check engine LAND ROVER DISCOVERY 2002 Service Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 241 of 1672

ENGINE - TD5

12-1-102 OVERHAUL

Crankshaft

$% 12.21.33.01

Disassembly

1.Remove timing chain and sprockets.

+ ENGINE - Td5, OVERHAUL, Timing

chain and sprockets.

2.Remove crankshaft rear oil seal.

+ ENGINE - Td5, OVERHAUL, Seal -

crankshaft - rear - manual models.

3.Remove connecting rod bearings.

+ ENGINE - Td5, OVERHAUL,

Bearings - connecting rods.

4.Check that cylinder reference number is on

each main bearing cap and make alignment

marks between each main bearing cap and

cylinder block.

5.Starting at No.3 main bearing cap and working

outwards, progressively loosen, then remove 2

bolts securing each cap. Discard main bearing

cap bolts. 6.Fit 2 slave bolts into main bearing cap in turn

and ease bearing caps from cylinder block.

7.Remove and discard plain bearing shells from

each main bearing cap.

8.Using assistance, remove crankshaft.

9.Remove and discard grooved main bearing

shells and 2 thrust washers from cylinder

block.

10.Remove Torx screw securing each oil squirt jet

to cylinder block, remove squirt jets.

11.Clean main bearing shell and thrust washer

locations in cylinder block, ensure bolt holes

are clean and dry.

12.Clean main bearing caps.

13.Clean crankshaft bearing journals, check

oilways are clear.

14.Ensure drillings in oil squirt jets are clear.

Page 242 of 1672

ENGINE - TD5

OVERHAUL 12-1-103

15.Check core plugs in cylinder block for corrosion

or signs of leakage, seal replacement plugs

with Loctite 243.

Crankshaft - Inspection

1.Check crankshaft main and big-end bearings

for scoring, wear and ovality, make 3 checks at

120

° intervals in centre of journals.

lMain bearings = 62.0 mm

± 0.013 mm

(2.441 in

± 0.001 in).

lBig-end bearings = 54.000 mm

± 0.01 mm

(2.125 in

± 0.0004 in).

2. Crankshafts may not be reground, only one

size of main and big-end bearing shell is

available and if journals are found to be

scored, oval or worn, crankshaft must be

replaced. Main and big-end bearing shells

and thrust washers must be replaced

whenever they are removed.

3.Check crankshaft spigot bush for wear, replace

if necessary using the following procedures:

4.Secure crankshaft in a suitably padded vice.

5.Tap a thread in spigot bush to accommodate a

suitable impulse extractor.

6.Fit impulse extractor to spigot bush.

7.Remove spigot bush.

8.Clean spigot bush recess in crankshaft.

9.Fit new spigot bush to crankshaft using a

suitable mandrel. Reassembly

1.Fit oil squirt jets, fit Torx screws and tighten to

8 Nm (6 lbf.ft).

2.Lubricate new, grooved, main bearing shells

with engine oil and fit to cylinder block.

3.Lubricate new thrust washers with engine oil

and fit, grooved side facing outward, to recess

in each side of No.3 main bearing in cylinder

block.

4.Lubricate crankshaft journals with engine oil

and using assistance, position crankshaft in

cylinder block.

5.Lubricate new, plain, main bearing shells with

engine oil and fit to main bearing caps.

6.Fit main bearing caps in their original fitted

positions ensuring reference marks are

aligned.

7.Fit and lightly tighten new main bearing cap

bolts. Do not lubricate bolt threads.

8.Starting with No.3 main bearing cap and

working outwards, tighten main bearing cap

bolts to:

lStage 1 - 33 Nm (24 lbf.ft)

lStage 2 - Further 90

°

CAUTION: Do not carry out stages 1 and

2 in one operation.

9.Check that crankshaft rotates smoothly.

10. Attach a magnetic base DTI to front of cylinder

block with stylus of gauge on end of crankshaft.

Page 254 of 1672

ENGINE - V8

ADJUSTMENTS 12-2-11

ADJUST ME NTS

Engine oil pressure check

$% 12.90.09.01

Check

1.Remove oil pressure switch.

+ ENGINE - V8, REPAIRS, Switch - oil

pressure.

