ABS LAND ROVER DISCOVERY 2002 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 1067 of 1672

BRAKES

70-22 DESCRIPTION AND OPERATION

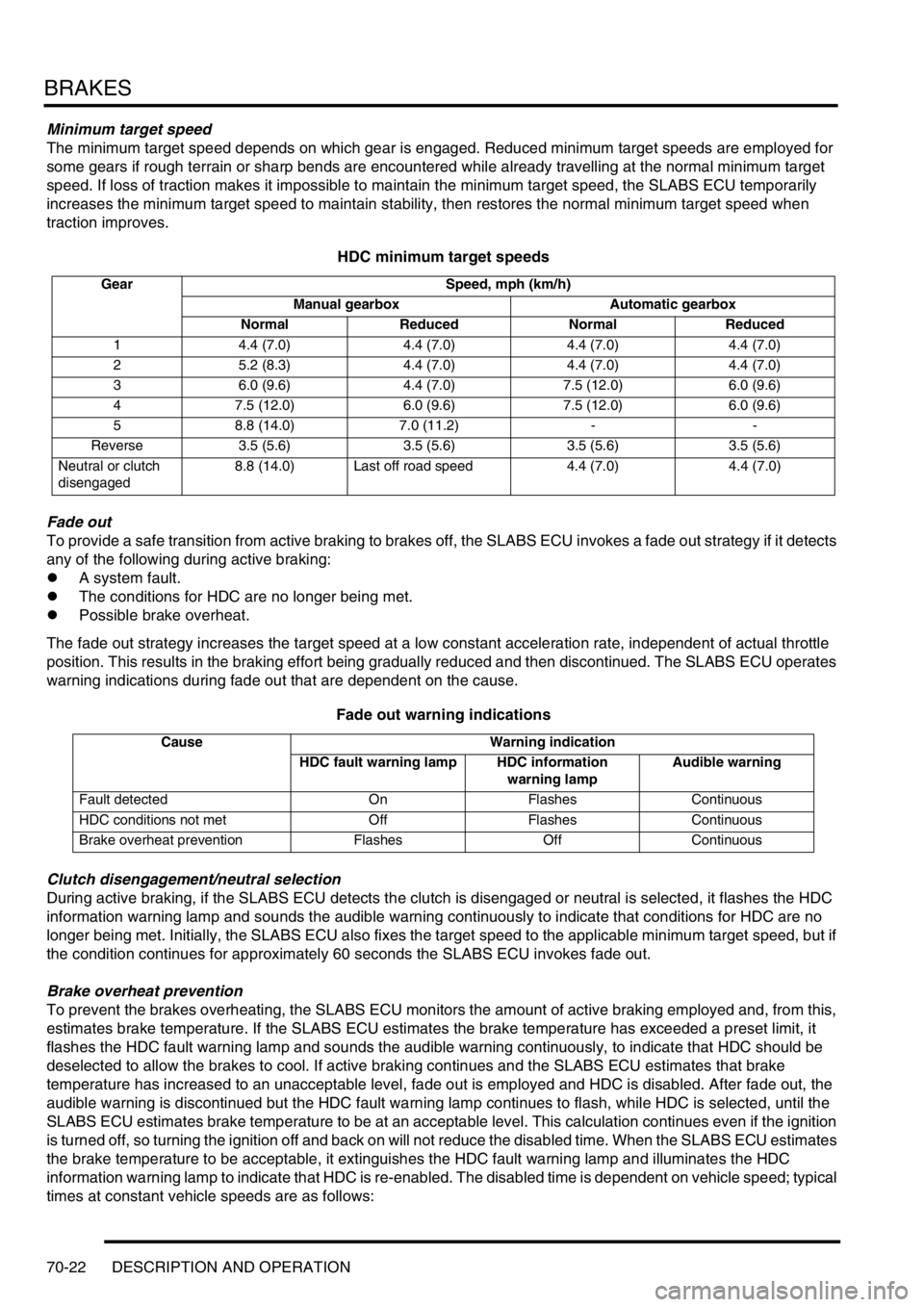

Minimum target speed

The minimum target speed depends on which gear is engaged. Reduced minimum target speeds are employed for

some gears if rough terrain or sharp bends are encountered while already travelling at the normal minimum target

speed. If loss of traction makes it impossible to maintain the minimum target speed, the SLABS ECU temporarily

increases the minimum target speed to maintain stability, then restores the normal minimum target speed when

traction improves.

