LAND ROVER DISCOVERY 2002 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 771 of 1672

TRANSFER BOX - LT230SE

41-38 REPAIRS

Page 772 of 1672

TRANSFER BOX - LT230SE

OVERHAUL 41-39

OVERHAUL

Intermediate gear assembly

$% 41.20.10

Disassembly

1.Remove and discard 10 bolts securing bottom

cover, remove cover.

2.Remove and discard 7 bolts securing

differential lock selector side cover.

3.Remove side cover. 4.Release staking from intermediate shaft nut,

remove and discard nut.

5.Remove bolt securing intermediate shaft

retaining plate, remove plate.

6.Remove intermediate shaft and discard 2 'O'

rings.

Page 773 of 1672

TRANSFER BOX - LT230SE

41-40 OVERHAUL

7.Remove intermediate gear assembly and

collect bearings and selective spacer.

8.Secure gear assembly in a soft jawed vice and

using a suitable drift, remove and discard

bearing tracks.

9.Up to 03 MY: Remove and discard circlips.

Reassembly

1.Clean gears, bearings, circlips and shaft.

Note: Intermediate gear cluster and bearing

assemblies fitted to 03 MY transfer boxes may

be fitted as replacements to pre 03 MY transfer

boxes.2.Up to 03 MY: Fit new circlips and using tools

LRT-99-003 and LRT-41-006 fit bearing tracks

to intermediate gear, ensuring that the bearing

tracks are fully seated against the circlips.

3.03 MY onwards: Using tools LRT-99-003 and

LRT-41-006, fit bearing tracks to intermediate

gears ensuring that tracks are fully seated

against shoulders in gears.

