tow LAND ROVER DISCOVERY 2002 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 104 of 1672

LIFTING AND TOWING

08-3

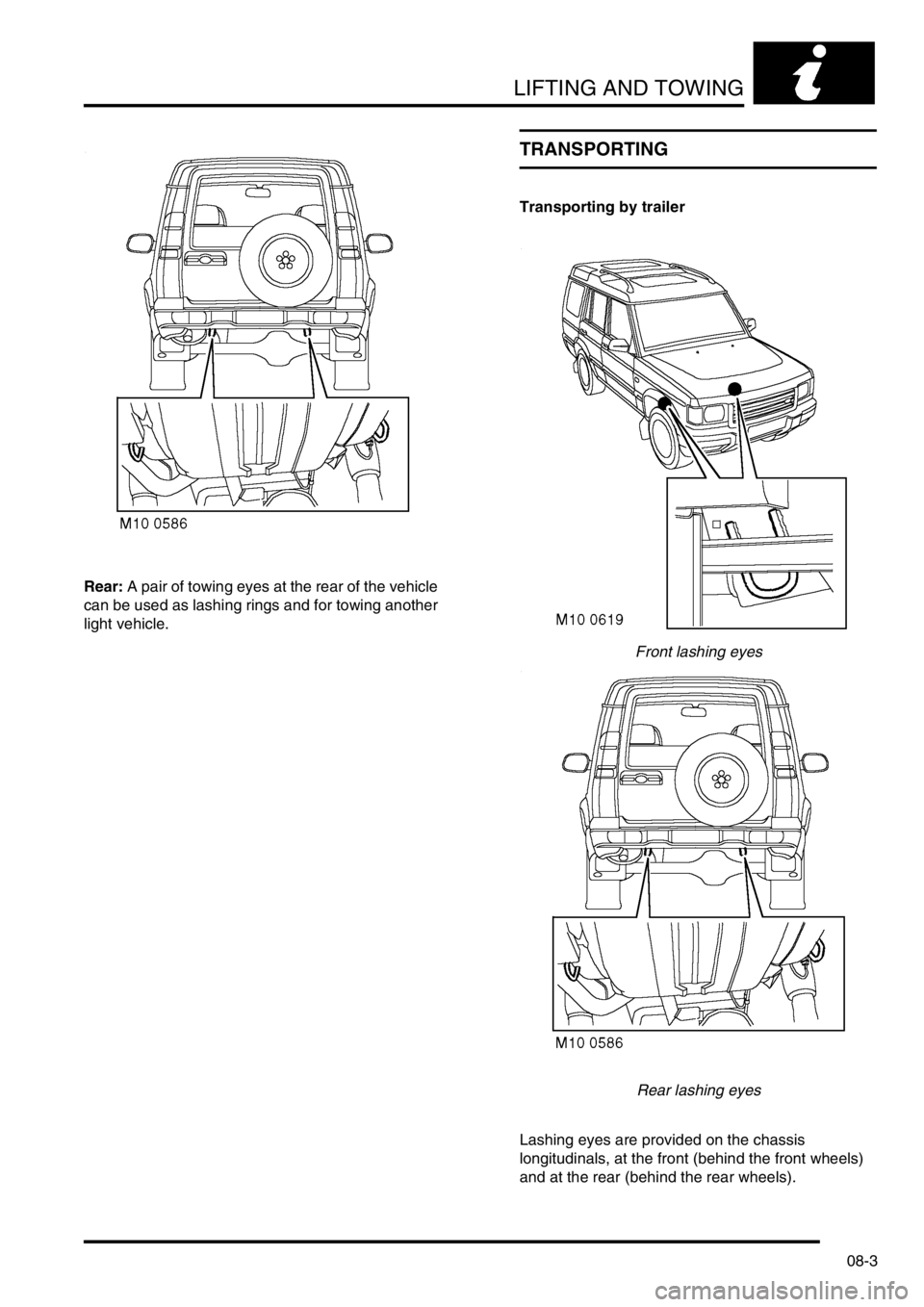

Rear: A pair of towing eyes at the rear of the vehicle

can be used as lashing rings and for towing another

light vehicle.