2.Connect pressure check kit LRT-12-052C

adaptor and gauge to oil pressure switch

position on timing gear cover.

3.Check and if necessary top up engine oil.

4.Run engine at idle speed and check that oil

pressure is within limits given.

+ GENERAL DATA, Engine - V8.

5.Switch off ignition.

6.Remove pressure check kit LRT-12-052C.

7.Clean oil spillage.

8.Fit oil pressure switch.

+ ENGINE - V8, REPAIRS, Switch - oil

pressure.

Adjust

1.If engine oil pressure is below figures given,

check condition of oil pump and/or main and

big end bearings.

Page 258 of 1672

ENGINE - V8

REPAIRS 12-2-15

10.Remove cylinder head.

CAUTION: Support both ends of cylinder

head on blocks of wood.

11.Remove cylinder head gasket.

Refit

1.Clean mating faces of cylinder block and head

using suitable gasket removal spray and a

plastic scraper, ensure that bolt holes in block

are clean and dry. Clean mating faces of

cylinder head and exhaust manifold.

CAUTION: Do not use a metal scraper or

machined surfaces may be damaged.

2.Check head and block faces for warping and

pitting. If out of specification, renew head.

3.Fit cylinder head gasket with the word 'TOP'

uppermost.

CAUTION: Gaskets must be fitted dry.

4.Carefully fit cylinder head and locate on

dowels.

5.Lightly lubricate new cylinder head bolt threads

with clean engine oil. 6.Noting that bolts 1, 3 and 5 are longer than the

remainder, fit cylinder head bolts and tighten in

the sequence shown to 20 Nm (15 lbf.ft) then

90

° , and finally a further 90° .

CAUTION: Do not tighten bolts 180

° in one

operation.

7. Models with SAI: Fit new air injection adapters

and tighten to 33 Nm (24 lbf.ft).

8.Clean push rods.

9.Lubricate ends of push rods with clean engine

oil.

10.Fit push rods in their removed order.

11.Clean bases of rocker pillars and mating faces

on cylinder head.

12.Clean contact surfaces on rockers, valves and

push rods.

13.Lubricate contact surfaces and rocker shaft

with clean engine oil.

14.Fit rocker shaft assembly and engage push

rods.

15.Fit rocker shaft bolts and progressively tighten

to 40 Nm (30 lbf.ft).

16.Using new gaskets, position exhaust manifold

to cylinder head, fit bolts and using sequence

shown, tighten initially to 15 Nm (11 lbf.ft), then

finally to 36 Nm (28 lbf.ft).

Page 261 of 1672

ENGINE - V8

12-2-18 REPAIRS

Refit

1.Clean mating faces of cylinder block and head

using suitable gasket removal spray and a

plastic scraper, ensure that bolt holes in block

are clean and dry. Clean mating faces of

cylinder head and exhaust manifold.

CAUTION: Do not use a metal scraper or

machined surfaces may be damaged.

2.Check head and block faces for warping and

pitting. If out of specification, renew head.

3.Fit cylinder head gasket with the word 'TOP'

uppermost.

CAUTION: Gaskets must be fitted dry.

4.Carefully fit cylinder head and locate on

dowels.

5.Lightly lubricate new cylinder head bolt threads

with clean engine oil.

6.Noting that bolts 1, 3 and 5 are longer than the

remainder, fit bolts and tighten in the sequence

shown to 20 Nm (15 lbf.ft) then 90

°, and finally

a further 90

°.

CAUTION: Do not tighten bolts 180

° in one

operation.

7. Models with SAI: Fit new air injection adapters

and tighten to 33 Nm (24 lbf.ft).

8.Clean push rods.

9.Lubricate ends of push rods with clean engine

oil.

10.Fit push rods in their removed order.

11.Clean bases of rocker pillars and mating faces

on cylinder head.

12.Clean contact surfaces on rockers, valves and

push rods.

13.Lubricate contact surfaces and rocker shaft

with clean engine oil.

14.Fit rocker shaft assembly and engage push

rods.

15.Fit rocker shaft bolts and progressively tighten

to 40 Nm (30 lbf.ft). 16.Position alternator mounting bracket, fit bolts

and tighten to 40 Nm (30 lbf.ft).

