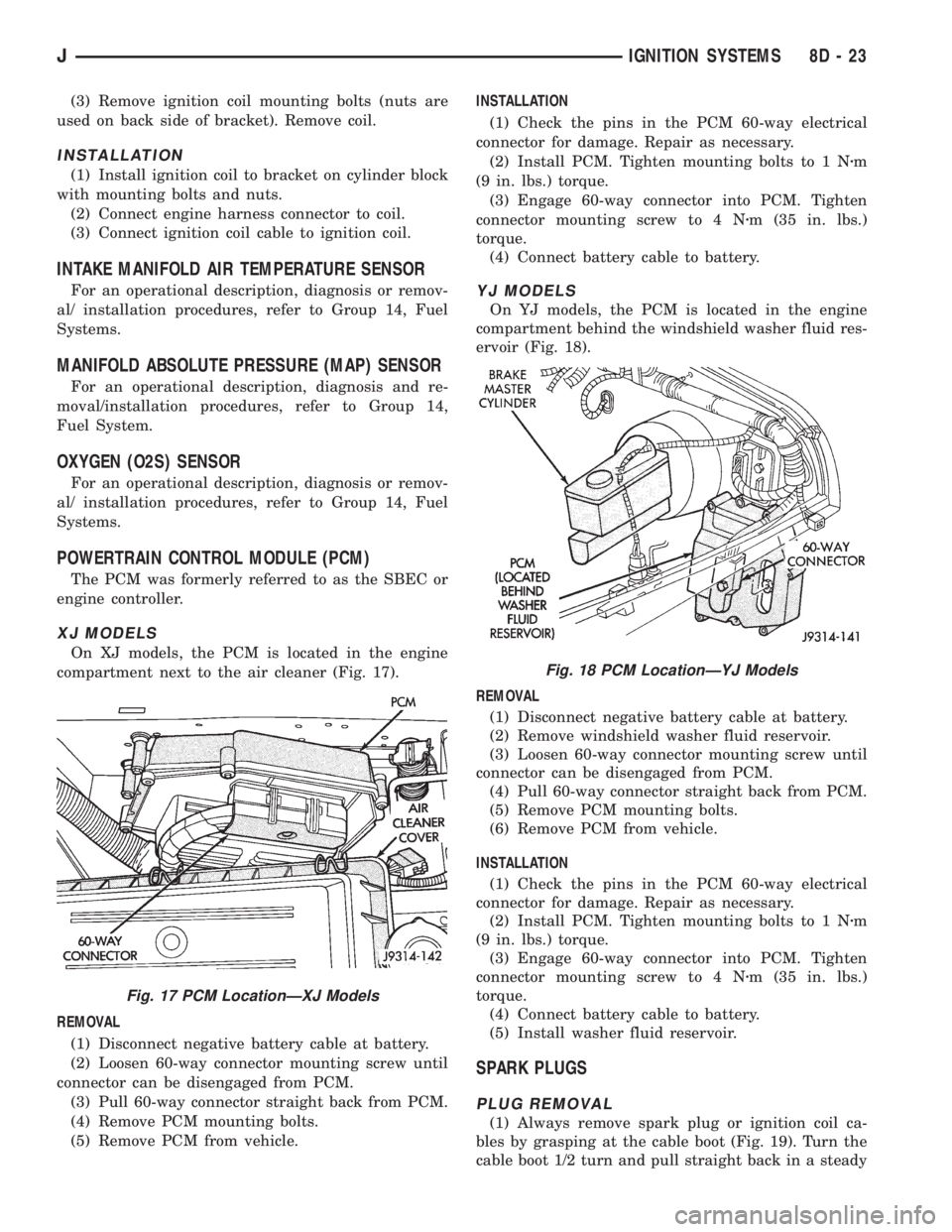

IGNITION COIL

The ignition coil is an epoxy filled type. If the coil

is replaced, it must be replaced with the same type.

REMOVAL

On the 2.5L 4-cylinder engine, the ignition coil is

mounted to a bracket on the side of the engine (to

the rear of the distributor).

On the 4.0L 6-cylinder engine, the ignition coil is

mounted to a bracket on the side of the engine (to

the front of the distributor) (Fig. 16).

(1) Disconnect the ignition coil secondary cable

from ignition coil (Fig. 16).

(2) Disconnect engine harness connector from igni-

tion coil.

Fig. 14 Distributor Engaged PositionÐ2.5L

4-Cylinder Engine

Fig. 15 Distributor Engaged PositionÐ4.0L

6-Cylinder Engine

Fig. 16 Ignition CoilÐTypical (4.0L Shown)

8D - 22 IGNITION SYSTEMSJ

Page 334 of 2198

(3) Remove ignition coil mounting bolts (nuts are

used on back side of bracket). Remove coil.

INSTALLATION

(1) Install ignition coil to bracket on cylinder block

with mounting bolts and nuts.

(2) Connect engine harness connector to coil.

(3) Connect ignition coil cable to ignition coil.

