LAND ROVER DISCOVERY 2002 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 781 of 1672

TRANSFER BOX - LT230SE

41-48 OVERHAUL

11.Check differential lock selector fork for cracks

and wear.

12.Check selector fork finger width.

lFinger width = 7.92 to 7.97 mm (0.311 to

0.313 in).

13.Check differential lock selector fork clips for

wear and damage. Check spring for distortion

and free length.

lSpring free length = 84.58 mm (3.33 in).

14.Check dog clutch internal teeth and grooves

and teeth on output shaft for wear and

damage. Check selector fork groove width.

lGroove width = 8.05 to 8.20 mm (0.32 to

0.33 in).

15.Carry out the following inspection procedures

for all transfer boxes.

16.Check threads and splines of output shaft for

damage and wear. Check dog clutch teeth on

shaft for wear and damage.17.03 MY onwards: Compress high/low selector

fork spring and remove retaining clips from

each end of spring, remove high/low selector

shaft.

18.Check detent grooves in high/low selector shaft

for wear. Do not remove fork from shaft

unless either component is being renewed.

If fork is removed from shaft, coat the

threads of the set screw with Loctite 290

prior to assembling.

Note: High/low selector shaft fitted to pre 03 MY

illustrated.

Page 782 of 1672

TRANSFER BOX - LT230SE

OVERHAUL 41-49

19.Check width of high/low selector groove.

lGroove width = 16.0 to 16.1 mm (0.63 to

0.64 in).

20.Check high/low selector fork for cracks and

wear. Check selector fork finger width.

lFinger width = 7.37 to 7.47 mm (0.290 to

0.294 in).

21.03 MY onwards: Check high/low selector fork

clips for wear and damage. Check spring for

distortion, check free length of spring:

lSpring free length = 75 mm (2.95 in)

Note: High/low selector shaft, fork and spring

fitted to 03 MY transfer boxes may be fitted to

pre 03 MY boxes as an assembly.

22.Check differential sun and planet gears for

wear, cracks and chipping of teeth.

23.Check cross shafts and recesses in both halves

of differential carrier for damage and

wear.Ensure planet gears are retained with

their respective shafts.

24.Check retaining ring for distortion.

25.Check differential splines for wear and

damage.26.Check high/low hub for cracks, chipping and

uneven wear. Check width of selector fork

groove.

lGroove width = 7.5 to 7.6 mm (0.295 to 0.30

in).

27.Check splines and teeth on high/low selector

sleeve for uneven wear, cracks, damage and

chipping.

28.Check teeth of high and low range gears for

cracks, chipping and uneven wear.

29.Check high range gear bush for wear and

damage.

Reassembly

1.Lubricate all components with recommended

oil and lightly oil the differential bolt threads.

Page 783 of 1672

TRANSFER BOX - LT230SE

41-50 OVERHAUL

2.Secure rear half of differential carrier in a soft

jawed vice.

3.Fit each planet gear to its respective cross

shaft, fit new dished thrust washer to each

gear.

4.Fit cross shafts, planet gears and dished thrust

washers in rear half of carrier.Ensure that

cross shafts are fitted correctly. Do not fit

the sun gear into the rear half carrier at this

stage.

5.Fit retaining ring.

6.Fit a 1.05 mm (0.04 in) thrust washer to sun

gear from front half of carrier. Position gear in

front half of carrier.

7.Ensuring that assembly marks are aligned, fit

both halves of carrier together.

8.Fit the differential carrier bolts and, working in a

diagonal sequence, tighten the bolts to 60 Nm,

(44 lbf.ft).9.Insert the front output shaft into the front half of

the carrier and check that the gears rotate

freely.

10.Fit output flange on to the splines of the output

shaft, but do not fit flange nut at this stage.

11.Fit transmission brake drum to output flange

and secure the drum using 2 nuts.

12.Secure a length of cord around the drum and

attach one end of the cord to a spring balance.

13.Pull on the spring balance and note the load at

which the brake drum starts to turn. Used

gears should rotate smoothly, while new

gears will have a 'notchy' feel as they rotate.

14.Compare the figure obtained with the following.

lUsed gears = 0.45 kg (1.0 lb)

lNew gears = 1.72 kg (3.8 lb)

15.If the load to turn figure is below the specified

limits, proceed as follows.

16.Remove the front output shaft and brake drum.

17.Remove the 8 bolts securing the two halves of

the differential carrier

18.Separate the differential carrier and remove the

sun gear and thrust washer from the front half.