HDC minimum target speeds

Fade out

To provide a safe transition from active braking to brakes off, the SLABS ECU invokes a fade out strategy if it detects

any of the following during active braking:

lA system fault.

lThe conditions for HDC are no longer being met.

lPossible brake overheat.

The fade out strategy increases the target speed at a low constant acceleration rate, independent of actual throttle

position. This results in the braking effort being gradually reduced and then discontinued. The SLABS ECU operates

warning indications during fade out that are dependent on the cause.

Fade out warning indications

Clutch disengagement/neutral selection

During active braking, if the SLABS ECU detects the clutch is disengaged or neutral is selected, it flashes the HDC

information warning lamp and sounds the audible warning continuously to indicate that conditions for HDC are no

longer being met. Initially, the SLABS ECU also fixes the target speed to the applicable minimum target speed, but if

the condition continues for approximately 60 seconds the SLABS ECU invokes fade out.

Brake overheat prevention

To prevent the brakes overheating, the SLABS ECU monitors the amount of active braking employed and, from this,

estimates brake temperature. If the SLABS ECU estimates the brake temperature has exceeded a preset limit, it

flashes the HDC fault warning lamp and sounds the audible warning continuously, to indicate that HDC should be

deselected to allow the brakes to cool. If active braking continues and the SLABS ECU estimates that brake

temperature has increased to an unacceptable level, fade out is employed and HDC is disabled. After fade out, the

audible warning is discontinued but the HDC fault warning lamp continues to flash, while HDC is selected, until the

SLABS ECU estimates brake temperature to be at an acceptable level. This calculation continues even if the ignition

is turned off, so turning the ignition off and back on will not reduce the disabled time. When the SLABS ECU estimates

the brake temperature to be acceptable, it extinguishes the HDC fault warning lamp and illuminates the HDC

information warning lamp to indicate that HDC is re-enabled. The disabled time is dependent on vehicle speed; typical

times at constant vehicle speeds are as follows:

Gear Speed, mph (km/h)

Manual gearbox Automatic gearbox

Normal Reduced Normal Reduced

1 4.4 (7.0) 4.4 (7.0) 4.4 (7.0) 4.4 (7.0)

2 5.2 (8.3) 4.4 (7.0) 4.4 (7.0) 4.4 (7.0)

3 6.0 (9.6) 4.4 (7.0) 7.5 (12.0) 6.0 (9.6)

4 7.5 (12.0) 6.0 (9.6) 7.5 (12.0) 6.0 (9.6)

5 8.8 (14.0) 7.0 (11.2) - -

Reverse 3.5 (5.6) 3.5 (5.6) 3.5 (5.6) 3.5 (5.6)

Neutral or clutch

disengaged8.8 (14.0) Last off road speed 4.4 (7.0) 4.4 (7.0)

Cause Warning indication

HDC fault warning lamp HDC information

warning lampAudible warning

Fault detected On Flashes Continuous

HDC conditions not met Off Flashes Continuous

Brake overheat prevention Flashes Off Continuous

Page 1068 of 1672

BRAKES

DESCRIPTION AND OPERATION 70-23

Typical disabled times

Diagnostics

While the ignition is on, the diagnostics function of the SLABS ECU monitors the system for faults. In addition, the

return pump is tested by pulsing it briefly immediately after the engine starts provided vehicle speed exceeded 4.4

mph (7 km/h) during the previous ignition cycle. If a fault exists in a warning lamp circuit, the lamp will not illuminate

during the lamp check at ignition on but, provided there are no other faults, the related function will otherwise be fully

operational. If a fault is detected during the power up, the SLABS ECU stores a related fault code in memory and

illuminates the appropriate fault warning lamps. If a fault is detected later in the drive cycle, the SLABS ECU also

sounds the audible warning three times.