INTAKE MANIFOLD AIR TEMPERATURE SENSOR

For an operational description, diagnosis or remov-

al/ installation procedures, refer to Group 14, Fuel

Systems.

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

For an operational description, diagnosis and re-

moval/installation procedures, refer to Group 14,

Fuel System.

OXYGEN (O2S) SENSOR

For an operational description, diagnosis or remov-

al/ installation procedures, refer to Group 14, Fuel

Systems.

POWERTRAIN CONTROL MODULE (PCM)

The PCM was formerly referred to as the SBEC or

engine controller.

XJ MODELS

On XJ models, the PCM is located in the engine

compartment next to the air cleaner (Fig. 17).

REMOVAL

(1) Disconnect negative battery cable at battery.

(2) Loosen 60-way connector mounting screw until

connector can be disengaged from PCM.

(3) Pull 60-way connector straight back from PCM.

(4) Remove PCM mounting bolts.

(5) Remove PCM from vehicle.INSTALLATION

(1) Check the pins in the PCM 60-way electrical

connector for damage. Repair as necessary.

(2) Install PCM. Tighten mounting bolts to 1 Nzm

(9 in. lbs.) torque.

(3) Engage 60-way connector into PCM. Tighten

connector mounting screw to 4 Nzm (35 in. lbs.)

torque.

(4) Connect battery cable to battery.

YJ MODELS

On YJ models, the PCM is located in the engine

compartment behind the windshield washer fluid res-

ervoir (Fig. 18).

REMOVAL

(1) Disconnect negative battery cable at battery.

(2) Remove windshield washer fluid reservoir.

(3) Loosen 60-way connector mounting screw until

connector can be disengaged from PCM.

(4) Pull 60-way connector straight back from PCM.

(5) Remove PCM mounting bolts.

(6) Remove PCM from vehicle.

INSTALLATION

(1) Check the pins in the PCM 60-way electrical

connector for damage. Repair as necessary.

(2) Install PCM. Tighten mounting bolts to 1 Nzm

(9 in. lbs.) torque.

(3) Engage 60-way connector into PCM. Tighten

connector mounting screw to 4 Nzm (35 in. lbs.)

torque.

(4) Connect battery cable to battery.

(5) Install washer fluid reservoir.