19.Select a thicker thrust washer from the range

available. 5 different thrust washers are

available, rising in increments of 0.10 mm

(0.004 in) from 1.05 mm to 1.45 mm (0.04 to

0.06 in).

20.Repeat steps 7 to 19 as necessary until the

load to turn figure is as specified

21.When specified load to turn is obtained,

proceed as follows.

22.Remove the front output shaft and brake drum.

23.Remove the 8 bolts securing the two halves of

the differential carrier

24.Separate the differential carrier and remove the

sun gear and thrust washer from the front

half.Retain the selected thrust washer with

its sun gear.

Page 784 of 1672

TRANSFER BOX - LT230SE

OVERHAUL 41-51

25.Remove retaining ring, then remove the planet

gears and cross shafts.

26.Fit a 1.05 mm (0.04 in) thrust washer to sun

gear from rear half of carrier. Position gear in

rear half of carrier.

27.Fit planet gears, cross shafts and dished thrust

washers to rear half of carrier. Ensure that

cross shafts are fitted correctly. Do not fit

the sun gear into the rear half carrier at this

stage.

28.Fit retaining ring.

29.Ensuring that assembly marks are aligned, fit

both halves of carrier together.

30.Fit the differential carrier bolts and, working in a

diagonal sequence, tighten the bolts to 60 Nm,

(44 lbf.ft).31.Invert the assembly in the vice, insert the rear

output shaft into the rear half of the carrier and

check that the gears rotate freely.

32.Fit output flange on to the splines of the output

shaft, but do not fit flange nut at this stage.

33.Fit transmission brake drum to output flange

and secure the drum using 2 nuts.

34.Carry out the load to turn check, using the same

method as for the front half carrier. Record the

shim thickness when the load to turn is correct.

35.Fit the sun gear and selected thickness shim to

the front half carrier.

36.Ensuring that assembly marks are aligned, fit

both halves of carrier together.

37.Fit the differential carrier bolts and, working in a

diagonal sequence, tighten the bolts to 60 Nm,

(44 lbf.ft).

38.With differential assembled, fit rear output shaft

and brake drum, then check overall load to turn.

This should be approximately the same as the

combined load to turn figure of both front and

rear half carriers.

lUsed gears = 0.90 kg (2.0 lb)

lNew gears = 3.44 kg (7.6 lb)