Fault codes and diagnostic routines can be accessed by connecting Testbook to the vehicle's diagnostic connector

in the driver's footwell.

Warning lamp fault operation

After detecting a fault, the SLABS ECU selects an appropriate default strategy which, where possible, retains some

operational capability. A shuttle valve switch fault and throttle position signal fault are classified as permanent faults.

If a permanent fault is detected, the related warning lamp illumination and default strategies are automatically

employed in subsequent ignition cycles, even if the fault is intermittent, until the fault has been rectified and cleared

from memory. If a non permanent fault is detected, the related warning lamp illumination and default strategies will

only be employed in subsequent ignition cycles if the fault is still present.

After rectification of an ABS sensor fault, the ABS and ETC functions are disabled, and the ABS warning lamp remains

illuminated after the lamp check, until vehicle speed exceeds 9.4 mph (15 km/h) (to allow additional checks to be

performed).

Vehicle speed, mph (km/h) Time, minutes

1.3 (2) 40

12.5 (20) 33

15.6 (25) 17

25.0 (40) 9

31.3 (50) 6

Item Check Warning lamp

ABS Brake ETC HDC

fault

ABS sensors Resistance (to check status) On On On On

Brake lamps relay Open/Short circuit Off Off Off On

Engine data Sticking throttle, signal failure, data corruption Off Off On On

Inlet solenoid valves Open/Short circuit On On On On

