LAND ROVER DISCOVERY 2002 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 851 of 1672

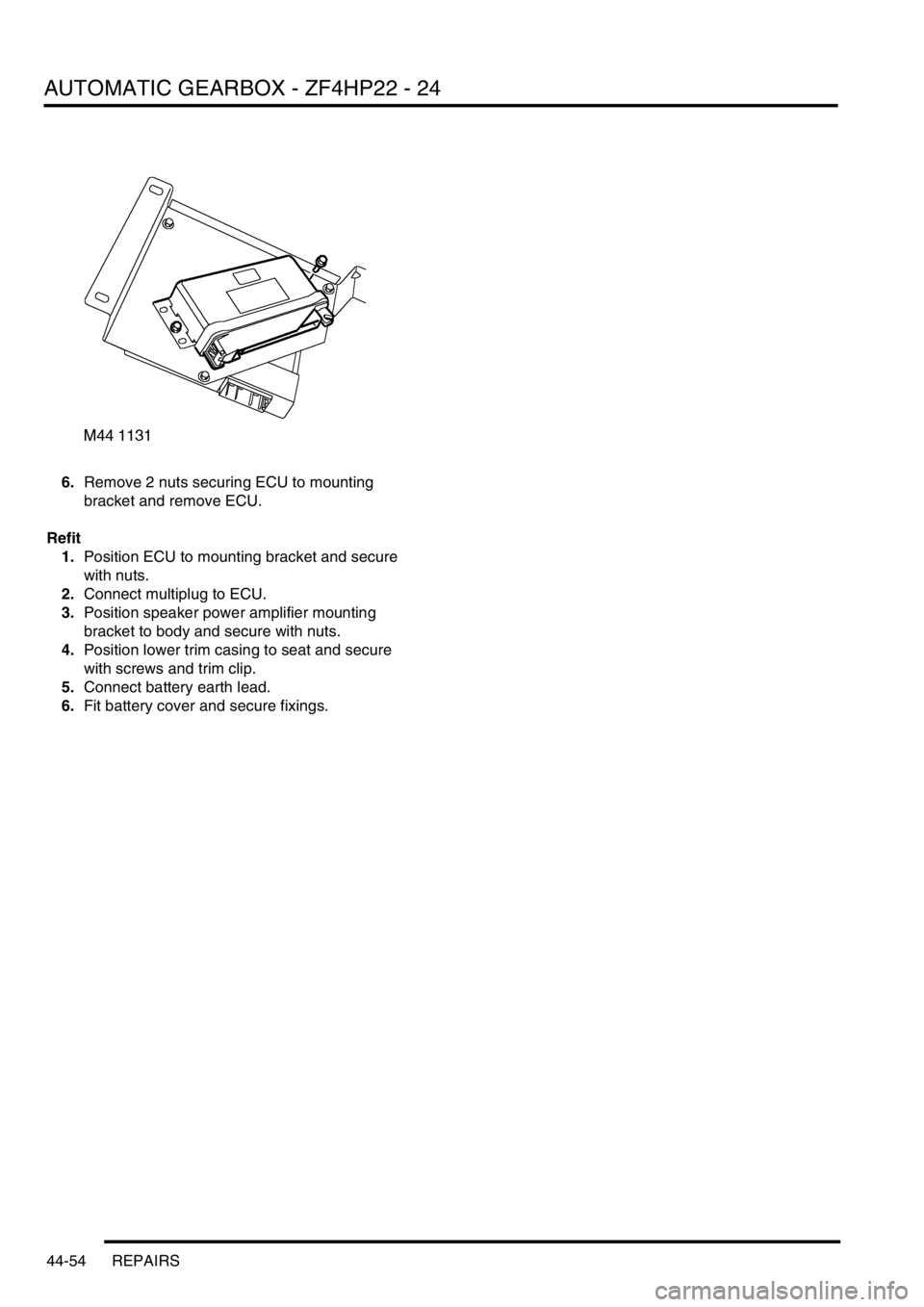

AUTOMATIC GEARBOX - ZF4HP22 - 24

44-54 REPAIRS

6.Remove 2 nuts securing ECU to mounting

bracket and remove ECU.

Refit

1.Position ECU to mounting bracket and secure

with nuts.

2.Connect multiplug to ECU.

3.Position speaker power amplifier mounting

bracket to body and secure with nuts.

4.Position lower trim casing to seat and secure

with screws and trim clip.

