LAND ROVER DISCOVERY 1995 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1995, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1995Pages: 873, PDF Size: 12.89 MB

Page 611 of 873

BRAKES

9

REPAIR SERVO ASSEMBLY

Service repair no - 70.50.01

Remove

Before starting repair refer to general brake service

practice.

See General Brake Service Practice

NOTE: The filter, non-return valve and

grommet, are the only serviceable

components, in event of failure or damage

fit a new unit.

1.Disconnect battery negative lead.

2.Disconnect electrical plug to low fluid level

switch.

3.Thoroughly clean immediate area around all

master cylinder outlet ports. Remove each brake

pipe, sealing each pipe and outlet port to prevent

ingress of foreign matter.

4.Disconnect vacuum supply hose to servo.

5.Remove lower dash panel to gain access to

servo push rod to brake pedal.

6.Remove clevis pin securing servo push rod to

brake pedal.

7.Remove two nuts and plain washers securing

servo.

8.Remove servo and master cylinder assembly.

9.Drain brake fluid into a suitable container. (If

master cylinder is kept horizontal it is not

necessary to drain fluid).10.Detach spacer from pedal box mounting face of

servo.

NOTE: Retain spacer for reassembly. The

spacer ensures stringent pedal to servo

operating dimensions are maintained.

11.Remove master cylinder from existing servo and

refit to new servo, if fitting new unit.

Refit

12.Fit spacer to servo.

13.Fit servo to pedal box.

14.Lightly grease brake pedal around area servo

push rod pivots.

15.Fit push rod to lower hole of brake pedal. Fit

clevis pin and clip.

16.Secure servo with two nuts and plain washers.

Tighten nuts to

26 Nm.

17.Refit lower dash panel.

18.Fit master cylinder to servo, refit nuts, plain and

spring washers. Tighten nuts to

26 Nm.

19.Remove all sealing plugs. Refit brake pipes to

respective ports. Tighten brake pipes to

15 Nm.

20.Refit vacuum supply hose.

21.Fill master cylinder to correct level using correct

grade of brake fluid.