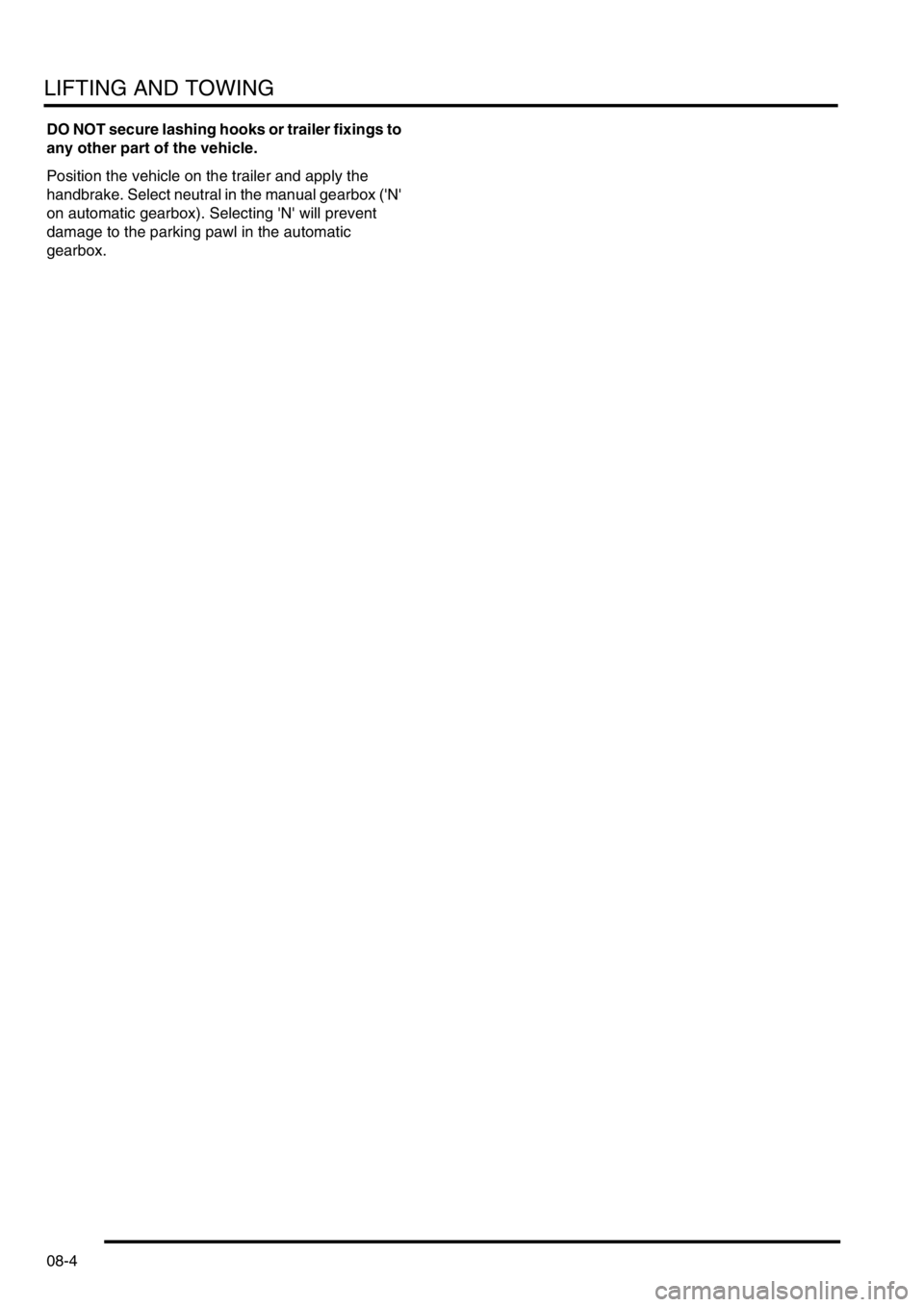

TRANSPORTING

Transporting by trailer

Front lashing eyes

Rear lashing eyes

Lashing eyes are provided on the chassis

longitudinals, at the front (behind the front wheels)

and at the rear (behind the rear wheels).

Page 105 of 1672

LIFTING AND TOWING

08-4

DO NOT secure lashing hooks or trailer fixings to

any other part of the vehicle.

Position the vehicle on the trailer and apply the

handbrake. Select neutral in the manual gearbox ('N'

on automatic gearbox). Selecting 'N' will prevent

damage to the parking pawl in the automatic

gearbox.

Page 136 of 1672

MAINTENANCE

PROCEDURES 10-27

2.Check security of fixings.

+ TORQUE WRENCH SETTINGS,

Front suspension.

+ TORQUE WRENCH SETTINGS, Rear

suspension.

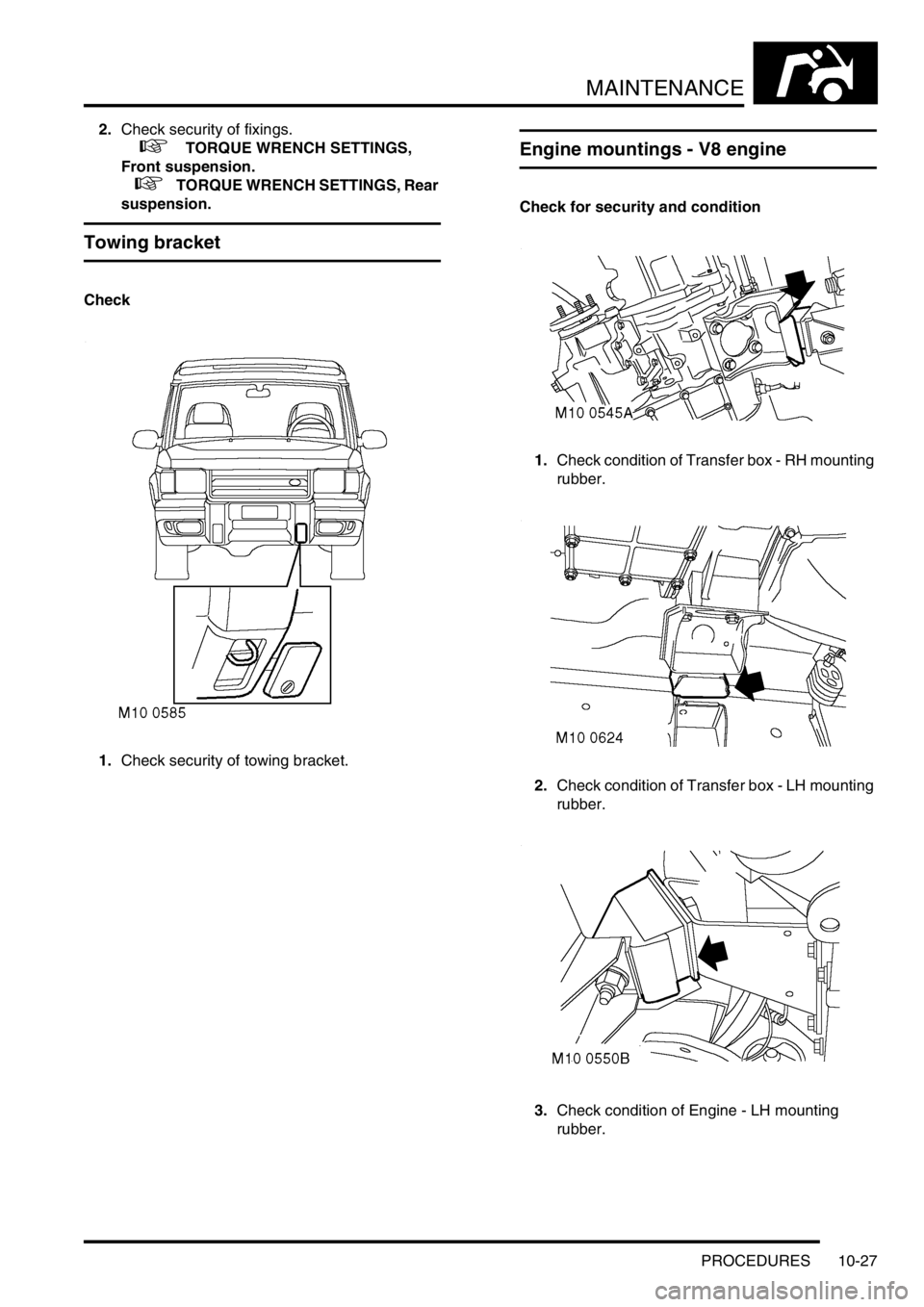

Towing bracket

Check

1.Check security of towing bracket.

