sensor LAND ROVER DISCOVERY 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 1999Pages: 1529, PDF Size: 34.8 MB

Page 628 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-31

40.Fit suitable strap to retain torque converter.

Refit

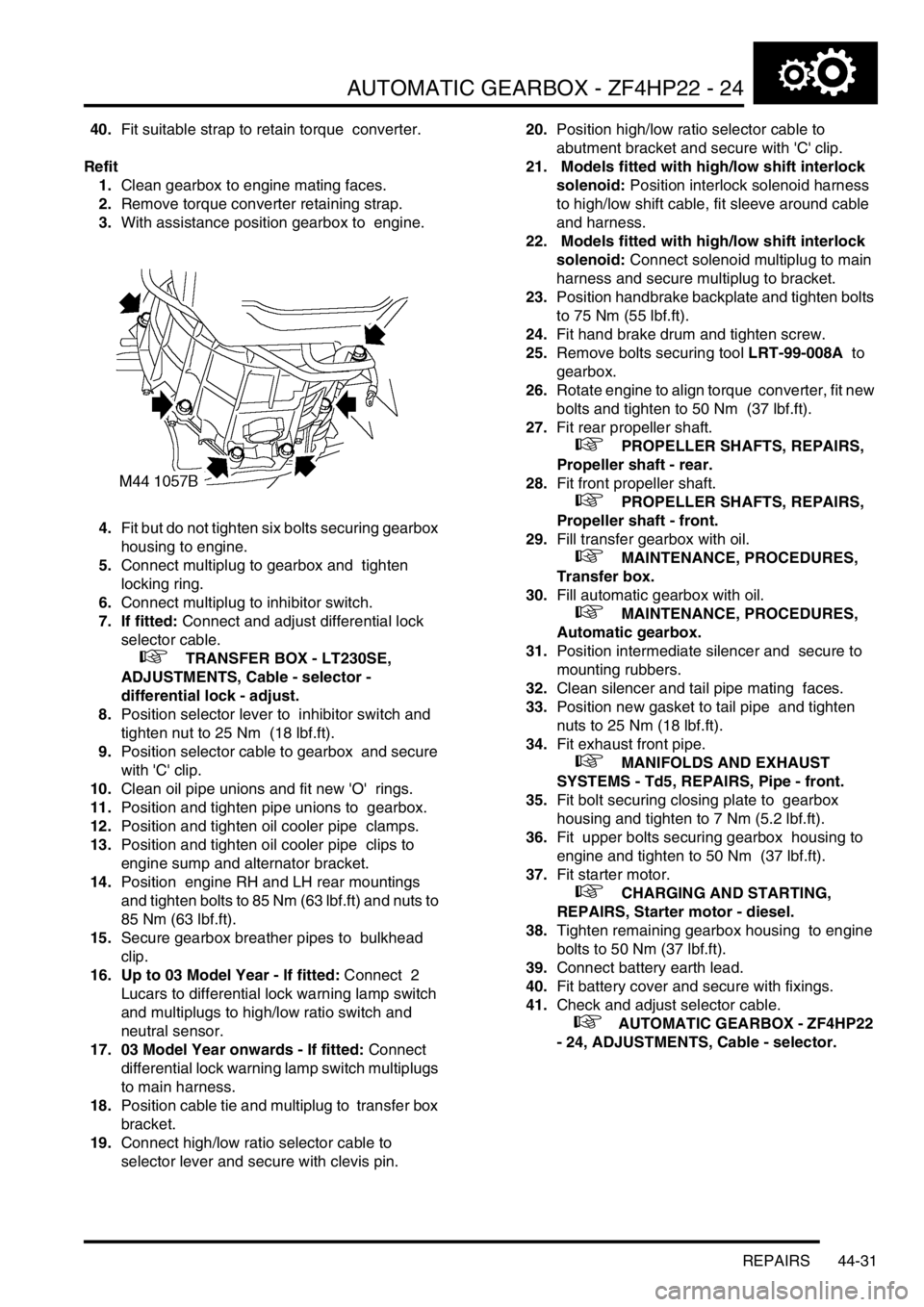

1.Clean gearbox to engine mating faces.

2.Remove torque converter retaining strap.

3.With assistance position gearbox to engine.

4.Fit but do not tighten six bolts securing gearbox

housing to engine.