Page 785 of 1672

TRANSFER BOX - LT230SE

41-52 OVERHAUL

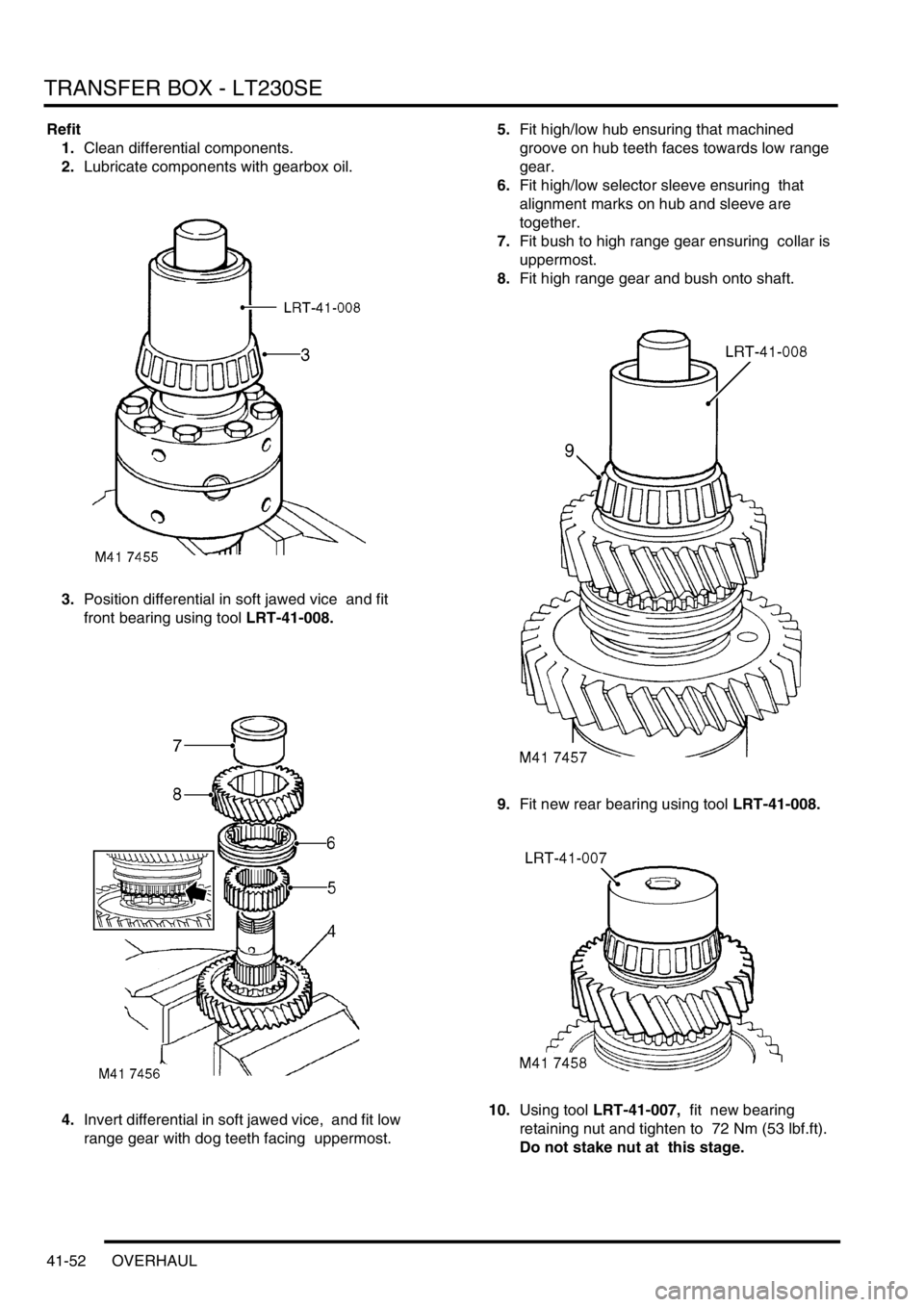

Refit

1.Clean differential components.

2.Lubricate components with gearbox oil.

3.Position differential in soft jawed vice and fit

front bearing using tool LRT-41-008.

4.Invert differential in soft jawed vice, and fit low

range gear with dog teeth facing uppermost. 5.Fit high/low hub ensuring that machined

groove on hub teeth faces towards low range

gear.

6.Fit high/low selector sleeve ensuring that

alignment marks on hub and sleeve are

together.

7.Fit bush to high range gear ensuring collar is

uppermost.

8.Fit high range gear and bush onto shaft.

9.Fit new rear bearing using tool LRT-41-008.

10.Using tool LRT-41-007, fit new bearing

retaining nut and tighten to 72 Nm (53 lbf.ft).

Do not stake nut at this stage.

Page 786 of 1672

TRANSFER BOX - LT230SE

OVERHAUL 41-53

11.Using feeler gauges, determine clearance

between low range gear and high/low hub:

lClearance = 0.05 to 0.15 mm (0.002 to

0.006 in).

12.If clearance is not as specified, fit a new low

range gear and high/low hub and re-check.

13.Using feeler gauges, determine clearance

between high range gear and high/low hub:

lClearance = 0.05 to 0.15 mm (0.002 to

0.006 in).

14.If clearance is not as specified, fit new high

range gear and high/low hub and re-check. 15.Using a suitable drift, stake collar of nut into

differential shaft recess.

16.Using LRT-51-009, fit new rear bearing track

into main casing.

17.Using a straight edge and feeler gauges, check

that bearing track is recessed 1 mm (0.04 in)

below outer face of main casing.

18.Apply sealant, Part No. STC 3254 to rear

output shaft housing face.

19.Position housing to main casing.

20.Apply Loctite 290 to bolt threads fit housing to

main case bolts and tighten by diagonal

selection to 45 Nm (33 lbf.ft).

21.03 MY only: Fit high/low selector fork and

spring to high/low selector shaft, fit retaining

clips.

CAUTION: Ensure ends of spring are fully

seated in recess in clips.

22.Position high/low selector shaft and fork to

differential ensuring that fingers of selector fork

are located in selector sleeve.

23.Position differential assembly into main casing

ensuring that splines of rear output shaft are

engaged in differential.

24.Position new differential front bearing track

ensuring that track is seated squarely.

Page 787 of 1672

TRANSFER BOX - LT230SE

41-54 OVERHAUL

25.Position tool LRT-41-014/3 onto main casing.

26.Screw tool LRT-41-014/4 into tapped hole in

main casing and attach suitable DTI to pillar.

27.Position stylus of gauge to setting block LRT-

41-014/3 and zero gauge.

