sensor LAND ROVER DISCOVERY 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 555 of 1529

TRANSFER BOX - LT230SE

41-30 REPAIRS

12. If fitted: Release and remove clevis pin

securing differential lock selector cable to

transfer gearbox.

13. If fitted: Loosen locknuts securing differential

lock selector cable to differential lock selector

cable abutment bracket.

14. If fitted: Release and remove differential lock

selector cable from differential lock selector

cable abutment bracket.

15.Remove clevis pin and 'C' clip securing high/

low ratio selector cable to selector lever and

release cable from abutment bracket.

16.Remove 2 cable ties securing cable to fuel

pipes. 17. If fitted: Disconnect 2 Lucars from oil

temperature sensor and disconnect reverse

lamp switch multiplug.

18.Remove banjo bolt securing breather pipe and

discard washers.

19. Up to 03 Model Year - if fitted: Disconnect 2

Lucars from differential lock switch and

multiplugs from high/low ratio switch and

neutral sensor.

20.Disconnect multiplug from reverse light switch.

Page 557 of 1529

TRANSFER BOX - LT230SE

41-32 REPAIRS

Refit

1.Fit new input shaft oil seal.

+ TRANSFER BOX - LT230SE,

REPAIRS, Oil seal - input shaft.

2.Clean transfer box to gearbox mating faces.

3.Raise transfer box on jack and align to guide

studs LRT-41-009.

4.Clean transfer box to gearbox bolt threads.

5.Apply sealant, Part No. STC 50552 to bolt and

stud threads.

6.Fit and lightly tighten 2 bolts and nut securing

transfer box to gearbox. If new stud is to be

fitted, apply sealant, Part No. STC 50552 to

stud threads and tighten to 45 Nm (33 lbf.ft).

7.Remove guide studs, fit and lightly tighten 3

bolts.

8.Tighten bolts and nut by diagonal selection to

45 Nm (33 lbf.ft.

9.Position gearbox RH mounting and tighten

bolts to 85 Nm (63 lbf.ft).

10.Tighten gearbox RH mounting nut to 48 Nm

(35 lbf.ft).

11.Fit nut to LH mounting and tighten to 48 Nm (35

lbf.ft).

12.Remove 4 bolts securing support plate to

gearbox jack.

13.Remove 4 bolts securing support plate LRT-99-

010 to transfer box and remove plate.

14.Clean threads of bottom plate bolts.

15.Apply sealant, Part No. STC 50552 to threads

of 4 bottom plate bolts.

16.Fit 4 bolts securing bottom plate and tighten to

25 Nm (18 lbf.ft).

17.Using new washers position breather pipe and

tighten banjo bolt.

18.Connect multiplug to transfer box neutral switch

and secure harness.

19. Up to 03 Model Year - if fitted : Connect

Lucars to differential lock switch and multiplugs

to high/low ratio switch and neutral sensor.

20. 03 Model Year onwards - if fitted: Connect

differential lock warning lamp multiplugs,

secure harness.

21.Connect multiplug to reverse lamp switch.

22. If fitted: Connect Lucars to oil temperature

switch.

23.Position high/low ratio selector cable and

secure with 'C' clip and clevis pin.

24. If fitted: Position differential lock selector cable

to differential lock selector cable abutment

bracket and tighten locknuts sufficiently to

retain cable.

25. If fitted: Fit differential lock selector cable to

transfer gearbox and secure with clevis pin.

26. If fitted: Adjust differential lock selector cable.

+ TRANSFER BOX - LT230SE,

ADJUSTMENTS, Cable - selector -

differential lock - adjust.27. Models fitted with high/low shift interlock

solenoid: Position interlock solenoid harness

to high/low shift cable, fit sleeve around cable

and harness; secure sleeve.

28. Models fitted with high/low shift interlock

solenoid: Connect solenoid multiplug to main

harness and secure multiplug to bracket.

29.Secure cable to fuel pipes with new cable ties.

30.Clean handbrake back plate and mating face.

31.Position handbrake back plate, fit bolts and

tighten to 75 Nm (55 lbf.ft).

