lock LAND ROVER FREELANDER 2001 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 2001, Model line: FREELANDER, Model: LAND ROVER FREELANDER 2001Pages: 1007, PDF Size: 23.47 MB

Page 422 of 1007

INTERMEDIATE REDUCTION DRIVE

REPAIRS 41-19

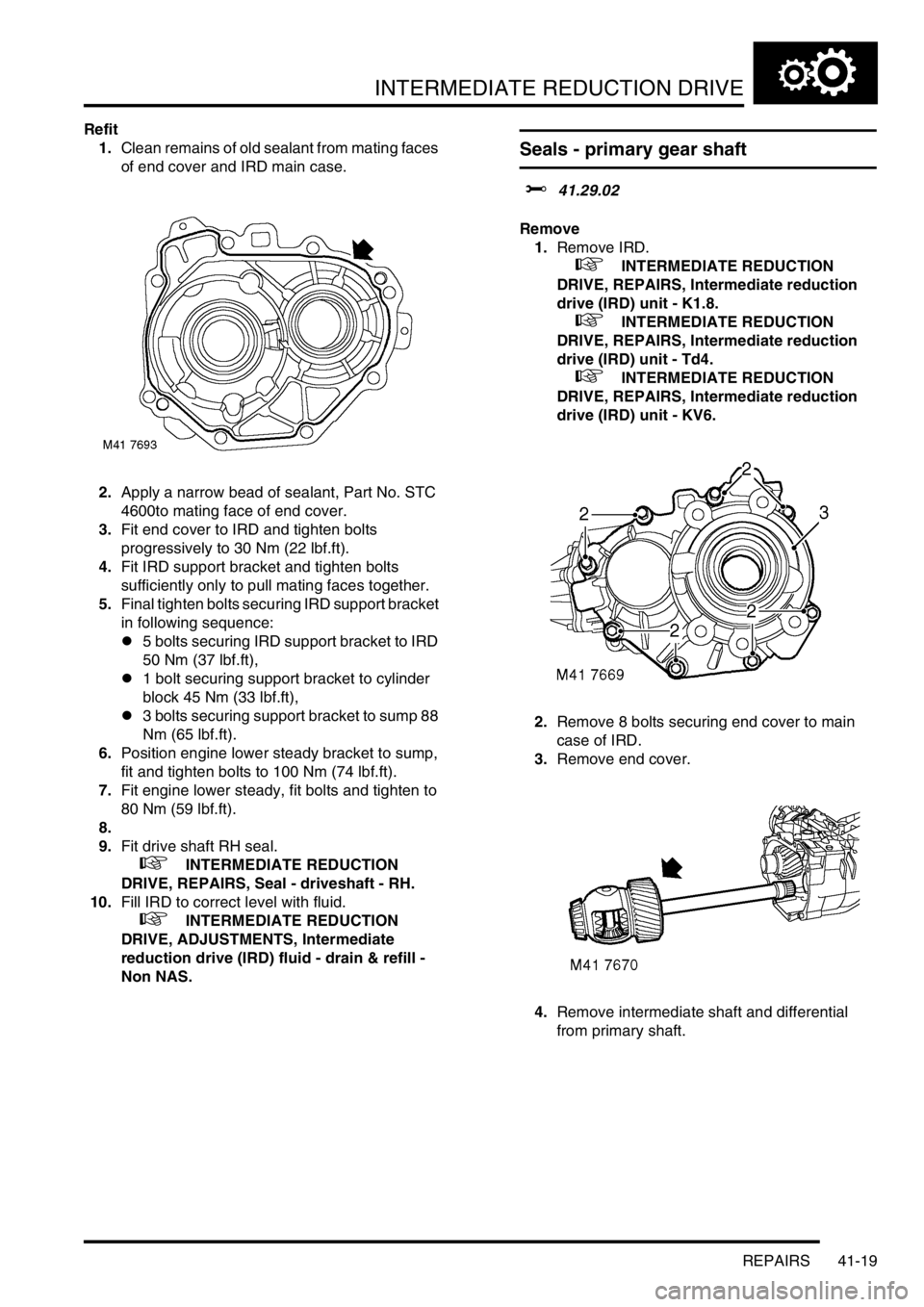

Refit

1.Clean remains of old sealant from mating faces

of end cover and IRD main case.

2.Apply a narrow bead of sealant, Part No. STC

4600to mating face of end cover.

3.Fit end cover to IRD and tighten bolts

progressively to 30 Nm (22 lbf.ft).

4.Fit IRD support bracket and tighten bolts

sufficiently only to pull mating faces together.

5.Final tighten bolts securing IRD support bracket

in following sequence:

l5 bolts securing IRD support bracket to IRD

50 Nm (37 lbf.ft),

l1 bolt securing support bracket to cylinder

block 45 Nm (33 lbf.ft),

l3 bolts securing support bracket to sump 88

Nm (65 lbf.ft).

6.Position engine lower steady bracket to sump,

fit and tighten bolts to 100 Nm (74 lbf.ft).

7.Fit engine lower steady, fit bolts and tighten to

80 Nm (59 lbf.ft).

8.

9.Fit drive shaft RH seal.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Seal - driveshaft - RH.

10.Fill IRD to correct level with fluid.

+ INTERMEDIATE REDUCTION

DRIVE, ADJUSTMENTS, Intermediate

reduction drive (IRD) fluid - drain & refill -

Non NAS.

Seals - primary gear shaft

$% 41.29.02

Remove

1.Remove IRD.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Intermediate reduction

drive (IRD) unit - K1.8.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Intermediate reduction

drive (IRD) unit - Td4.

+ INTERMEDIATE REDUCTION

DRIVE, REPAIRS, Intermediate reduction

drive (IRD) unit - KV6.