5.Connect multiplug to gearbox and tighten

locking ring.

6.Connect multiplug to inhibitor switch.

7. If fitted: Connect and adjust differential lock

selector cable.

+ TRANSFER BOX - LT230SE,

ADJUSTMENTS, Cable - selector -

differential lock - adjust.

8.Position selector lever to inhibitor switch and

tighten nut to 25 Nm (18 lbf.ft).

9.Position selector cable to gearbox and secure

with 'C' clip.

10.Clean oil pipe unions and fit new 'O' rings.

11.Position and tighten pipe unions to gearbox.

12.Position and tighten oil cooler pipe clamps.

13.Position and tighten oil cooler pipe clips to

engine sump and alternator bracket.

14.Position engine RH and LH rear mountings

and tighten bolts to 85 Nm (63 lbf.ft) and nuts to

85 Nm (63 lbf.ft).

15.Secure gearbox breather pipes to bulkhead

clip.

16. Up to 03 Model Year - If fitted: Connect 2

Lucars to differential lock warning lamp switch

and multiplugs to high/low ratio switch and

neutral sensor.

17. 03 Model Year onwards - If fitted: Connect

differential lock warning lamp switch multiplugs

to main harness.

18.Position cable tie and multiplug to transfer box

bracket.

19.Connect high/low ratio selector cable to

selector lever and secure with clevis pin. 20.Position high/low ratio selector cable to

abutment bracket and secure with 'C' clip.

21. Models fitted with high/low shift interlock

solenoid: Position interlock solenoid harness

to high/low shift cable, fit sleeve around cable

and harness.

22. Models fitted with high/low shift interlock

solenoid: Connect solenoid multiplug to main

harness and secure multiplug to bracket.

23.Position handbrake backplate and tighten bolts

to 75 Nm (55 lbf.ft).

24.Fit hand brake drum and tighten screw.

25.Remove bolts securing tool LRT-99-008A to

gearbox.

26.Rotate engine to align torque converter, fit new

bolts and tighten to 50 Nm (37 lbf.ft).

27.Fit rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

28.Fit front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

29.Fill transfer gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Transfer box.

30.Fill automatic gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Automatic gearbox.

31.Position intermediate silencer and secure to

mounting rubbers.

32.Clean silencer and tail pipe mating faces.

33.Position new gasket to tail pipe and tighten

nuts to 25 Nm (18 lbf.ft).

34.Fit exhaust front pipe.

+ MANIFOLDS AND EXHAUST

SYSTEMS - Td5, REPAIRS, Pipe - front.

35.Fit bolt securing closing plate to gearbox

housing and tighten to 7 Nm (5.2 lbf.ft).

36.Fit upper bolts securing gearbox housing to

engine and tighten to 50 Nm (37 lbf.ft).

37.Fit starter motor.

+ CHARGING AND STARTING,

REPAIRS, Starter motor - diesel.

38.Tighten remaining gearbox housing to engine

bolts to 50 Nm (37 lbf.ft).

39.Connect battery earth lead.

40.Fit battery cover and secure with fixings.

41.Check and adjust selector cable.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, ADJUSTMENTS, Cable - selector.

Page 630 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-33

16. Models fitted with high/low shift interlock

solenoid: Release interlock solenoid multiplug

and disconnect multiplug from main harness.

17. Models fitted with high/low shift interlock

solenoid: Remove sleeve retaining rings and

remove sleeve from high/low selector cable.

18. If fitted Remove and discard clevis pin

securing differential lock selector cable to

transfer gearbox.

19. If fitted Loosen locknuts securing differential

lock selector cable to differential lock selector

cable abutment bracket.

20. If fitted Release and remove differential lock

selector cable from differential lock selector

cable abutment bracket.

21.Remove clevis pin securing high/low ratio

selector cable to selector lever, remove 'C' clip

and remove outer cable from abutment bracket22. Up to 03 Model Year - If fitted: Disconnect 2

Lucars from differential lock switch and

multiplugs from high/low ratio switch and

neutral sensor.

23. 03 Model Year onwards - If fitted: Release

and disconnect both differential lock warning

lamp switch multiplugs from main harness.

24.Release transfer and automatic gearbox

breather pipes from clip at rear of cylinder

block.