32.Clean handbrake drum.

33.Fit handbrake drum and tighten retaining

screw.

34.Fit front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

35.Fit rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

36.Clean exhaust silencer and tail pipe mating

faces.

37.Position silencer and secure on mountings,

using a new gasket align to tail pipe, fit nuts

and tighten to 25 Nm (18 lbf.ft).

38.Position rear cross member, fit bolts and

tighten to 26 Nm (19 lbf.ft).

39.Refill transfer box with oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

40.Fit front exhaust pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Front pipe.

Page 566 of 1529

TRANSFER BOX - LT230SE

REPAIRS 41-41

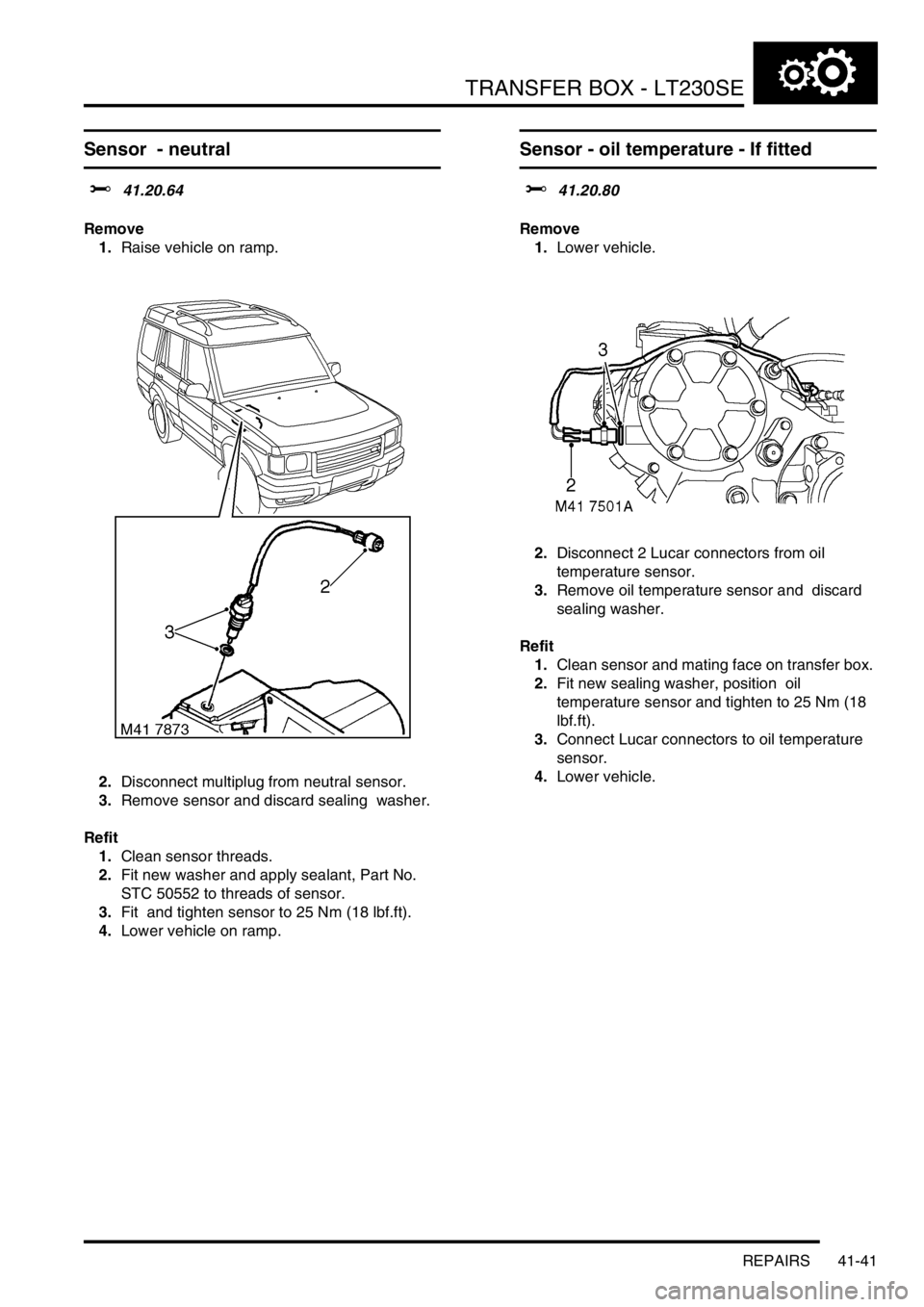

Sensor - neutral

$% 41.20.64

Remove

1.Raise vehicle on ramp.