17.Position auxiliary drive belt tensioner, fit bolt

and tighten to 45 Nm (33 lbf.ft).

18.Connect ht leads to spark plugs in their fitted

order.

19. Using new gaskets, fit exhaust manifold to

cylinder head. Fit bolts and using sequence

shown, tighten initially to 15 Nm (11 lbf.ft), then

finally tighten to 36 Nm (28 lbf.ft).

20. RH drive models: Fit brake servo heat shield.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Heat shield -

brake servo - Without Secondary Air

Injection.

21.Position engine earth lead, fit bolt and tighten to

22 Nm (16 lbf.ft).

22.Fit inlet manifold gasket.

+ MANIFOLDS AND EXHAUST

SYSTEMS - V8, REPAIRS, Gasket - inlet

manifold - lower.

Page 277 of 1672

ENGINE - V8

12-2-34 REPAIRS

4.Ensure ring gear is correctly seated around the

complete circumference of flywheel and allow

to cool.

5.Fit flywheel.

+ ENGINE - V8, REPAIRS, Flywheel.

Filter - oil

$% 12.60.04

Remove

1.Clean area around filter head and place a

container beneath engine.

2.Using a strap wrench, unscrew and discard

filter.

Refit

1.Clean mating face of filter head.

2.Lubricate sealing ring of new filter with clean

engine oil.

3.Fit filter and tighten by hand until it seats then

tighten a further half turn.

4.Start and run engine to check for leaks.

5.Stop engine, wait a few minutes, then check oil

level.

6.Top up engine oil.