28.Position stylus onto front bearing outer track

and record reading. 29.Taking care not to disturb bearing, position

stylus on opposite side of bearing track and

record reading.

30.Obtain average of the 2 readings and record

figure.

31.Position depth block tool LRT-41-014/2 and

cross bar tool LRT-41-014/1 to front output

housing.

32.Position DTI to tool LRT-41-014/1 cross bar

and zero DTI on depth block.

33.Position DTI to cross bar and record reading

obtained.

34. Using the formula: 3.05 mm (0.120 in)+B-

A=D where: B=Height difference recorded

between depth block and cross bar.

A=Average of readings to differential front

bearing outer track. D=Thickness of shim

required to give differential bearing pre-load of

0.05 mm (0.002 in).

35.From the resultant figure obtained, select

appropriate thickness shim from the range

available.

36.Shims are available from 2.00 to 3.25 mm

(0.08 to 0.13 in) thickness, rising in increments

of 0.05 mm (0.002 in).

Page 788 of 1672

TRANSFER BOX - LT230SE

OVERHAUL 41-55

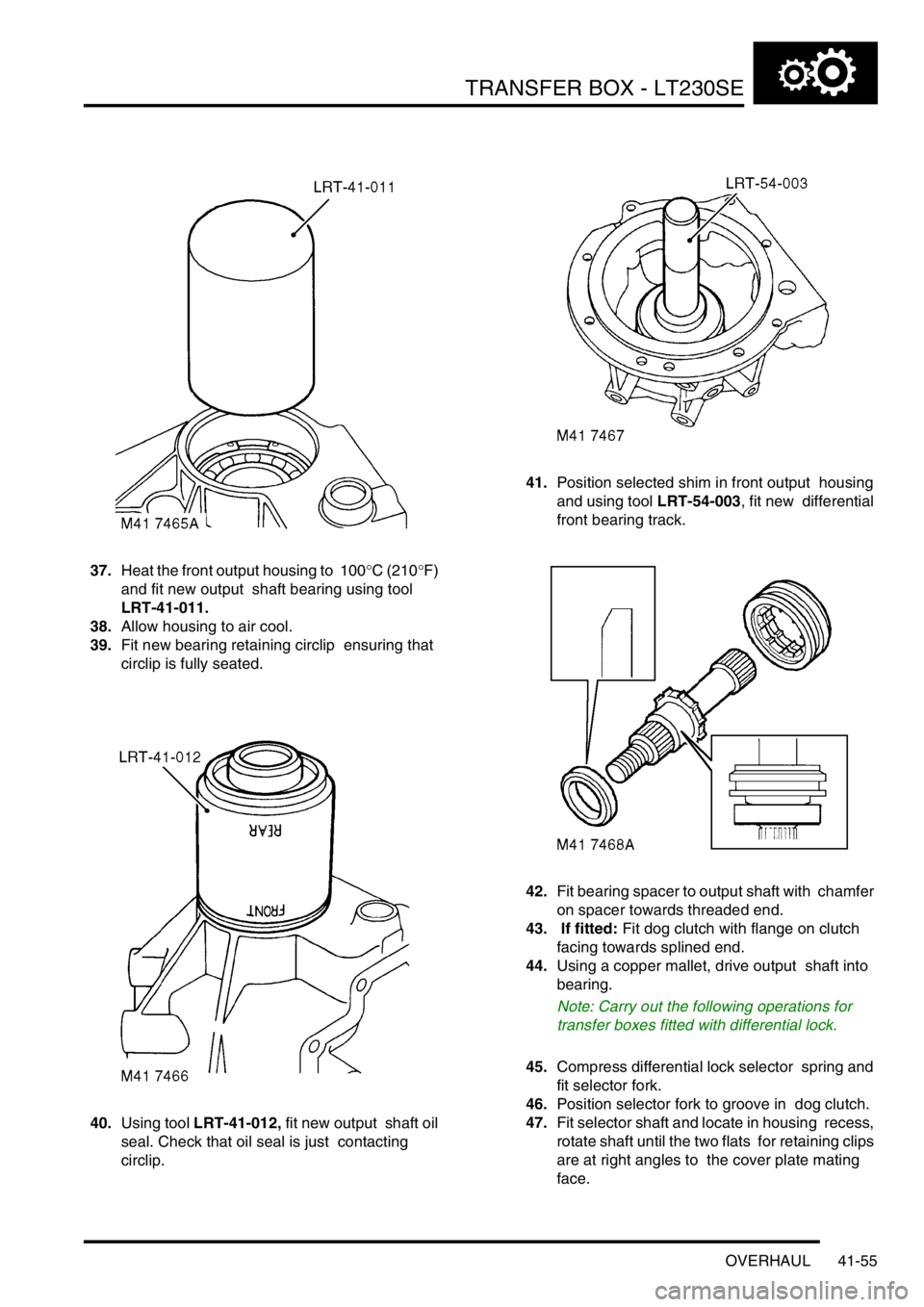

37.Heat the front output housing to 100°C (210°F)

and fit new output shaft bearing using tool

LRT-41-011.