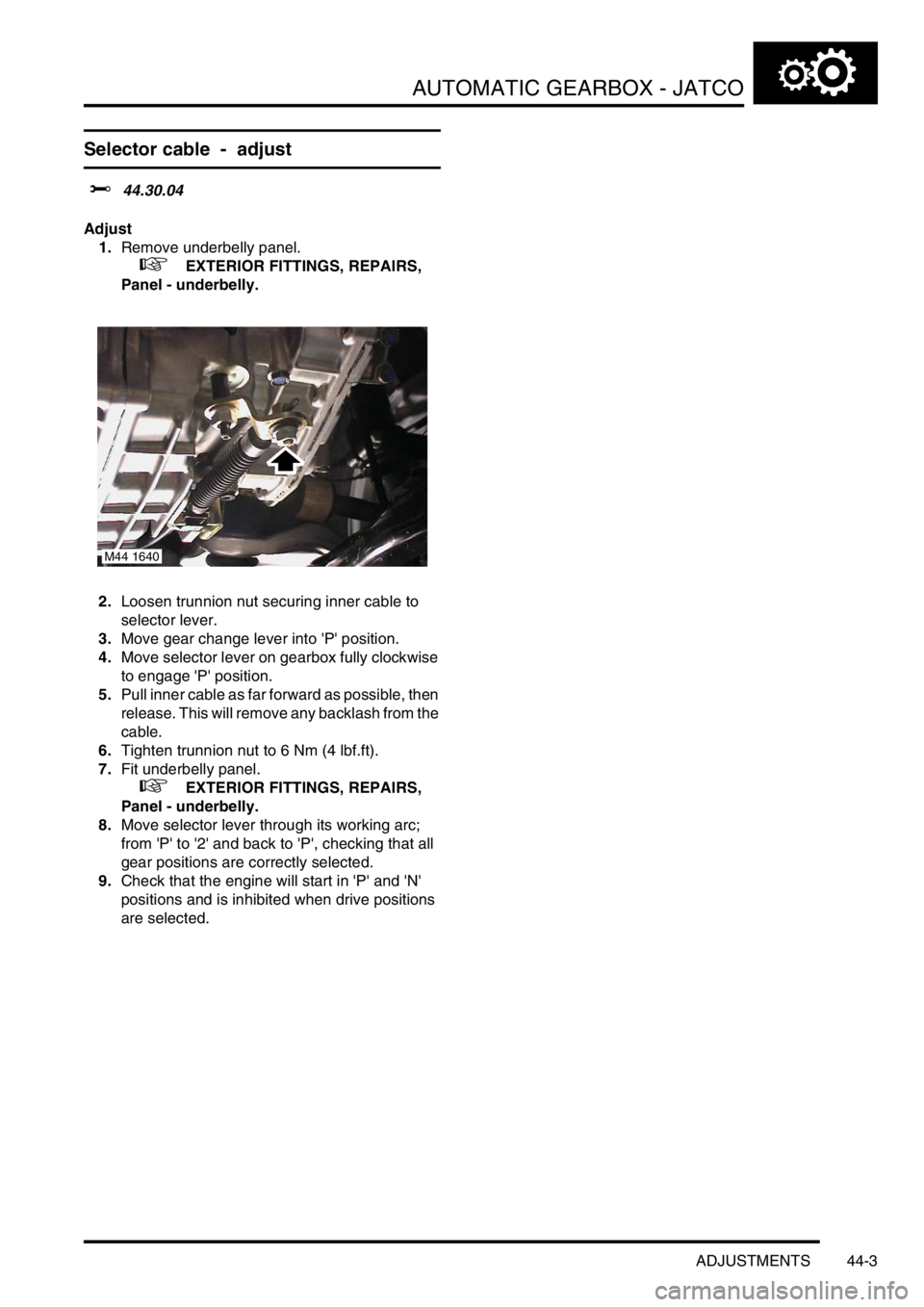

2.Remove 8 bolts securing end cover to main

case of IRD.

3.Remove end cover.

4.Remove intermediate shaft and differential

from primary shaft.

Page 438 of 1007

AUTOMATIC GEARBOX - JATCO

ADJUSTMENTS 44-3

Selector cable - adjust

$% 44.30.04

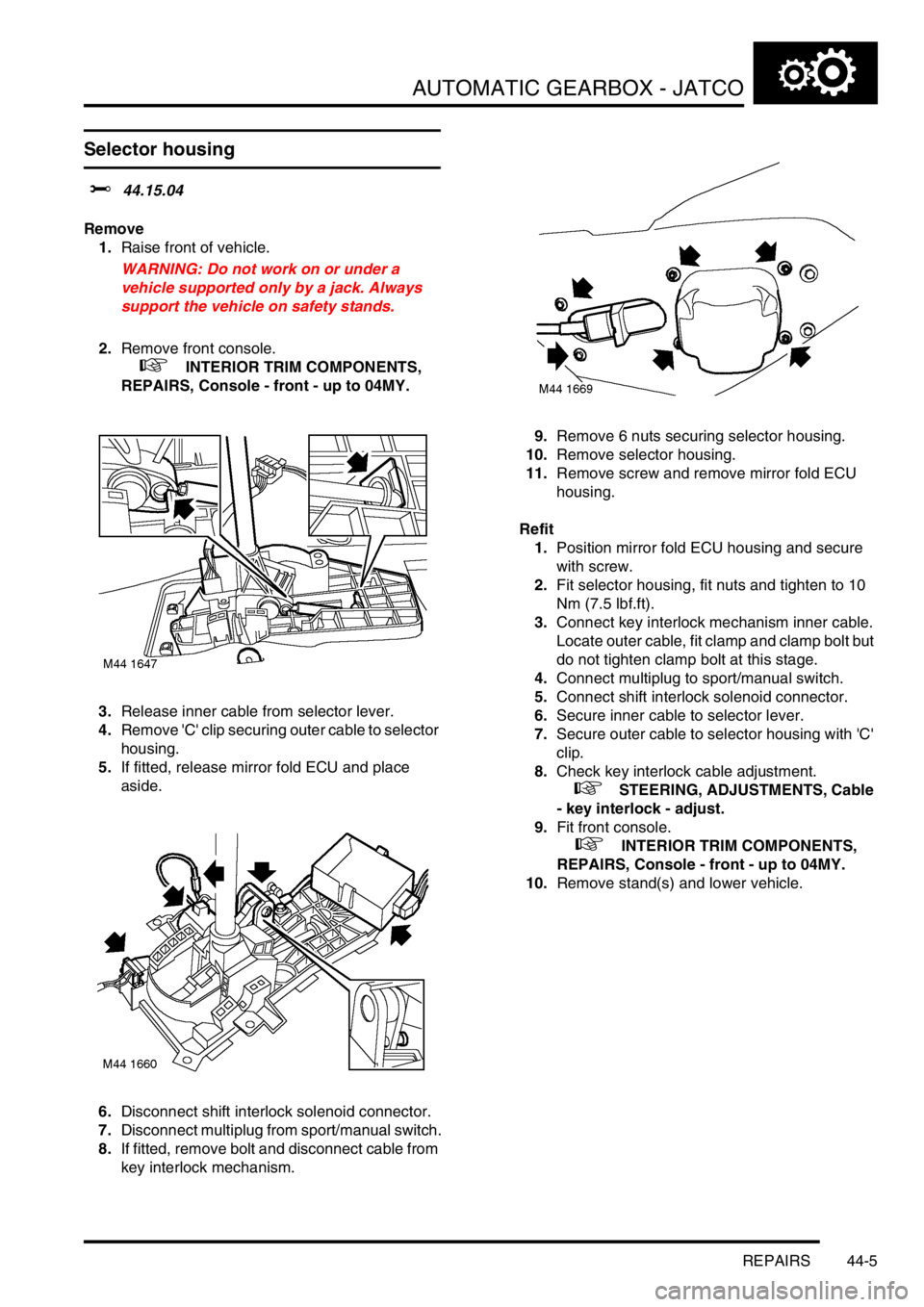

Adjust

1.Remove underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

2.Loosen trunnion nut securing inner cable to

selector lever.