Engine mountings - V8 engine

Check for security and condition

1.Check condition of Transfer box - RH mounting

rubber.

2.Check condition of Transfer box - LH mounting

rubber.

3.Check condition of Engine - LH mounting

rubber.

Page 173 of 1672

ENGINE - TD5

12-1-34 DESCRIPTION AND OPERATION

A tapping towards the right hand side of the cylinder head diverts oil supply from the cast-in groove down to a stub

pipe which attaches to a feed line to the vacuum pump. An hydraulic tensioner is located below the vacuum stub pipe

which receives oil through a small hole in the side of the tensioner body to force a plunger against a plastic faced

adjuster shoe for timing chain tensioning. Oil from the vacuum pump is returned to a port in the timing chain cover via

a short hose which connects to stub pipes at both ends using spring clips.

Page 218 of 1672

ENGINE - TD5

OVERHAUL 12-1-79

24.Compare figures obtained with camshaft

bearing clearance:

lCamshaft bearing clearance = 0.04 to 0.10

mm (0.002 to 0.004 in)

25.If any bearing clearance is found to exceed

figures given, repeat the above procedures

using a new camshaft. If, after repeating the

clearance check using a new camshaft the

clearances are still excessive, a new cylinder

head and camshaft carrier assembly must be

fitted.

26.Remove all traces of Plastigage using an oily

cloth, do not use a scraper.

27.On completion, discard camshaft carrier bolts.

28.Check free length of valve springs:

lFree length = 46.75 to 47.25 mm (1.84 to

1.86 in)

29. Replace valve springs as a set, if springs

are to be refitted, keep them in their fitted

order.

30.Clean carbon from valves, check valves for

burning, pitting or cracking; replace as

necessary.

31.Clean carbon from valve seat inserts, remove

all loose particles on completion.

32.Check valve seat inserts for pitting and burning.

It is not permissible to recut or replace valve

seat inserts.

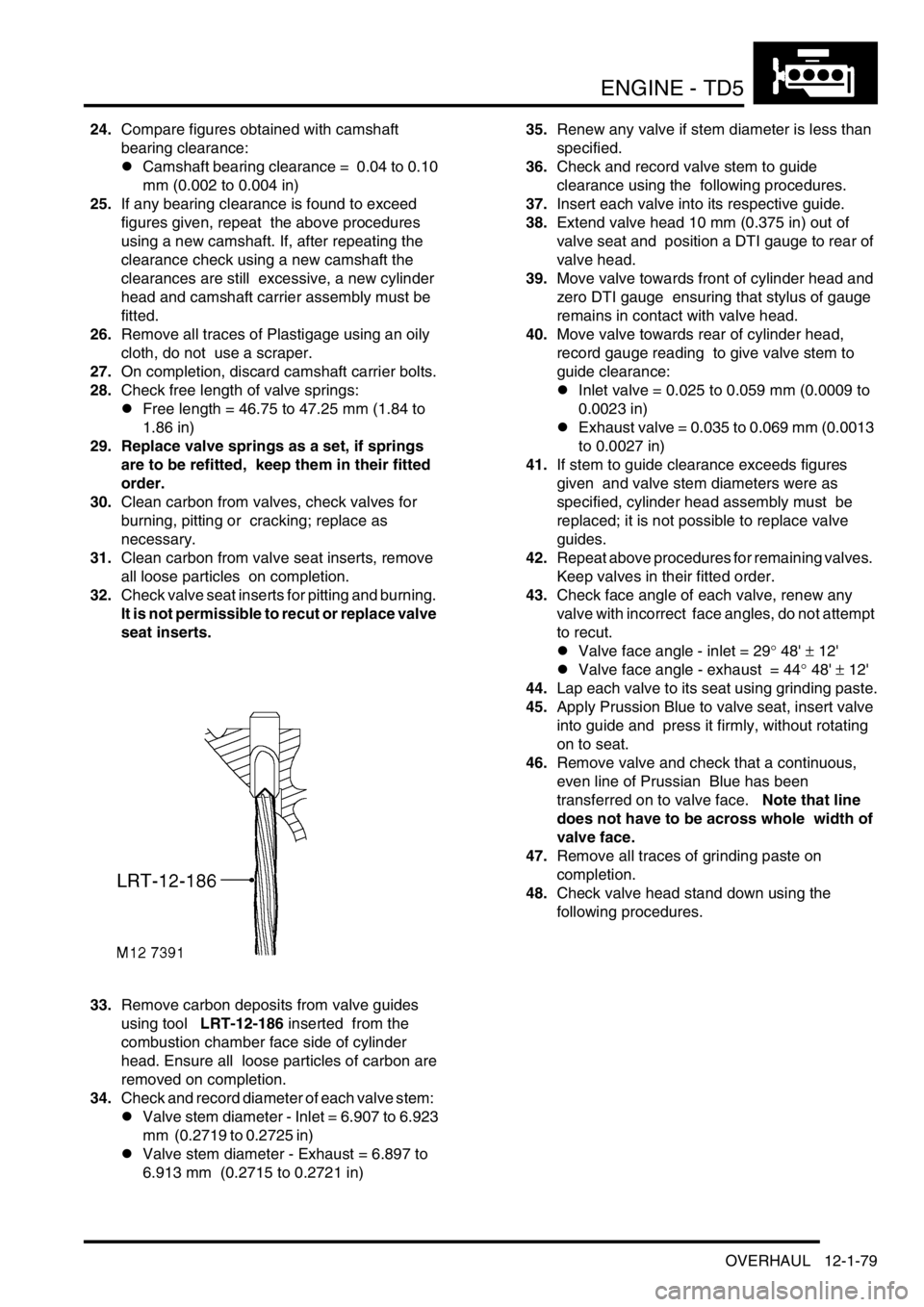

33.Remove carbon deposits from valve guides

using tool LRT-12-186 inserted from the

combustion chamber face side of cylinder

head. Ensure all loose particles of carbon are

removed on completion.