Page 304 of 1672

ENGINE - V8

OVERHAUL 12-2-61

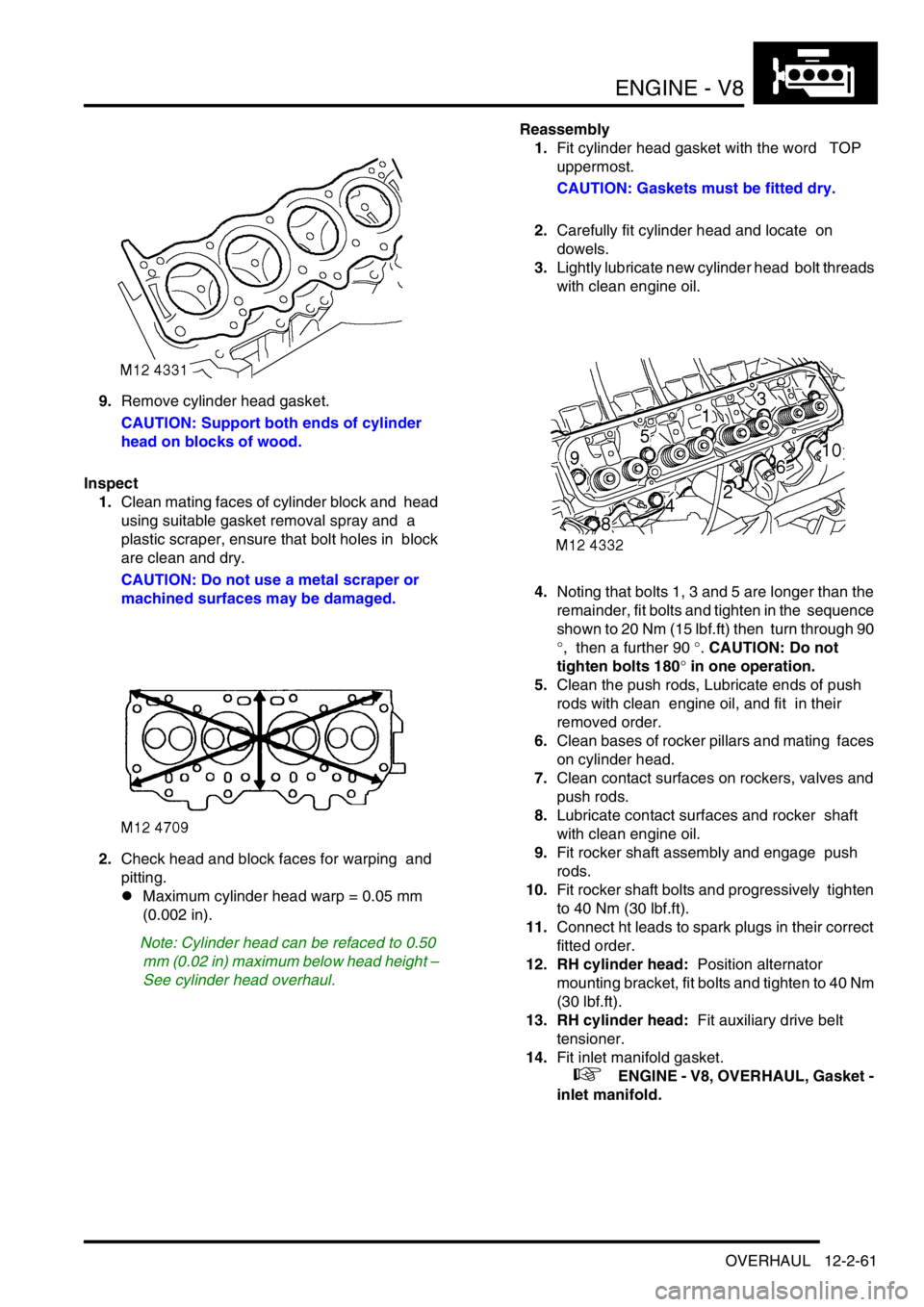

9.Remove cylinder head gasket.

CAUTION: Support both ends of cylinder

head on blocks of wood.

Inspect

1.Clean mating faces of cylinder block and head

using suitable gasket removal spray and a

plastic scraper, ensure that bolt holes in block

are clean and dry.

CAUTION: Do not use a metal scraper or

machined surfaces may be damaged.

2.Check head and block faces for warping and

pitting.

lMaximum cylinder head warp = 0.05 mm

(0.002 in).

Note: Cylinder head can be refaced to 0.50

mm (0.02 in) maximum below head height –

See cylinder head overhaul.Reassembly

1.Fit cylinder head gasket with the word TOP

uppermost.

CAUTION: Gaskets must be fitted dry.

2.Carefully fit cylinder head and locate on

dowels.

3.Lightly lubricate new cylinder head bolt threads

with clean engine oil.

4.Noting that bolts 1, 3 and 5 are longer than the

remainder, fit bolts and tighten in the sequence

shown to 20 Nm (15 lbf.ft) then turn through 90

°, then a further 90 °. CAUTION: Do not

tighten bolts 180

° in one operation.

5.Clean the push rods, Lubricate ends of push

rods with clean engine oil, and fit in their

removed order.

6.Clean bases of rocker pillars and mating faces

on cylinder head.

7.Clean contact surfaces on rockers, valves and

push rods.

8.Lubricate contact surfaces and rocker shaft

with clean engine oil.

9.Fit rocker shaft assembly and engage push

rods.

10.Fit rocker shaft bolts and progressively tighten

to 40 Nm (30 lbf.ft).

11.Connect ht leads to spark plugs in their correct

fitted order.

12. RH cylinder head: Position alternator

mounting bracket, fit bolts and tighten to 40 Nm

(30 lbf.ft).

13. RH cylinder head: Fit auxiliary drive belt

tensioner.

14.Fit inlet manifold gasket.

+ ENGINE - V8, OVERHAUL, Gasket -

inlet manifold.

Page 305 of 1672

ENGINE - V8

12-2-62 OVERHAUL

Cylinder head - overhaul

$% 12.29.19.01

Disassembly

1.Remove cylinder head gasket.

+ ENGINE - V8, OVERHAUL, Gasket -

cylinder head.

2.Loosen screw on tool LRT-12-034.

3.Fit tool LRT-12-034 to valve and tighten screw

to compress valve spring sufficiently to release

collets from valve spring cap.

4.Remove 2 collets and release valve spring

compressor.

5.Remove valve spring cap and valve spring.

6.Remove valve from cylinder head.

7.Remove and discard valve stem oil seal.

8.Repeat above operations for remaining valves.

9.Keep valves, springs, caps and collets in their

fitted order. Inspect

1.Clean mating faces of cylinder block and head

using suitable gasket removal spray and a

plastic scraper, ensure that bolt holes in block

are clean and dry.