Page 774 of 1672

TRANSFER BOX - LT230SE

OVERHAUL 41-41

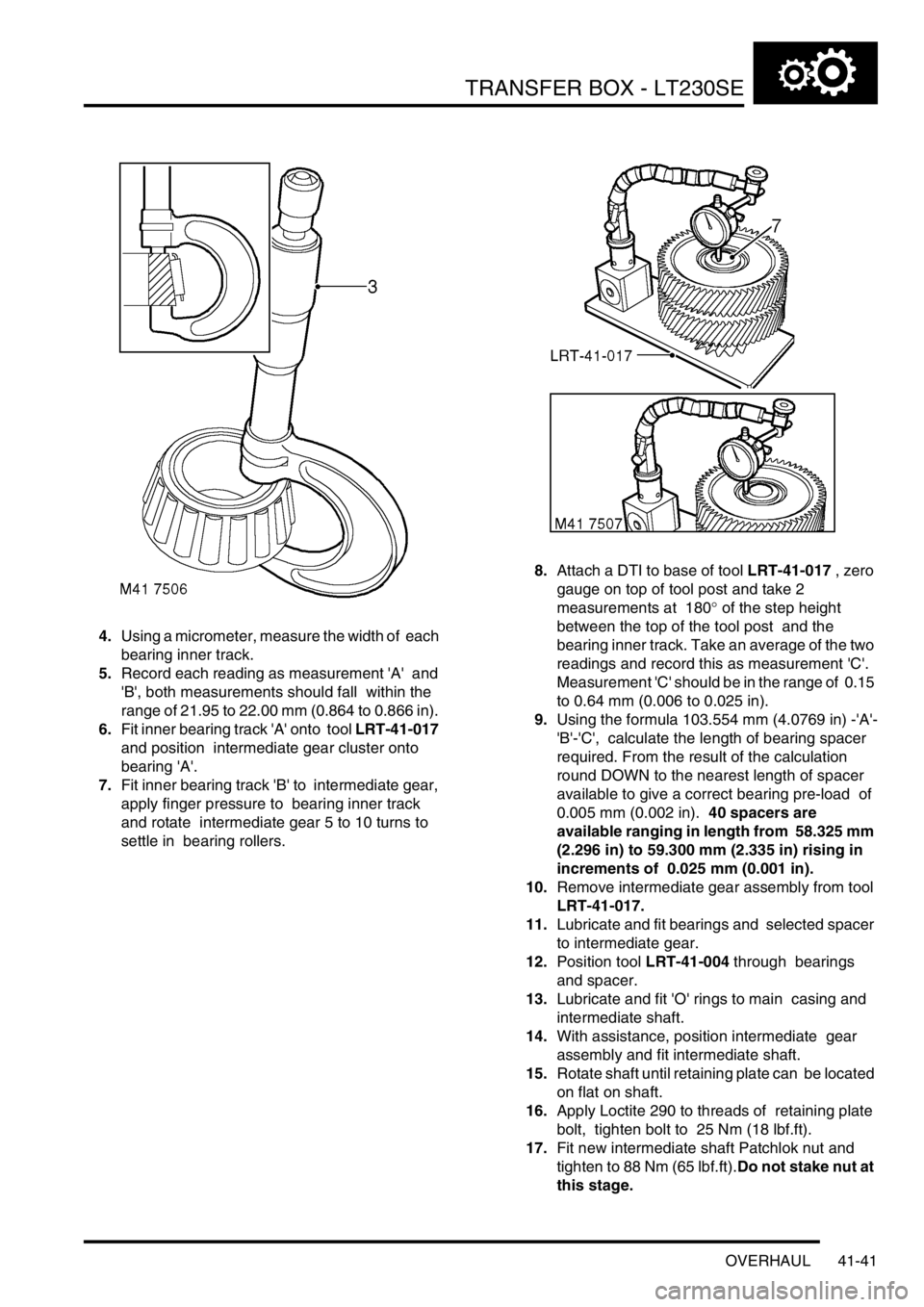

4.Using a micrometer, measure the width of each

bearing inner track.

5.Record each reading as measurement 'A' and

'B', both measurements should fall within the

range of 21.95 to 22.00 mm (0.864 to 0.866 in).

6.Fit inner bearing track 'A' onto tool LRT-41-017

and position intermediate gear cluster onto

bearing 'A'.

7.Fit inner bearing track 'B' to intermediate gear,

apply finger pressure to bearing inner track

and rotate intermediate gear 5 to 10 turns to

settle in bearing rollers. 8.Attach a DTI to base of tool LRT-41-017 , zero

gauge on top of tool post and take 2

measurements at 180

° of the step height

between the top of the tool post and the

bearing inner track. Take an average of the two

readings and record this as measurement 'C'.

Measurement 'C' should be in the range of 0.15

to 0.64 mm (0.006 to 0.025 in).

9.Using the formula 103.554 mm (4.0769 in) -'A'-

'B'-'C', calculate the length of bearing spacer

required. From the result of the calculation

round DOWN to the nearest length of spacer

available to give a correct bearing pre-load of

0.005 mm (0.002 in). 40 spacers are

available ranging in length from 58.325 mm

(2.296 in) to 59.300 mm (2.335 in) rising in

increments of 0.025 mm (0.001 in).

10.Remove intermediate gear assembly from tool

LRT-41-017.

11.Lubricate and fit bearings and selected spacer

to intermediate gear.

12.Position tool LRT-41-004 through bearings

and spacer.

13.Lubricate and fit 'O' rings to main casing and

intermediate shaft.

14.With assistance, position intermediate gear

assembly and fit intermediate shaft.

15.Rotate shaft until retaining plate can be located

on flat on shaft.

16.Apply Loctite 290 to threads of retaining plate

bolt, tighten bolt to 25 Nm (18 lbf.ft).

17.Fit new intermediate shaft Patchlok nut and

tighten to 88 Nm (65 lbf.ft).Do not stake nut at

this stage.

Page 775 of 1672

TRANSFER BOX - LT230SE

41-42 OVERHAUL

18.Select neutral.

19.Screw a suitable bolt into tapped hole of tool

LRT-41-005.

20.Insert tool LRT-41-005 in end of mainshaft.

21.Using a suitable torque meter on tool LRT-41-

005, check torque to turn of gear train. Torque

to turn = 2.2 Nm (19 lbf.ft). If torque to turn

figure is incorrect, repeat intermediate gear

bearing pre-load setting and re-check.

22.On completion, remove tool LRT-41-005 and

stake flange of nut into recess on intermediate

shaft.

23.Clean transfer box bottom and side covers.

24.Apply sealant, Part No. STC 3254 to both

covers.

25.Clean bottom and side cover bolt threads.

26.Apply Loctite 290 to bolt threads.

27.Position side cover and tighten bolts to 25 Nm

(18 lbf.ft).

28.Position bottom cover and tighten bolts to 25

Nm (18 lbf.ft).

Differential assembly

$% 41.20.13

Remove

1.Remove intermediate gear cluster.

+ TRANSFER BOX - LT230SE,

OVERHAUL, Intermediate gear assembly.

2.Remove 6 bolts securing high/low cross shaft

housing to front output shaft housing and

remove housing.

3.Note position of longest bolt and remove 8 bolts

securing front output shaft housing to main

casing and remove housing.