5.Connect battery earth lead.

6.Fit battery cover and secure fixings.

Page 852 of 1672

PROPELLER SHAFTS

DESCRIPTION AND OPERATION 47-1

PROPELLER SH AFTS DESCRIPTION AND OPERAT ION

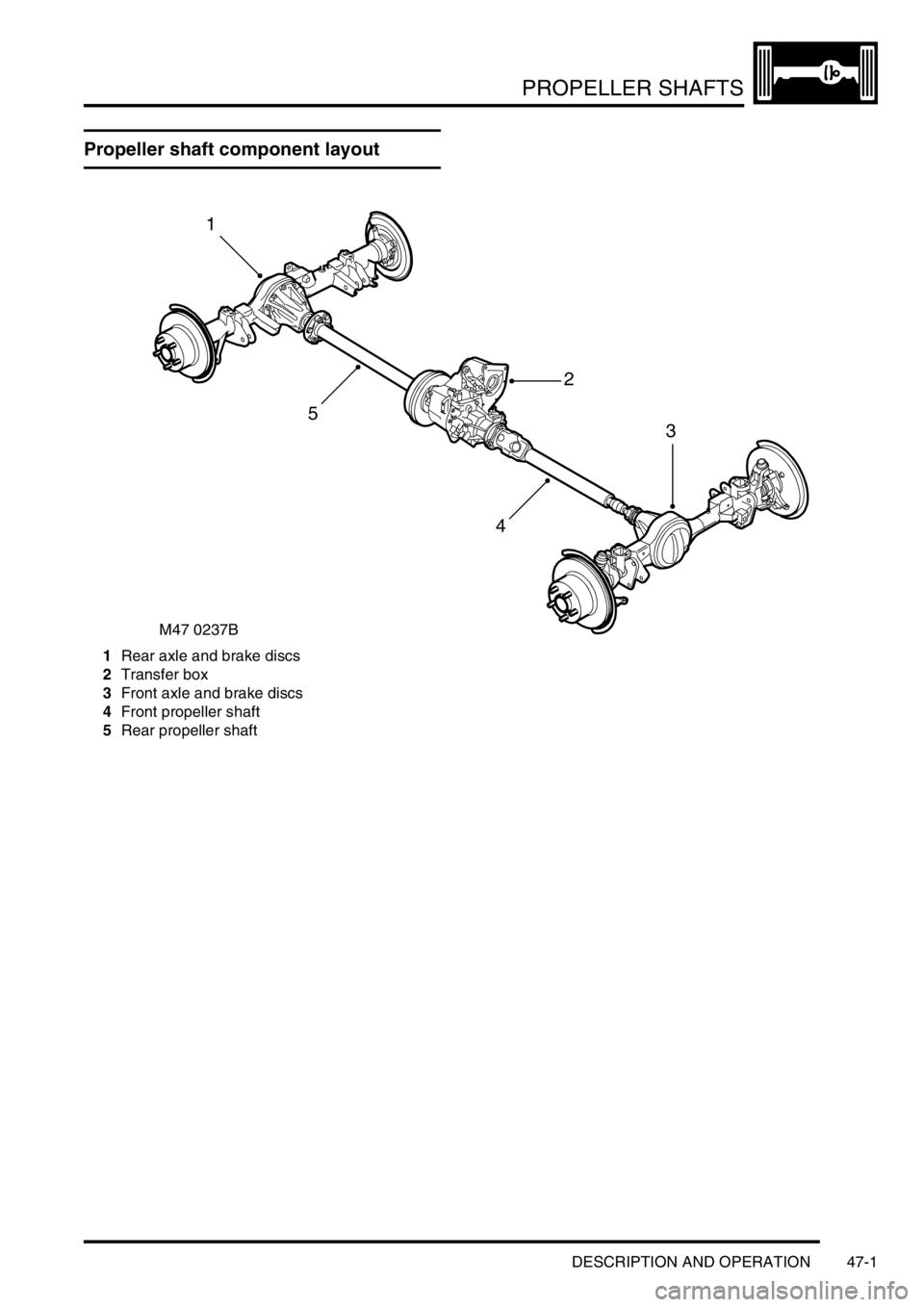

Propeller shaft component layout

1Rear axle and brake discs

2Transfer box

3Front axle and brake discs

4Front propeller shaft

5Rear propeller shaft

M47 0237B

1

2

3

4

5

Page 853 of 1672

PROPELLER SHAFTS

47-2 DESCRIPTION AND OPERATION

Description

General

Front and rear propeller shafts transmit the drive from the transfer box to the axles.