CAUTION: Do not use a metal scraper or

machined surfaces may be damaged.

2.Clean cylinder head, valve springs, valves and

inlet valve guide bores. Ensure all loose

particles of carbon are removed on completion.

3.Check head and block faces for warping and

pitting. Maximum warp = 0.05 mm (0.002 in).

4.Check cylinder head height at each end of

head. Renew a head which is outside limits.

a22.94 mm (0.903 in) - New

b62.56 mm (2.463 in) - New

5.Cylinder head can be refaced to 0.50 mm (0.02

in) max. below head height.

Page 307 of 1672

ENGINE - V8

12-2-64 OVERHAUL

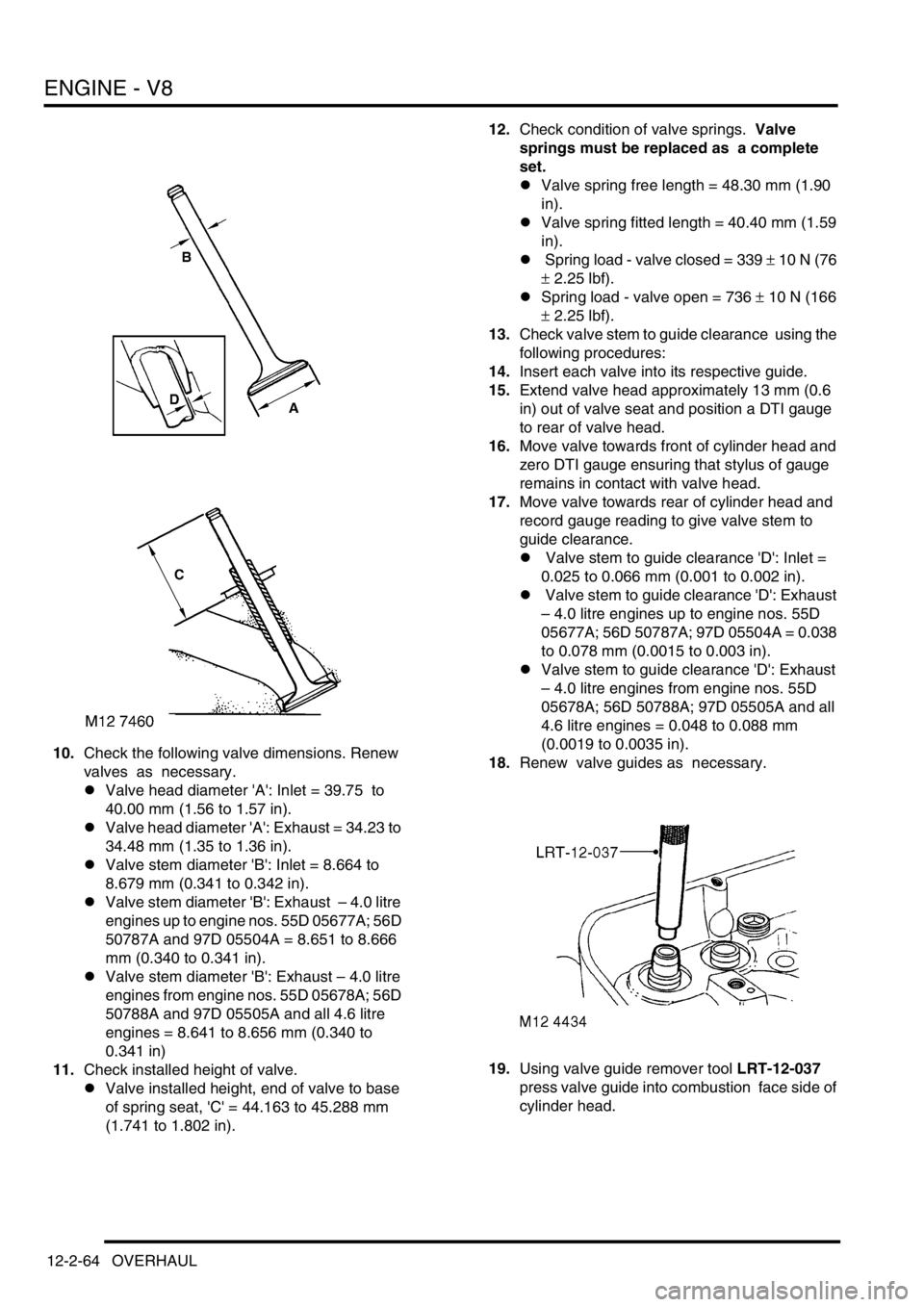

10.Check the following valve dimensions. Renew

valves as necessary.