3.Move gear change lever into 'P' position.

4.Move selector lever on gearbox fully clockwise

to engage 'P' position.

5.Pull inner cable as far forward as possible, then

release. This will remove any backlash from the

cable.

6.Tighten trunnion nut to 6 Nm (4 lbf.ft).

7.Fit underbelly panel.

+ EXTERIOR FITTINGS, REPAIRS,

Panel - underbelly.

8.Move selector lever through its working arc;

from 'P' to '2' and back to 'P', checking that all

gear positions are correctly selected.

9.Check that the engine will start in 'P' and 'N'

positions and is inhibited when drive positions

are selected.

M44 1640

Page 440 of 1007

AUTOMATIC GEARBOX - JATCO

REPAIRS 44-5

REPAIRS

Selector housing

$% 44.15.04

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove front console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - front - up to 04MY.

3.Release inner cable from selector lever.

4.Remove 'C' clip securing outer cable to selector

housing.

5.If fitted, release mirror fold ECU and place

aside.

6.Disconnect shift interlock solenoid connector.

7.Disconnect multiplug from sport/manual switch.

8.If fitted, remove bolt and disconnect cable from

key interlock mechanism.9.Remove 6 nuts securing selector housing.

10.Remove selector housing.

11.Remove screw and remove mirror fold ECU

housing.

Refit

1.Position mirror fold ECU housing and secure

with screw.

2.Fit selector housing, fit nuts and tighten to 10

Nm (7.5 lbf.ft).

3.Connect key interlock mechanism inner cable.

Locate outer cable, fit clamp and clamp bolt but

do not tighten clamp bolt at this stage.

4.Connect multiplug to sport/manual switch.

5.Connect shift interlock solenoid connector.

6.Secure inner cable to selector lever.

7.Secure outer cable to selector housing with 'C'

clip.

8.Check key interlock cable adjustment.

+ STEERING, ADJUSTMENTS, Cable

- key interlock - adjust.

9.Fit front console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - front - up to 04MY.

10.Remove stand(s) and lower vehicle.

Page 478 of 1007

DRIVESHAFTS

REPAIRS 47-11

Propeller shaft - front

$% 47.15.02

Remove

1.With assistance remove complete propeller

shaft assembly.

+ DRIVESHAFTS, REPAIRS, Propeller

shaft assembly.

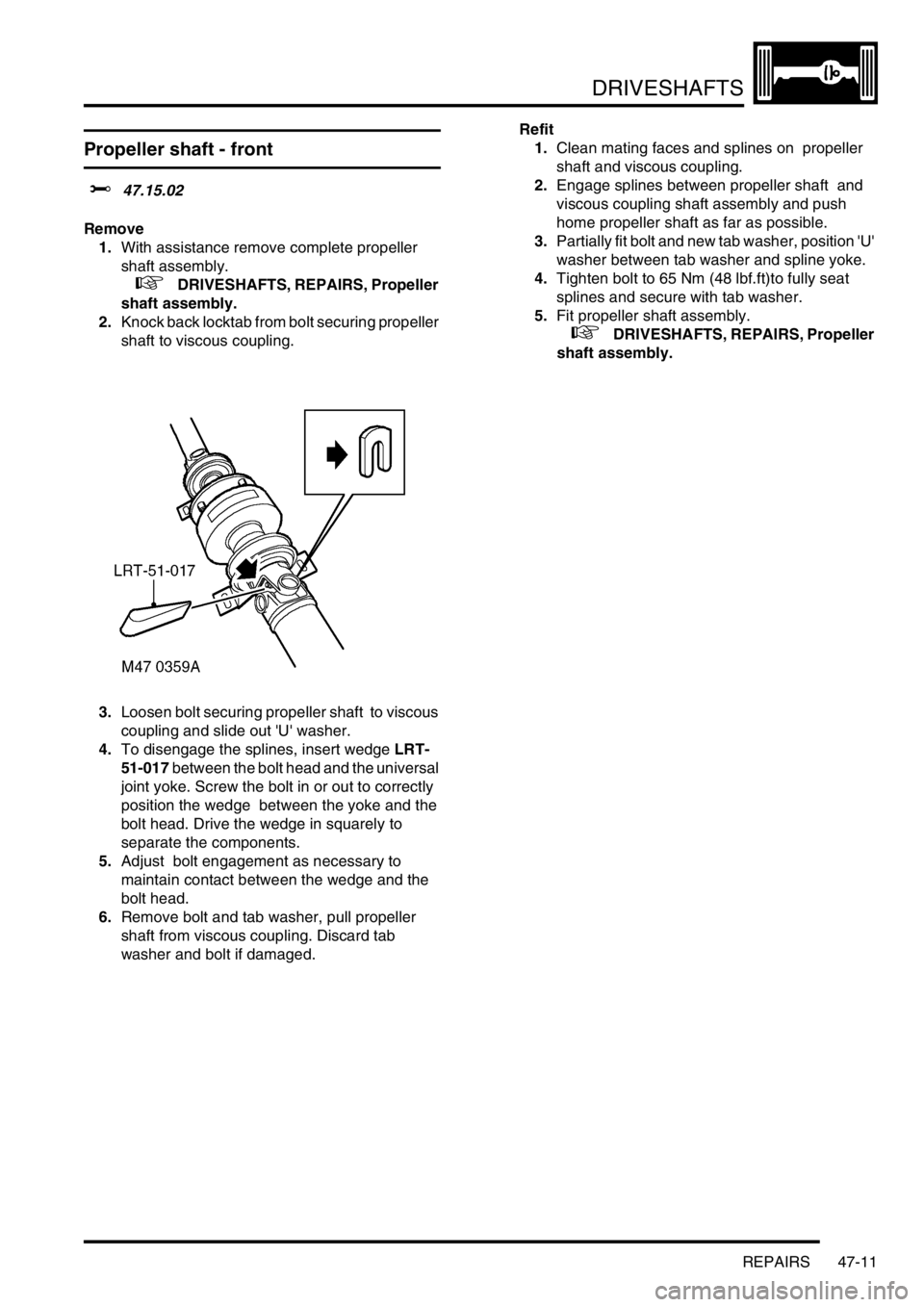

2.Knock back locktab from bolt securing propeller

shaft to viscous coupling.