See LUBRICANTS,

FLUIDS AND CAPACITIES, Information,

Recommended Lubricants and Fluids

22.Bleed brake system.See Brake System Bleed

Page 612 of 873

70BRAKES

10

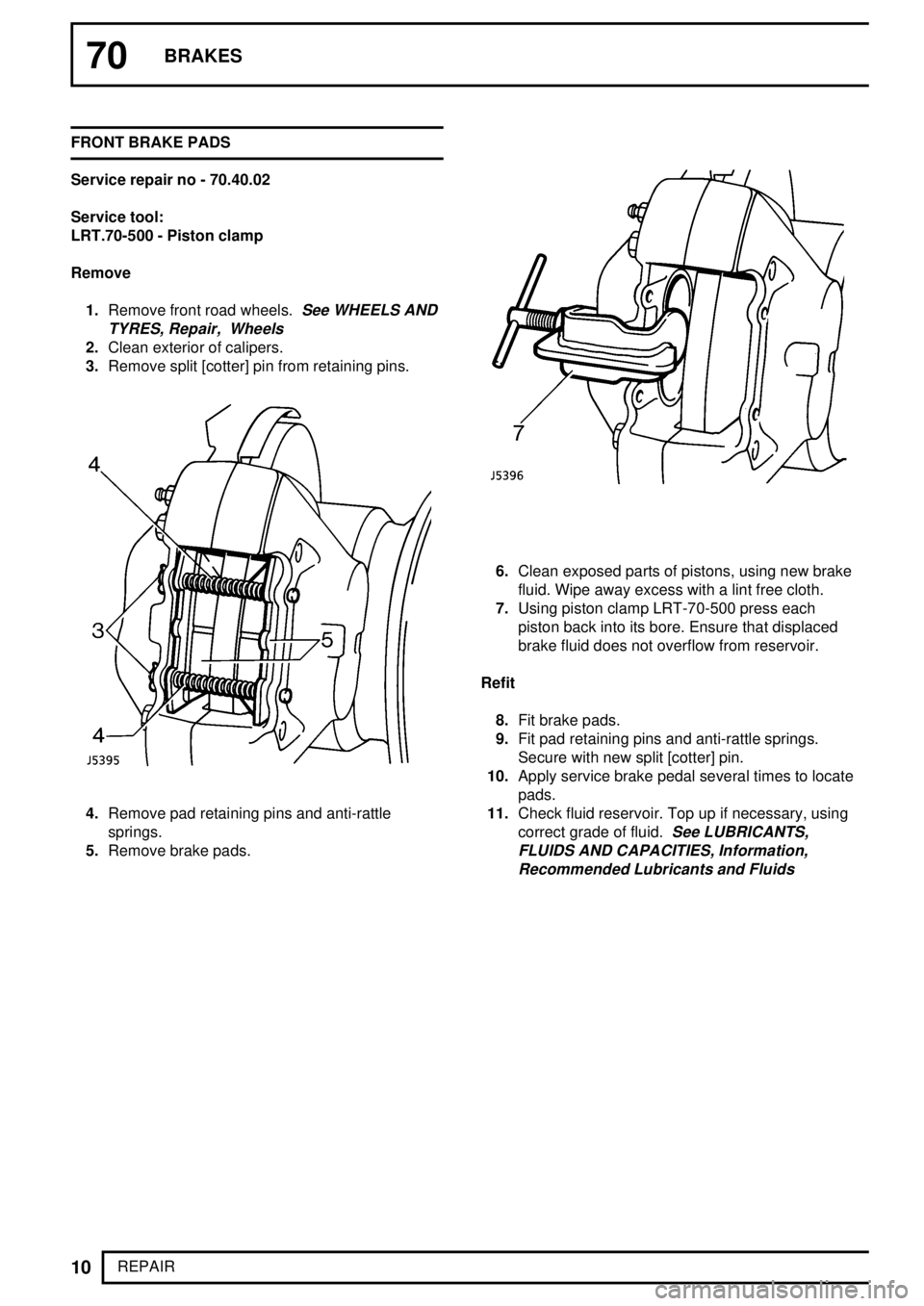

REPAIR FRONT BRAKE PADS

Service repair no - 70.40.02

Service tool:

LRT.70-500 - Piston clamp

Remove

1.Remove front road wheels.

See WHEELS AND

TYRES, Repair, Wheels

2.Clean exterior of calipers.

3.Remove split [cotter] pin from retaining pins.

4.Remove pad retaining pins and anti-rattle

springs.

5.Remove brake pads.

6.Clean exposed parts of pistons, using new brake

fluid. Wipe away excess with a lint free cloth.

7.Using piston clamp LRT-70-500 press each

piston back into its bore. Ensure that displaced

brake fluid does not overflow from reservoir.

Refit

8.Fit brake pads.

9.Fit pad retaining pins and anti-rattle springs.

Secure with new split [cotter] pin.

10.Apply service brake pedal several times to locate

pads.

11.Check fluid reservoir. Top up if necessary, using

correct grade of fluid.

See LUBRICANTS,

FLUIDS AND CAPACITIES, Information,

Recommended Lubricants and Fluids

Page 613 of 873

BRAKES

11

REPAIR REAR BRAKE PADS

Service repair no - 70.40.03

Service tool:

LRT-70-500 - Piston clamp

Remove

1.Remove rear road wheels.

See WHEELS AND

TYRES, Repair, Wheels

2.Disconnect battery negative lead.

3.Clean exterior of calipers.

4.Remove pad retaining pins and springs.

5.Remove brake pads.

6.Clean exposed parts of pistons, using new brake

fluid. Wipe away excess with a lint free cloth.

7.Using piston clamp LRT-70-500 press each

piston back into its bore. Ensure that displaced

brake fluid does not overflow from reservoir.Refit

8.Insert brake pads.

9.Position pad retaining springs, fit new pins and

spread ends.

10.Apply service brake pedal several times to locate

pads.

11.Check fluid reservoir, top up if necessary, using

correct grade of fluid.