On vehicles from 03 model year fitted with the 4.6l V8 engine and 4HP24 transmission, the front propeller shaft is 15

mm (0.6 in) longer and the rear propeller shaft is 15mm (0.6 in) shorter than those used on vehicles with the 4.0l V8

and Td5 engines. This is to accomodate an increase in length of the 4HP24 transmission.

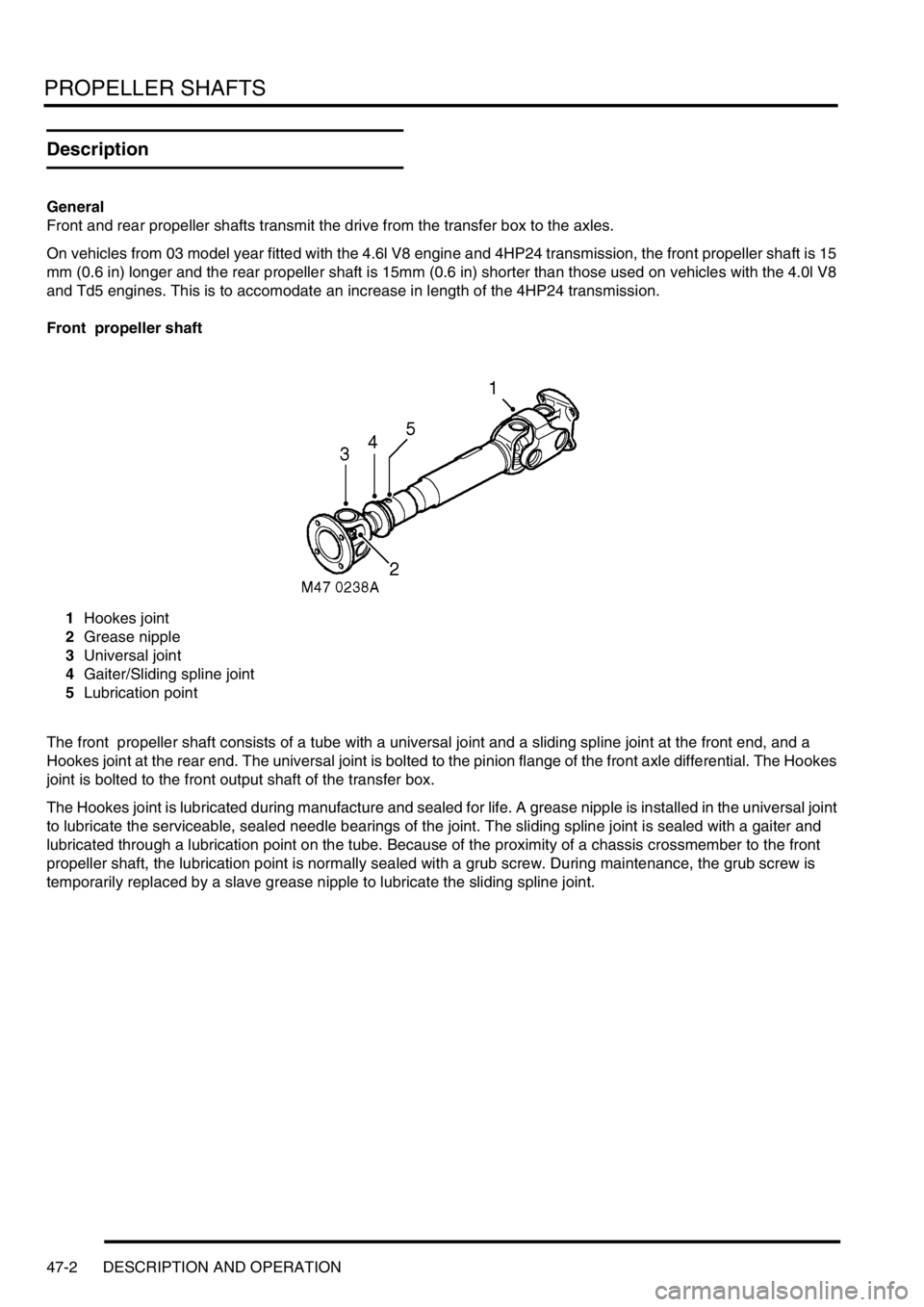

Front propeller shaft

1Hookes joint

2Grease nipple

3Universal joint

4Gaiter/Sliding spline joint

5Lubrication point

The front propeller shaft consists of a tube with a universal joint and a sliding spline joint at the front end, and a

Hookes joint at the rear end. The universal joint is bolted to the pinion flange of the front axle differential. The Hookes

joint is bolted to the front output shaft of the transfer box.