3.Loosen bolt securing propeller shaft to viscous

coupling and slide out 'U' washer.

4.To disengage the splines, insert wedge LRT-

51-017 between the bolt head and the universal

joint yoke. Screw the bolt in or out to correctly

position the wedge between the yoke and the

bolt head. Drive the wedge in squarely to

separate the components.

5.Adjust bolt engagement as necessary to

maintain contact between the wedge and the

bolt head.

6.Remove bolt and tab washer, pull propeller

shaft from viscous coupling. Discard tab

washer and bolt if damaged.Refit

1.Clean mating faces and splines on propeller

shaft and viscous coupling.

2.Engage splines between propeller shaft and

viscous coupling shaft assembly and push

home propeller shaft as far as possible.

3.Partially fit bolt and new tab washer, position 'U'

washer between tab washer and spline yoke.

4.Tighten bolt to 65 Nm (48 lbf.ft)to fully seat

splines and secure with tab washer.

5.Fit propeller shaft assembly.

+ DRIVESHAFTS, REPAIRS, Propeller

shaft assembly.

Page 479 of 1007

DRIVESHAFTS

47-12 REPAIRS

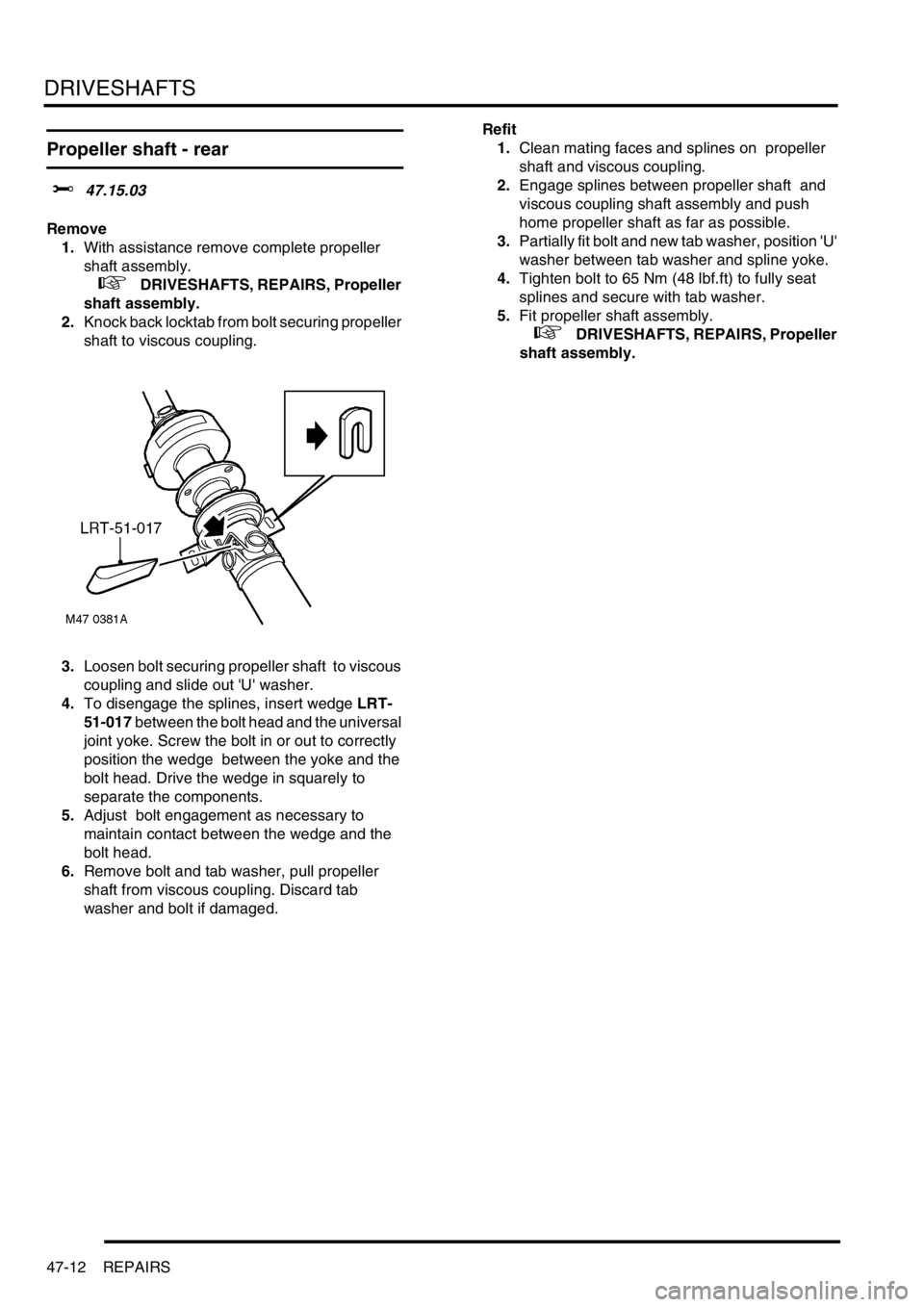

Propeller shaft - rear

$% 47.15.03

Remove

1.With assistance remove complete propeller

shaft assembly.

+ DRIVESHAFTS, REPAIRS, Propeller

shaft assembly.

2.Knock back locktab from bolt securing propeller

shaft to viscous coupling.

3.Loosen bolt securing propeller shaft to viscous

coupling and slide out 'U' washer.

4.To disengage the splines, insert wedge LRT-

51-017 between the bolt head and the universal

joint yoke. Screw the bolt in or out to correctly

position the wedge between the yoke and the

bolt head. Drive the wedge in squarely to

separate the components.

5.Adjust bolt engagement as necessary to

maintain contact between the wedge and the

bolt head.

6.Remove bolt and tab washer, pull propeller

shaft from viscous coupling. Discard tab

washer and bolt if damaged.Refit

1.Clean mating faces and splines on propeller

shaft and viscous coupling.

2.Engage splines between propeller shaft and

viscous coupling shaft assembly and push

home propeller shaft as far as possible.

3.Partially fit bolt and new tab washer, position 'U'

washer between tab washer and spline yoke.

4.Tighten bolt to 65 Nm (48 lbf.ft) to fully seat

splines and secure with tab washer.

5.Fit propeller shaft assembly.

+ DRIVESHAFTS, REPAIRS, Propeller

shaft assembly.