SPARK PLUGS

PLUG REMOVAL

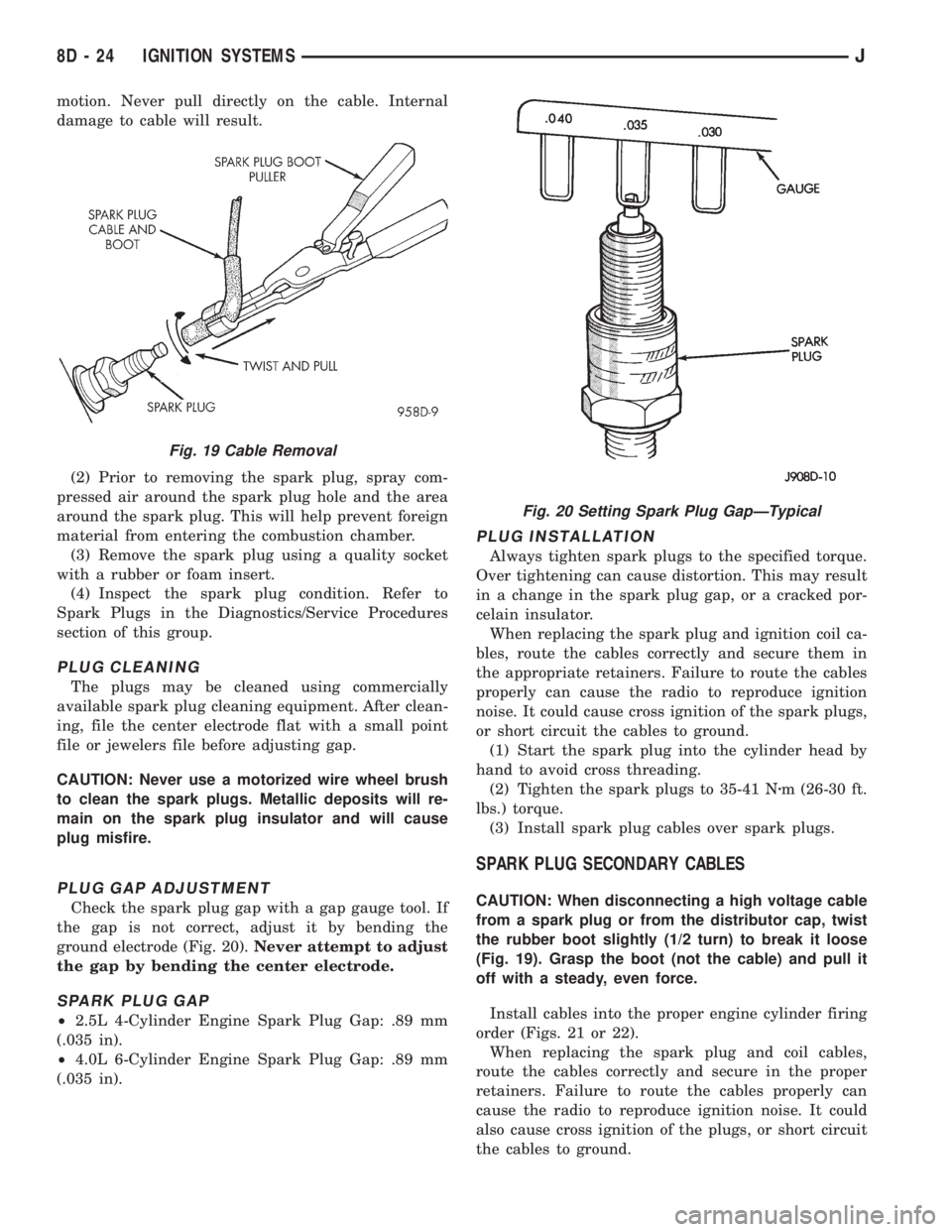

(1) Always remove spark plug or ignition coil ca-

bles by grasping at the cable boot (Fig. 19). Turn the

cable boot 1/2 turn and pull straight back in a steady

Fig. 17 PCM LocationÐXJ Models

Fig. 18 PCM LocationÐYJ Models

JIGNITION SYSTEMS 8D - 23

Page 335 of 2198

motion. Never pull directly on the cable. Internal

damage to cable will result.

(2) Prior to removing the spark plug, spray com-

pressed air around the spark plug hole and the area

around the spark plug. This will help prevent foreign

material from entering the combustion chamber.

(3) Remove the spark plug using a quality socket

with a rubber or foam insert.

(4) Inspect the spark plug condition. Refer to

Spark Plugs in the Diagnostics/Service Procedures

section of this group.

PLUG CLEANING

The plugs may be cleaned using commercially

available spark plug cleaning equipment. After clean-

ing, file the center electrode flat with a small point

file or jewelers file before adjusting gap.

CAUTION: Never use a motorized wire wheel brush

to clean the spark plugs. Metallic deposits will re-

main on the spark plug insulator and will cause

plug misfire.