Outlet solenoid valves Open/Short circuit On On On On

Reference earth Connection to earth On On On On

Return pump monitor Correct pump operation On On On On

Return pump relay Open/Short circuit On On On On

Shuttle valve switches Open/Short circuit On On On On

SLABS ECU Internal failure On On On On

Supply voltages Range (10 to 16 V) On On On On

Page 1069 of 1672

BRAKES

70-24 DESCRIPTION AND OPERATION

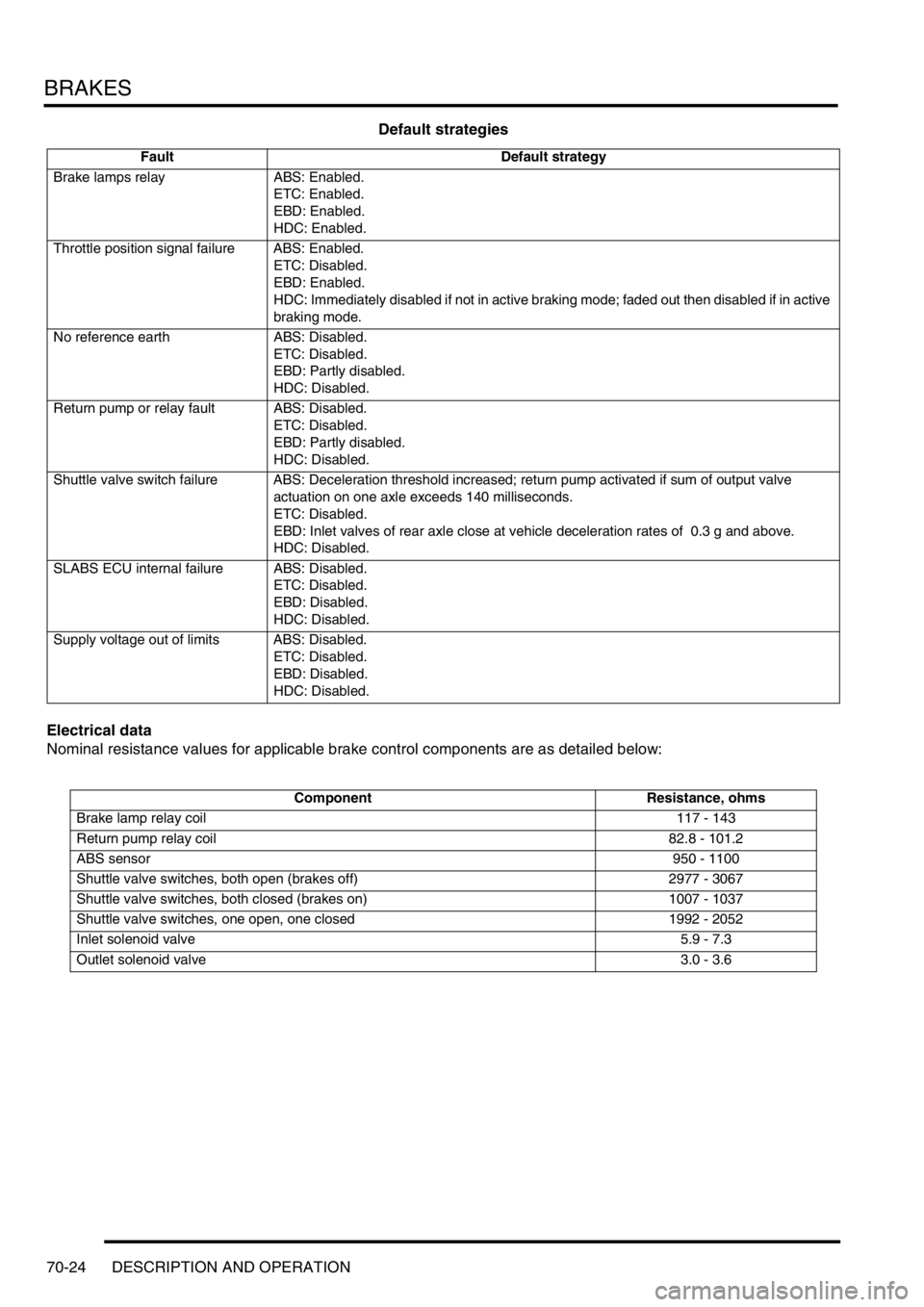

Default strategies

Electrical data

Nominal resistance values for applicable brake control components are as detailed below:

Fault Default strategy

Brake lamps relay ABS: Enabled.

ETC: Enabled.

EBD: Enabled.

HDC: Enabled.

Throttle position signal failure ABS: Enabled.

ETC: Disabled.

EBD: Enabled.

HDC: Immediately disabled if not in active braking mode; faded out then disabled if in active

braking mode.

No reference earth ABS: Disabled.

ETC: Disabled.

EBD: Partly disabled.

HDC: Disabled.

Return pump or relay fault ABS: Disabled.

ETC: Disabled.

EBD: Partly disabled.

HDC: Disabled.

Shuttle valve switch failure ABS: Deceleration threshold increased; return pump activated if sum of output valve

actuation on one axle exceeds 140 milliseconds.

ETC: Disabled.

EBD: Inlet valves of rear axle close at vehicle deceleration rates of 0.3 g and above.

HDC: Disabled.

SLABS ECU internal failure ABS: Disabled.

ETC: Disabled.

EBD: Disabled.

HDC: Disabled.

Supply voltage out of limits ABS: Disabled.

ETC: Disabled.

EBD: Disabled.

HDC: Disabled.