Page 486 of 1007

REAR AXLE & FINAL DRIVE

REPAIRS 51-1

REAR AXLE & FINA L D RIVE REPAIRS

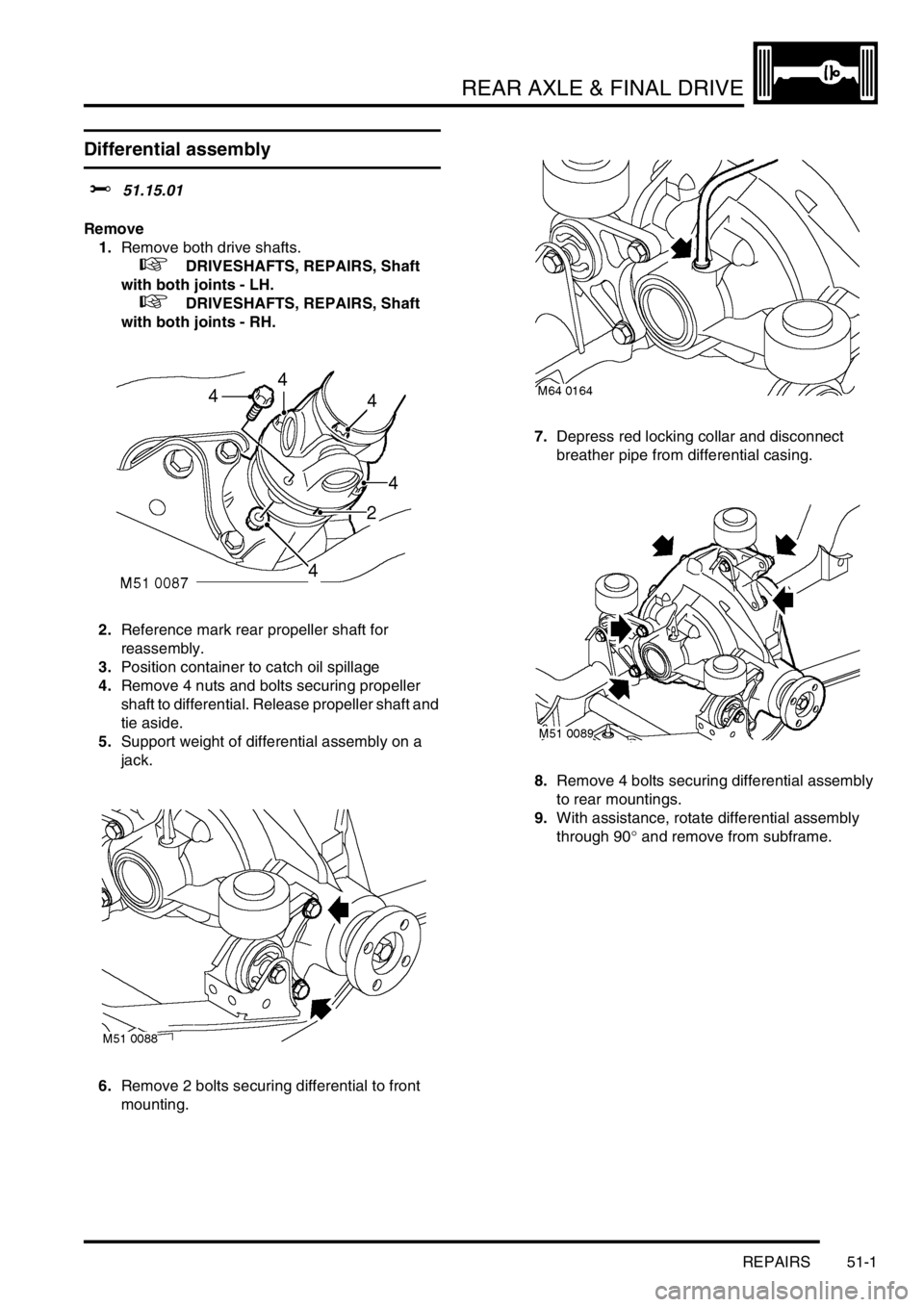

Differential assembly

$% 51.15.01

Remove

1.Remove both drive shafts.

+ DRIVESHAFTS, REPAIRS, Shaft

with both joints - LH.

+ DRIVESHAFTS, REPAIRS, Shaft

with both joints - RH.

2.Reference mark rear propeller shaft for

reassembly.

3.Position container to catch oil spillage

4.Remove 4 nuts and bolts securing propeller

shaft to differential. Release propeller shaft and

tie aside.

5.Support weight of differential assembly on a

jack.

6.Remove 2 bolts securing differential to front

mounting.7.Depress red locking collar and disconnect

breather pipe from differential casing.

8.Remove 4 bolts securing differential assembly

to rear mountings.

9.With assistance, rotate differential assembly

through 90° and remove from subframe.