34.Check and record diameter of each valve stem:

lValve stem diameter - Inlet = 6.907 to 6.923

mm (0.2719 to 0.2725 in)

lValve stem diameter - Exhaust = 6.897 to

6.913 mm (0.2715 to 0.2721 in)35.Renew any valve if stem diameter is less than

specified.

36.Check and record valve stem to guide

clearance using the following procedures.

37.Insert each valve into its respective guide.

38.Extend valve head 10 mm (0.375 in) out of

valve seat and position a DTI gauge to rear of

valve head.

39.Move valve towards front of cylinder head and

zero DTI gauge ensuring that stylus of gauge

remains in contact with valve head.

40.Move valve towards rear of cylinder head,

record gauge reading to give valve stem to

guide clearance:

lInlet valve = 0.025 to 0.059 mm (0.0009 to

0.0023 in)

lExhaust valve = 0.035 to 0.069 mm (0.0013

to 0.0027 in)

41.If stem to guide clearance exceeds figures

given and valve stem diameters were as

specified, cylinder head assembly must be

replaced; it is not possible to replace valve

guides.

42.Repeat above procedures for remaining valves.

Keep valves in their fitted order.

43.Check face angle of each valve, renew any

valve with incorrect face angles, do not attempt

to recut.

lValve face angle - inlet = 29

° 48' ± 12'

lValve face angle - exhaust = 44

° 48' ± 12'

44.Lap each valve to its seat using grinding paste.

45.Apply Prussion Blue to valve seat, insert valve

into guide and press it firmly, without rotating

on to seat.

46.Remove valve and check that a continuous,

even line of Prussian Blue has been

transferred on to valve face. Note that line

does not have to be across whole width of

valve face.

47.Remove all traces of grinding paste on

completion.

48.Check valve head stand down using the

following procedures.

Page 233 of 1672

ENGINE - TD5

12-1-94 OVERHAUL

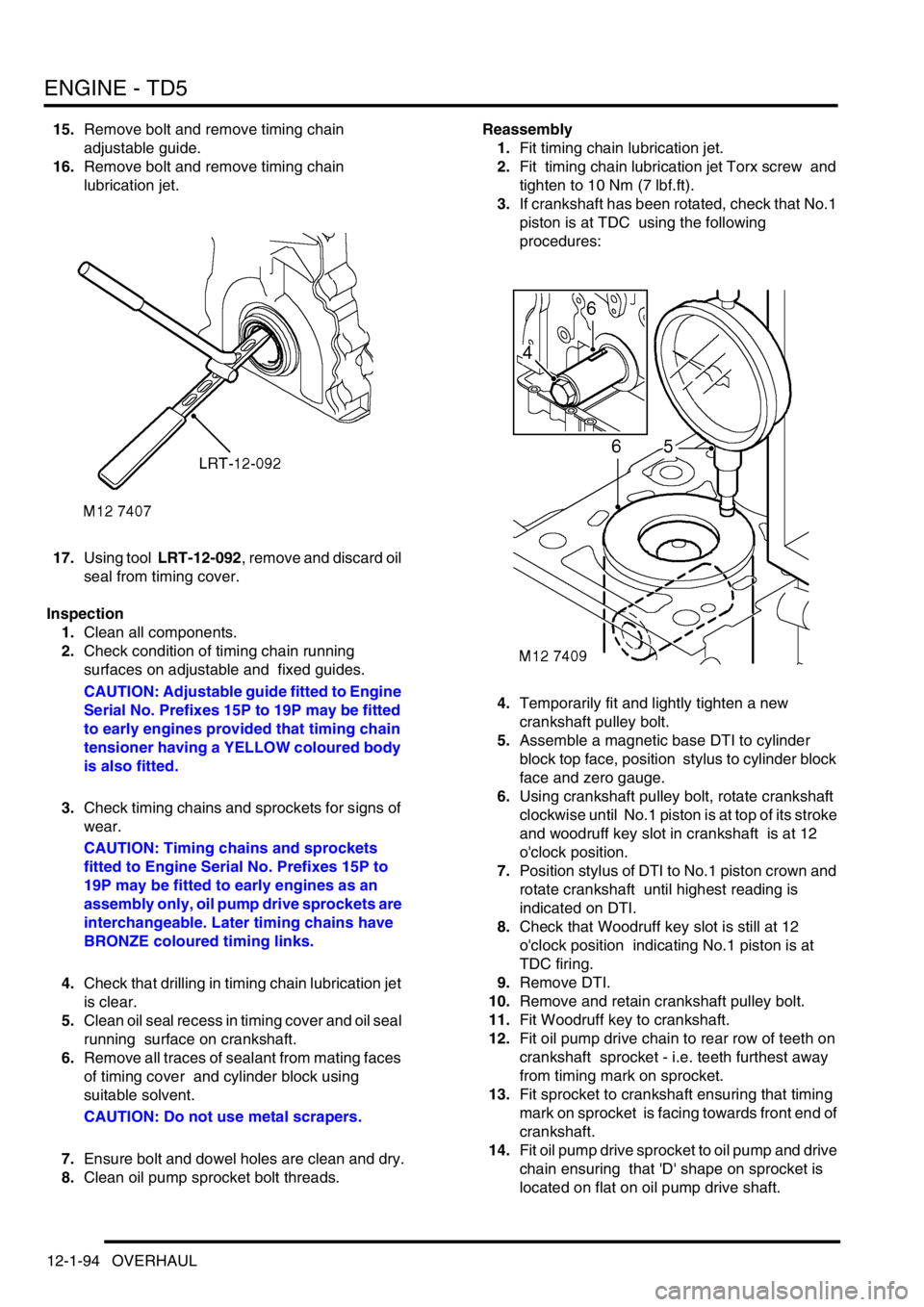

15.Remove bolt and remove timing chain

adjustable guide.

16.Remove bolt and remove timing chain

lubrication jet.

17.Using tool LRT-12-092, remove and discard oil

seal from timing cover.

Inspection

1.Clean all components.

2.Check condition of timing chain running

surfaces on adjustable and fixed guides.