The Hookes joint is lubricated during manufacture and sealed for life. A grease nipple is installed in the universal joint

to lubricate the serviceable, sealed needle bearings of the joint. The sliding spline joint is sealed with a gaiter and

lubricated through a lubrication point on the tube. Because of the proximity of a chassis crossmember to the front

propeller shaft, the lubrication point is normally sealed with a grub screw. During maintenance, the grub screw is

temporarily replaced by a slave grease nipple to lubricate the sliding spline joint.

Page 854 of 1672

PROPELLER SHAFTS

DESCRIPTION AND OPERATION 47-3

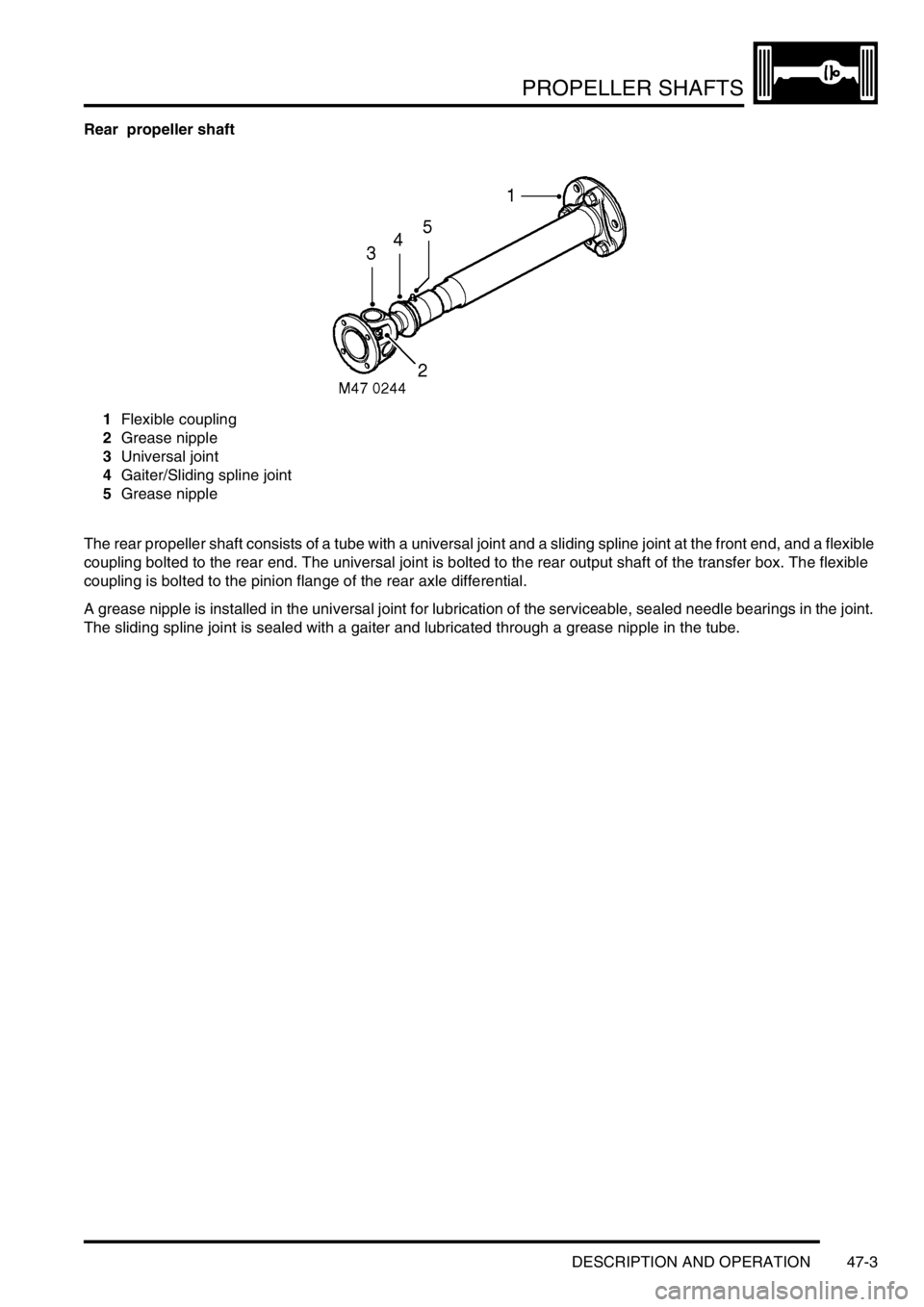

Rear propeller shaft

1Flexible coupling

2Grease nipple

3Universal joint

4Gaiter/Sliding spline joint

5Grease nipple

The rear propeller shaft consists of a tube with a universal joint and a sliding spline joint at the front end, and a flexible

coupling bolted to the rear end. The universal joint is bolted to the rear output shaft of the transfer box. The flexible

coupling is bolted to the pinion flange of the rear axle differential.

A grease nipple is installed in the universal joint for lubrication of the serviceable, sealed needle bearings in the joint.

The sliding spline joint is sealed with a gaiter and lubricated through a grease nipple in the tube.