Page 494 of 1007

STEERING

ADJUSTMENTS 57-1

STEERING ADJUST ME NTS

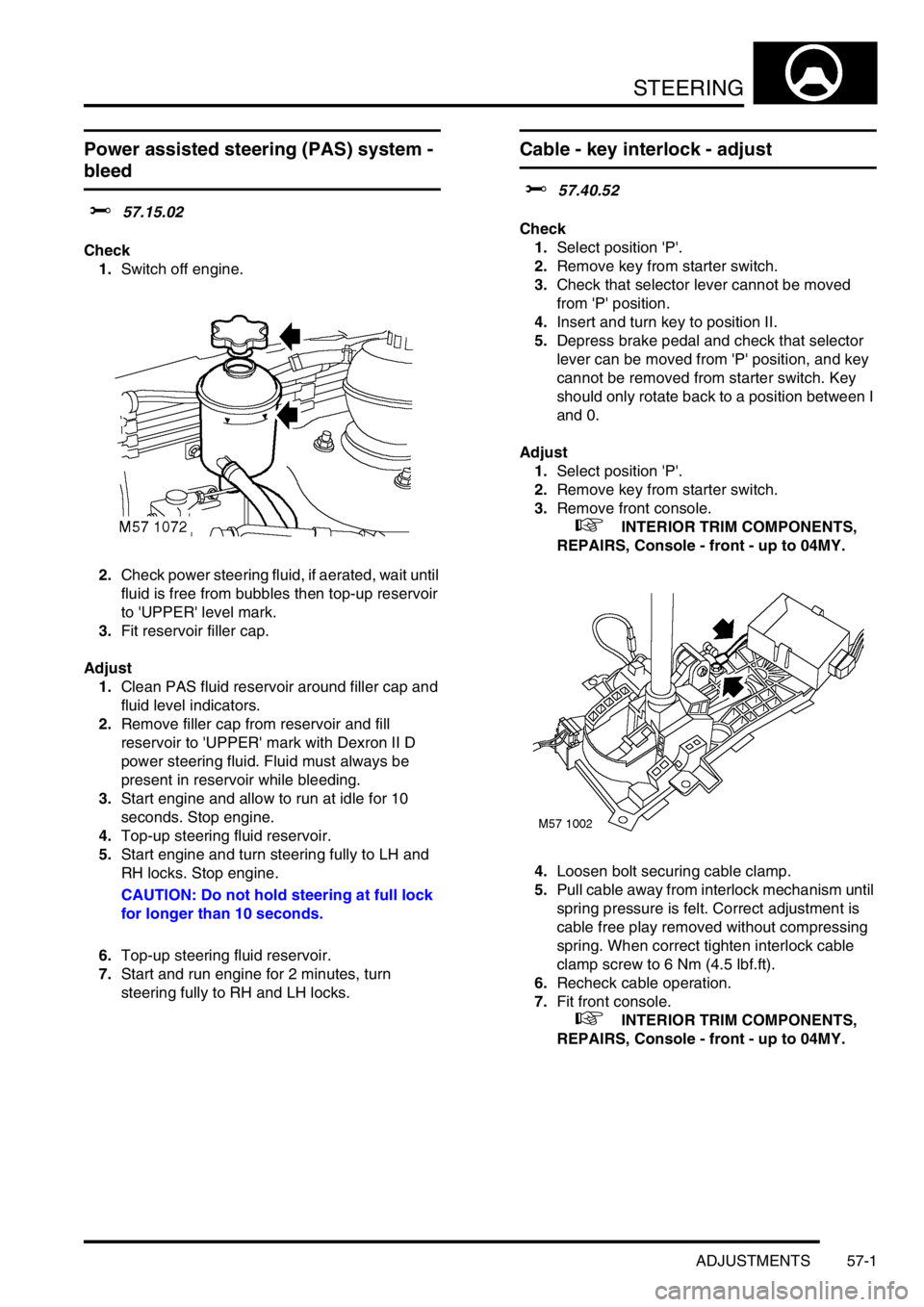

Power assisted steering (PAS) system -

bleed

$% 57.15.02

Check

1.Switch off engine.

2.Check power steering fluid, if aerated, wait until

fluid is free from bubbles then top-up reservoir

to 'UPPER' level mark.

3.Fit reservoir filler cap.

Adjust

1.Clean PAS fluid reservoir around filler cap and

fluid level indicators.

2.Remove filler cap from reservoir and fill

reservoir to 'UPPER' mark with Dexron II D

power steering fluid. Fluid must always be

present in reservoir while bleeding.

3.Start engine and allow to run at idle for 10

seconds. Stop engine.

4.Top-up steering fluid reservoir.

5.Start engine and turn steering fully to LH and

RH locks. Stop engine.

CAUTION: Do not hold steering at full lock

for longer than 10 seconds.

6.Top-up steering fluid reservoir.

7.Start and run engine for 2 minutes, turn

steering fully to RH and LH locks.

Cable - key interlock - adjust

$% 57.40.52

Check

1.Select position 'P'.

2.Remove key from starter switch.

3.Check that selector lever cannot be moved

from 'P' position.

4.Insert and turn key to position II.

5.Depress brake pedal and check that selector

lever can be moved from 'P' position, and key

cannot be removed from starter switch. Key

should only rotate back to a position between I

and 0.

Adjust

1.Select position 'P'.

2.Remove key from starter switch.

3.Remove front console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - front - up to 04MY.

4.Loosen bolt securing cable clamp.

5.Pull cable away from interlock mechanism until

spring pressure is felt. Correct adjustment is

cable free play removed without compressing

spring. When correct tighten interlock cable

clamp screw to 6 Nm (4.5 lbf.ft).

6.Recheck cable operation.

7.Fit front console.

+ INTERIOR TRIM COMPONENTS,

REPAIRS, Console - front - up to 04MY.