CAUTION: Adjustable guide fitted to Engine

Serial No. Prefixes 15P to 19P may be fitted

to early engines provided that timing chain

tensioner having a YELLOW coloured body

is also fitted.

3.Check timing chains and sprockets for signs of

wear.

CAUTION: Timing chains and sprockets

fitted to Engine Serial No. Prefixes 15P to

19P may be fitted to early engines as an

assembly only, oil pump drive sprockets are

interchangeable. Later timing chains have

BRONZE coloured timing links.

4.Check that drilling in timing chain lubrication jet

is clear.

5.Clean oil seal recess in timing cover and oil seal

running surface on crankshaft.

6.Remove all traces of sealant from mating faces

of timing cover and cylinder block using

suitable solvent.

CAUTION: Do not use metal scrapers.

7.Ensure bolt and dowel holes are clean and dry.

8.Clean oil pump sprocket bolt threads.Reassembly

1.Fit timing chain lubrication jet.

2.Fit timing chain lubrication jet Torx screw and

tighten to 10 Nm (7 lbf.ft).

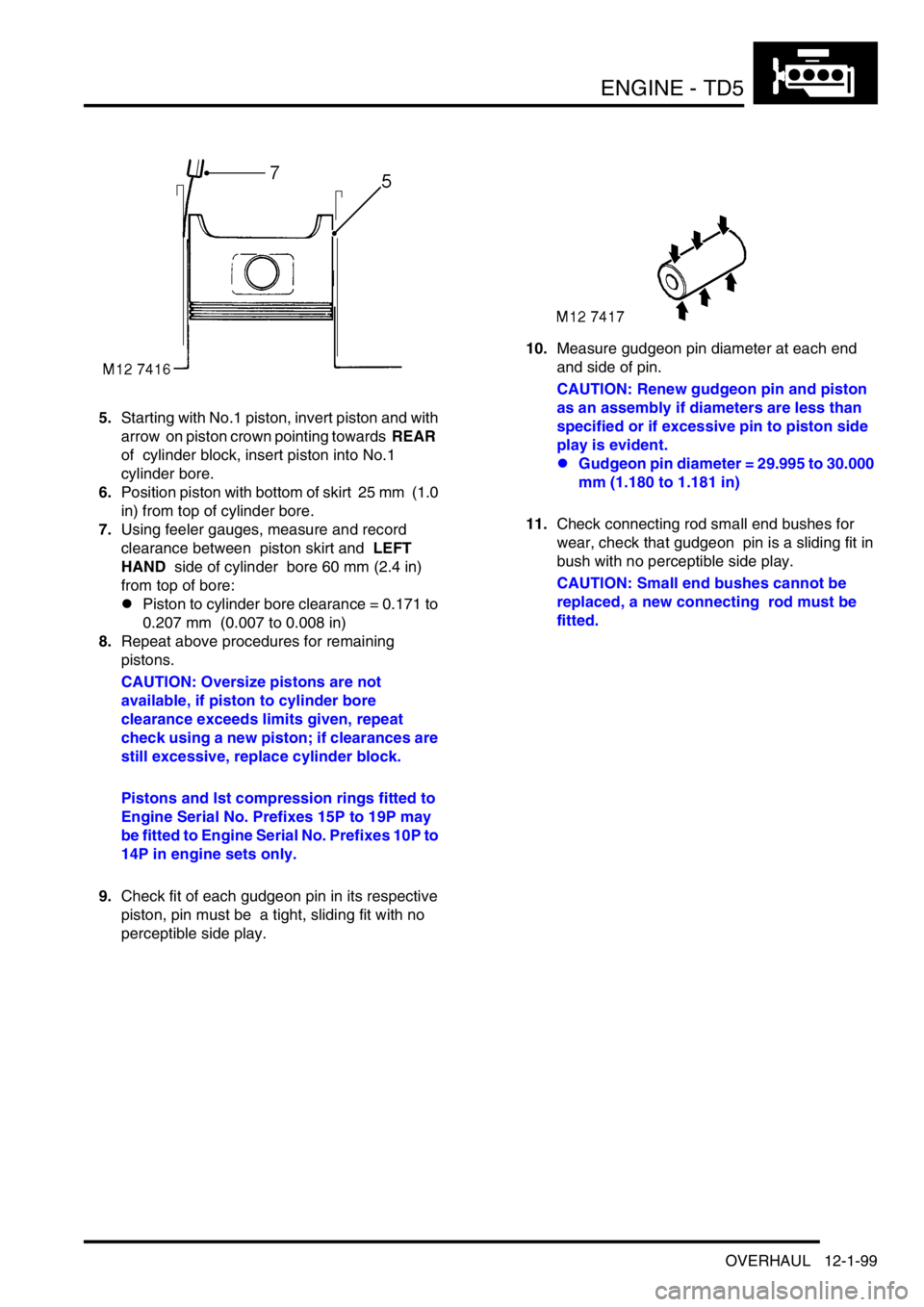

3.If crankshaft has been rotated, check that No.1

piston is at TDC using the following

procedures:

4.Temporarily fit and lightly tighten a new

crankshaft pulley bolt.

5.Assemble a magnetic base DTI to cylinder

block top face, position stylus to cylinder block

face and zero gauge.

6.Using crankshaft pulley bolt, rotate crankshaft

clockwise until No.1 piston is at top of its stroke

and woodruff key slot in crankshaft is at 12

o'clock position.

7.Position stylus of DTI to No.1 piston crown and

rotate crankshaft until highest reading is

indicated on DTI.

8.Check that Woodruff key slot is still at 12

o'clock position indicating No.1 piston is at

TDC firing.

9.Remove DTI.

10.Remove and retain crankshaft pulley bolt.

11.Fit Woodruff key to crankshaft.

12.Fit oil pump drive chain to rear row of teeth on

crankshaft sprocket - i.e. teeth furthest away

from timing mark on sprocket.

13.Fit sprocket to crankshaft ensuring that timing

mark on sprocket is facing towards front end of

crankshaft.

14.Fit oil pump drive sprocket to oil pump and drive

chain ensuring that 'D' shape on sprocket is

located on flat on oil pump drive shaft.