Component Resistance, ohms

Brake lamp relay coil117 - 143

Return pump relay coil82.8 - 101.2

ABS sensor950 - 1100

Shuttle valve switches, both open (brakes off) 2977 - 3067

Shuttle valve switches, both closed (brakes on) 1007 - 1037

Shuttle valve switches, one open, one closed 1992 - 2052

Inlet solenoid valve5.9 - 7.3

Outlet solenoid valve3.0 - 3.6

Page 1080 of 1672

BRAKES

REPAIRS 70-35

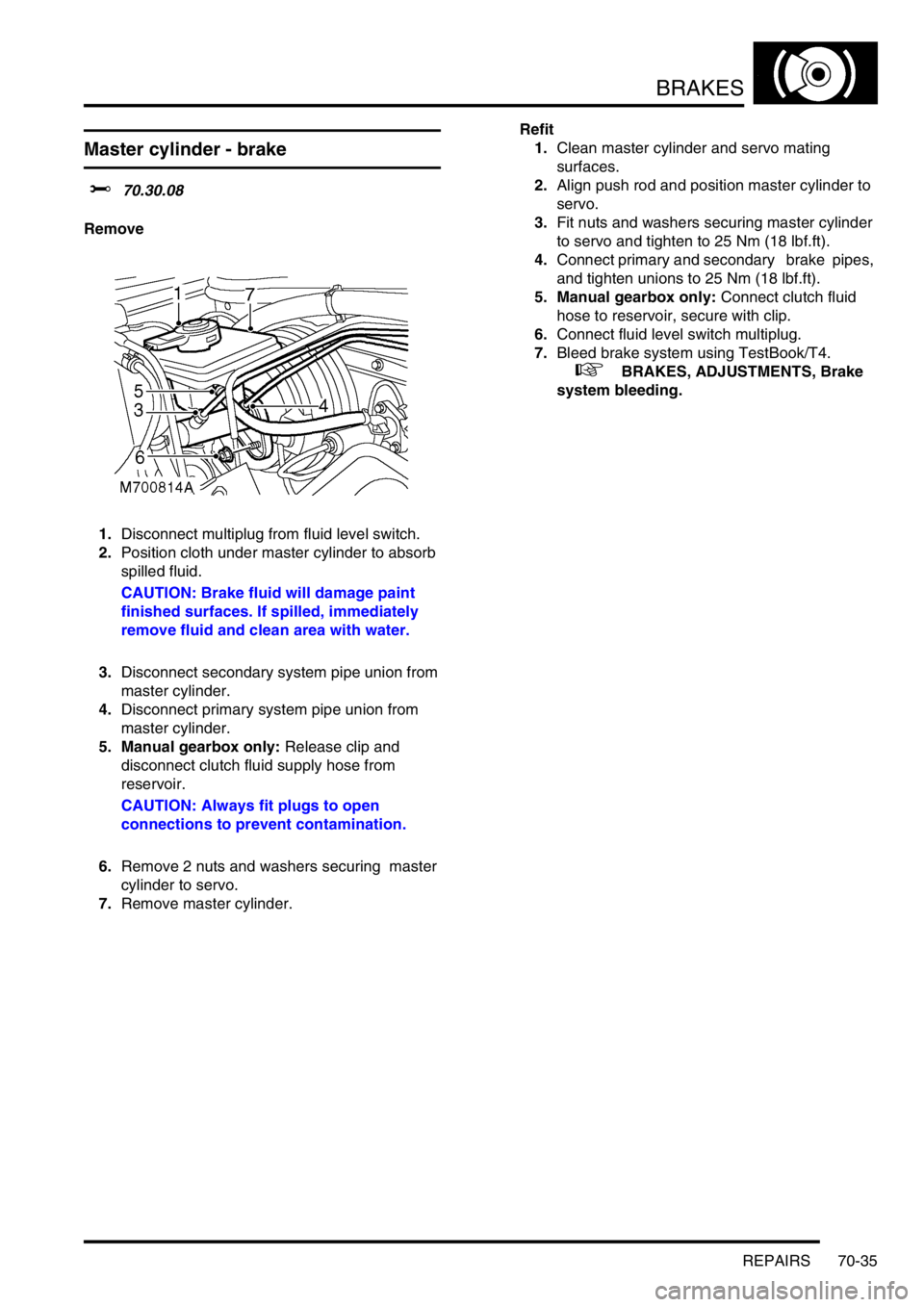

Master cylinder - brake

$% 70.30.08

Remove

1.Disconnect multiplug from fluid level switch.

2.Position cloth under master cylinder to absorb

spilled fluid.

CAUTION: Brake fluid will damage paint

finished surfaces. If spilled, immediately

remove fluid and clean area with water.

3.Disconnect secondary system pipe union from

master cylinder.