Page 496 of 1007

STEERING

ADJUSTMENTS 57-3

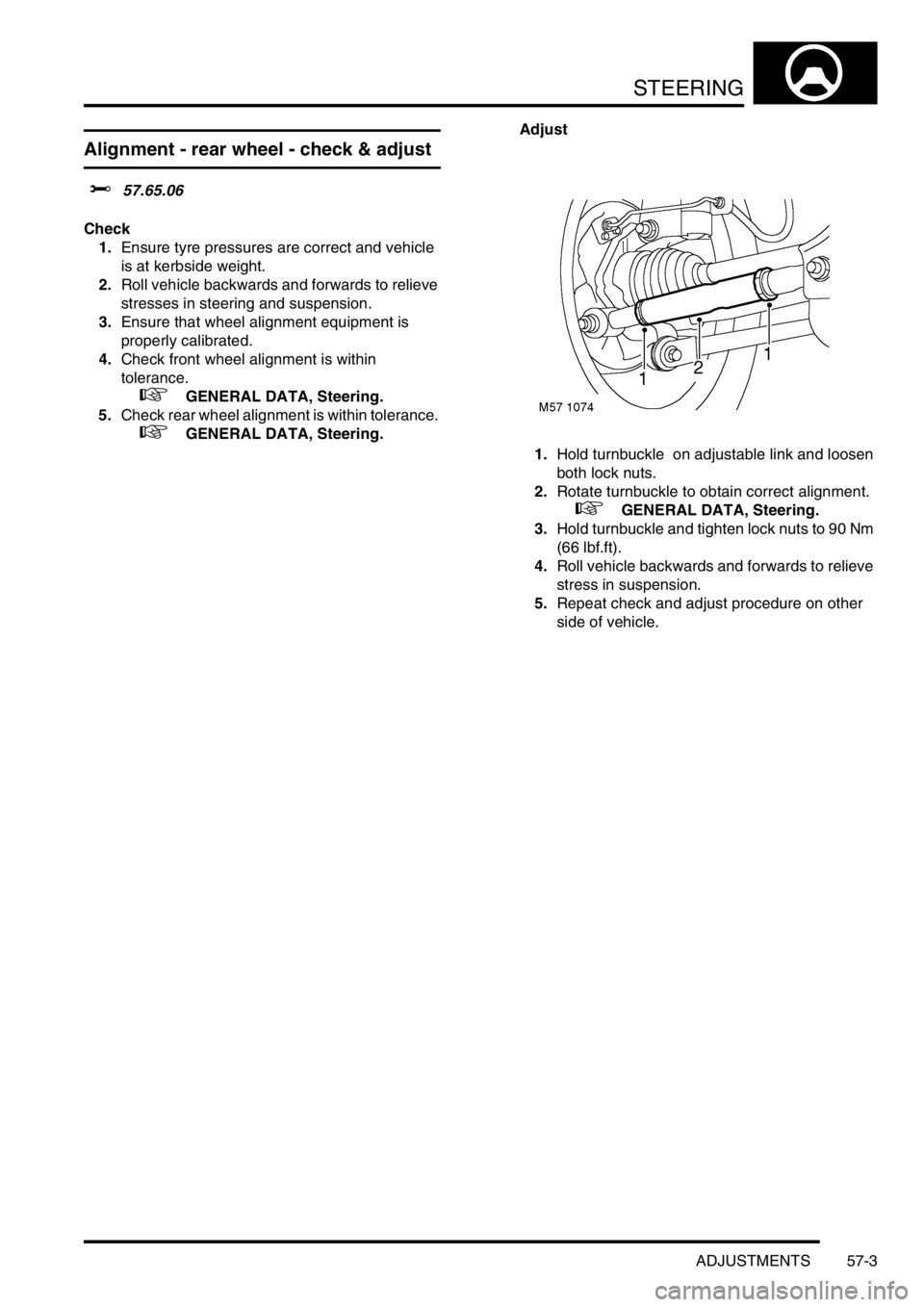

Alignment - rear wheel - check & adjust

$% 57.65.06

Check

1.Ensure tyre pressures are correct and vehicle

is at kerbside weight.

2.Roll vehicle backwards and forwards to relieve

stresses in steering and suspension.

3.Ensure that wheel alignment equipment is

properly calibrated.

4.Check front wheel alignment is within

tolerance.

+ GENERAL DATA, Steering.

5.Check rear wheel alignment is within tolerance.

+ GENERAL DATA, Steering.Adjust

1.Hold turnbuckle on adjustable link and loosen

both lock nuts.

2.Rotate turnbuckle to obtain correct alignment.

+ GENERAL DATA, Steering.

3.Hold turnbuckle and tighten lock nuts to 90 Nm

(66 lbf.ft).

4.Roll vehicle backwards and forwards to relieve

stress in suspension.

5.Repeat check and adjust procedure on other

side of vehicle.

Page 497 of 1007

STEERING

57-4 ADJUSTMENTS

Power steering - pressure test

$% 57.90.10.01

Check

1.Position absorbent cloth to catch spillage.

2.Remove bolt securing PAS high pressure pipe

clip to PAS pump.

3.Loosen union securing high pressure pipe to

PAS pump and release pipe.

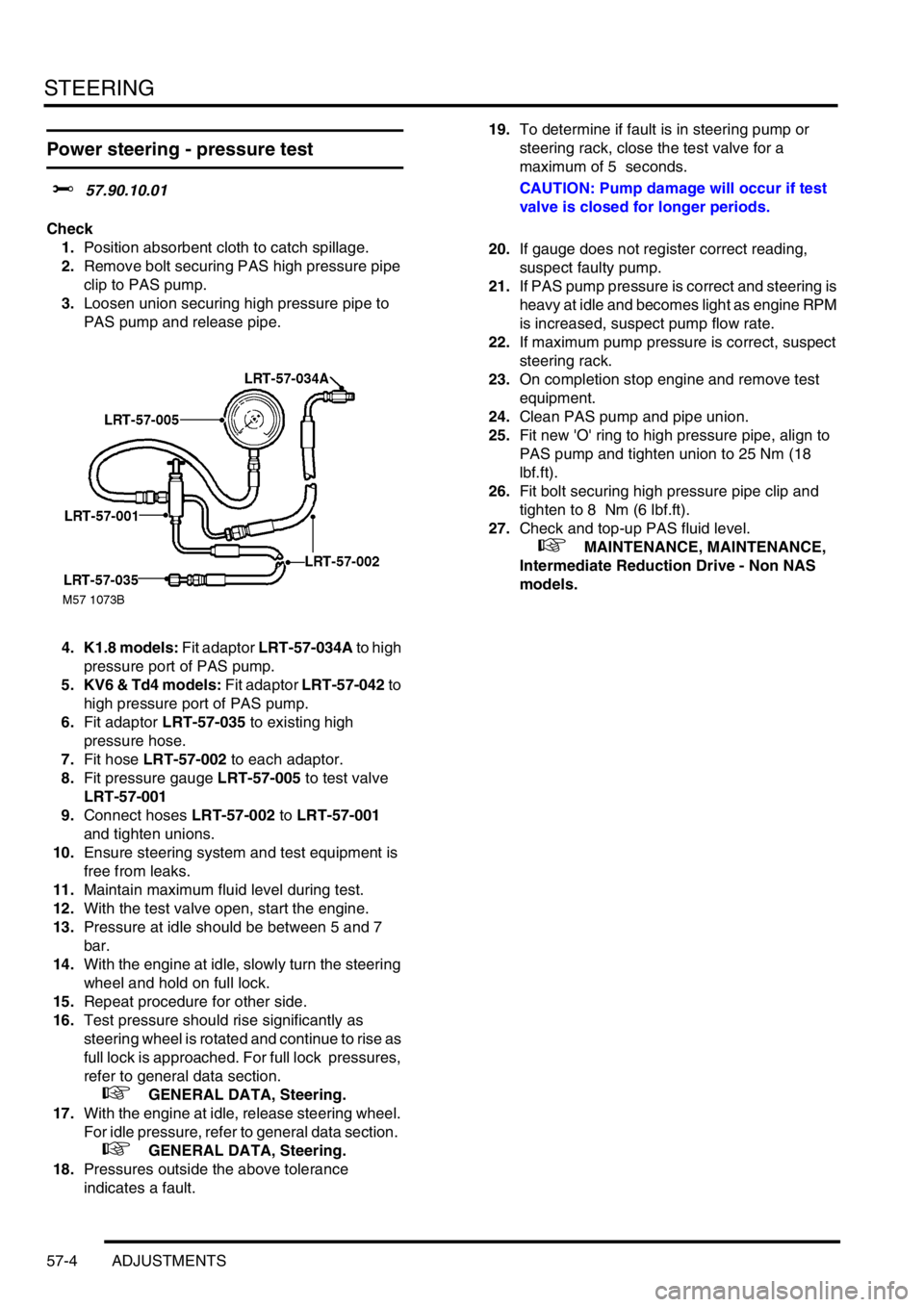

4. K1.8 models: Fit adaptor LRT-57-034A to high

pressure port of PAS pump.

5. KV6 & Td4 models: Fit adaptor LRT-57-042 to

high pressure port of PAS pump.

6.Fit adaptor LRT-57-035 to existing high

pressure hose.

7.Fit hose LRT-57-002 to each adaptor.