Page 855 of 1672

PROPELLER SHAFTS

47-4 DESCRIPTION AND OPERATION

Page 856 of 1672

PROPELLER SHAFTS

REPAIRS 47-5

REPAIRS

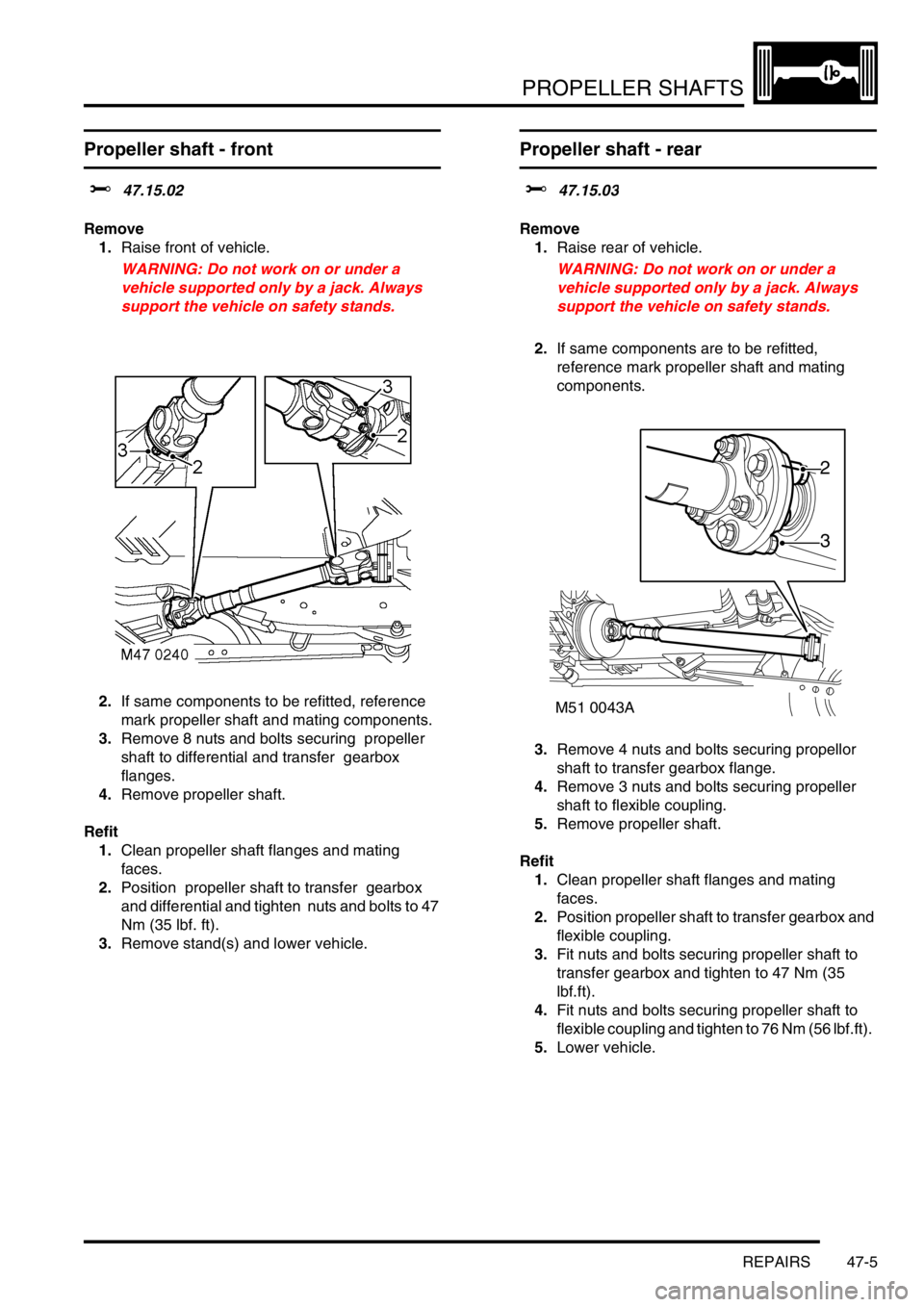

Propeller shaft - front

$% 47.15.02

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.If same components to be refitted, reference

mark propeller shaft and mating components.

3.Remove 8 nuts and bolts securing propeller

shaft to differential and transfer gearbox

flanges.

4.Remove propeller shaft.

Refit

1.Clean propeller shaft flanges and mating

faces.

2.Position propeller shaft to transfer gearbox

and differential and tighten nuts and bolts to 47

Nm (35 lbf. ft).

3.Remove stand(s) and lower vehicle.

Propeller shaft - rear

$% 47.15.03

Remove

1.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.If same components are to be refitted,

reference mark propeller shaft and mating

components.

3.Remove 4 nuts and bolts securing propellor

shaft to transfer gearbox flange.

4.Remove 3 nuts and bolts securing propeller

shaft to flexible coupling.

5.Remove propeller shaft.

Refit

1.Clean propeller shaft flanges and mating

faces.

2.Position propeller shaft to transfer gearbox and

flexible coupling.