4.Disconnect primary system pipe union from

master cylinder.

5. Manual gearbox only: Release clip and

disconnect clutch fluid supply hose from

reservoir.

CAUTION: Always fit plugs to open

connections to prevent contamination.

6.Remove 2 nuts and washers securing master

cylinder to servo.

7.Remove master cylinder. Refit

1.Clean master cylinder and servo mating

surfaces.

2.Align push rod and position master cylinder to

servo.

3.Fit nuts and washers securing master cylinder

to servo and tighten to 25 Nm (18 lbf.ft).

4.Connect primary and secondary brake pipes,

and tighten unions to 25 Nm (18 lbf.ft).

5. Manual gearbox only: Connect clutch fluid

hose to reservoir, secure with clip.

6.Connect fluid level switch multiplug.

7.Bleed brake system using TestBook/T4.

+ BRAKES, ADJUSTMENTS, Brake

system bleeding.

Page 1090 of 1672

BRAKES

REPAIRS 70-45

Refit

1.Rotate disc by hand and scrape all scale and

rust from around edge of disc. Clean location

surfaces on caliper bracket.

2.Clean dust from brake parts using brake

cleaning fluid.

WARNING: Do not use compressed air to

clean brake components. Dust from friction

materials can be harmful if inhaled.

3.Fit brake pads to caliper carrier.

4.Position caliper housing to carrier, align flats on

guide pins with caliper housing.

5.Fit guide pin bolts and tighten to 30 Nm (22

lbf.ft).

6.Clean banjo bolt and fit new sealing washers.

7.Position hose to caliper and tighten banjo bolt

to 32 Nm (24 lbf.ft).

8.Remove clamp from brake hose.

9.Bleed brakes.

+ BRAKES, ADJUSTMENTS, Brake

system bleeding.

10.Fit road wheel(s) and tighten nuts to 140 Nm

(103 lbf.ft).

11.Remove stand(s) and lower vehicle.

ECU - Self levelling and anti locking

brakes (SLABS)

$% 70.65.01

Remove

1.Remove BCU.

+ BODY CONTROL UNIT, REPAIRS,

Body control unit (BCU).

2.Remove 5 multiplugs from SLABS ECU.

3.Remove multiplug from ACE ECU.

4.Remove lower nut and loosen upper nut

securing SLABS and ACE ECU bracket to

body.

5.Remove ECU's and bracket assembly.

Page 1091 of 1672

BRAKES

70-46 REPAIRS

6.Remove 4 nuts securing SLABS ECU and

remove ECU.

Refit

1.Fit new SLABS ECU to bracket and secure with

nuts.

2.Fit ECU's and bracket assembly to body and

secure with nuts.

3.Connect multiplugs to ACE ECU and SLABS

ECU.

4.Fit BCU.

+ BODY CONTROL UNIT, REPAIRS,

Body control unit (BCU).

5.Programme the new SLABS ECU using

TestBook.

Sensor – ABS – front

$% 70.65.30

ABS sensor is supplied fitted to wheel hub and

must not be removed.

Remove

1.Remove wheel hub.

+ FRONT SUSPENSION, REPAIRS,

Wheel hub.

Refit

1.Fit wheel hub.

+ FRONT SUSPENSION, REPAIRS,

Wheel hub.

Page 1092 of 1672

BRAKES

REPAIRS 70-47

Sensor – ABS – rear

$% 70.65.31

ABS sensor is supplied fitted to wheel hub and

must not be removed.

Remove

1.Remove wheel hub.

+ REAR SUSPENSION, REPAIRS,

Wheel hub.

Refit

1.Fit wheel hub.

+ REAR SUSPENSION, REPAIRS,

Wheel hub.

Modulator unit - ABS

$% 70.65.49

Remove

1.Position cloth under modulator to absorb fluid

spillage.

CAUTION: Brake fluid will damage paint

finished surfaces. If spilled, immediately

remove fluid and clean area with water.

2.Disconnect 3 multiplugs from ABS modulator.

