KIA CARNIVAL 2007 Workshop Manual

CARNIVAL 2007

KIA

KIA

https://www.carmanualsonline.info/img/2/57045/w960_57045-0.png

KIA CARNIVAL 2007 Workshop Manual

Trending: engine oil capacity, air suspension, remote control, change key battery, airbag off, key, stop start

Page 571 of 1575

Page 572 of 1575

2007 > 2.7L V6 GASOLINE >

WHEEL ALIGNMENT

When using commercially available computerized four wheel alignment equipment (caster, camber, toe) to inspect the

front wheel alignment, always position the car on a level surface with the front wheels facing straight ahead.

Prior to inspection, make sure that the front suspension and steering system are in normal operating condition and

that the wheels and tires face straight ahead and the tires are inflated to the specified pressure.

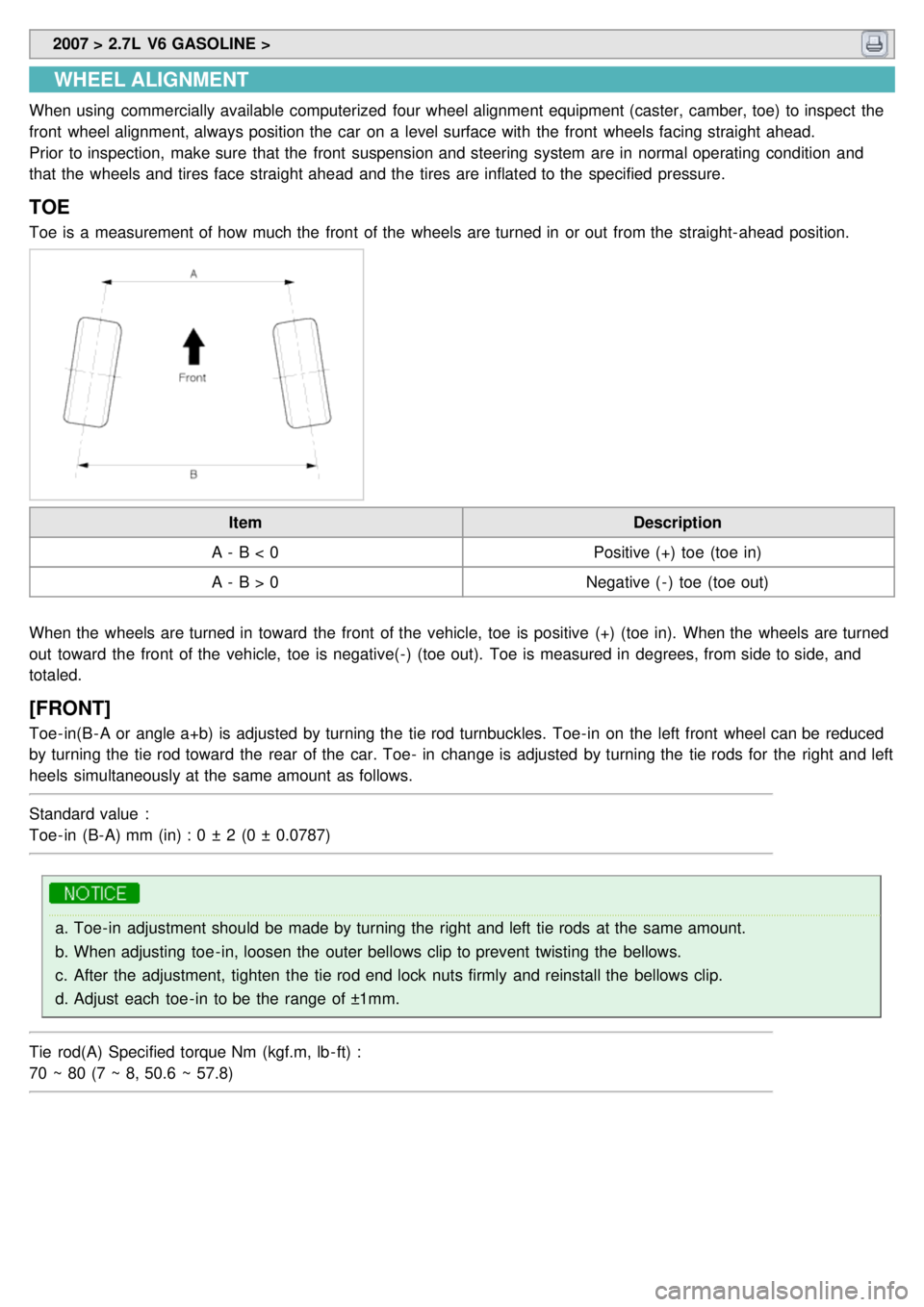

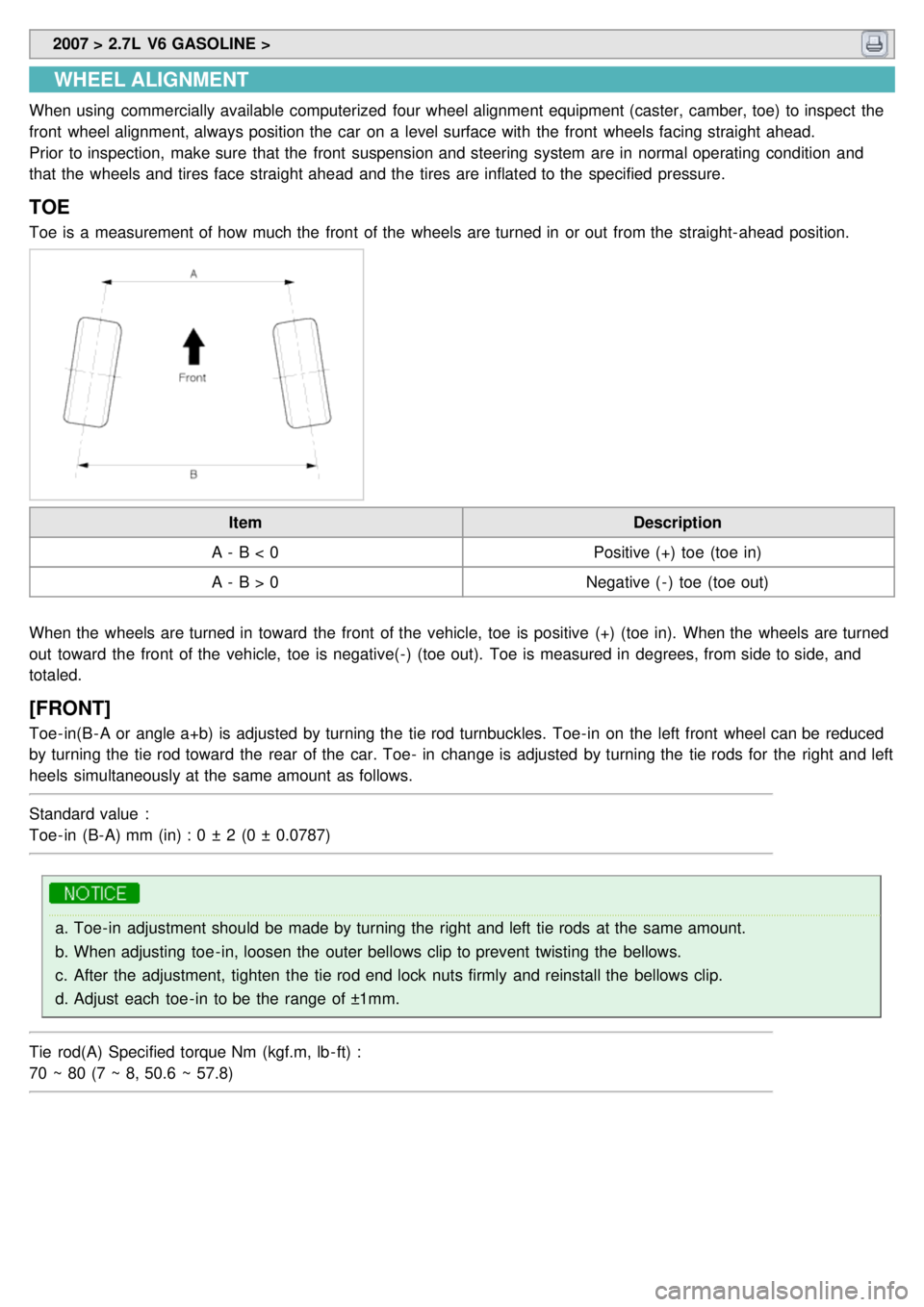

TOE

Toe is a measurement of how much the front of the wheels are turned in or out from the straight- ahead position.

Item Description

A - B < 0 Positive (+) toe (toe in)

A - B > 0 Negative ( - ) toe (toe out)