3.Fit nuts and bolts securing propeller shaft to

transfer gearbox and tighten to 47 Nm (35

lbf.ft).

4.Fit nuts and bolts securing propeller shaft to

flexible coupling and tighten to 76 Nm (56 lbf.ft).

5.Lower vehicle.

M51 0043A

2

3

Page 857 of 1672

PROPELLER SHAFTS

47-6 REPAIRS

Flexible coupling

$% 47.20.08

Remove

1.Raise rear of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.If same components to be refitted, reference

mark flexible coupling and mating components.

3.Remove 3 nuts and bolts securing propeller

shaft to flexible coupling.

4.Move propeller shaft forwards to release from

flexible coupling and differential drive flange

spigot.

5.Tie propeller shaft aside.

6.Remove 3 nuts and bolts securing flexible

coupling to differential drive flange and remove

flexible coupling.Refit

1.Ensure flexible coupling, spigot and drive

flanges are clean.

2.Align the arrows on the flexible coupling with

the securing bolt positions as illustrated. Fit

flexible coupling to differential drive flange and

tighten nuts and bolts to 76 Nm (56 lbf.ft).

3.Fit propeller shaft to spigot and flexible

coupling. Tighten nuts and bolts to 76 Nm (56

lbf.ft).

4.Remove stand(s) and lower vehicle.