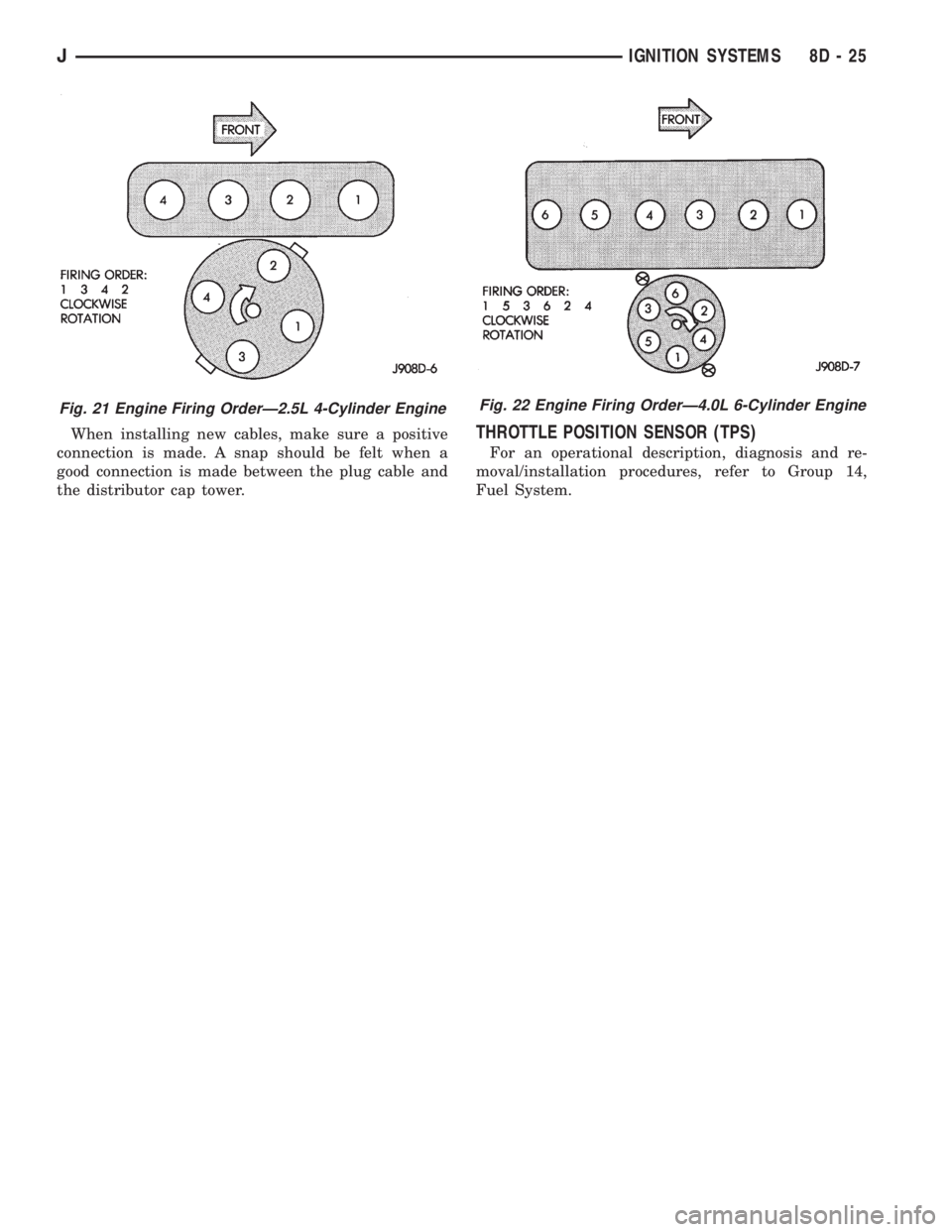

PLUG GAP ADJUSTMENT

Check the spark plug gap with a gap gauge tool. If

the gap is not correct, adjust it by bending the

ground electrode (Fig. 20).Never attempt to adjust

the gap by bending the center electrode.

SPARK PLUG GAP

²2.5L 4-Cylinder Engine Spark Plug Gap: .89 mm

(.035 in).

²4.0L 6-Cylinder Engine Spark Plug Gap: .89 mm

(.035 in).

PLUG INSTALLATION

Always tighten spark plugs to the specified torque.

Over tightening can cause distortion. This may result

in a change in the spark plug gap, or a cracked por-

celain insulator.

When replacing the spark plug and ignition coil ca-

bles, route the cables correctly and secure them in

the appropriate retainers. Failure to route the cables

properly can cause the radio to reproduce ignition

noise. It could cause cross ignition of the spark plugs,

or short circuit the cables to ground.

(1) Start the spark plug into the cylinder head by

hand to avoid cross threading.

(2) Tighten the spark plugs to 35-41 Nzm (26-30 ft.

lbs.) torque.

(3) Install spark plug cables over spark plugs.

SPARK PLUG SECONDARY CABLES

CAUTION: When disconnecting a high voltage cable

from a spark plug or from the distributor cap, twist

the rubber boot slightly (1/2 turn) to break it loose

(Fig. 19). Grasp the boot (not the cable) and pull it

off with a steady, even force.