3.Disconnect 2 inlet brake pipe unions from pump

side of modulator.

CAUTION: Always fit plugs to open

connections to prevent contamination.

4.Disconnect 4 outlet brake pipe unions from top

of modulator.

CAUTION: Always fit plugs to open

connections to prevent contamination.

5.Loosen 3 nuts securing modulator to mounting

bracket.

6.Release and remove modulator from mounting

bracket.

7.Remove 3 mounting rubbers from modulator.

Page 1093 of 1672

BRAKES

70-48 REPAIRS

Refit

1.Position mounting rubbers to modulator.

2.Position modulator to mounting bracket,

tighten nuts to 9 Nm (7 lbf.ft).

3.Clean brake pipe unions.

4.Connect brake pipe unions to modulator

ensuring pipes are connected to their correct

ports.

5.Tighten 13 mm unions to 22 Nm (16 lbf.ft) and

11 mm unions to 14 Nm (10 lbf.ft).

6.Connect multiplugs to modulator.

7.Bleed brakes.

+ BRAKES, ADJUSTMENTS, Brake

system bleeding.

8.To ensure correct operation, the ABS system

MUST be tested using TestBook.

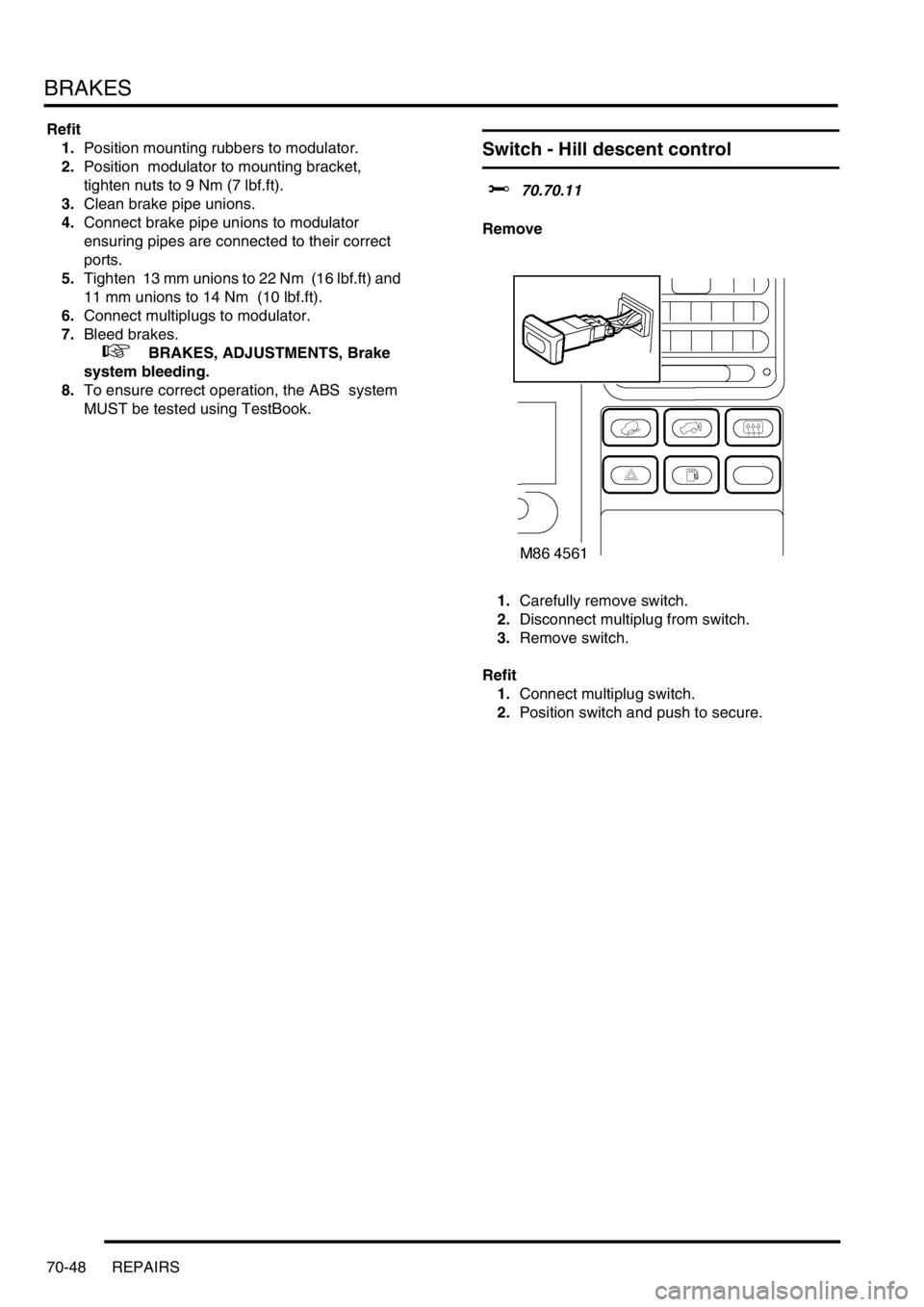

Switch - Hill descent control

$% 70.70.11

Remove

1.Carefully remove switch.

2.Disconnect multiplug from switch.

3.Remove switch.

Refit

1.Connect multiplug switch.

2.Position switch and push to secure.

Page 1276 of 1672

PANEL REPAIRS

REPAIRS 77-2-27

11.Fit headlamp.

+ LIGHTING, REPAIRS, Headlamp - up

to 03MY.

12. Diesel models: Fit gearbox fluid cooler.

13. Models with A/C: Fit condensor.

+ AIR CONDITIONING, REPAIRS,

Condenser.

14.Fit washer reservoir.

+ WIPERS AND WASHERS, REPAIRS,

Reservoir - washer - up to 03MY.

15.Connect leads/multiplug to alternator.

16.Connect battery leads, negative lead last.

Valance upper assembly - LH

In this procedure, the front wing, the valance outer

reinforcement and the bonnet alarm switch mounting