Page 632 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-35

32.Remove 'C' clip securing selector cable to

gearbox bracket.

33.Remove nut securing selector lever to inhibitor

switch and release lever.

34.Disconnect multiplug from inhibitor switch.

35.Loosen gearbox multiplug locking ring and

disconnect plug.

36.Lower gearbox sufficiently to access bell

housing bolts, take care not to trap any pipes or

cables when lowering gearbox.

37.Remove 14 bolts securing gearbox to engine.

38.With assistance remove gearbox from engine.39.Fit suitable strap to retain torque converter.

Refit

1.Clean gearbox to engine mating faces.

2.Remove torque converter retaining strap.

3.With assistance position gearbox to engine.

4.Fit gearbox bell housing bolts and tighten to 46

Nm (34 lbf.ft)..

5.Connect multiplug to gearbox and tighten

locking ring.

6.Connect inhibitor switch multiplug.

7. If fitted: Connect and adjust differential lock

selector cable.

+ TRANSFER BOX - LT230SE,

ADJUSTMENTS, Cable - selector -

differential lock - adjust.

8.Position selector lever to inhibitor switch and

tighten nut to 25 Nm (18 lbf.ft).

9.Position selector cable to gearbox and secure

with 'C' clip.

10.Clean oil pipe unions and fit new 'O' rings.

11.Position and tighten pipe unions to gearbox.

12.Position and tighten oil cooler pipe clamps.

13.Position and tighten oil cooler pipe clip to

engine sump.

14.Position engine RH and LH rear mountings

and tighten bolts to 85 Nm (63 lbf.ft) and nuts to

85 Nm (63 lbf.ft).

15.Secure gearbox breather pipes to bulkhead

clip.

16. Up to 03 Model Year - If fitted: Connect 2

Lucars to differential lock warning lamp switch

and multiplugs to high/low ratio switch and

neutral sensor.

17. 03 Model Year onwards - If fitted: Connect

differential lock warning lamp switch multiplugs

to main harness.

18.Position cable tie and multiplug to transfer

gearbox bracket.

19.Connect high/low ratio selector cable to

selector lever and secure with clevis pin.

20.Position high/low ratio selector cable to

abutment bracket and secure with 'C' clip.

Page 644 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-47

Refit

1.Clean park lock components.

2.Lubricate and fit new 'O' ring to output shaft.

3.Position park lock gear on the output shaft.

4. Td5 models: Fit the spacer.

CAUTION: Ensure that spacer is fitted on

output shaft - Tdi Models only. If spacer is

omitted, park gear and speed sensor may

move out of position.

5.Position pivot pin, spring and ratchet.

6.Position parking pawl guide and guide plate,

tighten Torx screw to 10 Nm (8 lbf.ft).

7.Clean extension housing and gearbox case.

8.Position new gasket to gearbox case.

9.Position extension housing and tighten bolts to

25 Nm (18 lbf.ft).

10.Fit transfer gearbox.

+ TRANSFER BOX - LT230SE,

REPAIRS, Transfer box - Diesel.

+ TRANSFER BOX - LT230SE,

REPAIRS, Transfer box - V8.

11.Fill automatic gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Automatic gearbox.

Gasket - oil sump

$% 44.24.05

Remove

1.Raise vehicle on ramp.

2.Drain automatic gearbox oil.

+ MAINTENANCE, PROCEDURES,

Automatic gearbox.

3.Remove 6 bolts and spacers securing oil sump

to gearbox, remove sump and discard gasket.

Refit

1.Clean oil sump and mating face.

2.Fit new gasket to oil sump, position sump to

gearbox.

3.Position spacers and tighten bolts to 8 Nm (6

lbf. ft).

4.Fill automatic gearbox with oil.

+ MAINTENANCE, PROCEDURES,

Automatic gearbox.

5.Lower vehicle.

Page 646 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-49

Cooler - fluid - Td5

$% 44.24.10

Remove

1.Remove intercooler.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Intercooler.

2.Disconnect fluid temperature sensor multiplug.

3.Position absorbent cloth under each gearbox

cooler hose connection to collect spillage.

4.Push against coupling release ring and

disconnect both fluid hoses from cooler.

5.Remove screw and release cooler from

radiator.

6.Carefully remove cooler.7.Remove temperature sensor and discard

sealing washer.