2.Disconnect multiplug from neutral sensor.

3.Remove sensor and discard sealing washer.

Refit

1.Clean sensor threads.

2.Fit new washer and apply sealant, Part No.

STC 50552 to threads of sensor.

3.Fit and tighten sensor to 25 Nm (18 lbf.ft).

4.Lower vehicle on ramp.

Sensor - oil temperature - If fitted

$% 41.20.80

Remove

1.Lower vehicle.

2.Disconnect 2 Lucar connectors from oil

temperature sensor.

3.Remove oil temperature sensor and discard

sealing washer.

Refit

1.Clean sensor and mating face on transfer box.

2.Fit new sealing washer, position oil

temperature sensor and tighten to 25 Nm (18

lbf.ft).

3.Connect Lucar connectors to oil temperature

sensor.

4.Lower vehicle.

Page 600 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

DESCRIPTION AND OPERATION 44-3

1Transmission high/low switch

2Mode switch

3Gear position switch connector

4Solenoid valve/speed sensor connector

5Electronic automatic transmission ECU

6Engine control module

7Diagnostic socket

8Instrument pack

9Transmission fluid temperature sensor

10Body control unit

11Battery power supply

12Ignition power supply

Page 606 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

DESCRIPTION AND OPERATION 44-9

Valve block

1Valve block

2Pressure regulating solenoid valve (MV 4)

3Shift control solenoid valve (MV 2)

4Shift control solenoid valve (MV 1)

5Lock-up solenoid valve (MV 3)

6Output shaft speed sensor

7Bolt

8Sensor retaining clip9Manual valve

10'O' ring

11Filter

12'O' ring

13Suction pipe

14Bolt

15Bolt

16Washer

Page 607 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-10 DESCRIPTION AND OPERATION

The lock-up and brake clutches are operated by pressurised transmission fluid from the valve block in the sump. A

manual valve and four solenoid valves, also known as Motorised Valves (MV), control the supply of pressurised

transmission fluid from the valve block:

lThe manual valve controls the supply in P, R, N and D.

lSolenoid valves MV 1 and MV 2 control the supplies that operate the brake clutches for shift control.

lSolenoid valve MV 3 controls the supply that operates the lock-up clutch.

lSolenoid valve MV 4 modulates the pressure of the supplies to the brake clutches, to control shift quality.

Operation of the manual valve is controlled by the selector lever assembly. In the gearbox, a selector shaft engages

with the manual valve. The selector shaft is connected to the selector lever assembly via the selector cable and a

selector lever on the left side of the gearbox. The selector shaft also operates a mechanism that locks the output shaft

when P is selected.

Operation of the solenoid valves is controlled by the EAT ECU.

An output shaft speed sensor in the gearbox housing outputs a signal to the EAT ECU. The EAT ECU compares

output shaft speed with engine speed to determine the engaged gear, and output shaft speed with vehicle speed to

confirm the range selected on the transfer box.

A bayonet lock electrical connector in the gearbox casing, to the rear of the selector lever, connects the solenoid

valves and the output shaft speed sensor to the vehicle wiring.

A pressed steel sump encloses the valve block and collects transmission fluid draining from the gearbox housing. A

suction pipe and filter on the underside of the valve block connect to the inlet side of the fluid pump. A magnet is

installed in the sump to collect any magnetic particles that may be present. A level plug and a drain plug are installed

in the sump for servicing.