38.Allow housing to air cool.

39.Fit new bearing retaining circlip ensuring that

circlip is fully seated.

40.Using tool LRT-41-012, fit new output shaft oil

seal. Check that oil seal is just contacting

circlip. 41.Position selected shim in front output housing

and using tool LRT-54-003, fit new differential

front bearing track.

42.Fit bearing spacer to output shaft with chamfer

on spacer towards threaded end.

43. If fitted: Fit dog clutch with flange on clutch

facing towards splined end.

44.Using a copper mallet, drive output shaft into

bearing.

Note: Carry out the following operations for

transfer boxes fitted with differential lock.

45.Compress differential lock selector spring and

fit selector fork.

46.Position selector fork to groove in dog clutch.

47.Fit selector shaft and locate in housing recess,

rotate shaft until the two flats for retaining clips

are at right angles to the cover plate mating

face.

Page 789 of 1672

TRANSFER BOX - LT230SE

41-56 OVERHAUL

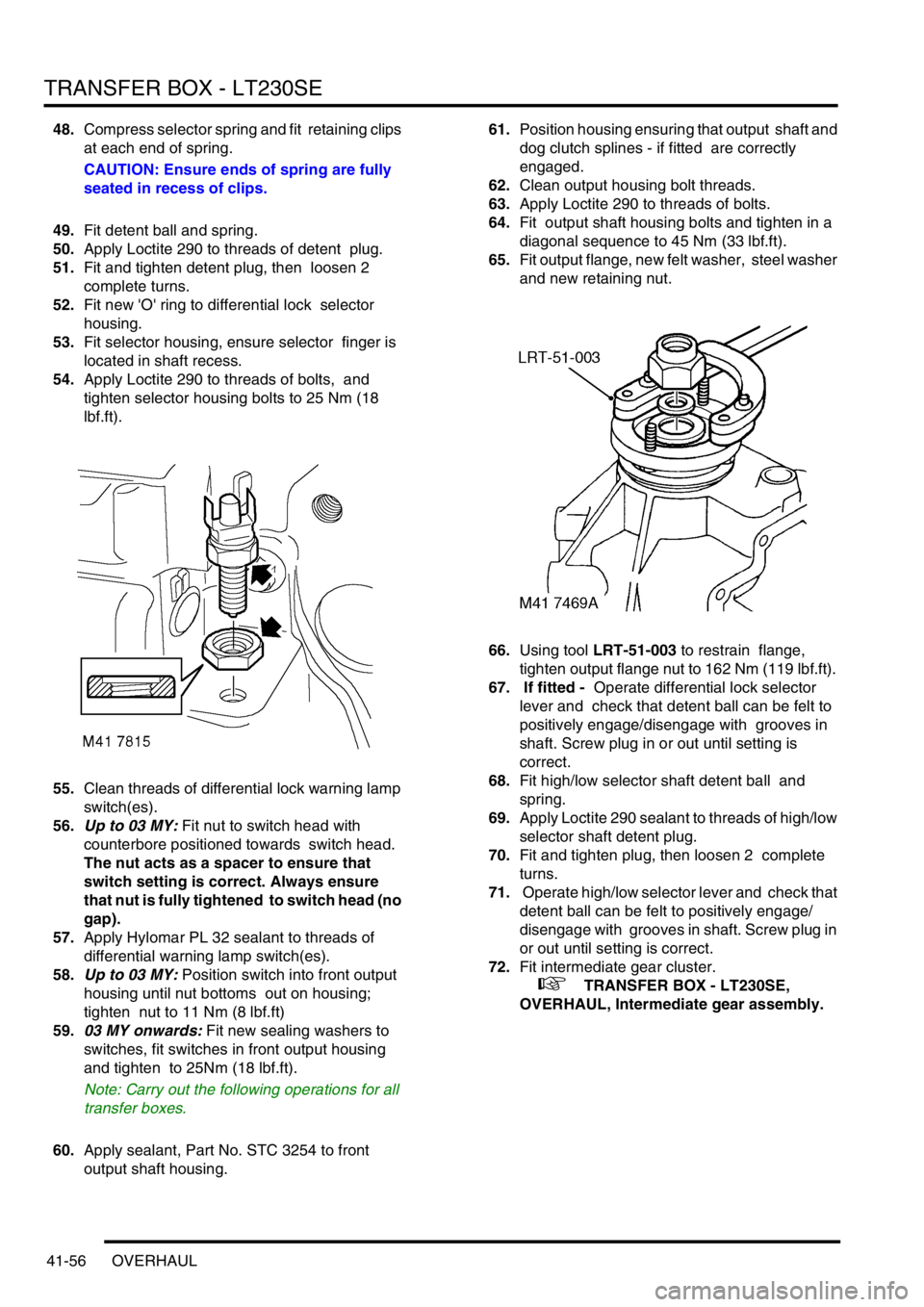

48.Compress selector spring and fit retaining clips

at each end of spring.

CAUTION: Ensure ends of spring are fully

seated in recess of clips.

49.Fit detent ball and spring.

50.Apply Loctite 290 to threads of detent plug.

51.Fit and tighten detent plug, then loosen 2

complete turns.

52.Fit new 'O' ring to differential lock selector

housing.

53.Fit selector housing, ensure selector finger is

located in shaft recess.

54.Apply Loctite 290 to threads of bolts, and

tighten selector housing bolts to 25 Nm (18

lbf.ft).

55.Clean threads of differential lock warning lamp

switch(es).

56.Up to 03 MY: Fit nut to switch head with

counterbore positioned towards switch head.

The nut acts as a spacer to ensure that

switch setting is correct. Always ensure

that nut is fully tightened to switch head (no

gap).

57.Apply Hylomar PL 32 sealant to threads of

differential warning lamp switch(es).

58.Up to 03 MY: Position switch into front output

housing until nut bottoms out on housing;

tighten nut to 11 Nm (8 lbf.ft)

59.03 MY onwards: Fit new sealing washers to

switches, fit switches in front output housing

and tighten to 25Nm (18 lbf.ft).

Note: Carry out the following operations for all

transfer boxes.