Page 858 of 1672

PROPELLER SHAFTS

OVERHAUL 47-7

OVERHAUL

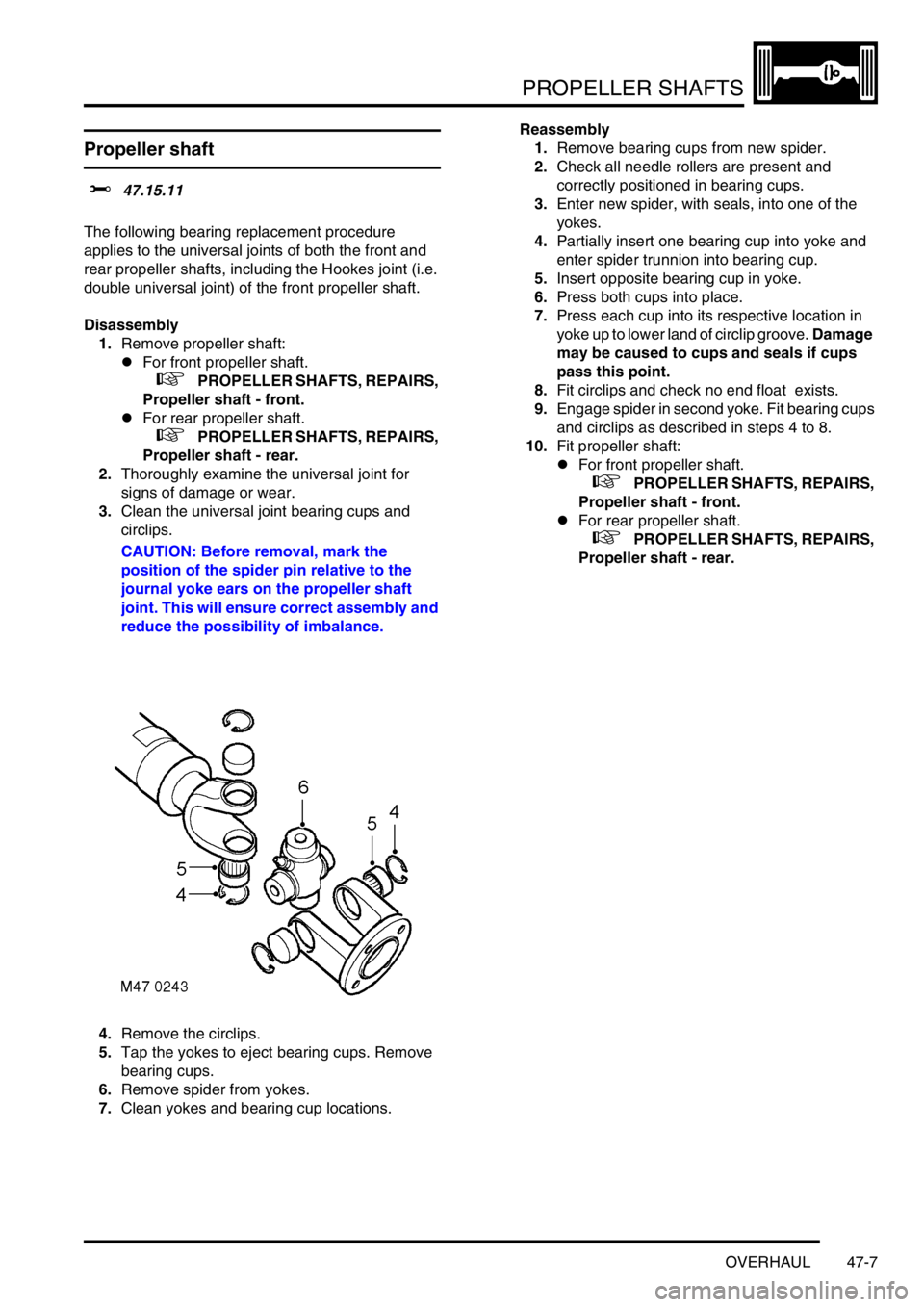

Propeller shaft

$% 47.15.11

The following bearing replacement procedure

applies to the universal joints of both the front and

rear propeller shafts, including the Hookes joint (i.e.

double universal joint) of the front propeller shaft.

Disassembly

1.Remove propeller shaft:

lFor front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

lFor rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

2.Thoroughly examine the universal joint for

signs of damage or wear.

3.Clean the universal joint bearing cups and

circlips.

CAUTION: Before removal, mark the

position of the spider pin relative to the

journal yoke ears on the propeller shaft

joint. This will ensure correct assembly and

reduce the possibility of imbalance.

4.Remove the circlips.

5.Tap the yokes to eject bearing cups. Remove

bearing cups.

6.Remove spider from yokes.

7.Clean yokes and bearing cup locations. Reassembly

1.Remove bearing cups from new spider.

2.Check all needle rollers are present and

correctly positioned in bearing cups.

3.Enter new spider, with seals, into one of the

yokes.

4.Partially insert one bearing cup into yoke and

enter spider trunnion into bearing cup.

5.Insert opposite bearing cup in yoke.

6.Press both cups into place.

7.Press each cup into its respective location in

yoke up to lower land of circlip groove. Damage

may be caused to cups and seals if cups

pass this point.

8.Fit circlips and check no end float exists.

9.Engage spider in second yoke. Fit bearing cups

and circlips as described in steps 4 to 8.

10.Fit propeller shaft:

lFor front propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - front.

lFor rear propeller shaft.

+ PROPELLER SHAFTS, REPAIRS,

Propeller shaft - rear.