Rear extension housing

The rear extension housing provides the interface between the gearbox housing and the transfer box. A splined

extension shaft, secured to the gearbox output shaft by a bolt, transmits the drive from the gearbox to the transfer

box. A seal in the rear of the housing prevents leakage past the extension shaft. A breather pipe, attached to the left

side of the rear extension housing, ventilates the interior of the gearbox and rear extension housings to atmosphere.

The open end of the breather pipe is located in the engine compartment at the right front corner of the engine sump

on gearboxes fitted to early vehicles and is clipped to the top of the gearbox on later vehicles.

Gearbox power flows

The following Figures show the power flow through the gearbox for each forward gear when D is selected, and for

reverse. The key to the Item numbers on the Figures, and in parenthesis in the accompanying text, can be found on

the 'Sectioned view of gearbox' Figure, above.

1st Gear (D selected)

Clutches (4) and (11) are engaged. The front planet gear carrier of gear set (9) locks against the gearbox housing

through freewheel (15) when the engine powers the vehicle, and freewheels when the vehicle is coasting. Gear set

(10) rotates as a solid unit with the front planet gear carrier. In 1st gear hold brake clutch (8) is applied to provide

overrun braking.

Page 610 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

DESCRIPTION AND OPERATION 44-13

Oil cooler

1Inlet connection

2Fixing bracket

3Outlet connection4Fixing bracket

5Temperature sensor

Transmission fluid from the gearbox is circulated through a cooler attached to the front of the radiator. Quick release

connectors on the transmission fluid lines attach to connections on each end tank of the cooler. A temperature sensor

on the RH end tank provides the instrument pack with an input of transmission fluid temperature. If the temperature

exceeds a preset limit, the instrument pack illuminates the transmission temperature warning lamp. The warning lamp

remains illuminated until the temperature of the fluid returns within limits.

EAT ECU

The EAT ECU operates the solenoid valves in the gearbox to provide automatic control of gear shifts and torque

converter lock-up. The EAT ECU is attached to a protective bracket which is secured to the cabin floor below the LH

front seat. A 55 pin connector links the EAT ECU to the vehicle wiring.

Software in the EAT ECU monitors hard wired inputs and exchanges information with the ECM on a Controller Area

Network (CAN) bus to determine gear shift and torque converter lock-up requirements. Resultant control signals are

then output to the gearbox solenoid valves.

Page 611 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-14 DESCRIPTION AND OPERATION

EAT ECU connector

EAT ECU connector pin details

Pin No. Description Inputs/Outputs

1 to 4 Not used -

5 Pressure regulator solenoid valve (MV 4) Output

6 Power earth -

7 Not used -

8 Gear position switch, X contacts Input

9 Gear position switch, Z contacts Input

10 to 12 Not used -

13 Transmission high/low switch Input

14 Gearbox output shaft speed sensor, negative Input

15 Gearbox output shaft speed sensor cable screen -

16 CAN, high Input/Output

17 to 24 Not used -

25 Sport mode warning lamp Output

26 Battery power supply Input

27 Not used -

28 Electronics earth -

29 Not used -

30 Shift control solenoid valve (MV 1) Output

31 Diagnostics, K line Input/Output

32 Converter lock-up solenoid valve (MV 3) Output

33 Shift control solenoid valve (MV 2) Output

34 Not used -

35 Not used -

36 Gear position switch, W contacts Input

37 Gear position switch, Y contacts Input

38 to 41 Not used -

42 Gearbox output shaft speed sensor, positive Input

43 Not used -

44 CAN, low Input/Output

45 Mode switch Input

46 to 50 Not used -

51 Manual mode warning lamp Output

52 Not used -

53 Solenoid valves power supply Output

54 Ignition power supply Input

55 Not used -

Page 615 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-18 DESCRIPTION AND OPERATION

Kickdown

The EAT ECU monitors the input of the throttle position sensor to determine when kickdown is required. When it

detects a kickdown situation, the EAT ECU immediately initiates a down shift provided the target gear will not cause

the engine speed limit to be exceeded.

Torque converter lock-up

The EAT ECU energises the lock-up solenoid valve to engage the lock-up clutch. Lock-up clutch operation is

dependent on throttle position, engine speed, operating mode and the range selected on the transfer box.