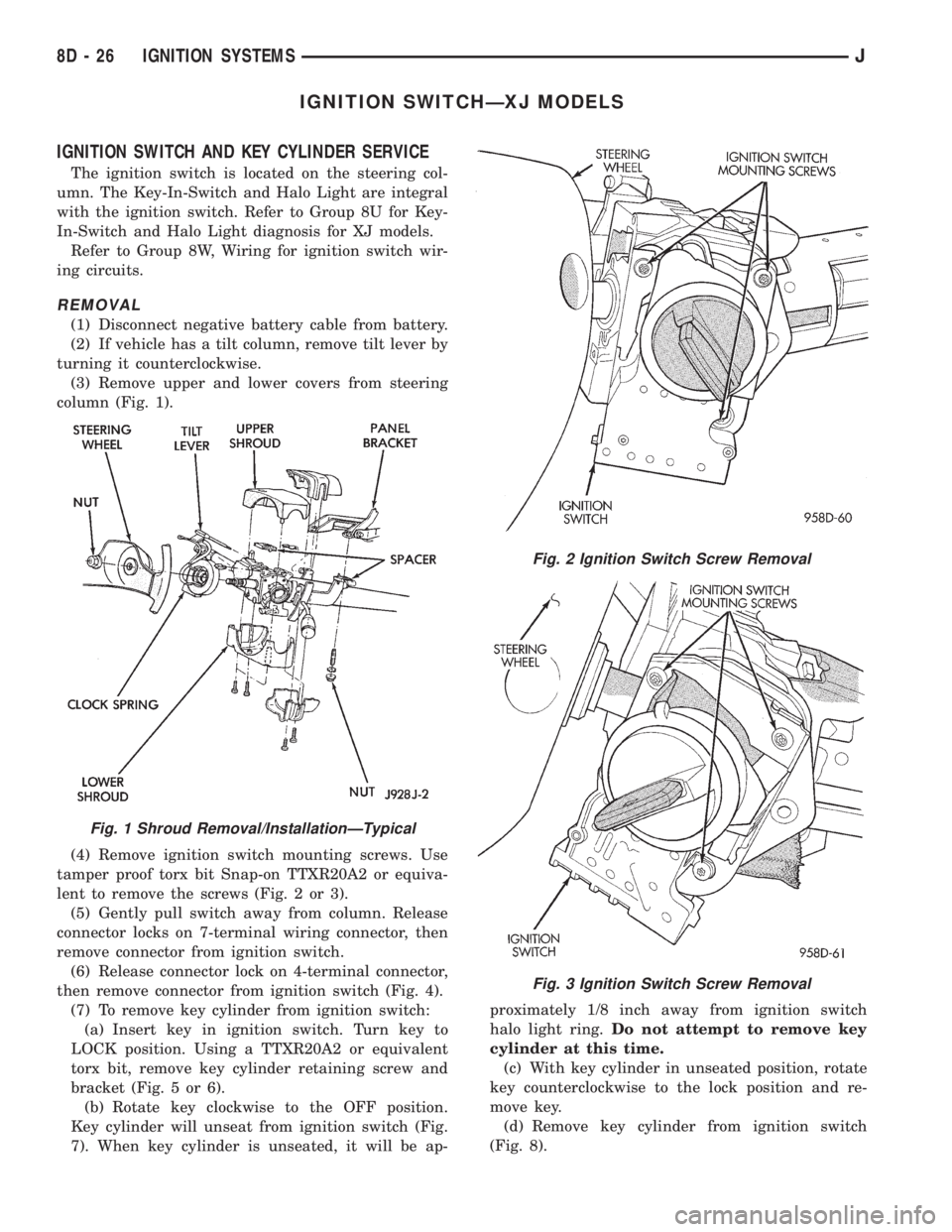

Install cables into the proper engine cylinder firing

order (Figs. 21 or 22).

When replacing the spark plug and coil cables,

route the cables correctly and secure in the proper

retainers. Failure to route the cables properly can

cause the radio to reproduce ignition noise. It could

also cause cross ignition of the plugs, or short circuit

the cables to ground.

Fig. 19 Cable Removal

Fig. 20 Setting Spark Plug GapÐTypical

8D - 24 IGNITION SYSTEMSJ

Page 336 of 2198

When installing new cables, make sure a positive

connection is made. A snap should be felt when a

good connection is made between the plug cable and

the distributor cap tower.THROTTLE POSITION SENSOR (TPS)

For an operational description, diagnosis and re-

moval/installation procedures, refer to Group 14,

Fuel System.

Fig. 22 Engine Firing OrderÐ4.0L 6-Cylinder EngineFig. 21 Engine Firing OrderÐ2.5L 4-Cylinder Engine