When the wheels are turned in toward the front of the vehicle, toe is positive (+) (toe in). When the wheels are turned

out toward the front of the vehicle, toe is negative(- ) (toe out). Toe is measured in degrees, from side to side, and

totaled.

[FRONT]

Toe- in(B - A or angle a+b) is adjusted by turning the tie rod turnbuckles. Toe- in on the left front wheel can be reduced

by turning the tie rod toward the rear of the car. Toe- in change is adjusted by turning the tie rods for the right and left

heels simultaneously at the same amount as follows.

Standard value :

Toe- in (B- A) mm (in) : 0 ± 2 (0 ± 0.0787)

a. Toe- in adjustment should be made by turning the right and left tie rods at the same amount.

b. When adjusting toe - in, loosen the outer bellows clip to prevent twisting the bellows.

c. After the adjustment, tighten the tie rod end lock nuts firmly and reinstall the bellows clip.

d. Adjust each toe - in to be the range of ±1mm.

Tie rod(A) Specified torque Nm (kgf.m, lb - ft) :

70 ~ 80 (7 ~ 8, 50.6 ~ 57.8)

Page 573 of 1575

[REAR]

Standard value :

Toe- in (B- A) mm (in) : 2.6 ± 2 (0.1024 ± 0.0787)

Adjust the toe - in by turning the cambolt of the assist arm.

Left cambolt : Clockwise → toe - in

Right cambolt : Clockwise → toe - out

The variation of toe by a rotation of the cambolt :

About 3.2 mm (0.126 in)

a. Each toe should be within ±1 mm (± 0.039 in).

If the difference between right and left is not within +2mm (0.079 in), repeat adjustment.

b. After adjusting the cambolt, tighten the nut to the specified torque.

Specified torque

90 ~ 120 Nm (9 ~ 12 kgf.m, 65.1 ~ 86.8 lb - ft)

CAMBER

[FRONT]

Camber is the inward or outward tilting of the wheels at the top.

Page 574 of 1575

ItemDescription

A Positive camber angle

B True vertical

When the wheel tilts out at the top, then the camber is positive (+).

When the wheel tilts in at the top, then the camber is negative(- ).

Standard value : 0° ± 30´

Difference between right and left angle is within 0° 30´

Camber is pre- set at the factory and doesn't need to be adjusted. If the camber is not within the standard value,

replace the bent or damaged parts.

[REAR]

Standard value : - 6´ ± 30´

Difference between right and left angle is within 0° 30´

Adjust the camber by turning the cambolt of the rear upper arm.