Page 859 of 1672

PROPELLER SHAFTS

47-8 OVERHAUL

Page 860 of 1672

REAR AXLE

DESCRIPTION AND OPERATION 51-1

REAR AXLE DESCRIPTION AND OPERAT ION

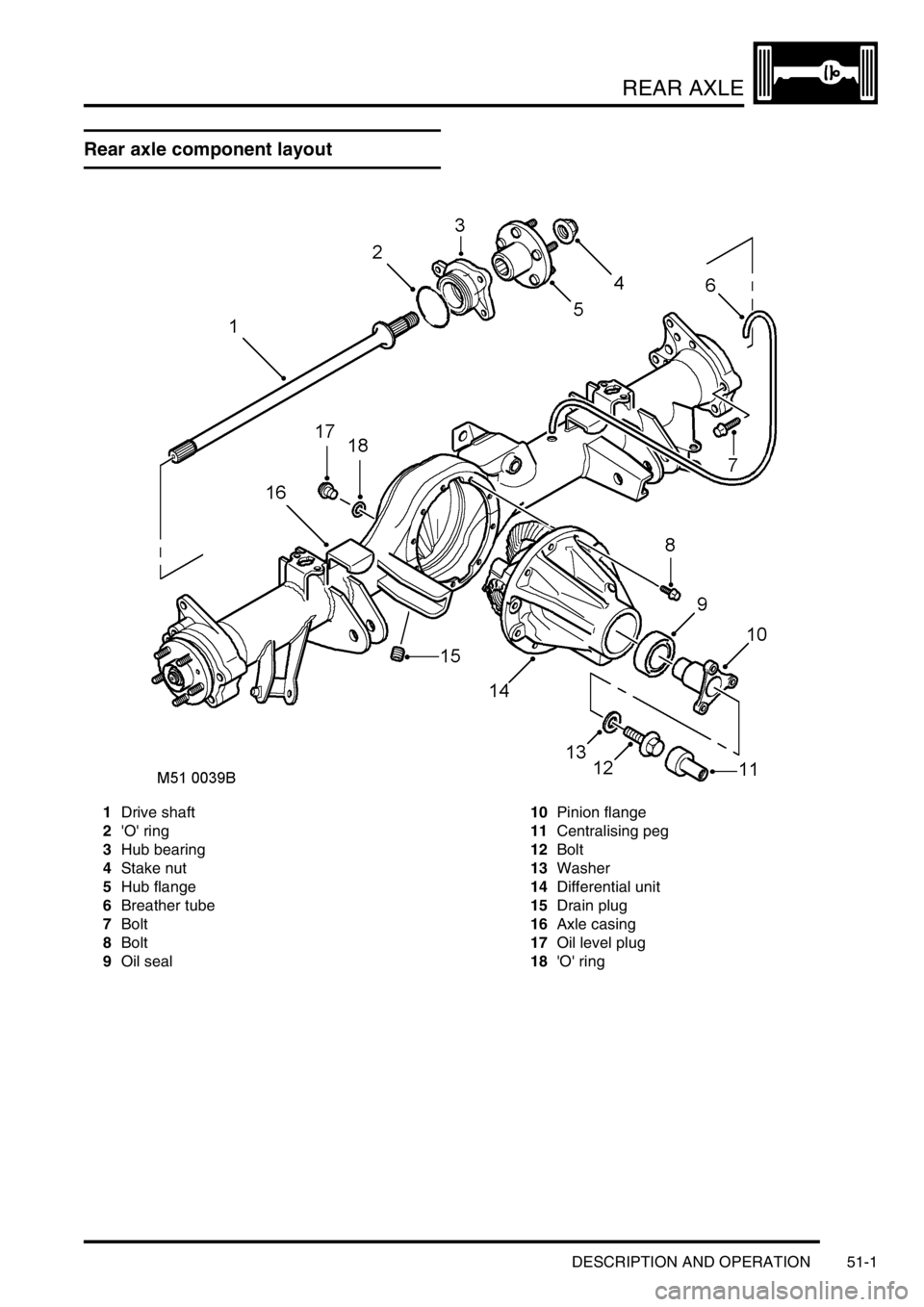

Rear axle component layout

1Drive shaft

2'O' ring

3Hub bearing

4Stake nut

5Hub flange

6Breather tube

7Bolt

8Bolt

9Oil seal10Pinion flange

11Centralising peg

12Bolt

13Washer

14Differential unit

15Drain plug

16Axle casing

17Oil level plug

18'O' ring