JIGNITION SYSTEMS 8D - 25

Page 337 of 2198

IGNITION SWITCHÐXJ MODELS

IGNITION SWITCH AND KEY CYLINDER SERVICE

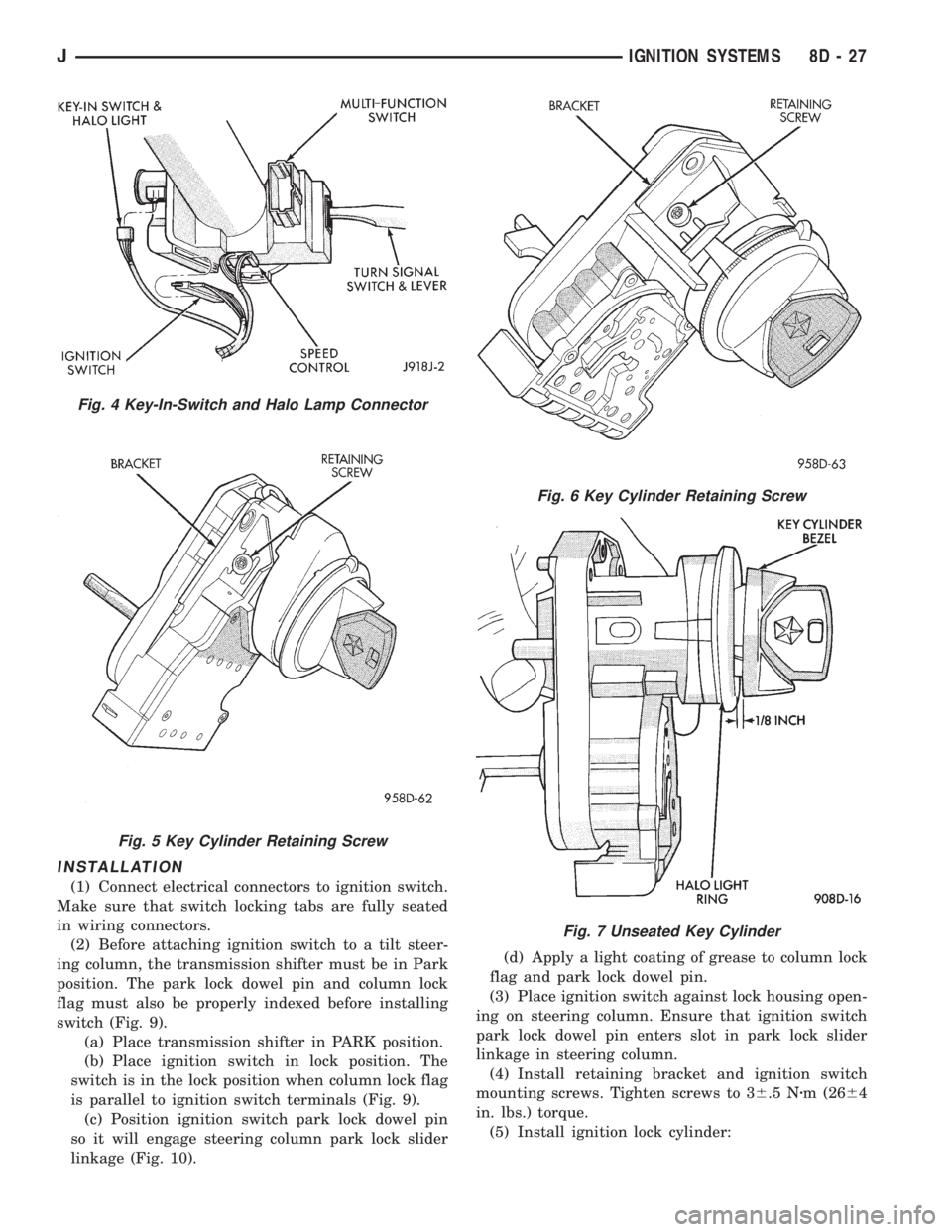

The ignition switch is located on the steering col-

umn. The Key-In-Switch and Halo Light are integral

with the ignition switch. Refer to Group 8U for Key-

In-Switch and Halo Light diagnosis for XJ models.

Refer to Group 8W, Wiring for ignition switch wir-

ing circuits.

REMOVAL

(1) Disconnect negative battery cable from battery.

(2) If vehicle has a tilt column, remove tilt lever by

turning it counterclockwise.

(3) Remove upper and lower covers from steering

column (Fig. 1).

(4) Remove ignition switch mounting screws. Use

tamper proof torx bit Snap-on TTXR20A2 or equiva-

lent to remove the screws (Fig. 2 or 3).

(5) Gently pull switch away from column. Release

connector locks on 7-terminal wiring connector, then

remove connector from ignition switch.

(6) Release connector lock on 4-terminal connector,

then remove connector from ignition switch (Fig. 4).

(7) To remove key cylinder from ignition switch:

(a) Insert key in ignition switch. Turn key to

LOCK position. Using a TTXR20A2 or equivalent

torx bit, remove key cylinder retaining screw and

bracket (Fig. 5 or 6).

(b) Rotate key clockwise to the OFF position.

Key cylinder will unseat from ignition switch (Fig.

7). When key cylinder is unseated, it will be ap-proximately 1/8 inch away from ignition switch

halo light ring.Do not attempt to remove key

cylinder at this time.

(c) With key cylinder in unseated position, rotate

key counterclockwise to the lock position and re-

move key.

(d) Remove key cylinder from ignition switch

(Fig. 8).

Fig. 1 Shroud Removal/InstallationÐTypical

Fig. 2 Ignition Switch Screw Removal

Fig. 3 Ignition Switch Screw Removal

8D - 26 IGNITION SYSTEMSJ

Page 338 of 2198

INSTALLATION

(1) Connect electrical connectors to ignition switch.

Make sure that switch locking tabs are fully seated

in wiring connectors.

(2) Before attaching ignition switch to a tilt steer-

ing column, the transmission shifter must be in Park

position. The park lock dowel pin and column lock

flag must also be properly indexed before installing

switch (Fig. 9).

(a) Place transmission shifter in PARK position.

(b) Place ignition switch in lock position. The

switch is in the lock position when column lock flag

is parallel to ignition switch terminals (Fig. 9).

(c) Position ignition switch park lock dowel pin

so it will engage steering column park lock slider

linkage (Fig. 10).(d) Apply a light coating of grease to column lock

flag and park lock dowel pin.

(3) Place ignition switch against lock housing open-

ing on steering column. Ensure that ignition switch

park lock dowel pin enters slot in park lock slider

linkage in steering column.

(4) Install retaining bracket and ignition switch

mounting screws. Tighten screws to 36.5 Nzm (2664

in. lbs.) torque.

(5) Install ignition lock cylinder:

Fig. 4 Key-In-Switch and Halo Lamp Connector

Fig. 5 Key Cylinder Retaining Screw

Fig. 6 Key Cylinder Retaining Screw

Fig. 7 Unseated Key Cylinder

JIGNITION SYSTEMS 8D - 27

Page 339 of 2198

(a) With lock cylinder and ignition switch in

Lock position, insert lock cylinder into ignition

switch until it bottoms.(b) Insert ignition key into lock cylinder. While

gently pushing lock cylinder in toward ignition

switch, rotate ignition key to end of travel.

(6) Install retaining screw into bracket and lock

cylinder. Tighten screw to 36.5 Nzm (2664 in. lbs.)

torque.

(7) Install steering column covers. Tighten screws

to2Nzm (17 in. lbs.) torque.

(8) If vehicle is equipped with a tilt steering col-

umn, install tilt lever.

(9) Connect negative cable to battery.

(10) Check for proper operation of halo light, shift

lock (if applicable), and column lock. Also check for

proper operation of ignition switch accessory, lock,

off, run, and start positions.

Fig. 10 Ignition Switch Mounting PadFig. 8 Key Cylinder Removal

Fig. 9 Ignition Switch View From Column

8D - 28 IGNITION SYSTEMSJ

Page 340 of 2198

IGNITION SWITCHÐYJ MODELS

GENERAL INFORMATION

This section will cover the electrical portion

of the ignition switch. To service the mechani-

cal ignition key switch, refer to Group 19,

Steering.