See LUBRICANTS,

FLUIDS AND CAPACITIES, Information,

Recommended Lubricants and Fluids

Page 614 of 873

![LAND ROVER DISCOVERY 1995 Workshop Manual 70BRAKES

12

REPAIR FRONT BRAKE CALIPER ASSEMBLY

Key to caliper

1. Caliper

2. Bleedscrew

3. Antirattle springs

4. Pad retaining pins

5. Split [cotter] pin

6. Friction pads

7. Piston

8. Wiper seal retai LAND ROVER DISCOVERY 1995 Workshop Manual 70BRAKES

12

REPAIR FRONT BRAKE CALIPER ASSEMBLY

Key to caliper

1. Caliper

2. Bleedscrew

3. Antirattle springs

4. Pad retaining pins

5. Split [cotter] pin

6. Friction pads

7. Piston

8. Wiper seal retai](/img/64/57248/w960_57248-613.png)

70BRAKES

12

REPAIR FRONT BRAKE CALIPER ASSEMBLY

Key to caliper

1. Caliper

2. Bleedscrew

3. Antirattle springs

4. Pad retaining pins

5. Split [cotter] pin

6. Friction pads

7. Piston

8. Wiper seal retainer

9. Wiper seal

10. Fluid seal

11. Brake disc

Page 615 of 873

BRAKES

13

REPAIR FRONT BRAKE CALIPERS

Service repair no - 70.55.03

Service repair no - 70.55.16

Service tool:

LRT-70-500 - Piston clamp

Before starting repair refer to general brake service

practice.

See General Brake Service Practice

Remove caliper

1.Loosen front wheel retaining nuts, raise front of

vehicle, lower onto axle stands, remove wheels.

2.Expose flexible brake hose by moving coiled

protective covering.

3.Using a recognised hose clamp, clamp hose to

prevent loss of brake fluid.

4.Disconnect rigid brake pipe from flexible hose,

seal exposed ends to prevent ingress of dirt.

5.Remove split [cotter] pin, retaining pins and

springs, withdraw pads. If refitting pads, identify

them for assembly to original locations.

6.Loosen bolts and remove caliper.

Repair

Do not separate caliper halves

7.Clean outer surfaces of caliper using aerosol

brake cleaner.

8.Using special tool LRT-70-500, clamp pistons in

inboard half of caliper. Gently, keeping fingers

clear, and withCAUTION,apply air pressure to

fluid inlet port to expel pistons. It is unlikely that

pistons will expel at same time, regulate rate

with a suitable piece of wood between

appropriate piston and caliper.

9.Finally remove pistons, identifying them with

their respective bores.

10.Remove wiper seal retainer by inserting a blunt

screwdriver between retainer and seal. Pry

retainer carefully from mouth of bore.

11.Taking care not to damage seal grooves, extract

wiper seal and fluid seal.

12.Clean bores, pistons and seal grooves using

clean brake fluid only. If caliper or pistons are

corroded, or their condition is not perfect, new

parts must be fitted.

Page 616 of 873

70BRAKES

14

REPAIR Assemble outboard pistons

13.Coat new fluid seal with brake fluid. Ease seal

into groove in bore using only fingers, ensuring it

is properly seated. Fluid seal and groove are not

same in section, so when seal is seated it feels

raised to touch at edge furthest away from

mouth of bore.

14.Coat appropriate piston with brake fluid. Insert it

squarely into bore by hand only. Do not tilt piston

during insertion, leave approximately 8mm

projecting from bore.

15.Coat new wiper seal with brake fluid and fit to

new seal retainer. Slide assembly, seal first, over

protruding piston and into bore recess. Use

piston clamp to press home seal retainer and

piston.

Mounting inboard pistons

16.Clamp outboard pistons and carry out same

procedure for removing and fitting outboard

pistons and seals, instructions 8 to 15.

Fit calipers and pads

17.Fit caliper, tighten bolts evenly to

82 Nm.

18.Connect brake flexible hoses to caliper. Tighten

to

15 Nm.

19.Remove hose clamps.

20.Insert pads. Fit pins and springs, secure using

new split [cotter] pin.

21.Bleed brake system.

See Brake System Bleed

22.Press brake pedal firmly several times to locate

friction pads.

23.Fit road wheels, remove axle stands. Finally

tighten road wheel nuts to

130 Nm.

24.Road test vehicle. Note that new friction pads

require 'bedding-in', this may take several

hundred miles before brakes are at maximum

efficiency.

Page 617 of 873

BRAKES

15

REPAIR REAR BRAKE CALIPERS

Service repair no - 70.55.06

Service repair no - 70.55.17

Service tool:

LRT-50-700 - Piston clamp

Before starting repair refer to general brake service

practice.

See General Brake Service Practice

Remove caliper

1.Loosen rear road wheel nuts. Jack up vehicle,

lower onto axle stands, remove wheels.

2.Using a recognised hose clamp, clamp flexible

brake hose above rear axle.

3.Remove brake pipe(s) from rear brake caliper(s).