Page 238 of 1672

ENGINE - TD5

OVERHAUL 12-1-99

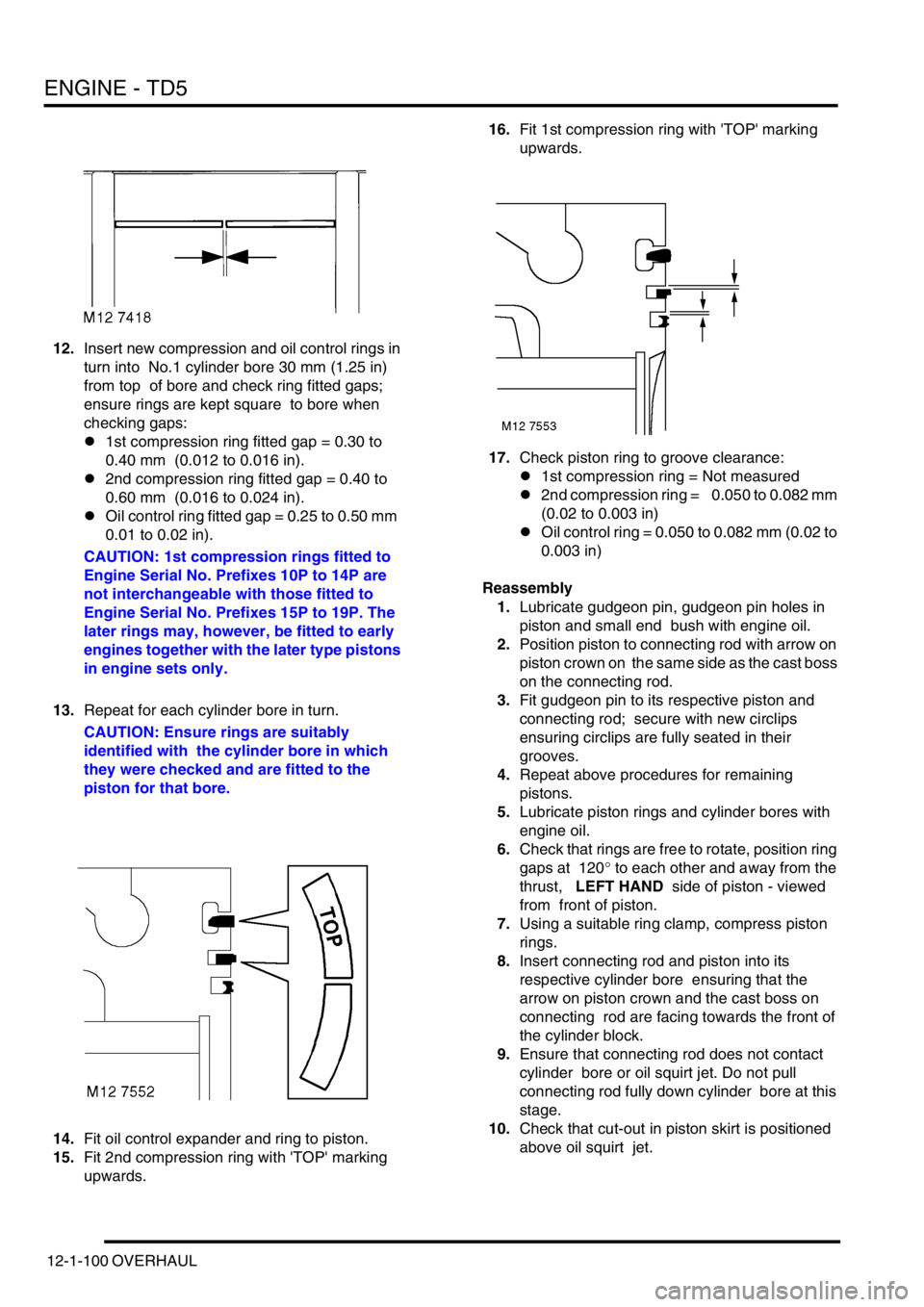

5.Starting with No.1 piston, invert piston and with

arrow on piston crown pointing towards REAR

of cylinder block, insert piston into No.1

cylinder bore.

6.Position piston with bottom of skirt 25 mm (1.0

in) from top of cylinder bore.

7.Using feeler gauges, measure and record

clearance between piston skirt and LEFT

HAND side of cylinder bore 60 mm (2.4 in)

from top of bore:

lPiston to cylinder bore clearance = 0.171 to

0.207 mm (0.007 to 0.008 in)

8.Repeat above procedures for remaining

pistons.

CAUTION: Oversize pistons are not

available, if piston to cylinder bore

clearance exceeds limits given, repeat

check using a new piston; if clearances are

still excessive, replace cylinder block.

Pistons and lst compression rings fitted to

Engine Serial No. Prefixes 15P to 19P may

be fitted to Engine Serial No. Prefixes 10P to

14P in engine sets only.

9.Check fit of each gudgeon pin in its respective

piston, pin must be a tight, sliding fit with no

perceptible side play.10.Measure gudgeon pin diameter at each end

and side of pin.

CAUTION: Renew gudgeon pin and piston

as an assembly if diameters are less than

specified or if excessive pin to piston side

play is evident.

lGudgeon pin diameter = 29.995 to 30.000

mm (1.180 to 1.181 in)

11.Check connecting rod small end bushes for

wear, check that gudgeon pin is a sliding fit in

bush with no perceptible side play.

CAUTION: Small end bushes cannot be

replaced, a new connecting rod must be

fitted.

Page 239 of 1672

ENGINE - TD5

12-1-100 OVERHAUL

12.Insert new compression and oil control rings in

turn into No.1 cylinder bore 30 mm (1.25 in)

from top of bore and check ring fitted gaps;

ensure rings are kept square to bore when

checking gaps:

l1st compression ring fitted gap = 0.30 to

0.40 mm (0.012 to 0.016 in).

l2nd compression ring fitted gap = 0.40 to

0.60 mm (0.016 to 0.024 in).

lOil control ring fitted gap = 0.25 to 0.50 mm

0.01 to 0.02 in).

CAUTION: 1st compression rings fitted to

Engine Serial No. Prefixes 10P to 14P are

not interchangeable with those fitted to

Engine Serial No. Prefixes 15P to 19P. The

later rings may, however, be fitted to early

engines together with the later type pistons

in engine sets only.