Left cambolt : Clockwise → camber(- )

Right cambolt : Clockwise →camber(+)

The variation of camber by a rotation of the cambolt :

About 0°8´35´´

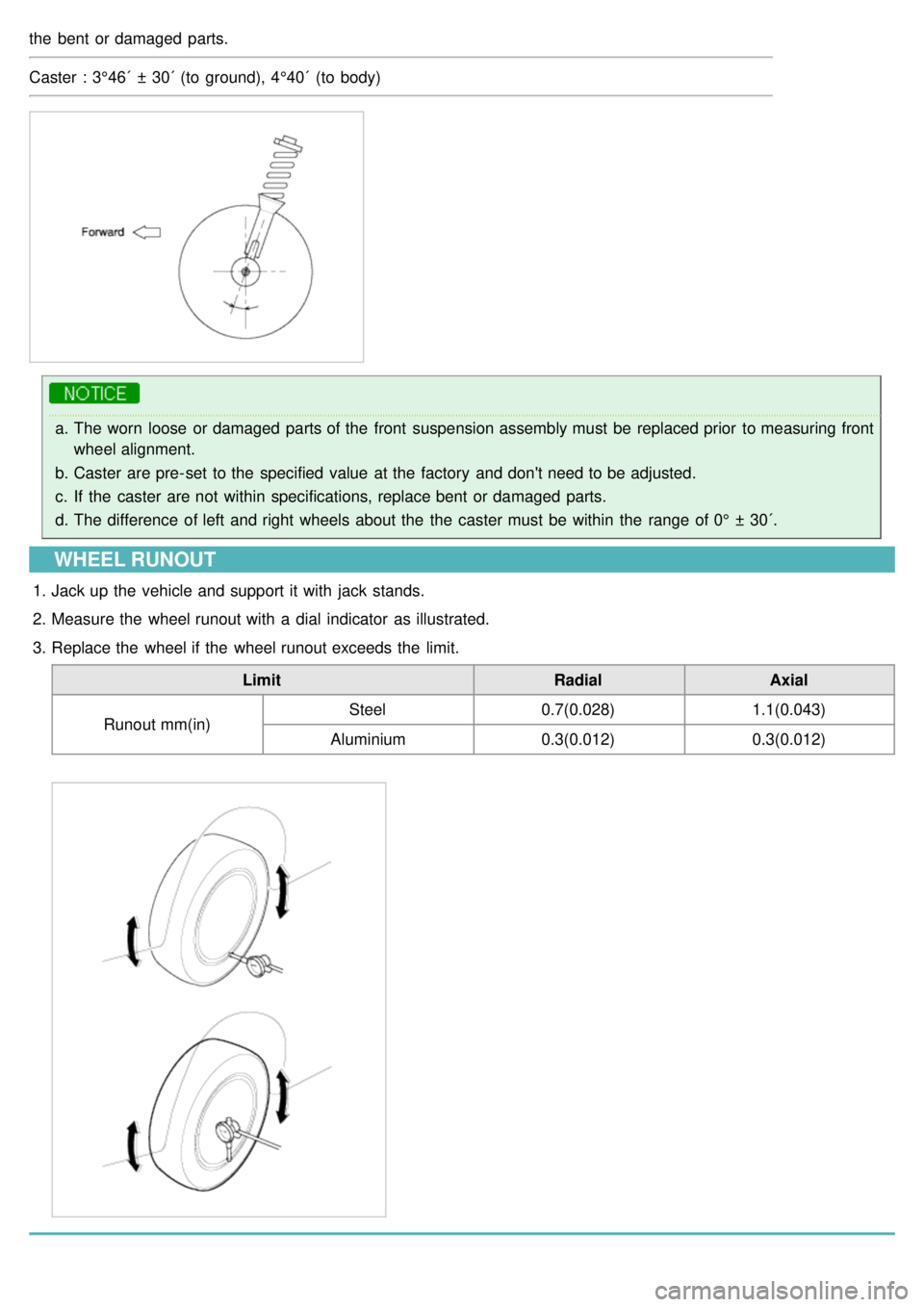

CASTER

Caster is the tilting of the strut axis either forward or backward from vertical. A backward tilt is positive (+) and a

forward tilt is negative ( - ).