4.Seal pipe ends to prevent ingress of dirt.

5.Remove retaining pins and springs and withdraw

pads. If same pads are to be refitted, identify

them for assembly in original positions.

6.Remove two bolts, withdraw caliper from axle.

Repair

Do not separate caliper halves

7.Clean outer surfaces of caliper with aerosol

brake cleaner.

8. WITH CAUTIONexpel pistons from their bores

by applying air pressure to fluid inlet port. It is

unlikely both pistons will expel at same time,

regulate rate with a suitable piece of wood

inserted between two pistons.

9.Finally, remove pistons keeping them identified

with their respective bores.

10.Remove wiper seal retainer by inserting a blunt

screwdriver between retainer and seal and pry

retainer carefully from mouth of bore.

11.Taking care not to damage seal grooves, extract

wiper seal and fluid seal.

12.Clean bores, pistons and particularly seal

grooves using clean brake fluid only. If caliper or

pistons are corroded or their condition is not

perfect new parts must be fitted.

Page 618 of 873

70BRAKES

16

REPAIR 13.Apply brake fluid to new seal. Fit seal into

groove in bore. When seal is seated it feels

raised to touch at edge furthest away from

mouth of bore.

14.Coat piston with brake fluid. Insert it squarely

into bore. Do not tilt piston during insertion and

leave 8mm projecting from bore.

15.Coat a new wiper seal with brake fluid and fit to

new seal retainer. Slide assembly, seal first, over

protruding piston into bore recess.

16.Using special tool LRT-70-500 - piston clamp,

press home seal retainer and piston.

Mounting inboard piston

17.Carry out same procedure as for removing and

fitting outboard piston and seals, instructions 8 to

16.

Fit calipers and pads to vehicle

18.Fit caliper to axle, tighten two bolts evenly to

82

Nm.

19.Connect brake pipe to caliper. Tighten to15Nm.

20.Remove clamp from flexible brake hose.

21.Insert pads and retaining springs, secure in

position with new retaining pins and spread

ends. Note correct position of retaining springs.

22.Bleed brake system.See Brake System Bleed

23.Press brake pedal firmly several times to locate

pads.

24.Fit road wheels, remove axle stands and finally

tighten road wheel nuts,

25.Road test vehicle. Note new brake pads require

'bedding-in', for several hundred miles before

brakes are at maximum efficiency.

PARKING BRAKE ADJUST

See SECTION 10,

Maintenance, Vehicle Interior

Page 619 of 873

BRAKES

17

REPAIR REAR BRAKE CALIPER ASSEMBLY

LH Rear Caliper illustrated

Key to caliper

1. Caliper

2. Bleed screw

3. Pad retaining springs

4. Brake pads

5. Piston6. Wiper seal retainer

7. Wiper seal

8. Fluid seal

9. Retaining pins

Page 620 of 873

70BRAKES

18

REPAIR SENSORS - FRONT

Service repair no - 70.65.32

CAUTION: If a sensor is removed for any

reason, a NEW sensor bush and seal must

be fitted.

Remove

1.Disconnect battery negative lead.

2.Disconnect required sensor electrical

connection, located on inner wing [fender] panel.

3.Remove sensor lead from clips.

4.Clean area surrounding sensor to prevent

ingress of dirt. Using a suitable lever pry sensor

from mounting bush.

5.Release harness cable ties, remove sensor lead

from vehicle.

6.Remove top swivel retaining bolts complete with

brake jump hose and sensor seal. Remove

sensor bush.

Refit

7.Insert new sensor bush and seal.

8.Refit brake jump hose bracket, coat bolts with

Loctite 270.

9.Lightly coat new sensor using EP 90 oil. Push

sensor through bush until it contacts exciter ring.

Sensor will be 'knocked back' to correct position

when vehicle is driven.

10.Secure sensor lead in original position.

11.Reconnect sensor electrical connection.

12.Drive vehicle to ensure ABS warning light is

extinguished.

SENSOR RINGS

The rear sensor ring is assembled to the rear brake

disc to form part of the rear hub assembly.

See

REAR AXLE AND FINAL DRIVE, Repair, Rear Hub

Assembly

The front sensor ring is a toothed ring on the axle

shaft which forms part of the front stub axle assembly.

See FRONT AXLE AND FINAL DRIVE, Overhaul,

Front Stub Axle, Constant Velocity Joint and

Swivel Pin Housing ABS