Refer to Group 8W, Wiring for ignition switch wir-

ing circuits.

The ignition switch is mounted under the instru-

ment panel on the lower section of the steering col-

umn. The headlamp dimmer switch is mounted

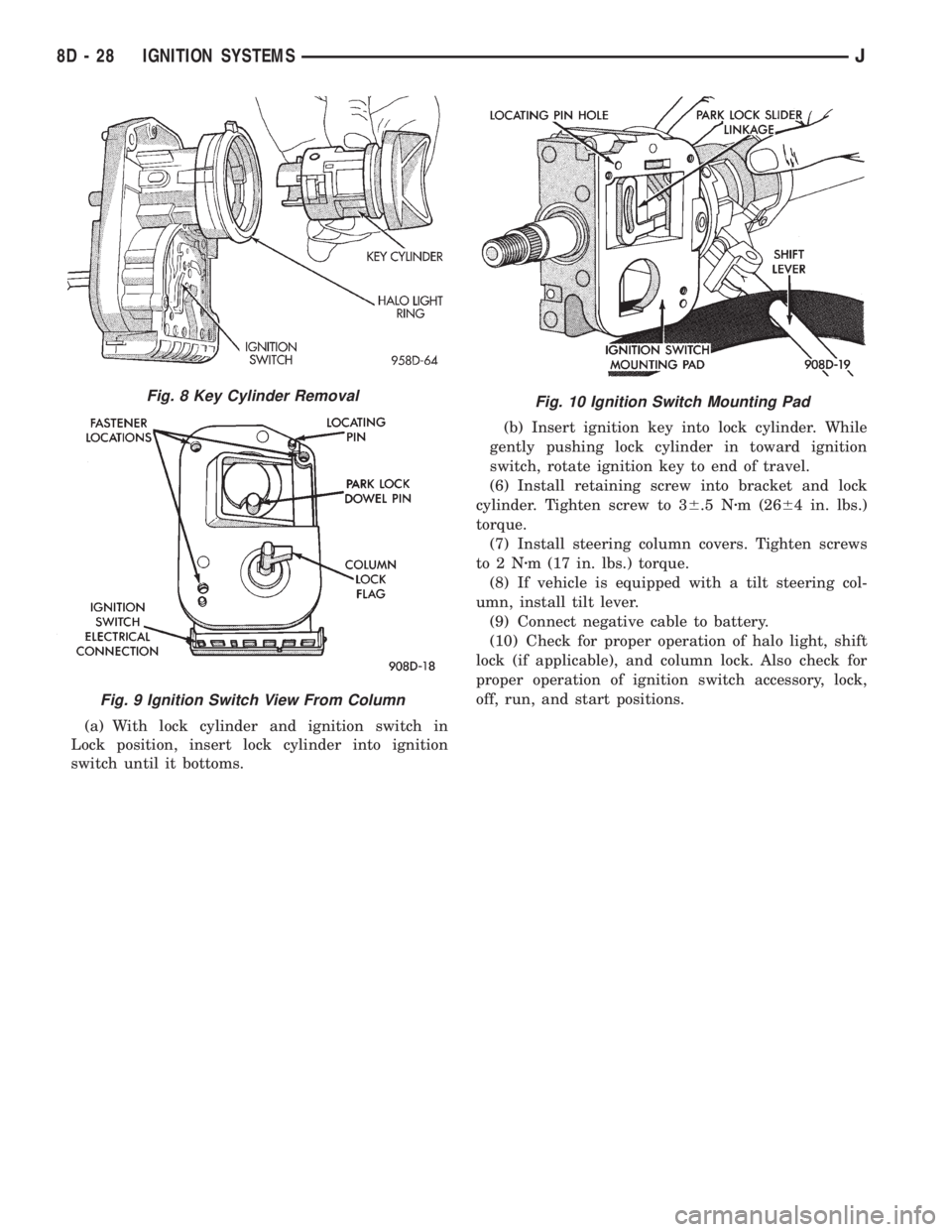

beside the ignition switch (Fig. 11). Both of these

switches (ignition and dimmer) share the same

mounting screws.