High range

Unique lock-up maps, similar to the shift maps, are incorporated in the economy and sport modes for all forward gears.

Engagement and disengagement of the lock-up clutch is dependent on throttle position and engine speed.

Low range

To enhance off road control, particularly when manoeuvring at low speeds, torque converter lock-up does not occur

when there is any degree of throttle opening. When the throttle is closed above a preset engine speed, the lock-up

clutch engages to provide maximum engine braking.

Increased load/reduced torque compensation

To aid performance and driveability in the high range economy mode, the EAT ECU has three adaptive shift and lock-

up maps. These maps delay upshifts and torque converter lock-up similar to the sport mode if the inputs from the

engine indicate:

lA sustained high load on the engine, such as occurs when the vehicle is ascending a steep gradient or towing a

trailer.

lA lower than normal engine torque, such as occurs at altitude or high ambient temperatures.

The EAT ECU monitors the engine inputs and selects the most appropriate adaptive map for the prevailing conditions.

Diagnostics

While the ignition is on, the EAT ECU diagnoses the system for faults. The extent of the diagnostic capability at any

particular time depends on the prevailing operating conditions, e.g. it is not possible to check torque converter lock-

up while the vehicle is stationary, or to check for a short circuit to earth if the circuit concerned is already at a low

potential.

If a fault is detected, the EAT ECU immediately stores a fault code and the values of three operating parameters

associated with the fault. Depending on the fault, there are four possible effects:

lThe fault has little effect on gearbox operation or vehicle emissions. The driver will probably not notice any

change and the warning lamps remain extinguished.

lThe fault has little effect on gearbox operation but may effect vehicle emissions. On NAS vehicles, if the fault is

detected on a second consecutive drive cycle, the MIL illuminates.

lAll gears are available but kickdown does not function. The sport and manual warning lamps flash. The MIL

remains extinguished.

lLimp home mode is selected and vehicle performance is greatly reduced. The sport and manual warning lamps

flash. In all markets, if the fault is detected on a second consecutive drive cycle, the MIL illuminates.

After the detection of a fault, the effects remain active for the remainder of the drive cycle. In subsequent drive cycles,

as soon as the EAT ECU diagnoses the fault is no longer present, it resumes normal control of the gearbox. The

conditions required to diagnose that the fault is no longer present depend on the fault. Some faults require the engine

to be started, others require only that the ignition is switched on.

After a fault has not recurred for forty warm-up cycles, the fault is deleted from the EAT ECU memory. Only five

different faults can be stored in the memory at any one time. If a further fault occurs, the fault with the lowest priority

will be replaced by the new fault.

Mechanical limp home

In the mechanical limp home mode, gear engagement is controlled by the manual valve. The gearbox is fixed in 4th

gear if the fault occurs while the vehicle is moving, or 3rd gear if the fault occurs while the vehicle is stationary. 3rd

gear is also engaged if a vehicle is brought to a stop and the selector lever is moved out of, and back into, D. Neutral

and reverse gear are also available.

Page 625 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-28 REPAIRS

15.Remove handbrake drum retaining screw and

remove brake drum.

16.Remove 4 bolts from handbrake back plate,

release back plate and tie aside.

17. Models fitted with high/low shift interlock

solenoid: Release interlock solenoid multiplug

and disconnect multiplug from main harness.

18. Models fitted with high/low shift interlock

solenoid: Remove sleeve retaining rings and

remove sleeve from high/low selector cable.

19. If fitted Remove and discard clevis pin

securing differential lock selector cable to

transfer gearbox.20. If fitted Loosen locknuts securing differential

lock selector cable to differential lock selector

cable abutment bracket.

21. If fitted Release and remove differential lock

selector cable from differential lock selector

cable abutment bracket.

22.Remove clevis pin securing high/low ratio

selector cable to selector lever, remove 'C' clip

and remove outer cable from abutment

bracket.

23. Up to 03 Model Year - If fitted: Disconnect

from differential lock warning lamp switch and

multiplugs from high/low ratio switch and

neutral sensor.