lValve head diameter 'A': Inlet = 39.75 to

40.00 mm (1.56 to 1.57 in).

lValve head diameter 'A': Exhaust = 34.23 to

34.48 mm (1.35 to 1.36 in).

lValve stem diameter 'B': Inlet = 8.664 to

8.679 mm (0.341 to 0.342 in).

lValve stem diameter 'B': Exhaust – 4.0 litre

engines up to engine nos. 55D 05677A; 56D

50787A and 97D 05504A = 8.651 to 8.666

mm (0.340 to 0.341 in).

lValve stem diameter 'B': Exhaust – 4.0 litre

engines from engine nos. 55D 05678A; 56D

50788A and 97D 05505A and all 4.6 litre

engines = 8.641 to 8.656 mm (0.340 to

0.341 in)

11.Check installed height of valve.

lValve installed height, end of valve to base

of spring seat, 'C' = 44.163 to 45.288 mm

(1.741 to 1.802 in).12.Check condition of valve springs. Valve

springs must be replaced as a complete

set.

lValve spring free length = 48.30 mm (1.90

in).

lValve spring fitted length = 40.40 mm (1.59

in).

l Spring load - valve closed = 339

± 10 N (76

± 2.25 lbf).

lSpring load - valve open = 736

± 10 N (166

± 2.25 lbf).

13.Check valve stem to guide clearance using the

following procedures:

14.Insert each valve into its respective guide.

15.Extend valve head approximately 13 mm (0.6

in) out of valve seat and position a DTI gauge

to rear of valve head.

16.Move valve towards front of cylinder head and

zero DTI gauge ensuring that stylus of gauge

remains in contact with valve head.

17.Move valve towards rear of cylinder head and

record gauge reading to give valve stem to

guide clearance.

l Valve stem to guide clearance 'D': Inlet =

0.025 to 0.066 mm (0.001 to 0.002 in).

l Valve stem to guide clearance 'D': Exhaust

– 4.0 litre engines up to engine nos. 55D

05677A; 56D 50787A; 97D 05504A = 0.038

to 0.078 mm (0.0015 to 0.003 in).

lValve stem to guide clearance 'D': Exhaust

– 4.0 litre engines from engine nos. 55D

05678A; 56D 50788A; 97D 05505A and all

4.6 litre engines = 0.048 to 0.088 mm

(0.0019 to 0.0035 in).

18.Renew valve guides as necessary.

19.Using valve guide remover tool LRT-12-037

press valve guide into combustion face side of

cylinder head.