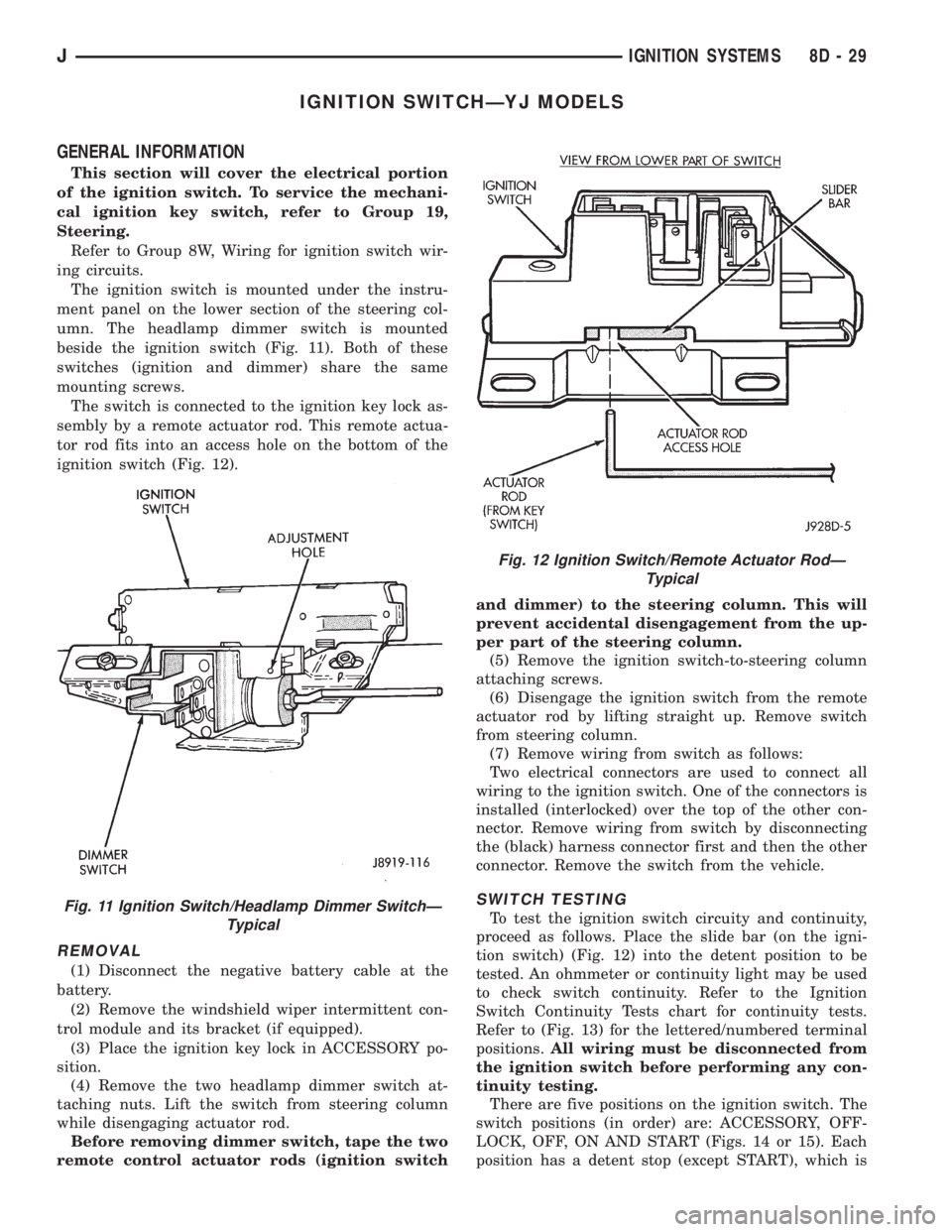

The switch is connected to the ignition key lock as-

sembly by a remote actuator rod. This remote actua-

tor rod fits into an access hole on the bottom of the

ignition switch (Fig. 12).

REMOVAL

(1) Disconnect the negative battery cable at the

battery.

(2) Remove the windshield wiper intermittent con-

trol module and its bracket (if equipped).

(3) Place the ignition key lock in ACCESSORY po-

sition.

(4) Remove the two headlamp dimmer switch at-

taching nuts. Lift the switch from steering column

while disengaging actuator rod.

Before removing dimmer switch, tape the two

remote control actuator rods (ignition switchand dimmer) to the steering column. This will

prevent accidental disengagement from the up-

per part of the steering column.

(5) Remove the ignition switch-to-steering column

attaching screws.

(6) Disengage the ignition switch from the remote

actuator rod by lifting straight up. Remove switch

from steering column.

(7) Remove wiring from switch as follows:

Two electrical connectors are used to connect all

wiring to the ignition switch. One of the connectors is

installed (interlocked) over the top of the other con-

nector. Remove wiring from switch by disconnecting

the (black) harness connector first and then the other

connector. Remove the switch from the vehicle.

SWITCH TESTING

To test the ignition switch circuity and continuity,

proceed as follows. Place the slide bar (on the igni-

tion switch) (Fig. 12) into the detent position to be

tested. An ohmmeter or continuity light may be used

to check switch continuity. Refer to the Ignition

Switch Continuity Tests chart for continuity tests.

Refer to (Fig. 13) for the lettered/numbered terminal

positions.All wiring must be disconnected from

the ignition switch before performing any con-

tinuity testing.

There are five positions on the ignition switch. The

switch positions (in order) are: ACCESSORY, OFF-

LOCK, OFF, ON AND START (Figs. 14 or 15). Each

position has a detent stop (except START), which isFig. 11 Ignition Switch/Headlamp Dimmer SwitchÐ

Typical

Fig. 12 Ignition Switch/Remote Actuator RodÐ

Typical

JIGNITION SYSTEMS 8D - 29