13.Repeat for each cylinder bore in turn.

CAUTION: Ensure rings are suitably

identified with the cylinder bore in which

they were checked and are fitted to the

piston for that bore.

14.Fit oil control expander and ring to piston.

15.Fit 2nd compression ring with 'TOP' marking

upwards. 16.Fit 1st compression ring with 'TOP' marking

upwards.

17.Check piston ring to groove clearance:

l1st compression ring = Not measured

l2nd compression ring = 0.050 to 0.082 mm

(0.02 to 0.003 in)

lOil control ring = 0.050 to 0.082 mm (0.02 to

0.003 in)

Reassembly

1.Lubricate gudgeon pin, gudgeon pin holes in

piston and small end bush with engine oil.

2.Position piston to connecting rod with arrow on

piston crown on the same side as the cast boss

on the connecting rod.

3.Fit gudgeon pin to its respective piston and

connecting rod; secure with new circlips

ensuring circlips are fully seated in their

grooves.

4.Repeat above procedures for remaining

pistons.

5.Lubricate piston rings and cylinder bores with

engine oil.

6.Check that rings are free to rotate, position ring

gaps at 120

° to each other and away from the

thrust, LEFT HAND side of piston - viewed

from front of piston.

7.Using a suitable ring clamp, compress piston

rings.

8.Insert connecting rod and piston into its

respective cylinder bore ensuring that the

arrow on piston crown and the cast boss on

connecting rod are facing towards the front of

the cylinder block.

9.Ensure that connecting rod does not contact

cylinder bore or oil squirt jet. Do not pull

connecting rod fully down cylinder bore at this

stage.

10.Check that cut-out in piston skirt is positioned

above oil squirt jet.

Page 275 of 1672

ENGINE - V8

12-2-32 REPAIRS

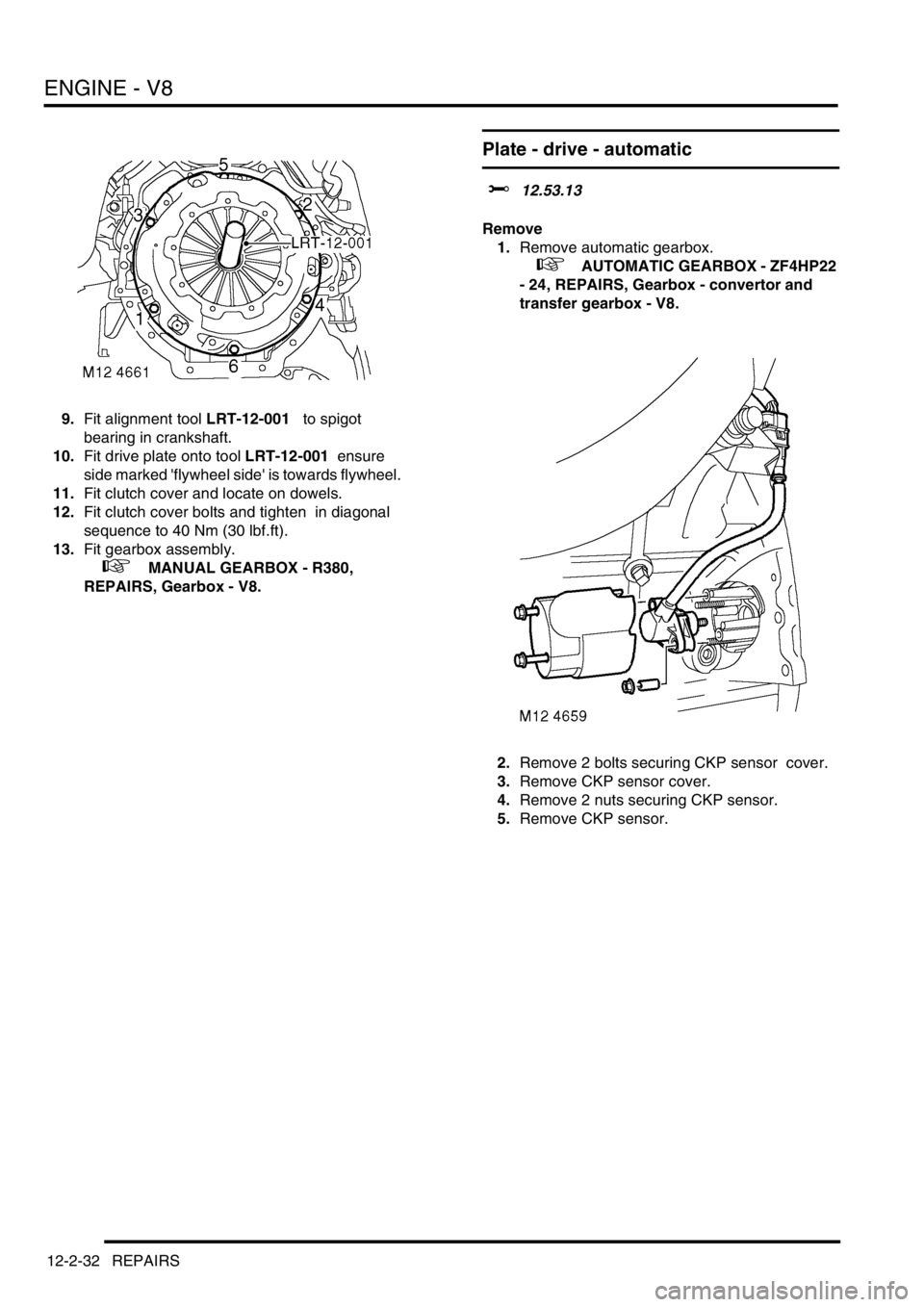

9.Fit alignment tool LRT-12-001 to spigot

bearing in crankshaft.

10.Fit drive plate onto tool LRT-12-001 ensure

side marked 'flywheel side' is towards flywheel.

11.Fit clutch cover and locate on dowels.

12.Fit clutch cover bolts and tighten in diagonal

sequence to 40 Nm (30 lbf.ft).

13.Fit gearbox assembly.

+ MANUAL GEARBOX - R380,

REPAIRS, Gearbox - V8.