Note: Carry out the following operations if

differential lock is fitted.

Page 776 of 1672

TRANSFER BOX - LT230SE

OVERHAUL 41-43

4.Remove 3 bolts securing differential lock

selector housing and remove housing.

5.Remove and discard 'O' ring from selector

housing.

6.Remove Allen plug and remove detent spring

and ball.

7.Remove differential lock warning lamp switch

and locknut.

Note: Locknut is only fitted to switches up to 03

MY, a modified switch and sealing washer is

fitted from 03 MY onwards.

8.03 MY onwards: Remove differential lock

warning lamp switch from end of front output

shaft housing, discard sealing washer.

9.Compress differential lock selector fork spring

and remove retaining clips from each end of

spring.

10.Withdraw differential lock selector shaft from

front output housing, recover spring and

remove selector fork.

Note: Carry out the following operations for all

transfer boxes.11.Position tool LRT-51-003 to output shaft drive

flange, remove and discard nut, steel and felt

washers; remove output shaft drive flange.

12.Using a copper mallet, drive output shaft from

housing, recover bearing spacer.

13. If fitted: Noting its fitted position, remove dog

clutch from output shaft.

Page 777 of 1672

TRANSFER BOX - LT230SE

41-44 OVERHAUL

14.Remove and discard oil seal from housing.

15.Remove and discard circlip retaining output

shaft bearing.

16.Support housing and drift out output shaft

bearing. 17.Remove and discard differential bearing track

and collect selective shim.

18.Remove Allen plug securing high/low selector

shaft detent spring and ball, remove spring and

ball.

19.Withdraw differential assembly together with

high/low selector shaft and fork.

20.Remove selector fork and shaft from

differential.

Note: Selector fork fitted to 03 MY onwards

illustrated.

Page 778 of 1672

TRANSFER BOX - LT230SE

OVERHAUL 41-45

21.Note position of shoulder bolt, remove 6 bolts

and remove rear output shaft housing.

22.Remove rear bearing track from main casing.

23.Secure differential in a soft jawed vice.

24.Release staking from bearing retaining nut.

25.Using tool LRT-41-007 remove and discard

bearing retaining nut. 26.Position tool LRT-99-002 to vice.

27.Position tool LRT-41-001 around rear

differential bearing, position differential to tool

LRT-99-002 and press off bearing.

28.Remove high range gear and bush.

Page 779 of 1672

TRANSFER BOX - LT230SE

41-46 OVERHAUL

29.Make suitable alignment marks between high/

low selector sleeve and hub, remove selector

sleeve.

30.Using a suitable press and thrust button LRT-

41-001 remove high/low hub and low range

gear.

31.Position tool LRT-41-002 around front

differential bearing and tool LRT-41-001 t h r u s t

button to differential shaft and press off

bearing. Disassembly

1.Secure rear half of differential carrier in a soft

jawed vice.

2.Make suitable alignment marks between front

and rear halves of differential carrier.

3.Remove 8 bolts securing front half of carrier to

rear and separate both halves of carrier.

4.Suitably identify front sun gear to front half of

carrier, then remove sun gear.

5.Remove and discard thrust washer.

6.Suitably identify each planet gear to its shaft

and fitted position of each cross shaft to rear

half of carrier

7.Remove retaining ring.

8.Remove planet gears and cross shafts, remove

and discard dished thrust washers.

9.Suitably identify rear sun gear to rear half of

carrier, then remove sun gear.

10.Remove and discard thrust washer.

Page 780 of 1672

TRANSFER BOX - LT230SE

OVERHAUL 41-47

Inspect

1.Check mating surfaces of cross shaft and

housing bore for wear.

2.Check core plug in housing for signs of leakage

or corrosion ; apply Loctite 326 to replacement

plug.

3.Measuring across widest portion of finger,

check high/low selector finger for wear.

lFinger width = 15.90 to 15.95 mm (0.625 to

0.627 in).

4.Check bearing track recesses in housing for

damage, rectify or replace housing as

necessary.

5. If fitted: Carry out inspection of differential

lock components using following procedures.

6.Check differential lock selector shaft and

housing bore for wear.

7.Measuring across the widest portion, check

differential lock finger for wear.

lFinger width = 15.90 to 15.95 mm (0.625 to

0.627 in).8.Check differential lock selector finger groove in

selector shaft.

lGroove width = 16.0 to 16.1 mm (0.63 to

0.64 in).

9.Check detent grooves in differential lock

selector shaft for wear.

10.Check differential lock detent ball for flat spots

and check detent spring for distortion.