8.Fit pressure gauge LRT-57-005 to test valve

LRT-57-001

9.Connect hoses LRT-57-002 to LRT-57-001

and tighten unions.

10.Ensure steering system and test equipment is

free from leaks.

11.Maintain maximum fluid level during test.

12.With the test valve open, start the engine.

13.Pressure at idle should be between 5 and 7

bar.

14.With the engine at idle, slowly turn the steering

wheel and hold on full lock.

15.Repeat procedure for other side.

16.Test pressure should rise significantly as

steering wheel is rotated and continue to rise as

full lock is approached. For full lock pressures,

refer to general data section.

+ GENERAL DATA, Steering.

17.With the engine at idle, release steering wheel.

For idle pressure, refer to general data section.

+ GENERAL DATA, Steering.

18.Pressures outside the above tolerance

indicates a fault.19.To determine if fault is in steering pump or

steering rack, close the test valve for a

maximum of 5 seconds.

CAUTION: Pump damage will occur if test

valve is closed for longer periods.

20.If gauge does not register correct reading,

suspect faulty pump.

21.If PAS pump pressure is correct and steering is

heavy at idle and becomes light as engine RPM

is increased, suspect pump flow rate.

22.If maximum pump pressure is correct, suspect

steering rack.

23.On completion stop engine and remove test

equipment.

24.Clean PAS pump and pipe union.

25.Fit new 'O' ring to high pressure pipe, align to

PAS pump and tighten union to 25 Nm (18

lbf.ft).

26.Fit bolt securing high pressure pipe clip and

tighten to 8 Nm (6 lbf.ft).

27.Check and top-up PAS fluid level.

+ MAINTENANCE, MAINTENANCE,

Intermediate Reduction Drive - Non NAS

models.

Page 498 of 1007

STEERING

REPAIRS 57-5

REPAIRS

Power steering rack

$% 57.10.01

Remove

1.Raise front of vehicle.

WARNING: Do not work on or under a

vehicle supported only by a jack. Always

support the vehicle on safety stands.

2.Remove front road wheels.

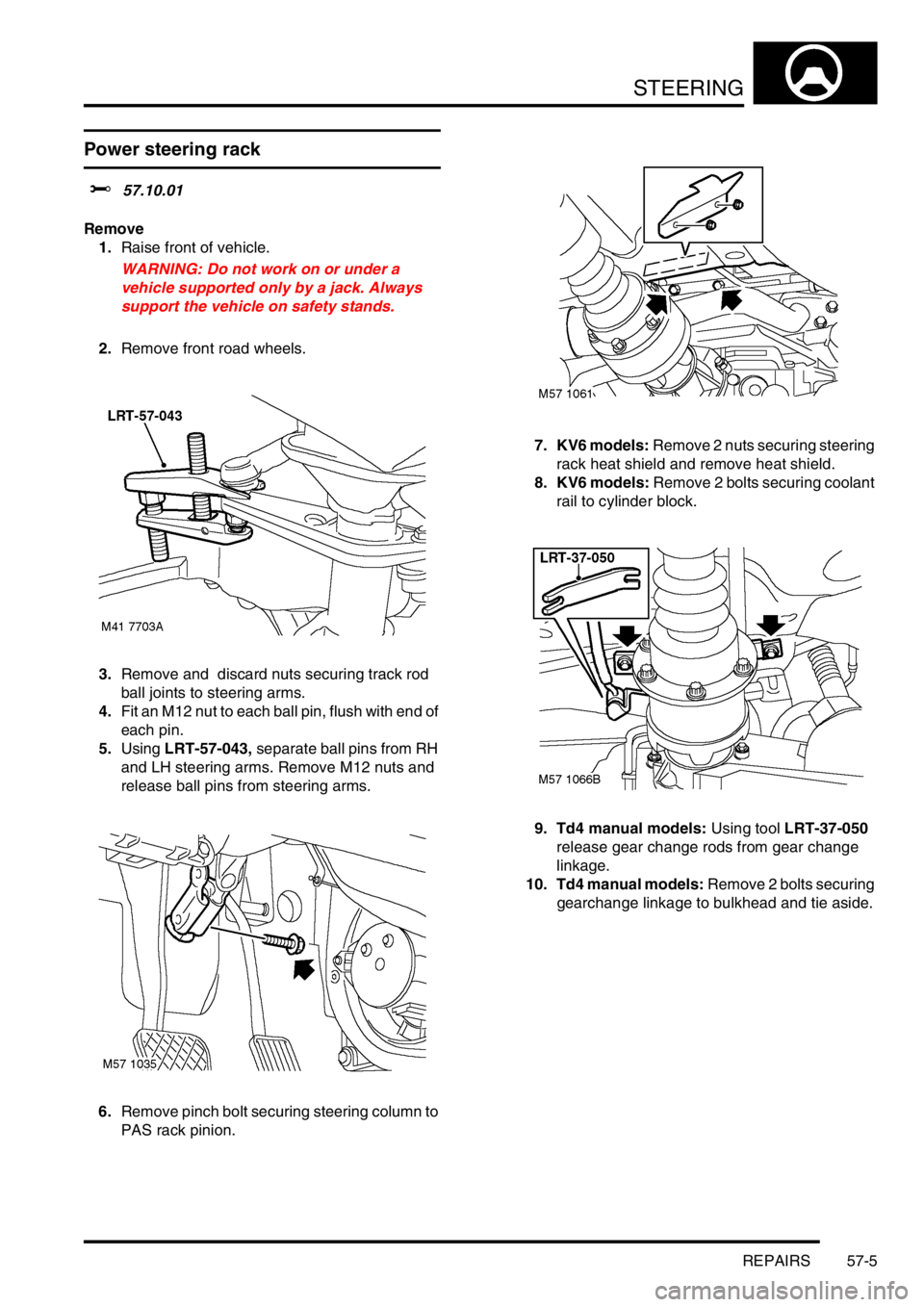

3.Remove and discard nuts securing track rod

ball joints to steering arms.

4.Fit an M12 nut to each ball pin, flush with end of

each pin.

5.Using LRT-57-043, separate ball pins from RH

and LH steering arms. Remove M12 nuts and

release ball pins from steering arms.

6.Remove pinch bolt securing steering column to

PAS rack pinion.7. KV6 models: Remove 2 nuts securing steering

rack heat shield and remove heat shield.

8. KV6 models: Remove 2 bolts securing coolant

rail to cylinder block.

9. Td4 manual models: Using tool LRT-37-050

release gear change rods from gear change

linkage.

10. Td4 manual models: Remove 2 bolts securing

gearchange linkage to bulkhead and tie aside.