Plate - drive - automatic

$% 12.53.13

Remove

1.Remove automatic gearbox.

+ AUTOMATIC GEARBOX - ZF4HP22

- 24, REPAIRS, Gearbox - convertor and

transfer gearbox - V8.

2.Remove 2 bolts securing CKP sensor cover.

3.Remove CKP sensor cover.

4.Remove 2 nuts securing CKP sensor.

5.Remove CKP sensor.

Page 283 of 1672

ENGINE - V8

12-2-40 REPAIRS

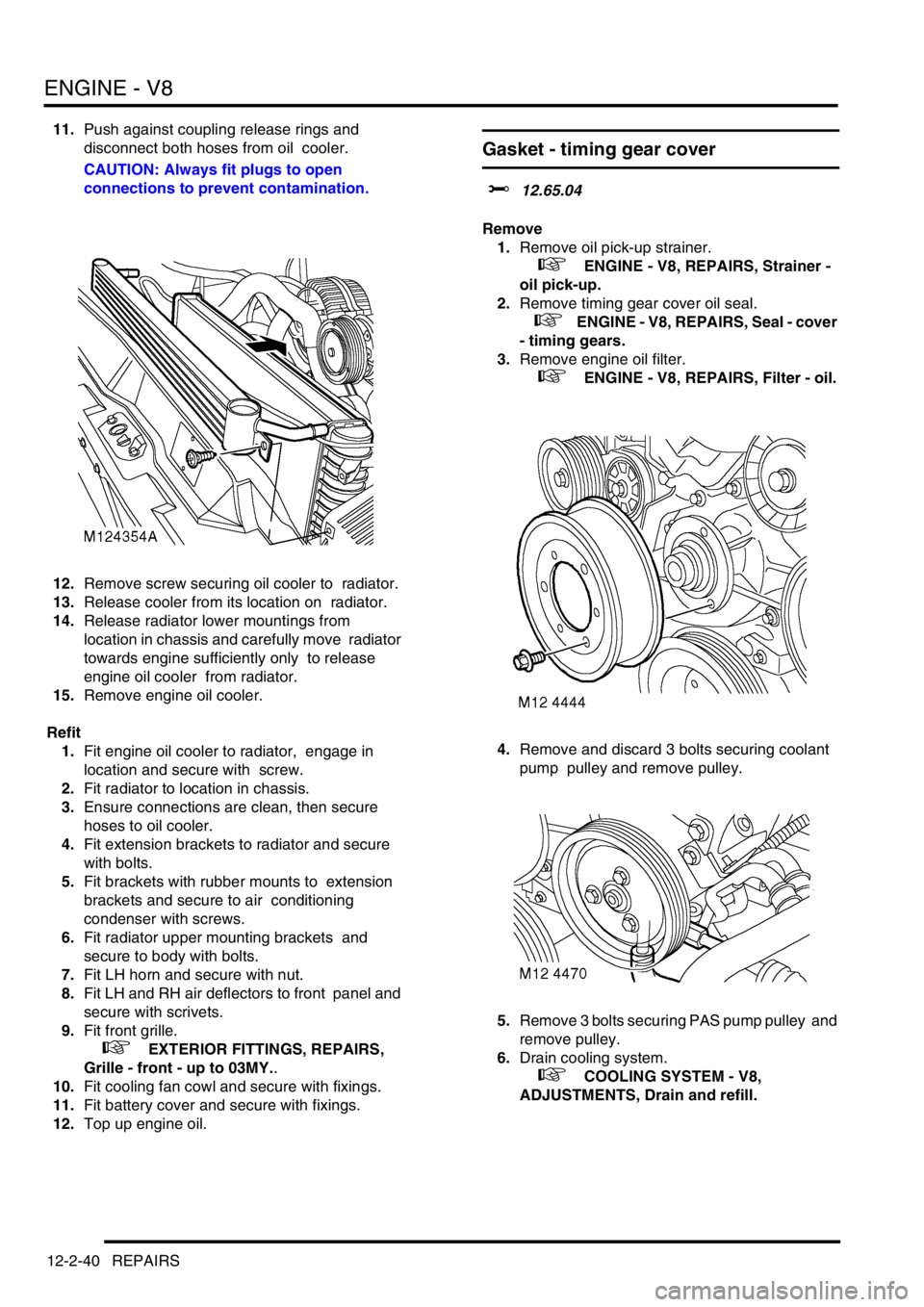

11.Push against coupling release rings and

disconnect both hoses from oil cooler.

CAUTION: Always fit plugs to open

connections to prevent contamination.

12.Remove screw securing oil cooler to radiator.

13.Release cooler from its location on radiator.

14.Release radiator lower mountings from

location in chassis and carefully move radiator

towards engine sufficiently only to release

engine oil cooler from radiator.

15.Remove engine oil cooler.

Refit

1.Fit engine oil cooler to radiator, engage in

location and secure with screw.

2.Fit radiator to location in chassis.

3.Ensure connections are clean, then secure

hoses to oil cooler.

4.Fit extension brackets to radiator and secure

with bolts.

5.Fit brackets with rubber mounts to extension

brackets and secure to air conditioning

condenser with screws.

6.Fit radiator upper mounting brackets and

secure to body with bolts.

7.Fit LH horn and secure with nut.

8.Fit LH and RH air deflectors to front panel and

secure with scrivets.

9.Fit front grille.

+ EXTERIOR FITTINGS, REPAIRS,

Grille - front - up to 03MY..

10.Fit cooling fan cowl and secure with fixings.

11.Fit battery cover and secure with fixings.

12.Top up engine oil.

Gasket - timing gear cover

$% 12.65.04

Remove

1.Remove oil pick-up strainer.

+ ENGINE - V8, REPAIRS, Strainer -

oil pick-up.

2.Remove timing gear cover oil seal.

+ ENGINE - V8, REPAIRS, Seal - cover

- timing gears.

3.Remove engine oil filter.

+ ENGINE - V8, REPAIRS, Filter - oil.

4.Remove and discard 3 bolts securing coolant

pump pulley and remove pulley.

5.Remove 3 bolts securing PAS pump pulley and

remove pulley.

6.Drain cooling system.

+ COOLING SYSTEM - V8,

ADJUSTMENTS, Drain and refill.