Caster is pre- set at the factory and doesn't need to be adjusted. If the caster is not within the standard value, replace

the bent or damaged parts.

Page 575 of 1575

the bent or damaged parts.

Caster : 3°46´ ± 30´ (to ground), 4°40´ (to body)

a.The worn loose or damaged parts of the front suspension assembly must be replaced prior to measuring front

wheel alignment.

b. Caster are pre- set to the specified value at the factory and don't need to be adjusted.

c. If the caster are not within specifications, replace bent or damaged parts.

d. The difference of left and right wheels about the the caster must be within the range of 0° ± 30´.

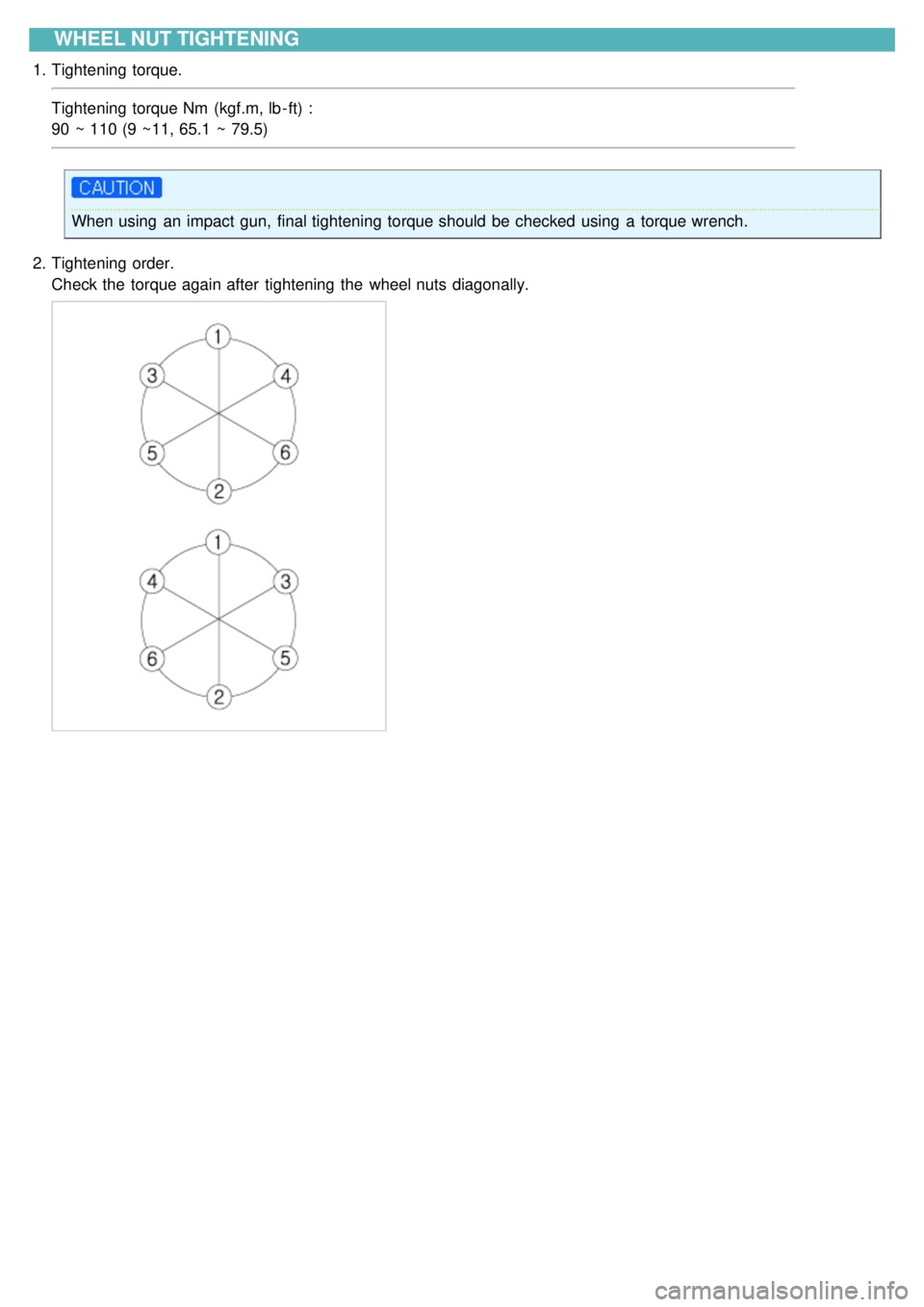

WHEEL RUNOUT

1.Jack up the vehicle and support it with jack stands.

2. Measure the wheel runout with a dial indicator as illustrated.

3. Replace the wheel if the wheel runout exceeds the limit.

Limit RadialAxial

Runout mm(in) Steel

0.7(0.028) 1.1(0.043)

Aluminium 0.3(0.012)0.3(0.012)