Page 308 of 1672

ENGINE - V8

OVERHAUL 12-2-65

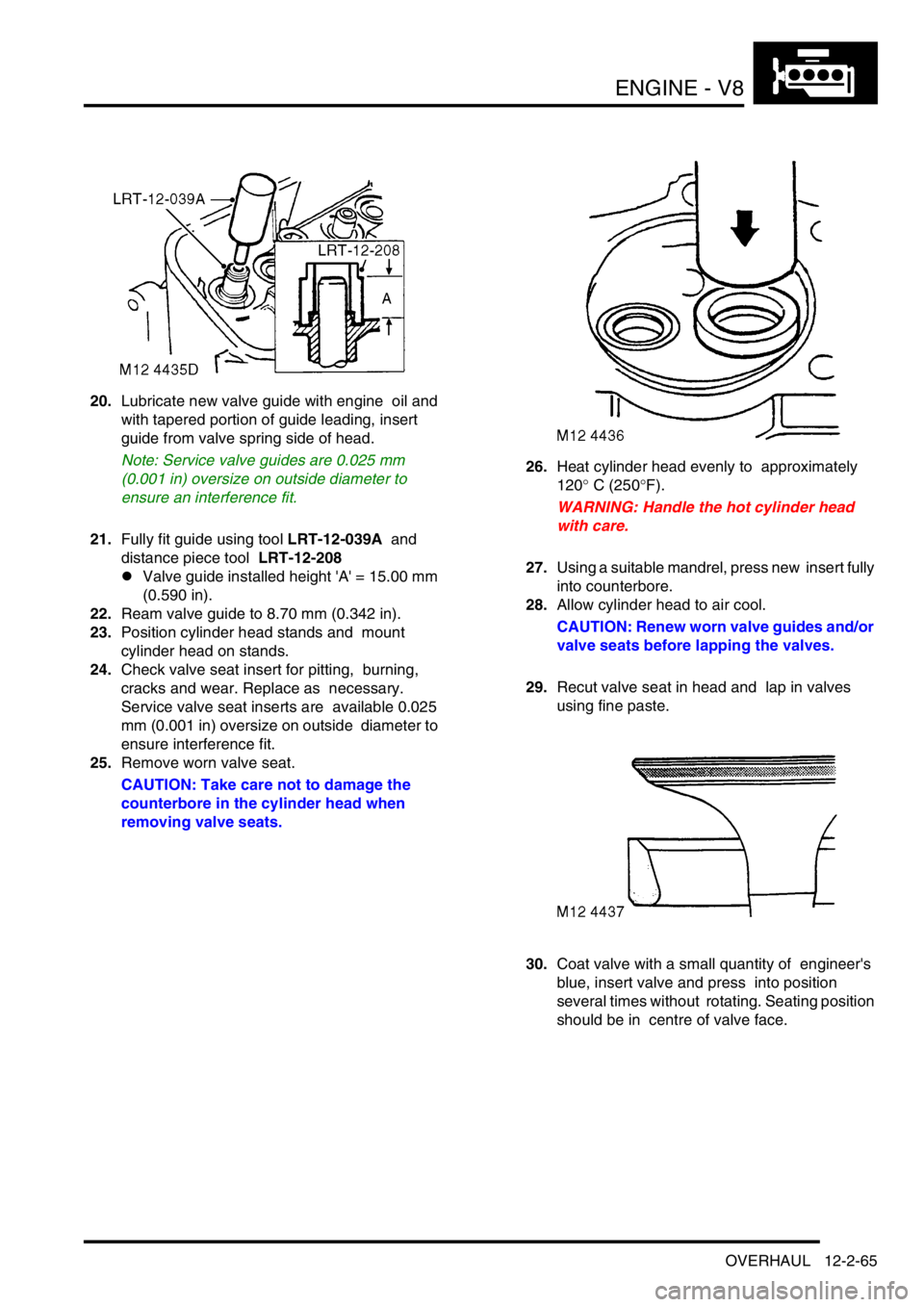

20.Lubricate new valve guide with engine oil and

with tapered portion of guide leading, insert

guide from valve spring side of head.

Note: Service valve guides are 0.025 mm

(0.001 in) oversize on outside diameter to

ensure an interference fit.

21.Fully fit guide using tool LRT-12-039A and

distance piece tool LRT-12-208

lValve guide installed height 'A' = 15.00 mm

(0.590 in).

22.Ream valve guide to 8.70 mm (0.342 in).

23.Position cylinder head stands and mount

cylinder head on stands.

24.Check valve seat insert for pitting, burning,

cracks and wear. Replace as necessary.

Service valve seat inserts are available 0.025

mm (0.001 in) oversize on outside diameter to

ensure interference fit.

25.Remove worn valve seat.

CAUTION: Take care not to damage the

counterbore in the cylinder head when

removing valve seats.26.Heat cylinder head evenly to approximately

120

° C (250°F).

WARNING: Handle the hot cylinder head

with care.

27.Using a suitable mandrel, press new insert fully

into counterbore.

28.Allow cylinder head to air cool.

CAUTION: Renew worn valve guides and/or

valve seats before lapping the valves.

29.Recut valve seat in head and lap in valves

using fine paste.

30.Coat valve with a small quantity of engineer's

blue, insert valve and press into position

several times without rotating. Seating position

should be in centre of valve face.