bracket are replaced in conjunction with the LH

valance upper assembly.

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect leads/multiplug from alternator.

3.Remove front wing.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front - up to 03MY.

4.Remove air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

5.Remove PAS/ACE reservoir.

6.Remove ABS modulator.

+ BRAKES, REPAIRS, Modulator unit

- ABS.

7.Remove brake pipes from valance.

8.Release harness from valance and position

aside.

9. Models with A/C: Depressurise A/C system

and remove pipes from valance.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery,

recycling and recharging.

Page 1277 of 1672

PANEL REPAIRS

77-2-28 REPAIRS

Repair

1.Remove existing panel(s), prepare panel joint

faces and install new panel(s) in accordance

with Panel Replacement Procedure. Punch or

drill holes in new panel for plug welding as

shown.

Refit

1. Models with A/C: Fit A/C pipes and recharge

A/C system.

+ AIR CONDITIONING, REFRIGERANT

RECOVERY, RECYCLING AND

RECHARGING, Refrigerant recovery,

recycling and recharging.

2.Fit harness to valance.

3.Fit brake pipes to valance.

4.Fit ABS modulator.

+ BRAKES, REPAIRS, Modulator unit

- ABS.

5.Fit PAS/ACE reservoir, refill fluids to correct

levelsand bleed ACE system.

+ FRONT SUSPENSION,

ADJUSTMENTS, ACE hydraulic system

bleeding.

+ CAPACITIES, FLUIDS AND

LUBRICANTS, Fluids.6.Fit air filter assembly.

+ ENGINE MANAGEMENT SYSTEM -

V8, REPAIRS, Air cleaner assembly.

+ ENGINE MANAGEMENT SYSTEM -

Td5, REPAIRS, Air filter assembly.

7.Fit front wing.

+ EXTERIOR FITTINGS, REPAIRS,

Wing - front - up to 03MY.

8.Connect leads/multiplug to alternator.

9.Connect battery leads, negative lead last.

M77 1743

M77 1690A