Page 576 of 1575

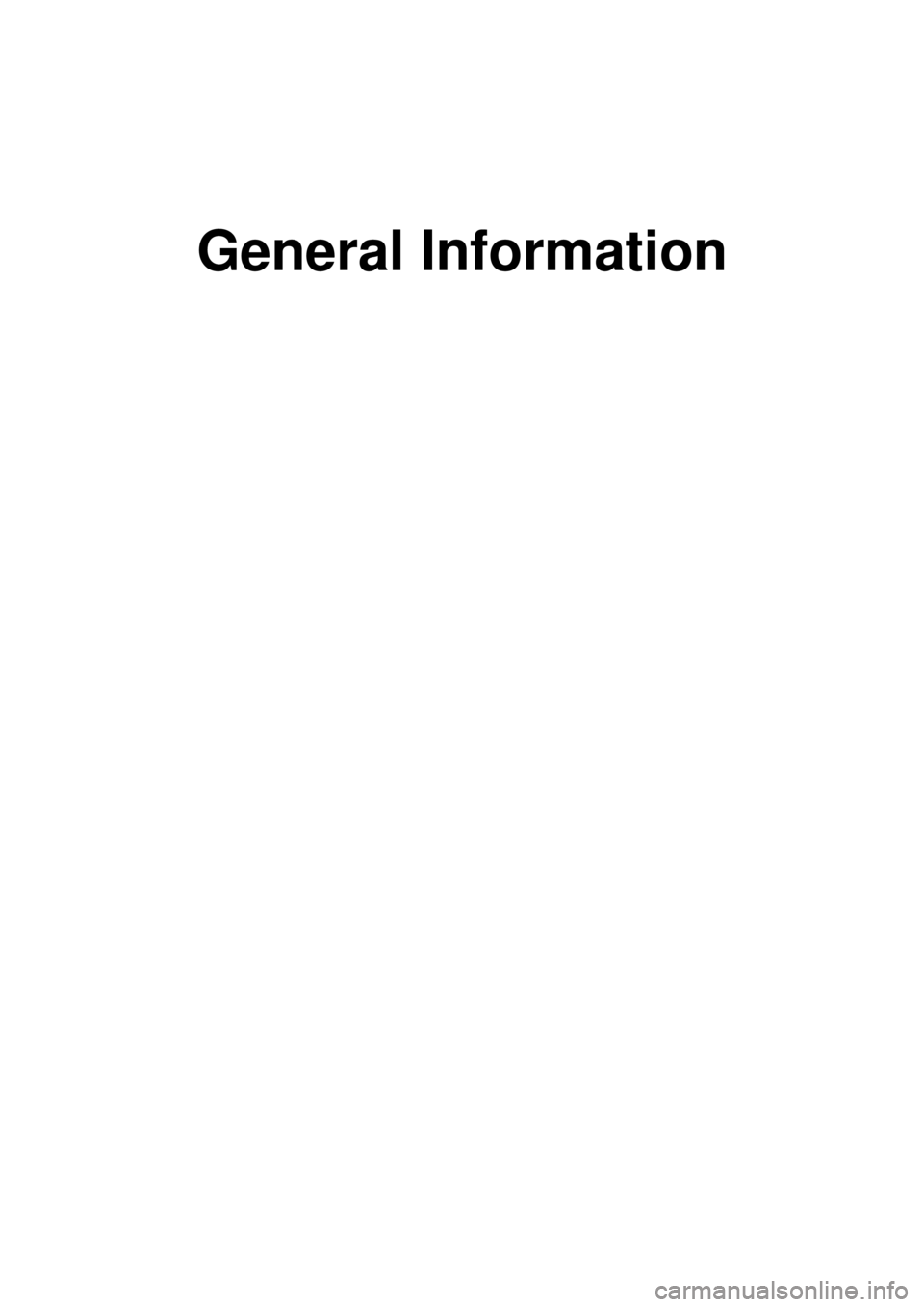

WHEEL NUT TIGHTENING

1.Tightening torque.

Tightening torque Nm (kgf.m, lb - ft) :

90 ~ 110 (9 ~11, 65.1 ~ 79.5)

When using an impact gun, final tightening torque should be checked using a torque wrench.

2. Tightening order.

Check the torque again after tightening the wheel nuts diagonally.

Page 577 of 1575

CHAPTER 10:

Steering System

Page 578 of 1575

Page 579 of 1575

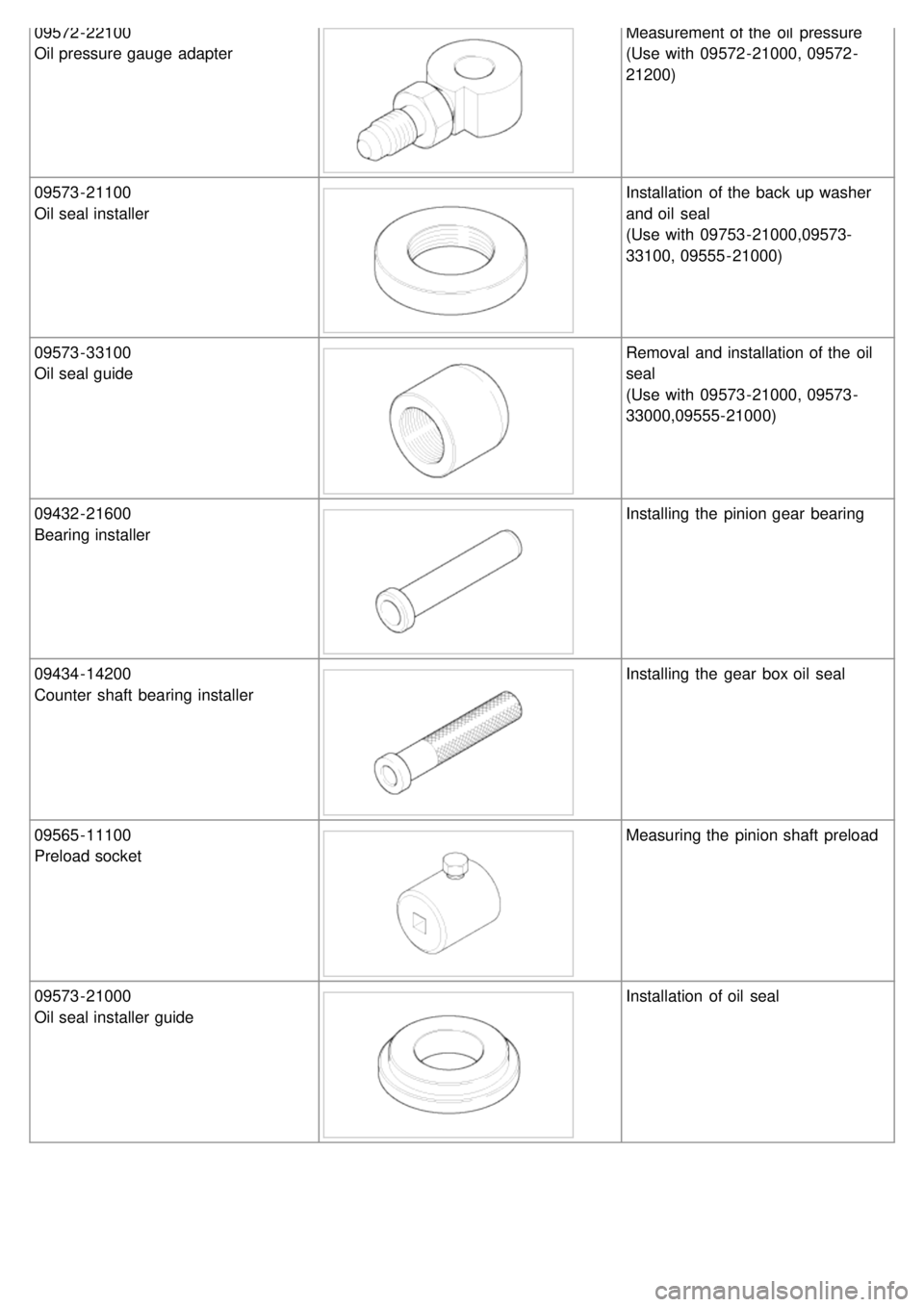

2007 > 2.7L V6 GASOLINE >

SPECIAL TOOLS

Tool (Number and Name) IllustrationUse

09222 - 32100

Valve stem oil seal installer

Installation of the oil pump oil seal

09555 - 21000

Bar

Removal and installation of the oil

seal

(Use with 09573 - 33100, 09573 -

33000,09573- 21000)

09561 - 11001

Steering wheel puller

Removal of steering wheel

09568 - 4A000

Tie rod end puller

Separation of the tie rod end bail

joint

09572 - 21000

Oil pressure gauge

Measurement of the oil pressure

(Use with 09572 - 22100, 09572 -

21200)

09572 - 21200

Oil pressure gauge adapter

Measurement of the oil pressure

(Use with 09572 - 21000, 09572 -

22100)

09572 - 22100 Measurement of the oil pressure

Page 580 of 1575

09572 - 22100

Oil pressure gauge adapterMeasurement of the oil pressure

(Use with 09572 - 21000, 09572 -

21200)

09573 - 21100

Oil seal installer

Installation of the back up washer

and oil seal

(Use with 09753 - 21000,09573-

33100, 09555 - 21000)

09573 - 33100

Oil seal guide

Removal and installation of the oil

seal

(Use with 09573 - 21000, 09573 -

33000,09555- 21000)

09432 - 21600

Bearing installer

Installing the pinion gear bearing

09434 - 14200

Counter shaft bearing installer

Installing the gear box oil seal

09565 - 11100

Preload socket

Measuring the pinion shaft preload

09573 - 21000

Oil seal installer guide

Installation of oil seal

Trending: overheating, keyless, mirror controls, park assist, oil type, keyless entry, low beam

![KIA CARNIVAL 2007 Workshop Manual [REAR]

Standard value :

Toe- in (B- A) mm (in) : 2.6 ± 2 (0.1024 ± 0.0787)

Adjust the toe - in by turning the cambolt of the assist arm.

Left cambolt : Clockwise → toe - in

Right camb KIA CARNIVAL 2007 Workshop Manual [REAR]

Standard value :

Toe- in (B- A) mm (in) : 2.6 ± 2 (0.1024 ± 0.0787)

Adjust the toe - in by turning the cambolt of the assist arm.

Left cambolt : Clockwise → toe - in

Right camb](/img/2/57045/w960_57045-572.png)