Refit

1.Use new sealing washer and tighten

temperature sensor to 14 Nm (10 lbf.ft).

2.Fit cooler, engage with radiator and secure with

screw.

3.Connect temperature sensor multiplug.

4.Ensure connections are clean and fit hoses to

cooler.

5.Fit intercooler.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Intercooler.

6.Check and if necessary top up gearbox fluid.

Page 647 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-50 REPAIRS

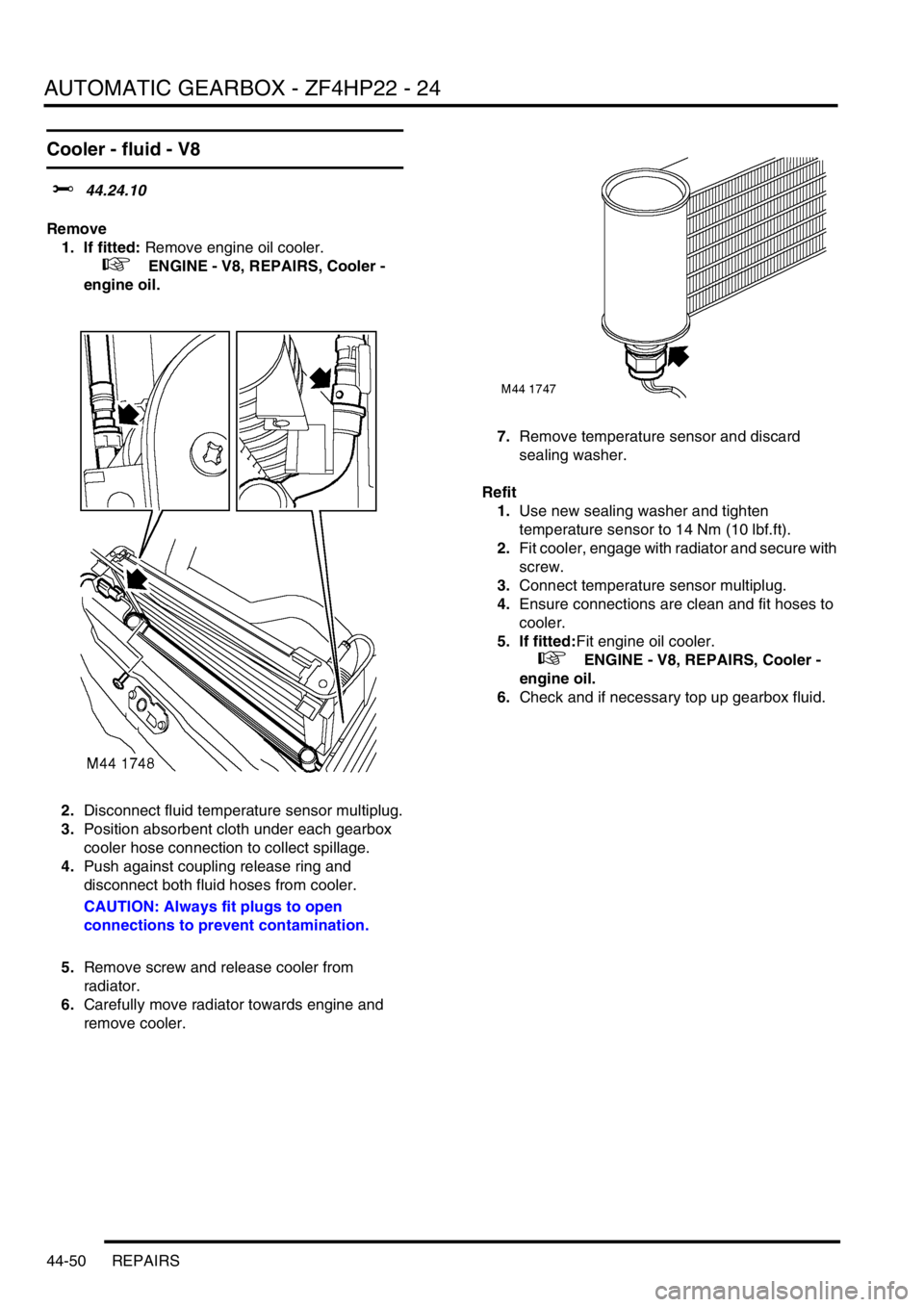

Cooler - fluid - V8

$% 44.24.10

Remove

1. If fitted: Remove engine oil cooler.

+ ENGINE - V8, REPAIRS, Cooler -

engine oil.