60.Apply sealant, Part No. STC 3254 to front

output shaft housing. 61.Position housing ensuring that output shaft and

dog clutch splines - if fitted are correctly

engaged.

62.Clean output housing bolt threads.

63.Apply Loctite 290 to threads of bolts.

64.Fit output shaft housing bolts and tighten in a

diagonal sequence to 45 Nm (33 lbf.ft).

65.Fit output flange, new felt washer, steel washer

and new retaining nut.

66.Using tool LRT-51-003 to restrain flange,

tighten output flange nut to 162 Nm (119 lbf.ft).

67. If fitted - Operate differential lock selector

lever and check that detent ball can be felt to

positively engage/disengage with grooves in

shaft. Screw plug in or out until setting is

correct.

68.Fit high/low selector shaft detent ball and

spring.

69.Apply Loctite 290 sealant to threads of high/low

selector shaft detent plug.

70.Fit and tighten plug, then loosen 2 complete

turns.

71. Operate high/low selector lever and check that

detent ball can be felt to positively engage/

disengage with grooves in shaft. Screw plug in

or out until setting is correct.

72.Fit intermediate gear cluster.

+ TRANSFER BOX - LT230SE,

OVERHAUL, Intermediate gear assembly.

Page 790 of 1672

TRANSFER BOX - LT230SE

OVERHAUL 41-57

Dog clutch - differential lock

$% 41.20.23

Disassembly

1.Remove 6 bolts securing high/low cross shaft

housing to front output shaft housing and

remove housing.

2.Note position of longest bolt and remove 8

bolts securing front output shaft housing to

main casing and remove housing.

3.Remove 3 bolts securing differential lock

selector housing and remove housing. 4.Remove and discard 'O' ring from selector

housing.

5.Remove differential warning lamp switch and

locknut.

Note: Locknut is only fitted to switches up to 03

MY, a modified switch and sealing washer is

fitted from 03 MY onwards..

6.03 MY onwards: Remove differential lock

warning lamp switch from end of front output

shaft housing, discard sealing washer.

7.Remove Allen plug and remove detent spring

and ball.

8.Compress differential lock selector fork spring

and remove retaining clips from each end of

spring.

9.Withdraw differential lock selector shaft from

front output housing, recover spring and

remove selector fork.