2.Disconnect fluid temperature sensor multiplug.

3.Position absorbent cloth under each gearbox

cooler hose connection to collect spillage.

4.Push against coupling release ring and

disconnect both fluid hoses from cooler.

CAUTION: Always fit plugs to open

connections to prevent contamination.

5.Remove screw and release cooler from

radiator.

6.Carefully move radiator towards engine and

remove cooler.7.Remove temperature sensor and discard

sealing washer.

Refit

1.Use new sealing washer and tighten

temperature sensor to 14 Nm (10 lbf.ft).

2.Fit cooler, engage with radiator and secure with

screw.

3.Connect temperature sensor multiplug.

4.Ensure connections are clean and fit hoses to

cooler.

5. If fitted:Fit engine oil cooler.

+ ENGINE - V8, REPAIRS, Cooler -

engine oil.

6.Check and if necessary top up gearbox fluid.

Page 648 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-51

Valve body assembly

$% 44.40.01

Remove

1.Remove gearbox oil filter.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Filter - oil.

2.Remove 2 bolts securing speed sensor

harness bracket to valve body.

3.Disconnect multiplug from gearbox housing.

4.Using a 30 mm socket, remove nut securing

multiplug connector block to gearbox housing. 5.Remove 6 long bolts securing valve body to

gearbox.

6.Remove 5 short bolts securing valve body to

gearbox.

Page 649 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-52 REPAIRS

7.Release speed sensor and remove valve body.

8.Remove and discard 'O' ring from multiplug

connector. Refit

1.Clean valve body and mating faces.

2.Fit new 'O' ring to multiplug connector block.

3.With assistance, position multiplug to gearbox

housing and tighten nut.

4.Align valve body to gearbox, ensure manual

valve is correctly located. Position speed

sensor retaining bracket, and tighten screws

to 8 Nm (6 lbf.ft).

5.Connect multiplug to gearbox connector.

6.Fit gearbox oil filter.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Filter - oil.

Page 654 of 1529

AUTOMATIC GEARBOX - ZF4HP22 - 24

REPAIRS 44-57

Harness - solenoid valves

$% 44.15.52

Remove

1.Remove valve body assembly.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Valve body assembly.

2.Release and remove clip securing pressure

regulator solenoid harness to valve body.

3.Disconnect multiplug from pressure regulator

solenoid valve.

4.Disconnect multiplugs from lock-up solenoid

valve, shift control solenoid valves MV 1 and

MV 2.

5.Release harness from 5 clips on valve body

and remove harness.6.Disconnect and remove speed sensor from

harness.

Refit

1.Connect speed sensor to harness multiplug.

2.Position harness to valve body.

3.Connect multiplugs to shift control solenoid

valves MV 1 and MV 2 and lock-up solenoid

valve.

4.Connect multiplug to pressure regulator

solenoid valve and secure solenoid valve

harness with clip to valve body.

5.Position and secure harness in clips on valve

body.

6.Fit valve body assembly.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Valve body assembly.

M44 1350

M44 1355

M44 1359

Page 668 of 1529

REAR AXLE

DESCRIPTION AND OPERATION 51-3

Wheel hub

Section through wheel hub

1'O' ring

2Hub bearing

3Hub flange

4Wheel stud5Stake nut

6ABS sensor ring

7Drive shaft

8Axle casing

Each wheel hub consists of a hub flange pressed into a hub bearing.

The hub flange is splined to accept the outboard end of the drive shaft, which is secured to the hub flange with a stake

nut. Five studs are installed in the hub flange for the wheel nuts, and a threaded hole is provided for the brake disc

securing screw.

The outer race of the hub bearing is bolted to the end of the axle casing. An 'O' ring seals the joint between the outer

race and the axle casing to prevent leakage of differential lubricating oil. The hub bearing is a sealed unit which

contains twin opposed roller bearings, pre-packed with grease during manufacture. A toothed ABS sensor ring is

integrated into the inner race of the hub bearing. An opening in the outer race of the hub bearing accommodates the

ABS sensor.

Drive shaft

Each drive shaft consists of a solid rod, splined at both ends.